Corroding method for metallographic specimen of high nickel-chromium alloy

A metallographic sample, high-nickel-chromium technology, applied in the field of metallographic corrosion of metal materials, can solve problems such as the inability to prevent alloy surface passivation, difficulty in controlling the degree of corrosion, etc., to achieve the elimination of surface passivation and the degree of corrosion Controllable and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

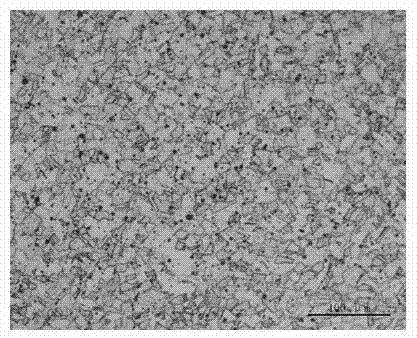

[0018] Sample 1:

[0019] Alloy grade: Cr20Ni80;

[0020] Composition (weight ratio): Cr: 20%, Ni: 80%;

[0021] Corrosive solution: hydrochloric acid + nitric acid + water, the volume ratio is 10:15:75;

[0022] Etching time: 1.5 minutes;

[0023] The metallographic photo of sample 1 after corrosion treatment is as follows: figure 2 shown.

Embodiment 2

[0025] Sample 2:

[0026] Alloy grade: Cr15Ni60;

[0027] Composition (weight ratio): Cr: 15%, Ni: 60%, Fe: 25%;

[0028] Corrosive solution: hydrochloric acid + nitric acid + water, the volume ratio is 10:15:75;

[0029] Etching time: 1 minute.

Embodiment 3

[0031] Sample 3:

[0032] Alloy grade: Cr30Ni70;

[0033] Composition (weight ratio): Cr: 30%, Ni: 70%;

[0034] Corrosive solution: hydrochloric acid + nitric acid + water, the volume ratio is 10:15:75;

[0035] Etching time: 3 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com