Method and device for manufacturing nanoparticle self-assembled structure

A technology of nanoparticles and production methods, which is applied in the field of nanomaterials and can solve problems such as the inability to precisely control the assembly position of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

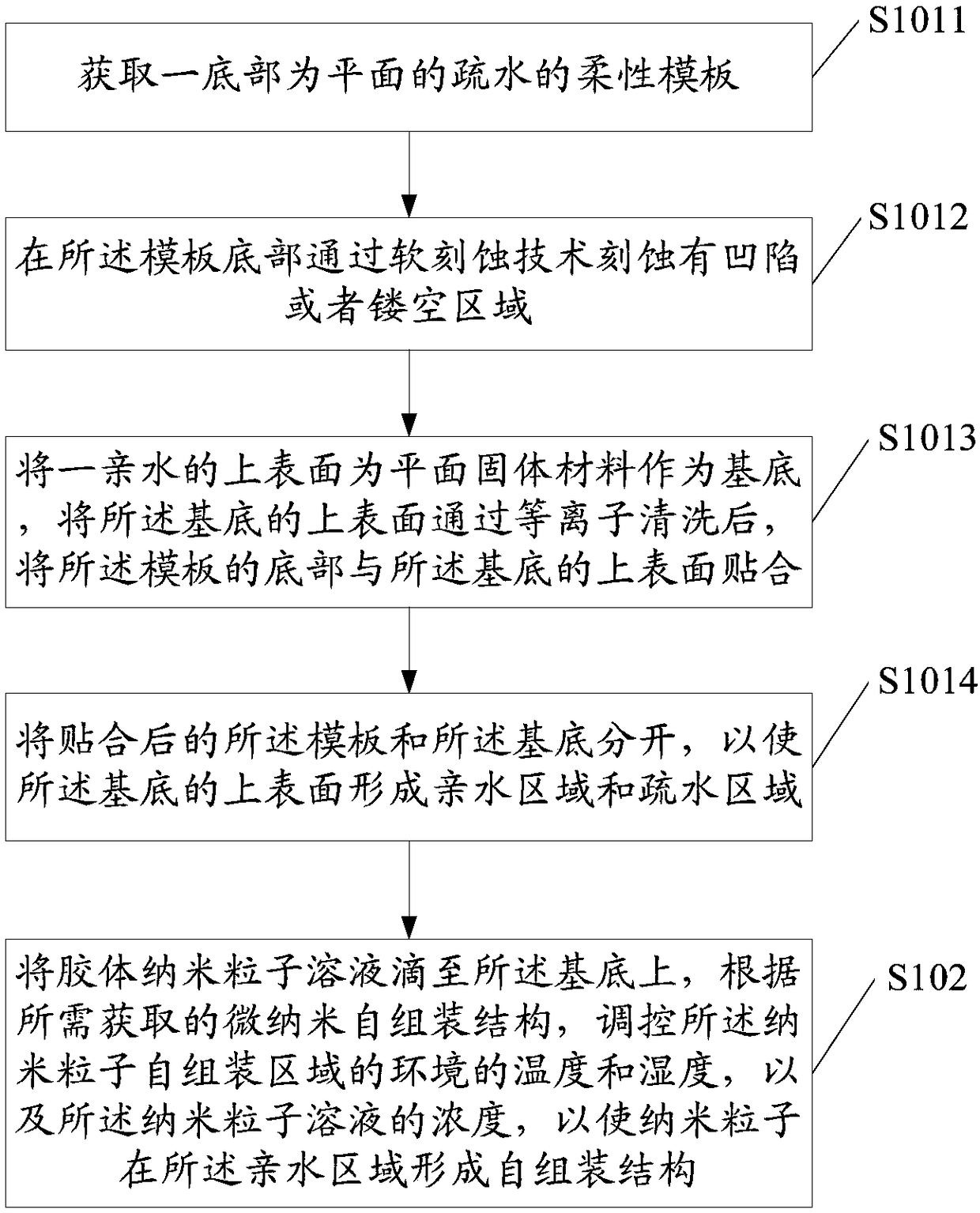

[0055] Such as figure 1As shown, the present invention provides a method for making a nanoparticle self-assembled structure, comprising:

[0056] S101, obtaining a substrate provided with hydrophilic regions and hydrophobic regions on the surface;

[0057] S1011, acquire a hydrophobic flexible template with a flat bottom; wherein, the flexible template can be a template made of polydimethylsiloxane PDMS or polymethyl methacrylate PMMA. The flexible template of the present application may also be any template material capable of soft etching.

