Method for preparing spherical nano-silver particles

A spherical nano silver and particle technology, applied in the field of inorganic nano materials, can solve the problems of uneven particle size distribution and uneven shape of nano silver particles, and achieve the effect of preventing silver salt precipitation and preventing crystal seed precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

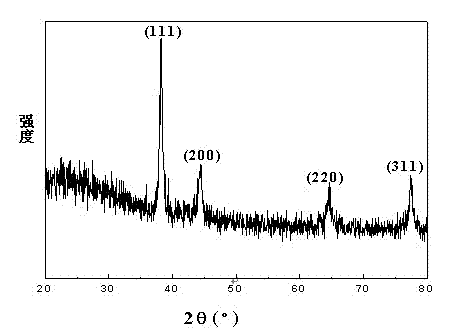

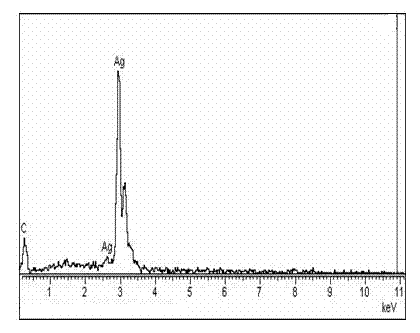

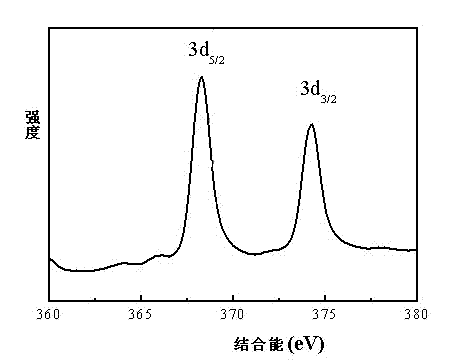

Image

Examples

Embodiment 1

[0032] (1) Add 0.1g of anhydrous Na 2 CO 3 Mix evenly with 10g of polyvinylpyrrolidone and 1g of ethylene glycol to obtain mixed solution A;

[0033] (2) Add 12g of AgNO 3 Dissolved in 0.5g of ethylene glycol to obtain mixed solution B;

[0034] (3) Add the mixed solution A to the mixed solution B dropwise, and mix evenly to obtain a colloidal solution;

[0035] (4) The colloidal solution obtained in the step (3) was heated and reacted under 300W microwave irradiation for 5 minutes, and cooled to room temperature to obtain spherical nano-silver particles.

Embodiment 2

[0037] (1) Add 0.15g of anhydrous Na 2 SO 4 and 11g of citric acid and 1.5g of glycerol were uniformly mixed by ultrasonic vibration to obtain a mixed solution A;

[0038] (2) Add 14g of AgNO 3 Dissolved in 1g of glycerol to obtain mixed solution B;

[0039] (3) Add the mixed solution A dropwise to the mixed solution B through a peristaltic pump with a rotating speed of 30 rad / min, and mix evenly to obtain a colloidal solution;

[0040] (4) The colloidal solution obtained in the step (3) was heated and reacted under 350W microwave irradiation for 4 minutes, and cooled to room temperature to obtain spherical nano-silver particles.

Embodiment 3

[0042] (1) 0.2 g of anhydrous NaI, 12 g of polyvinylpyrrolidone and 2 g of polyethylene glycol with a molecular weight of 200 were uniformly mixed by ultrasonic oscillation to obtain a mixed solution A;

[0043] (2) Add 15g of AgNO 3 Dissolved in 2 g of polyethylene glycol with a molecular weight of 200 to obtain a mixed solution B;

[0044] (3) Add the mixed solution A dropwise to the mixed solution B through a peristaltic pump with a rotating speed of 35 rad / min, and mix evenly to obtain a colloidal solution;

[0045] (4) The colloidal solution obtained in the step (3) was heated and reacted under 400W microwave irradiation for 3 minutes, and cooled to room temperature to obtain spherical nano-silver particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microwave power | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com