Method for manufacturing nanoparticle array, surface plasmon resonance-based sensor and method for analyzing using same

a surface plasmon resonance and nanoparticle technology, applied in the field of sensor technology, can solve the problems of affecting the quality of nanoparticle arrays, and limiting the substrate materials for nano-island formation, etc., and achieves enhanced detection sensitivity, easy to amplify the measurement sensitivity, and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

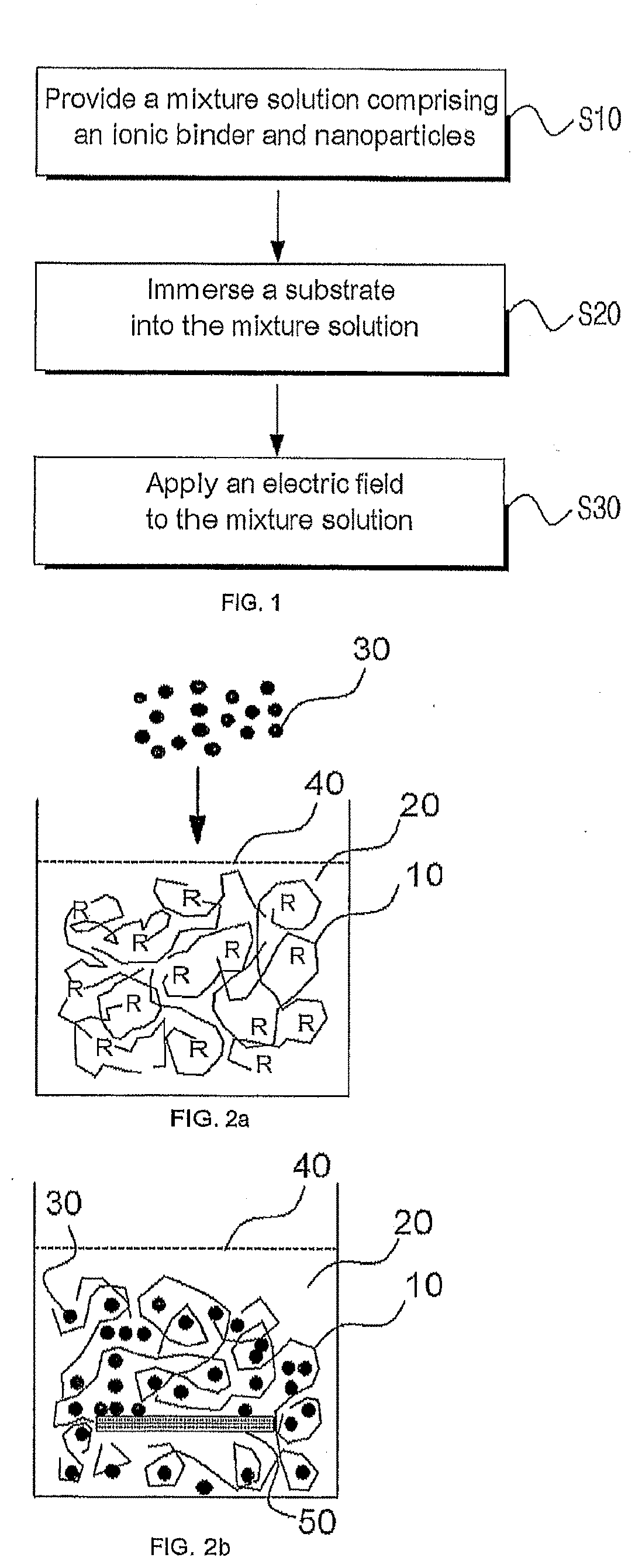

[0009]In the first embodiment to solve the stated technical problem, a method for manufacturing a nanoparticle array comprises a process providing a mixed solution of an ionic binder and conductive nanoparticles; a process dipping a substrate into the mixed solution; a process applying an electric field to the substrate-dipped mixed solution for inducing coating of conductive nanoparticles onto the substrate.

