A kind of submarine ship forward tubular propeller technology

A tubular, propeller technology, applied in the direction of rotating propellers, ships, ship construction, etc., can solve the problems of blade surface corrosion, lack of optimal design space, strong and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

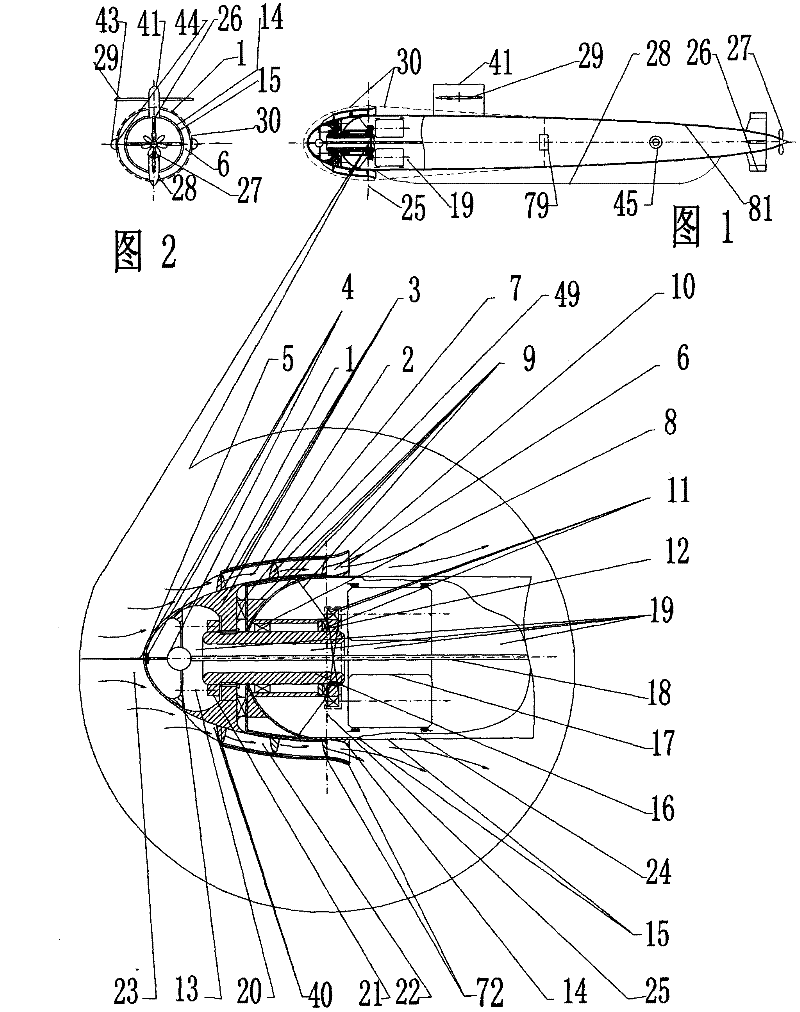

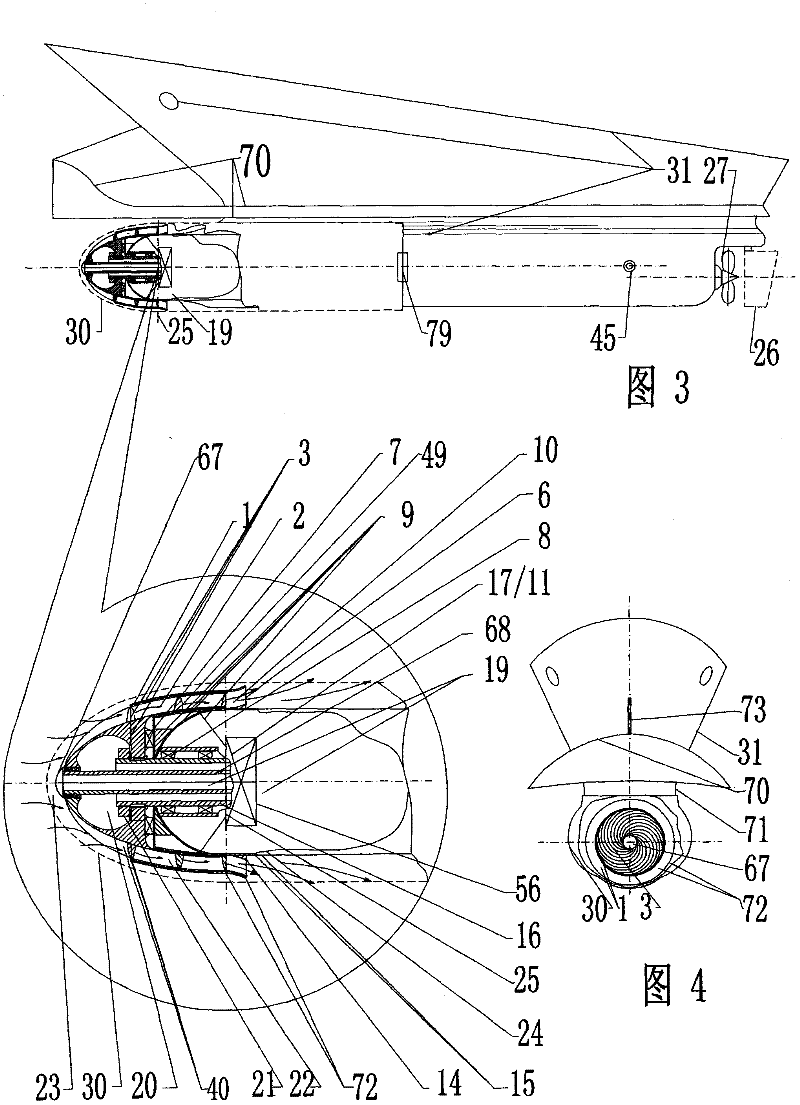

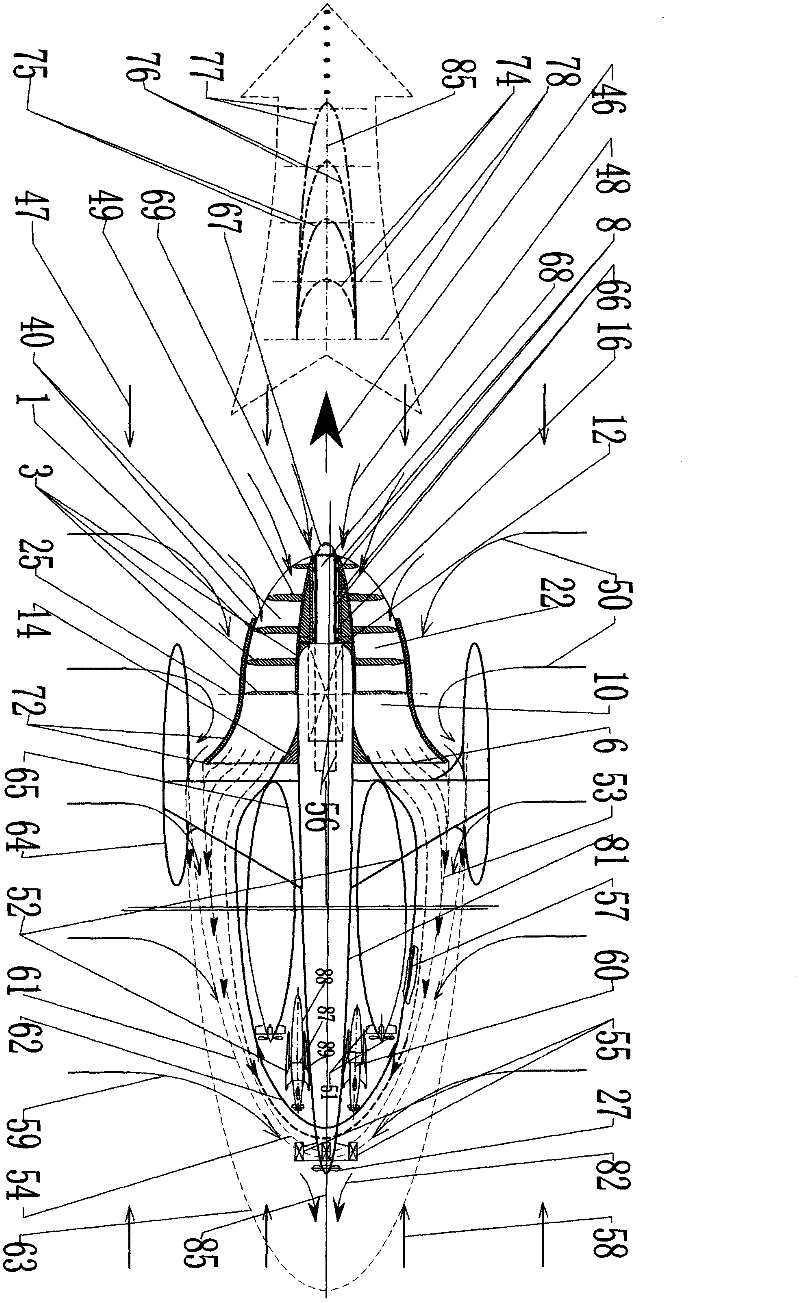

[0014] exist figure 1 Among them, the main body of the submarine is elongated into a "raindrop"-shaped streamline shape. The stern is provided with a conventional horizontal rudder 26 and a propeller 27. The front section of the hull under the horizontal enclosure rudder 29 of the bridge 41 is provided with a protective shell rudder. The bow in the 30 shell is provided with a tubular drill propeller. The through-flow drill bit propeller is sleeved on the front end of the inner and outer diameter of the bow cabin head wall and the axial main shaft bearing frame system 9, and the end face is provided with the thrust bearing frame 37 in the large paddle chamber 32 on the back of the rotor 3. Outer thrust bearing 7; the axial port 34 of the rotor wheel body 35 of the rotor 3 passes through the hollow shaft 16 and penetrates the boat cabin 19 above the main shaft bearing frame system 9; the rotor wheel body 35 is provided with a large paddle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com