Continuous Reactor and Method for Manufacturing Nanoparticles

a technology of continuous reactor and nanoparticles, which is applied in the direction of nanotechnology, material nanotechnology, transportation and packaging, etc., can solve the problems of not meeting the requirements of mass production and the large limitation of the flow rate of the reaction solution, so as to reduce the risk of solution leakage, prevent the blockage of the channel, and increase the flow rate tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Continuous Reactor for Manufacturing Nanoparticles

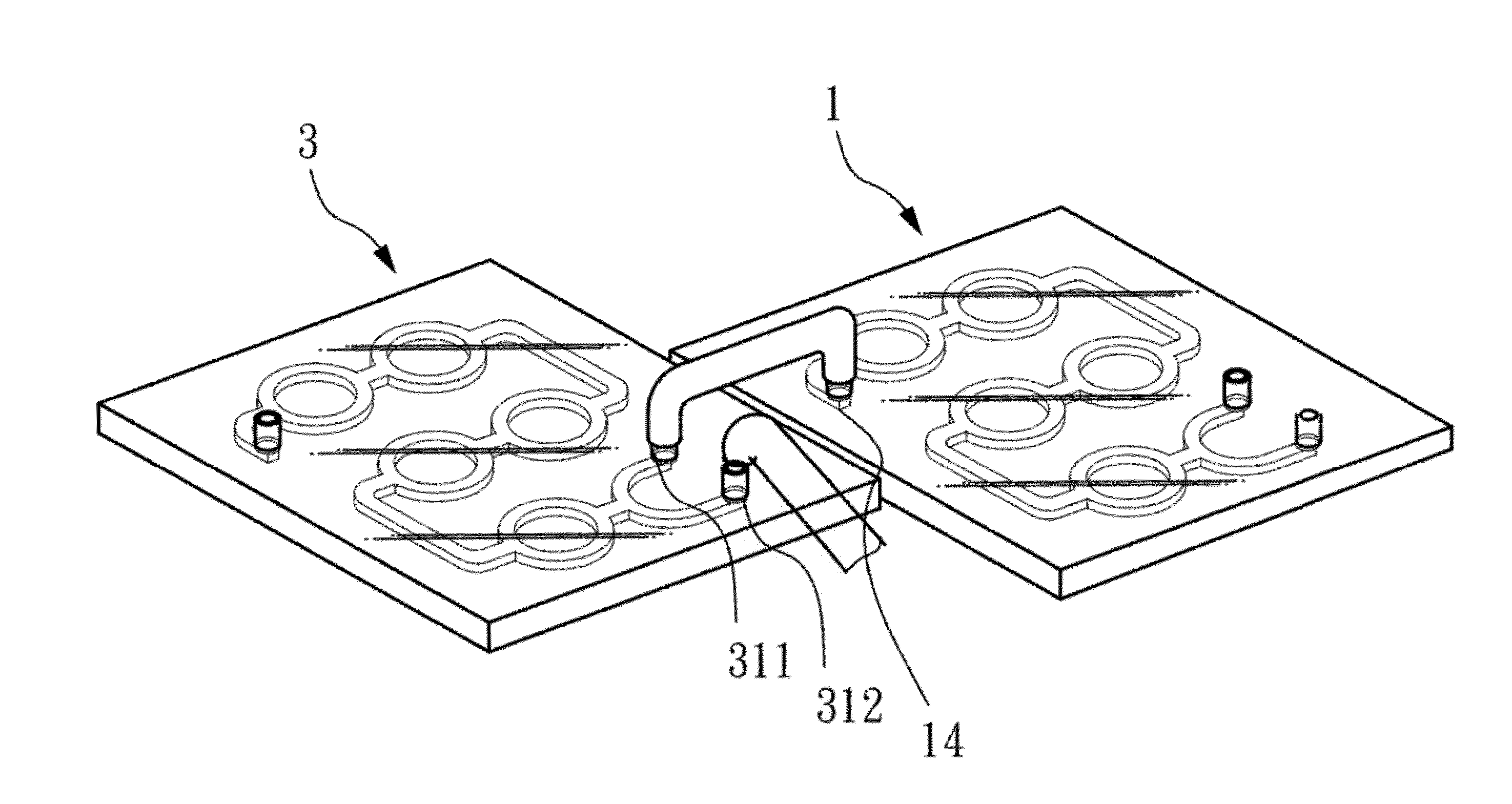

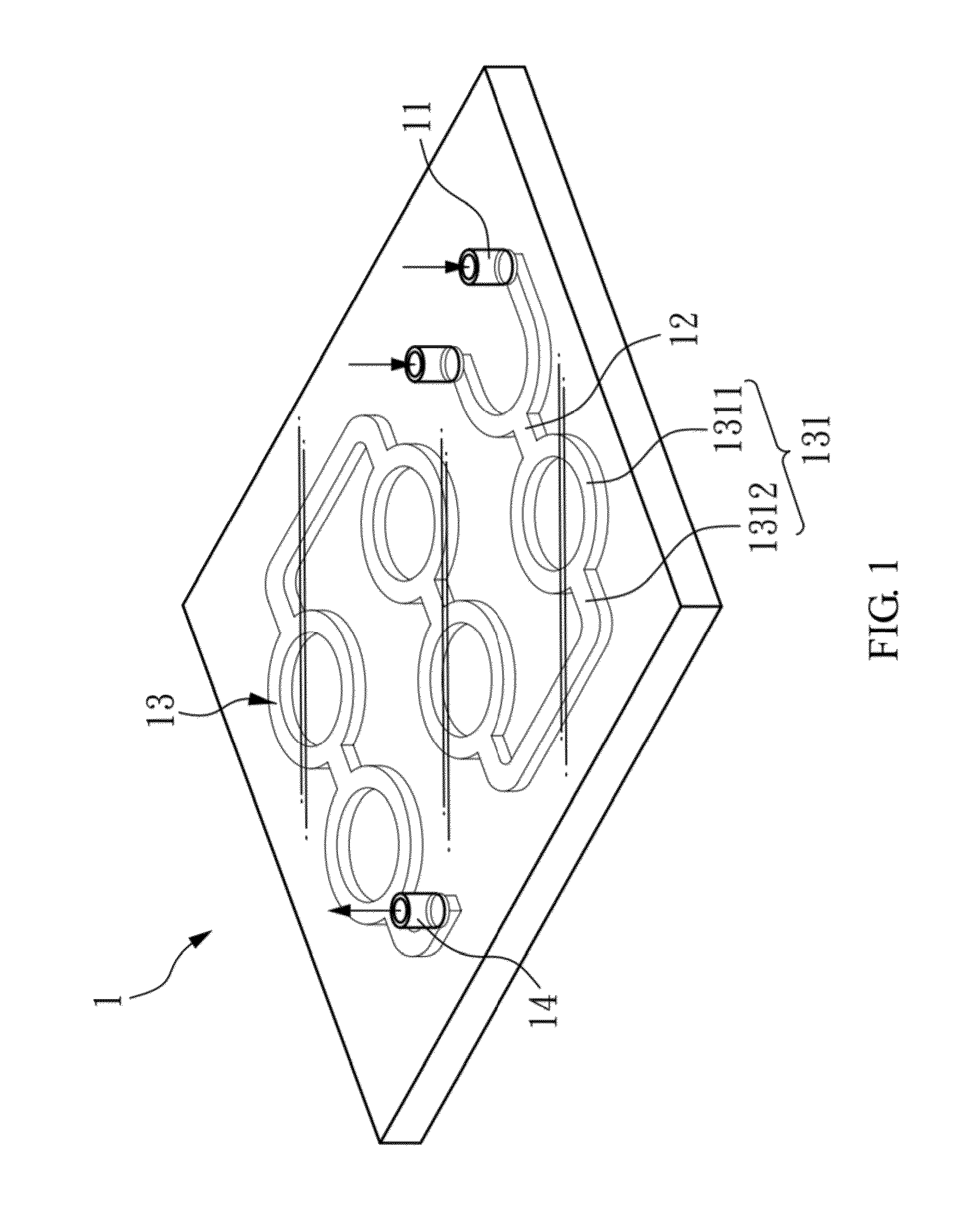

[0037]FIG. 1 shows a first reactor of the continuous reactor for manufacturing nanoparticles of Example 1, which comprises: two first inputs 11; a first mixing part 12 connected to the first inputs 11; a first reaction part 13 comprising five first reaction units 131, each comprising two first diverging channels 1311 and one first converging channel 1312 alternately connected to one another thereby connecting the five first reaction units 131 in series to form a five-times diverging-converging channels. Besides, the first diverging channels 1311 of the first one of the first reaction units 131 are connected to the first mixing part 12. Further, the continuous reactor for manufacturing nanoparticles of Example 1 also comprises a first output 14 connected to the first converging channel 1312 of the fifth one of the first reaction units 131 to output the produced nanoparticles.

