Antioxidation antireflex corrosion-resistant lens and preparation method thereof

An anti-reflection and corrosion-resistant technology, applied in the field of functional lenses, can solve problems such as easy oxidation and corrosion, and difficult processing of anti-reflection lenses, and achieve the effects of good surface oxidation resistance, eye protection, and increased light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

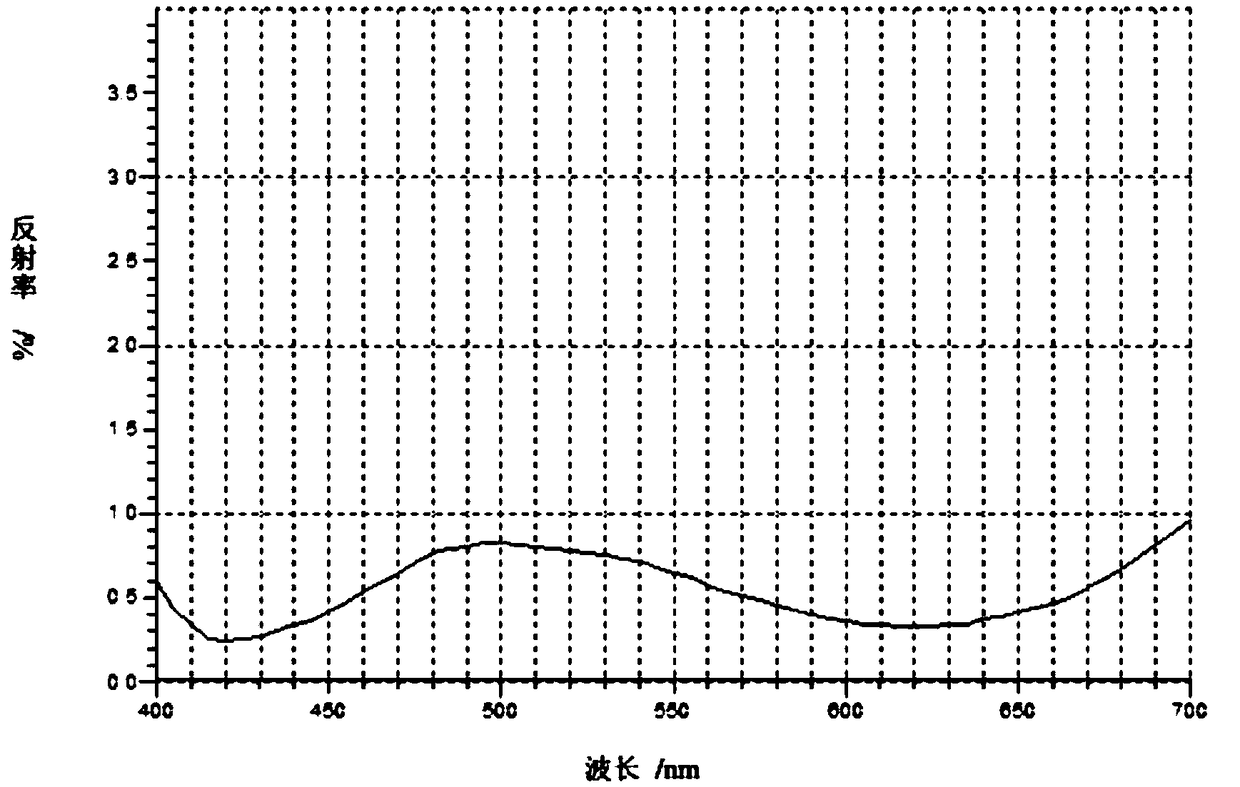

Image

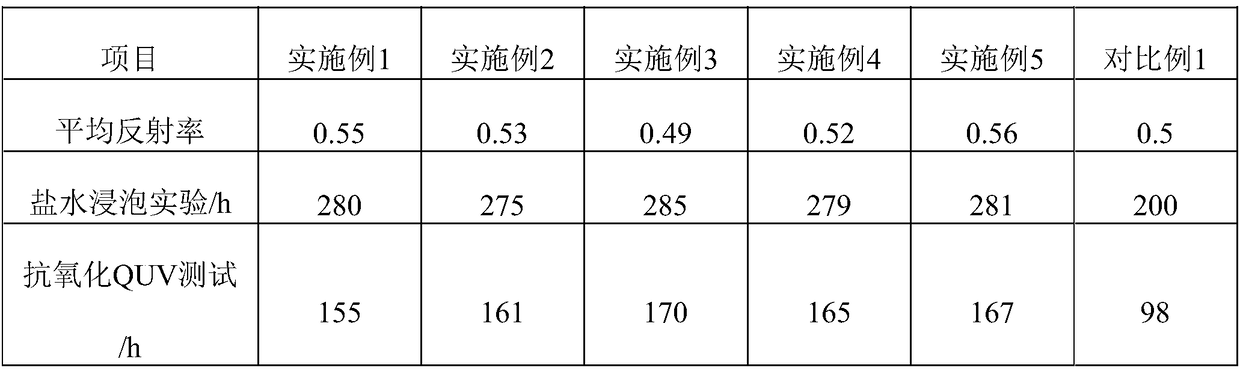

Examples

Embodiment 1

[0071] An anti-oxidation, anti-reflection and corrosion-resistant lens, comprising a resin substrate and a film layer arranged on the inner surface of the resin substrate, the film layer includes a first thin film layer, a second thin film layer, a second thin film layer stacked sequentially from inside to outside Three film layers, the fourth film layer, the fifth film layer, the sixth film layer and the seventh film layer, wherein the resin substrate is an acrylic substrate, the first film layer is a silicon-aluminum mixture, and the second film The layer is nickel-chromium alloy, the third film layer is trititanium pentoxide, the fourth film layer is a silicon-aluminum mixture, the fifth film layer is a nickel-chromium alloy, and the sixth film layer is a silicon-aluminum mixture , the seventh film layer is a waterproof layer.

[0072] The preparation method of the anti-oxidation, anti-reflection and corrosion-resistant lens is as follows:

[0073]Step 1: Clean and dry the...

Embodiment 2