[0058] S1012. Obtain a flexible template whose bottom is etched with a recess or a hollow area by soft etching technology. specific:

[0059] S1012.1, obtain a silicon template with a microstructure on the surface; the silicon template is a 4-inch wafer, and the microstructure is etched on its surface through photolithography and etching processes; the microstructure can be: according to the specified size Set a single area; set mult...

Embodiment 2

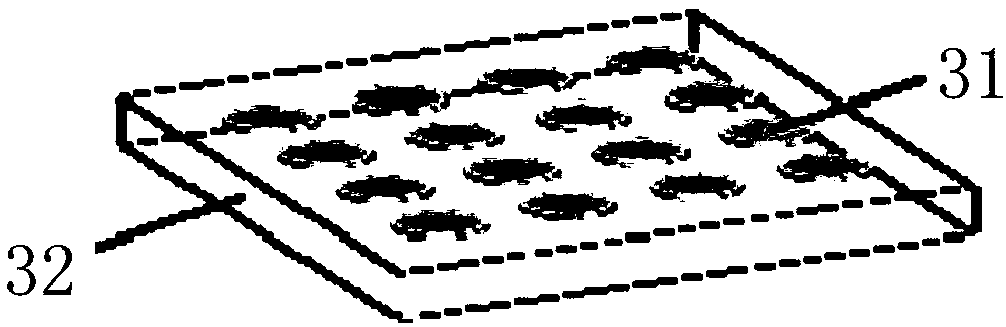

[0070] Such as Figure 4 As shown, the present application also provides a device for making a nanoparticle self-assembled structure, including:

[0071] A substrate 41 with hydrophilic regions and hydrophobic regions on its surface;

[0072] A structure for dropping the colloidal nanoparticle solution onto the substrate (it may be a dropper or a pipette gun, not shown in the figure).

[0073] Through the above device, the nanoparticles form a self-assembled structure in the hydrophilic region, and precise control of the self-assembled position of the nanoparticles can be realized.

[0074] In the manufacturing device of the present application, the manufacturing components of the substrate having a hydrophilic region and a hydrophobic region on the surface include:

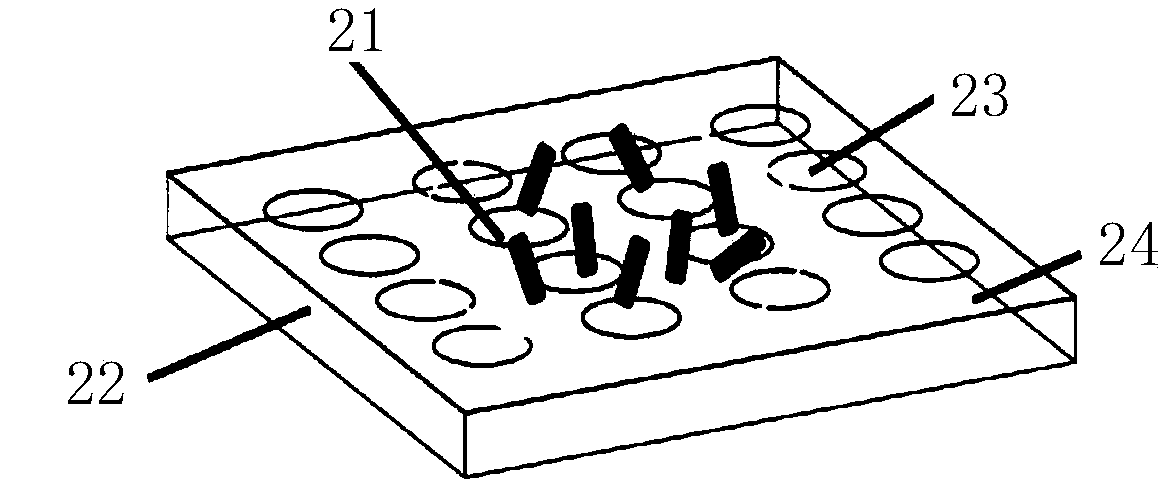

[0075] Such as Figure 5 As shown, a bottom is a planar hydrophobic flexible template 51; wherein, the bottom of the template is etched with a depression or a hollow area 52; wherein, the depression or hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com