Three-dimensional flexible sensor material and preparation method and application thereof

A flexible sensor, three-dimensional technology, applied in the field of sensors, can solve problems such as poor fit and high hardness, and achieve the effects of obvious resistance changes, good flexibility, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A three-dimensional flexible sensor, the preparation method of which comprises the following steps:

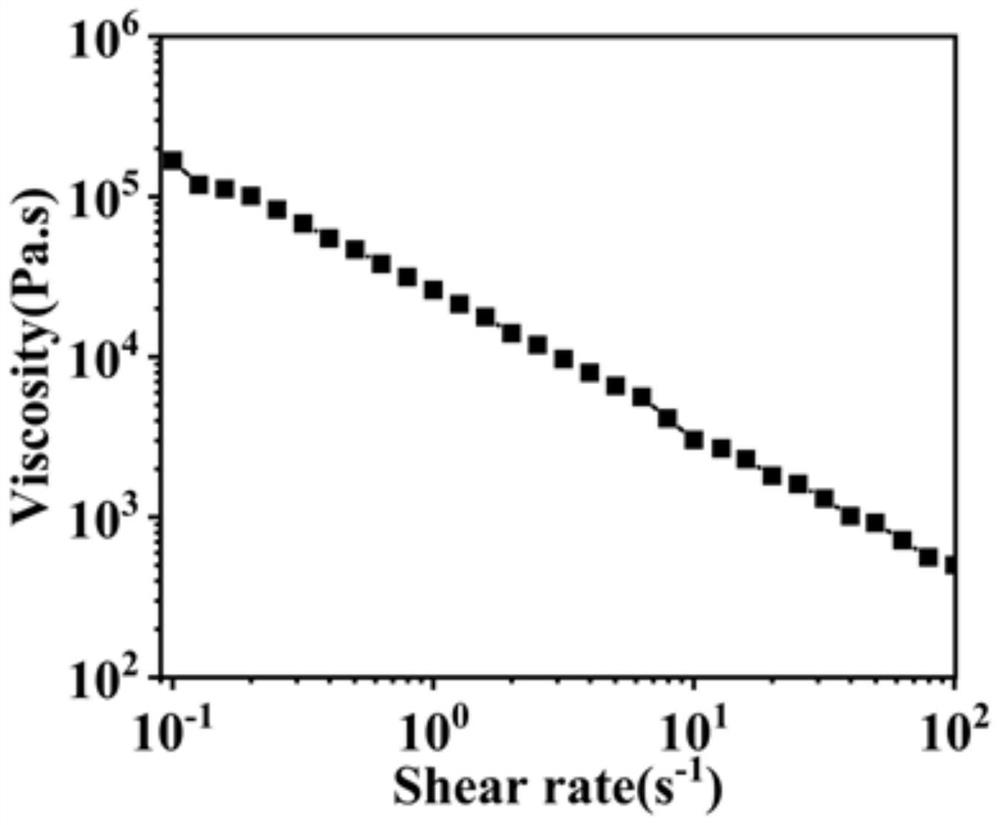

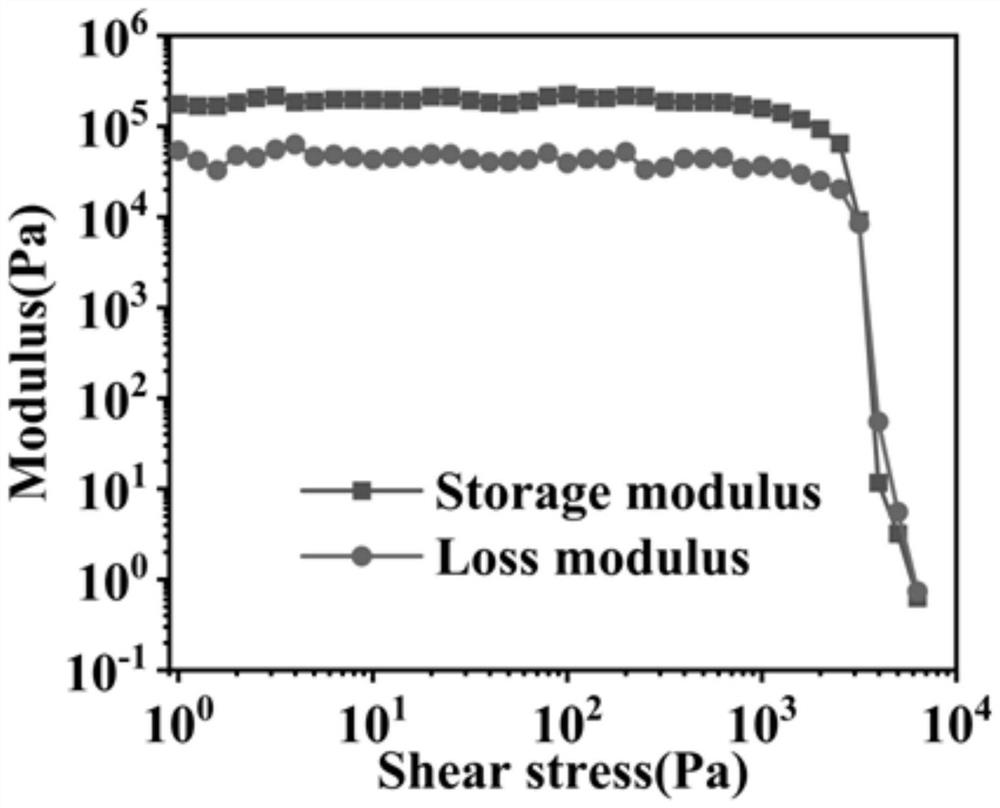

[0038] (1) First, add 1 g of cellulose to 10 mL of water, and disperse it by ultrasonic for 10 minutes; then add 0.1 g of graphene oxide, and disperse it by a high-speed disperser for 30 minutes at a speed of 20,000 rad / min; finally, add 1 g of carbon tube to the solution, Continue to use a high-speed disperser to disperse for 1h, and the rotation speed is 30000rad / min to form printing ink;

[0039] (2) The printing ink obtained in step (1) was placed in a 30CC syringe, a glass plate was used as the receiver and placed on the lower triaxial platform, the printing pressure was set to 30 psi, the diameter of the printing needle was 0.84 mm, and the triaxial platform was set The moving speed is 15mm / min, and the fork-shaped sample is obtained by printing according to the preset program, and the number of printing layers is 2;

[0040] (3) The printed sample obtained in st...

Embodiment 2

[0042] A three-dimensional flexible sensor, the preparation method of which comprises the following steps:

[0043] (1) First, add 1 g of chitosan to 12 mL of water, and use ultrasonic dispersion for 10 minutes; then add 0.2 g of graphene oxide, and use a high-speed disperser to disperse for 30 minutes at a speed of 25,000 rad / min; finally, add 1 g of graphene to the solution. , continue to use a high-speed disperser to disperse for 1h, and the rotation speed is 30000rad / min to form printing ink;