[0090] An anti-oxidation, anti-reflection and corrosion-resistant lens, comprising a resin substrate and a film layer arranged on the inner surface of the resin substrate, the film layer includes a first thin film layer, a second thin film layer, a second thin film layer stacked sequentially from inside to outside Three thin film layers, the fourth thin film layer, the fifth thin film layer, the sixth thin film layer and the seventh thin film layer, wherein the first thin film layer is a silicon-aluminum mixture, the second thin film layer is a nickel-chromium alloy, and the The third film layer is titanium monoxide, the fourth film layer is a silicon-aluminum mixture, the fifth film layer is a nickel-chromium alloy, the sixth film layer is a silicon-aluminum mixture, and the seventh film layer is waterproof layer.

[0091] The preparation method of the anti-oxidation, anti-reflection and corrosion-resistant lens is as follows:

[0092] Step 1: Clean and dry the resin substra...

Embodiment 3

[0109] An anti-oxidation, anti-reflection and corrosion-resistant lens, comprising a resin substrate and a film layer arranged on the inner surface of the resin substrate, the film layer includes a first thin film layer, a second thin film layer, a second thin film layer stacked sequentially from inside to outside Three thin film layers, the fourth thin film layer, the fifth thin film layer, the sixth thin film layer and the seventh thin film layer, wherein the first thin film layer is a silicon-aluminum mixture, the second thin film layer is a nickel-chromium alloy, and the The third film layer is titanium dioxide, the fourth film layer is a silicon-aluminum mixture, the fifth film layer is a nickel-chromium alloy, the sixth film layer is a silicon-aluminum mixture, and the seventh film layer is a waterproof layer.

[0110] The preparation method of the anti-oxidation, anti-reflection and corrosion-resistant lens is as follows:

[0111] Step 1: Clean and dry the resin substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com