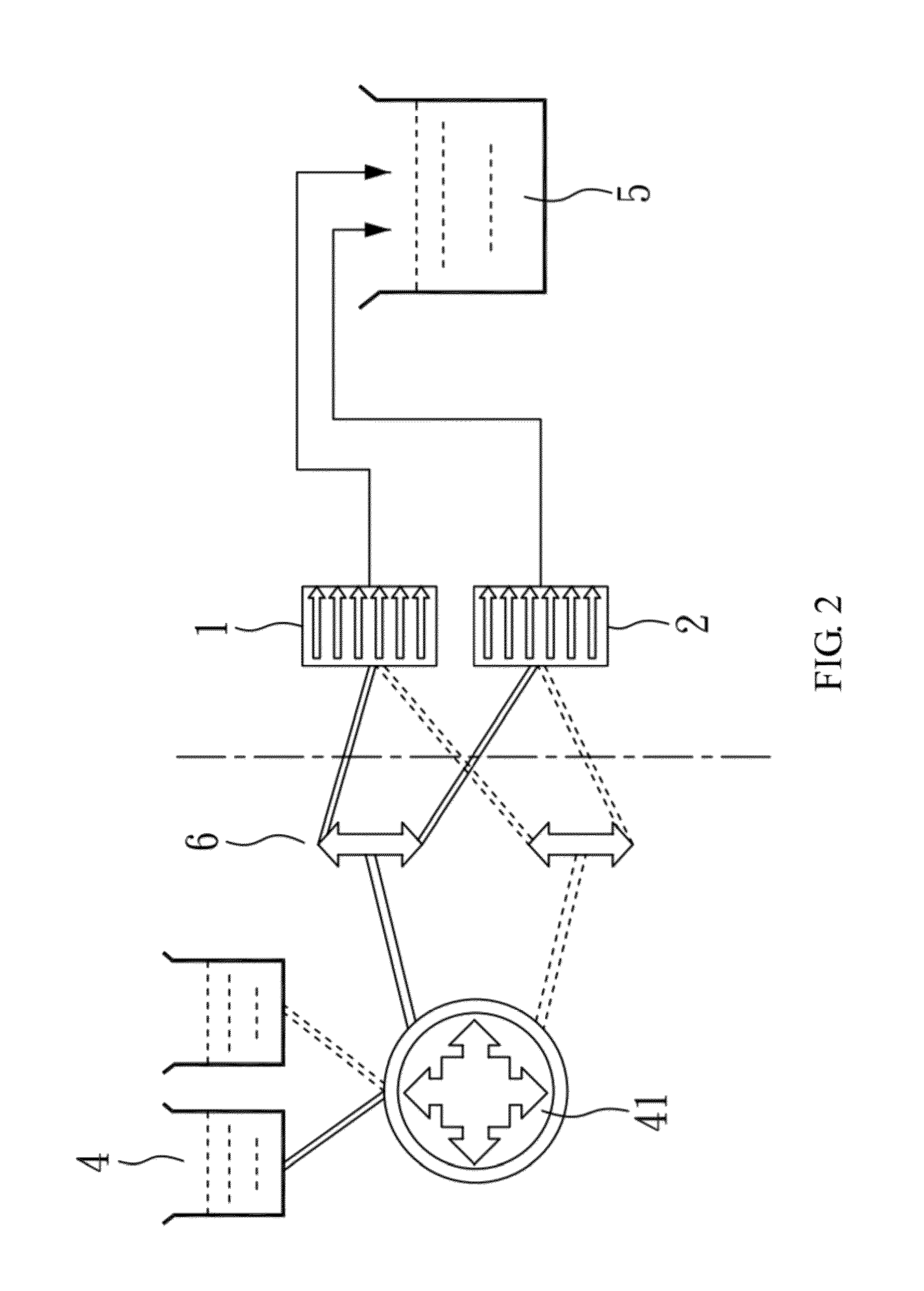

[0038]As illustrated in FIG. 2, in addition to the above fir...

example 2

Preparation of Water-Soluble Silver Nanoparticles

example 2-1

Preparation of Water-Soluble Silver Nanoparticles by the Method of the Present Invention

[0039]Referring to FIGS. 1 and 2 collectively, Example 2 illustrates the preparation of water-soluble silver nanoparticles using the reactors of Example 1.

[0040]16.9 g of silver nitrate and the same amount of polyvinyl pyrrolidone (PVP) molecule were dissolved in 0.5 L of deionized water to form a mixed solution of the silver precursor solution and the surfactant, and then 3.7 g of sodium borohydride was dissolved in 0.5 L of deionized water to form a precipitant solution. The mixed solution and the precipitant solution were placed in the reagent supply part 4 respectively, passed through the first inputs 11 by the pump 41, and primarily mixed in the first mixing part 12. Then, the obtained mixture was introduced into the first diverging channels 1311 of the first reaction unit 131 with a flow rate of 0.3 L / min, and converged in the first converging channel, thus completing the first time of dive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com