Bismuth oxide and bismuth niobate composite material for removing algae in water as well as preparation method and application of bismuth oxide and bismuth niobate composite material

A composite material, bismuth oxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., to enhance photocatalytic activity, green environmental stability, and photocatalytic activity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Bi 3 NbO 7 The method is: slowly drop the first solution into the second solution, stir at room temperature 20-25°C for 30 minutes, then add benzyl alcohol, slowly add 2mol / L potassium hydroxide aqueous solution to adjust the pH to 13, transfer to 100ml with In a polytetrafluoroethylene-lined stainless steel high-pressure reaction kettle, keep warm at 180°C for 24h, cool naturally to room temperature, centrifuge, wash the centrifuged solids three times with deionized water and absolute ethanol, and store them in a drying oven at 80°C Dry for 8h to get Bi 3 NbO 7 , wherein, the preparation method of the first solution is to mix bismuth nitrate and glacial acetic acid, and stir at room temperature 20-25°C for 30 minutes; the preparation method of the second solution is to mix niobium oxalate and methanol, and stir at room temperature 20-25°C for 30 minutes; The ratio of the mass fraction of bismuth nitrate and the volume fraction of glacial acetic acid i...

Embodiment 2

[0038] Embodiment 2 (comparison)

[0039] BiO 2-x The preparation method of monomer comprises the following steps:

[0040] Mix sodium hydroxide, sodium bismuthate and water, stir at room temperature for 30 minutes until uniform, transfer to a 100ml stainless steel autoclave with polytetrafluoroethylene lining, keep warm at 180°C for 6 hours, naturally cool to room temperature, centrifuge, The solid obtained by washing and centrifuging with deionized water and absolute ethanol was 3 times each, dried in a drying oven at 80°C for 8 hours, and ground to obtain BiO 2-x Monomer, wherein, the ratio of the mass fraction of sodium hydroxide, the mass fraction of sodium bismuthate and the volume fraction of water is 2.4:2.8:60, the unit of mass fraction is g, and the unit of volume fraction is mL .

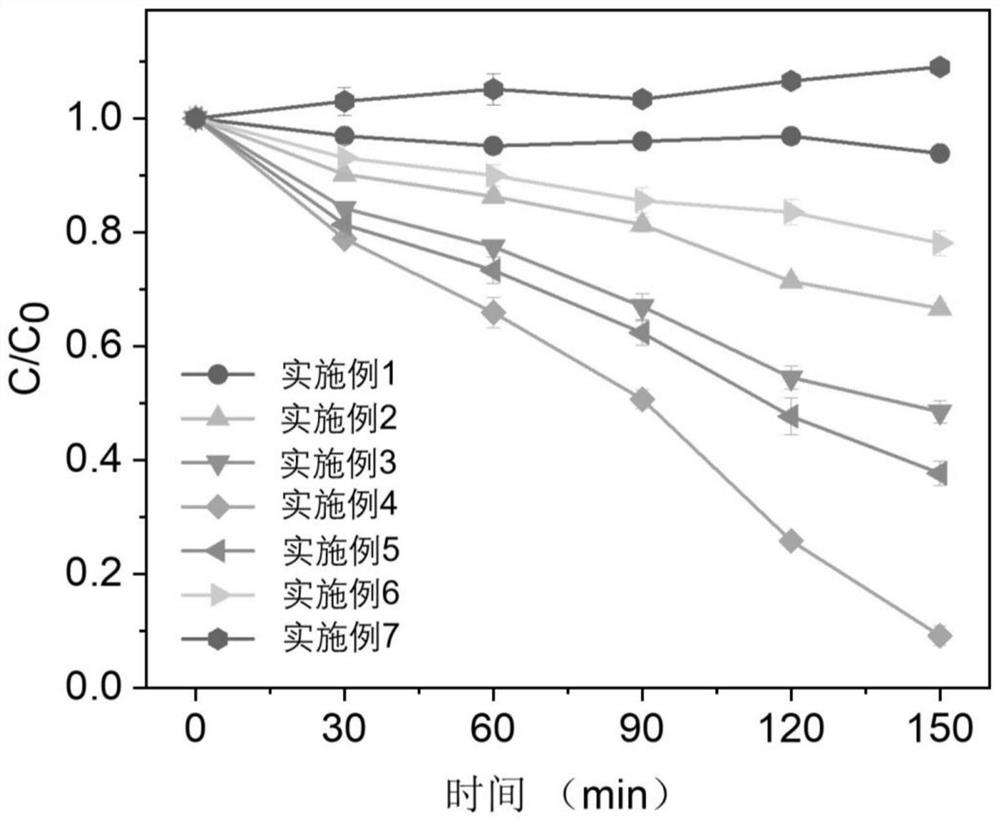

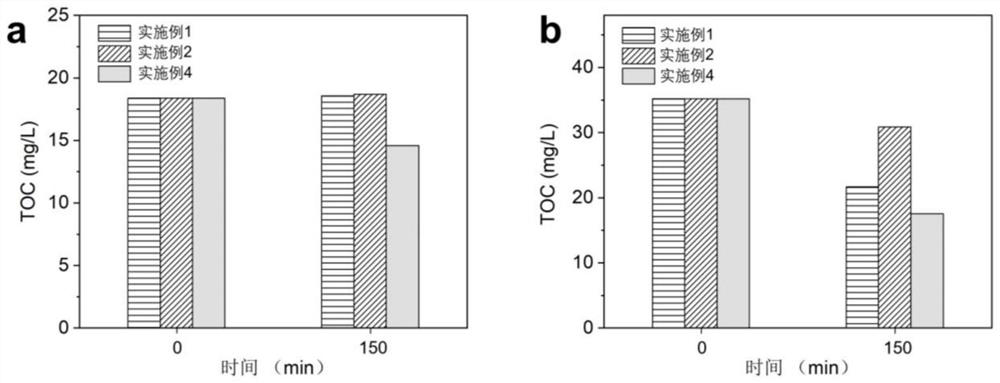

Embodiment 3~7

[0042] A bismuth oxide and bismuth niobate composite material (Bi 3 NbO 7 / BiO 2-x Composite material) preparation method, comprises the following steps:

[0043] Mix sodium hydroxide, sodium bismuthate and water, stir at room temperature for 30min until uniform, then add Bi obtained in Example 1 3 NbO 7 , stirred at room temperature for 20 minutes until uniform, transferred to a 100ml stainless steel autoclave lined with polytetrafluoroethylene, kept at 180°C for 6 hours, naturally cooled to room temperature, centrifuged, and washed with deionized water and absolute ethanol. The solids were dried 3 times in a drying oven at 80°C for 8 hours, and ground to obtain a bismuth oxide and bismuth niobate composite material, wherein the mass fraction of sodium hydroxide, the mass fraction of sodium bismuthate, and the volume fraction of water The ratio is 2.4:2.8:60, the unit of parts by mass is g, and the unit of parts by volume is mL. In terms of parts by mass, Bi 3 NbO 7 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com