second embodiment

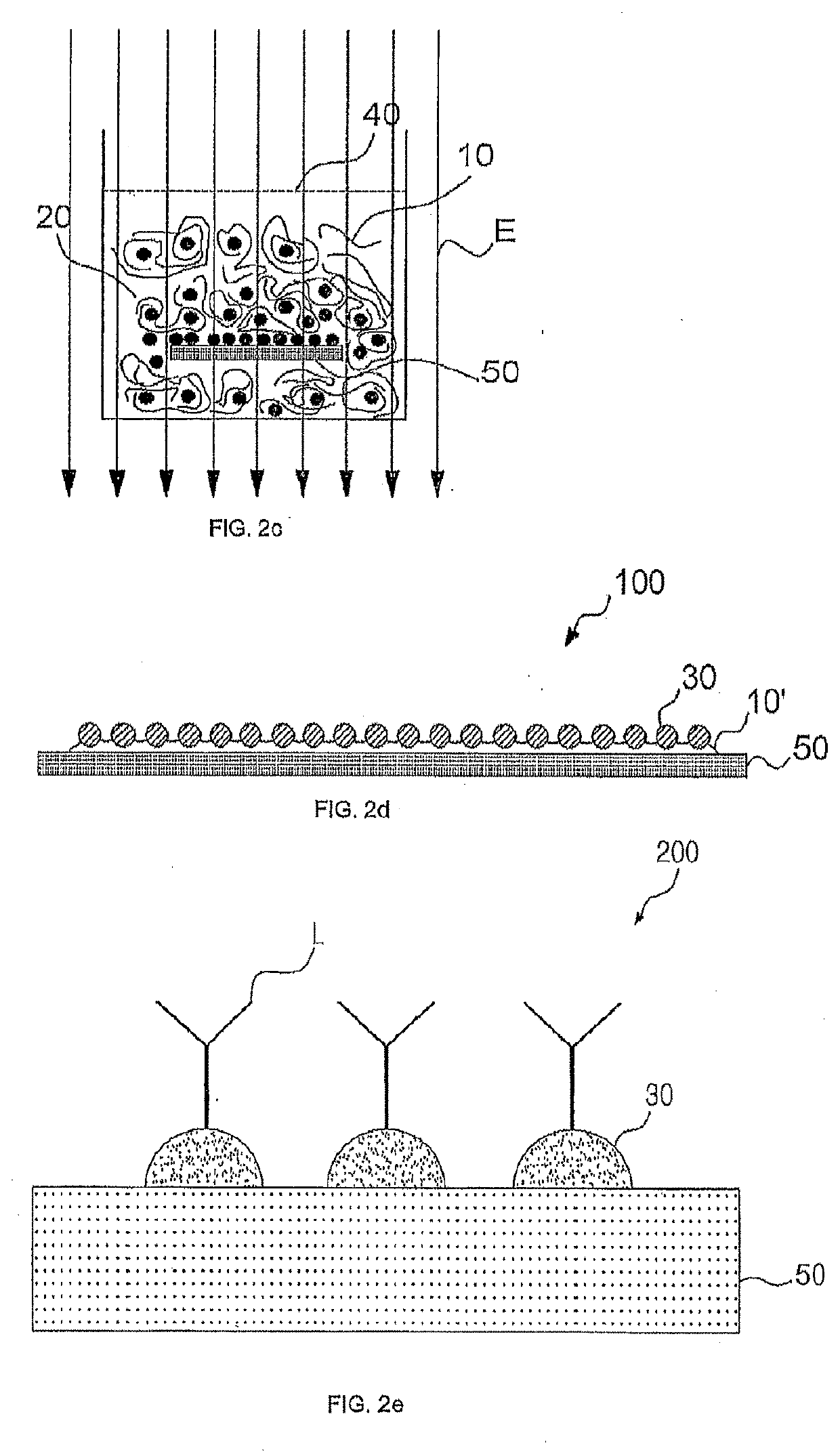

[0010]In the second embodiment to solve the stated different technical problem, a spectroscopic analysis sensor comprises a substrate; a polymer binder layer coated on the substrate; conductive nanoparticles dispersed and immobilized on the polymer binder layer. The sensor can be a SPR-based spectroscopic analysis sensor.

third embodiment

[0011]In the third embodiment to solve the stated another different technical problem, a spectroscopic analysis method comprises a process dipping a spectroscopic analysis sensor into a target analyte-dispersed solution; a process detecting change of reflected or transmitted light on a surface of the sensor using SPR or LSPR. In another different embodiment, the above stated spectroscopic analysis method includes a process dipping two or more sensors spacially isolated and stacked into a target analyte-dispersed solution; a process detecting change in SPR- or LSPR mode-coupled reflected or transmitted light upon applying an incident light onto the sensor.

Effect of the Invention

[0012]Referring to the present invention, a cost-effective wet method to manufacture a nanoparticle array can be offered through quick and high density coating of metal nanoparticles onto the substrate by dipping the substrate into a mixed solution of an ionic binder and conductive nanoparticles followed by ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com