[0044] (2) The printing ink obtained in step (1) is placed in a 30CC syringe, a glass plate is used as the receiver and placed on the lower triaxial platform, the printing pressure is set to 20 psi, the diameter of the printing needle is 0.5 mm, and the triaxial platform is set The moving speed is 15mm / min, and the fork-shaped sample is obtained by printing according to the preset program, and the number of printing layers is 2;

[0045] (3) The printed sample obtained in step (2) ...

Embodiment 3

[0047] A three-dimensional flexible sensor, the preparation method of which comprises the following steps:

[0048] (1) First, add 1 g of sodium alginate to 10 mL of water, and use ultrasonic dispersion for 10 minutes; then add 0.2 g of graphene oxide, and use a high-speed disperser to disperse for 60 minutes at a speed of 20,000 rad / min; finally, add 1.5 g of carbon fiber to the solution. , continue to use a high-speed disperser to disperse for 2h, and the rotation speed is 30000rad / min to form printing ink;

[0049] (2) The printing ink obtained in step (1) is placed in a 30CC syringe, a glass plate is used as the receiver and placed on the lower three-axis platform, the printing pressure is set to 20 psi, the diameter of the printing needle is 1 mm, and the three-axis platform is set to The moving speed is 10mm / min, and the fork-shaped sample is obtained by printing according to the preset program, and the number of printing layers is 2;

[0050] (3) The printed sample obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com