Machine tool state monitoring system and method based on running data flow

A technology of operating data and machine tool status, applied in the field of machine tool status monitoring system based on operating data flow, can solve problems such as insufficient processing capacity of machine tool operating data, and achieve the effects of low time delay, large data throughput, and high transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

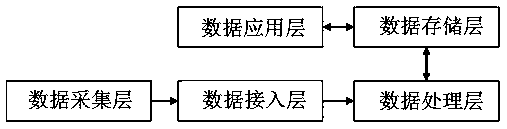

[0058] 1. The overall design of the machine tool condition monitoring system based on the operation data flow

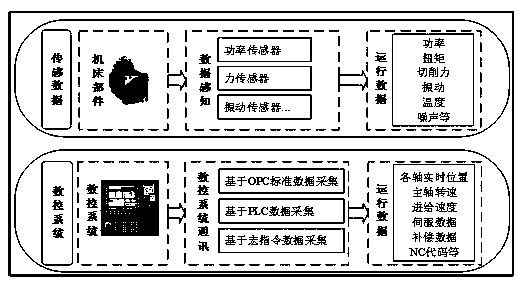

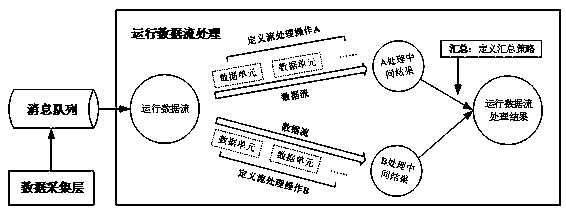

[0059] refer to figure 1 As shown, a machine tool status monitoring system based on the operation data flow includes a data acquisition layer for collecting machine tool operation data, the data acquisition layer is connected to the data processing layer through the data access layer; the data processing layer is connected to the data storage layer; The data processing layer includes a stream processing layer for performing stream processing on machine tool operation data.

[0060] The calculation method of stream processing can effectively process machine tool operation data in real time, and mainly solves the problem of "data is processed first and then stored". However, the machine tool abnormal state monitoring system also has the computing requirements of offline batch processing of "data stored first and then calculated", such as machine tool abnormal identifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com