Xylene gas sensor based on CoWO4-Co3O4 heterojunction nanostructure sensitive material, and preparation method thereof

A COWO4-CO3O4, gas sensor technology, applied in the direction of material electrochemical variables, etc., can solve the problems of less original form of sensing application, low response, etc., achieve the effect of lower detection limit of gas concentration, simple synthesis method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] use CoWO 4 -Co 3 o 4 Heterojunction nanostructures are used as sensitive materials to make xylene sensors. The specific manufacturing process:

[0045] (1) First measure 20mL of deionized water and 20mL of ethylene glycol, pour them into a beaker, and keep stirring;

[0046] (2) 0.50g cobalt acetate tetrahydrate and 0.24g urea are added to the beaker uniformly mixed with deionized water and ethylene glycol; after stirring for 15 minutes, add 0.1g cetyltrimethylammonium bromide, Finally add 0.24g WCl 6 , and keep stirring continuously until it is completely dissolved;

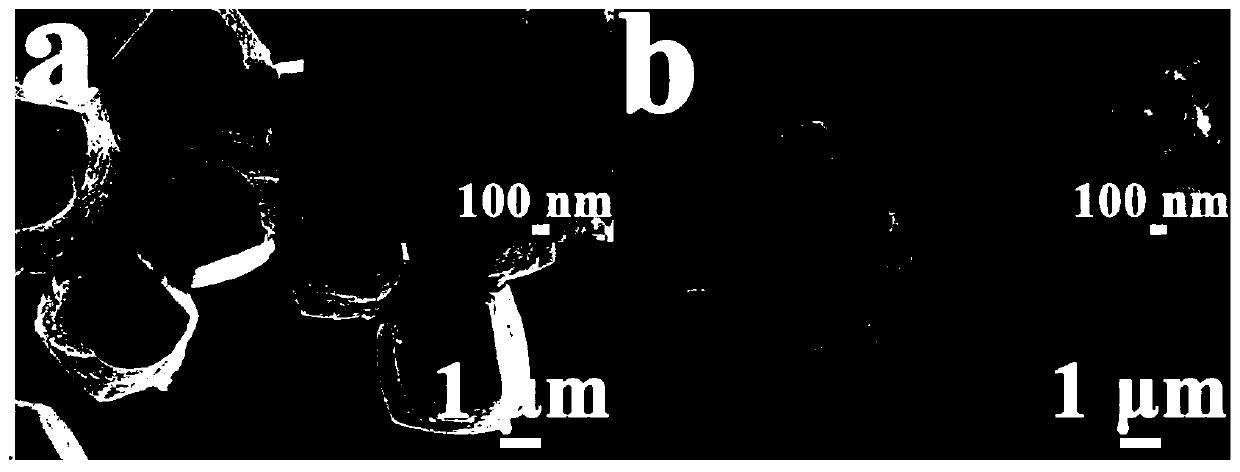

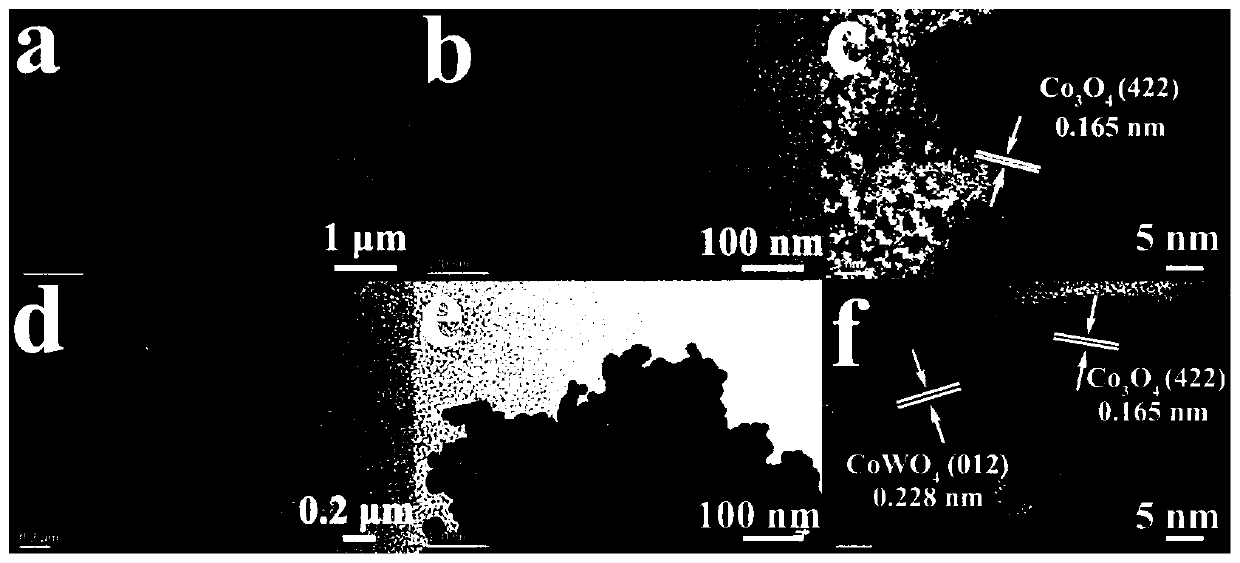

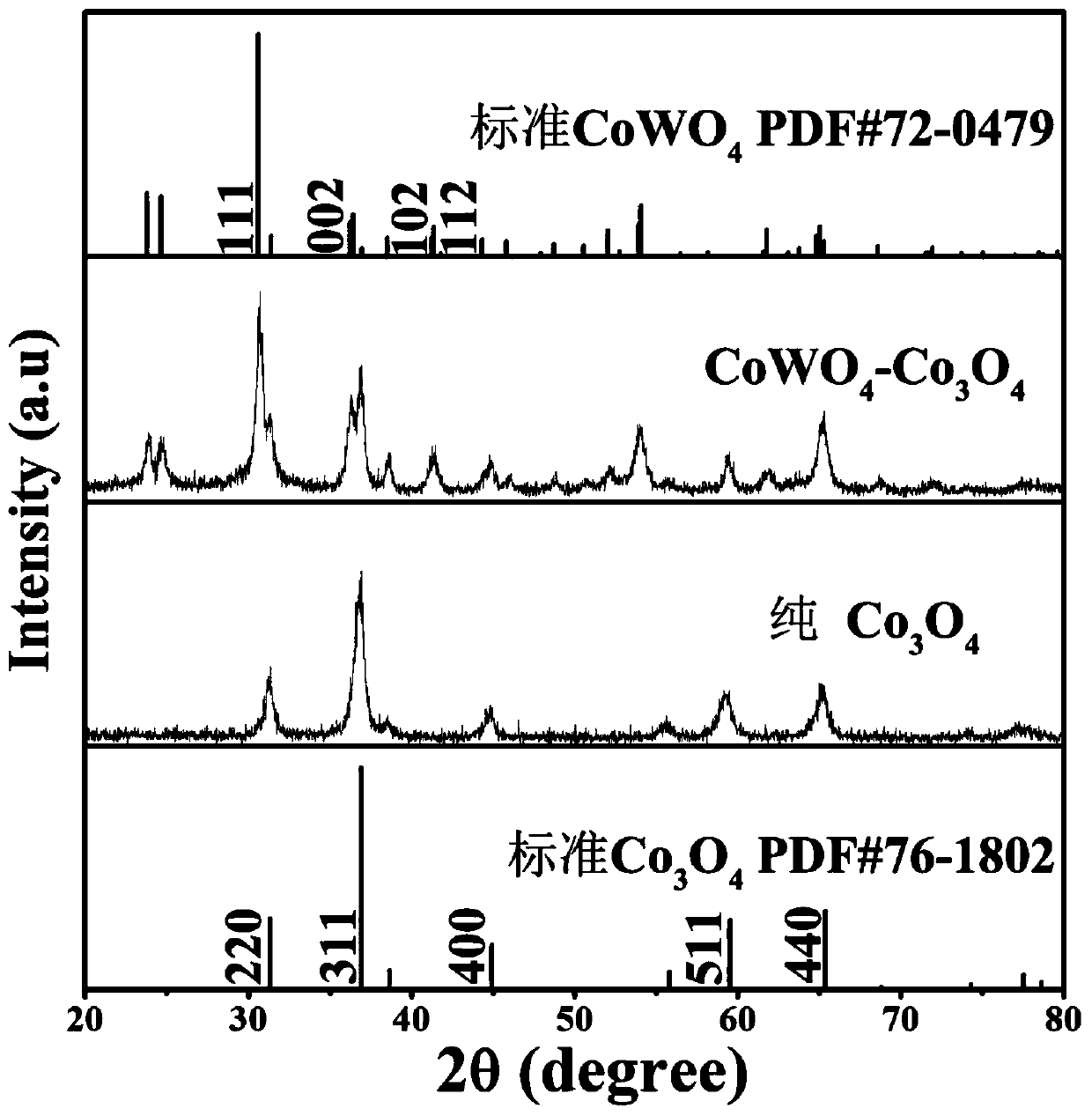

[0047] (3) Transfer the above solution to a hydrothermal kettle, keep it at 160°C for 12 hours, take it out, cool it down to room temperature naturally, wash the resulting precipitate with deionized water and ethanol for several times, and then dry it at room temperature. Calcined at 400 °C for 2 hours to obtain CoWO 4 -Co 3 o 4 Heterojunction Nanostructured Powders.

[0048] (4) Take appropriate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com