Small-sized efficient energy-saving over-current type equipment for electric flocculation process

A high-efficiency, energy-saving, flow-through technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of reduced flocculation effect, increased energy consumption and cost, and large space. To achieve the effect of improving the treatment effect, the electrode is not easy to passivate, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

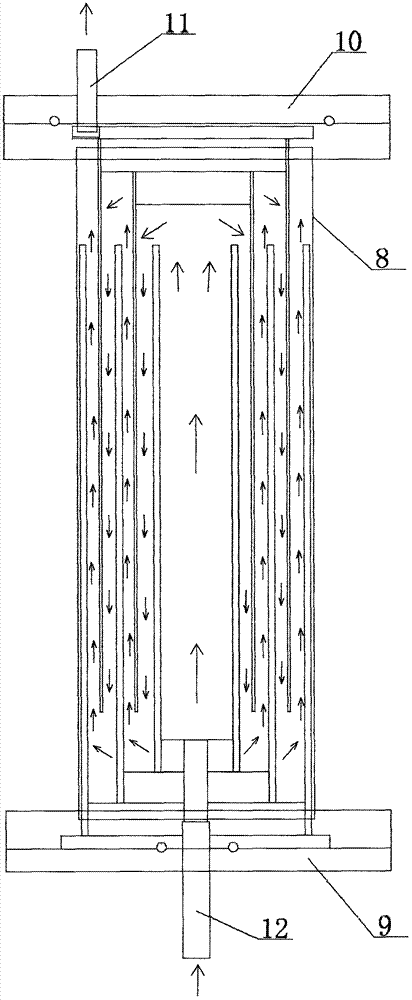

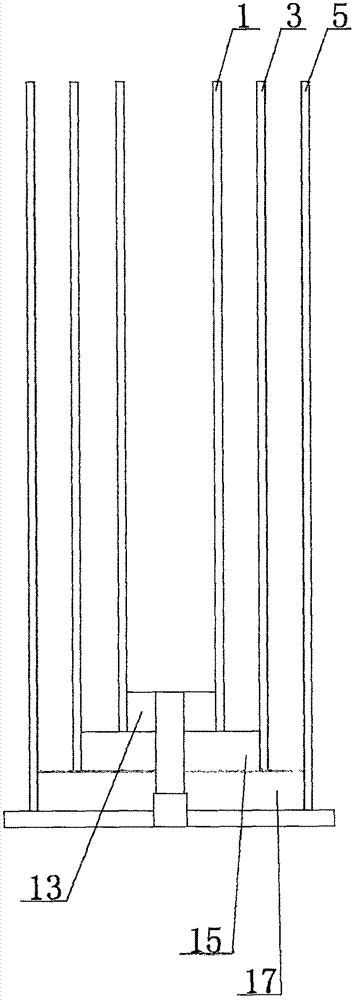

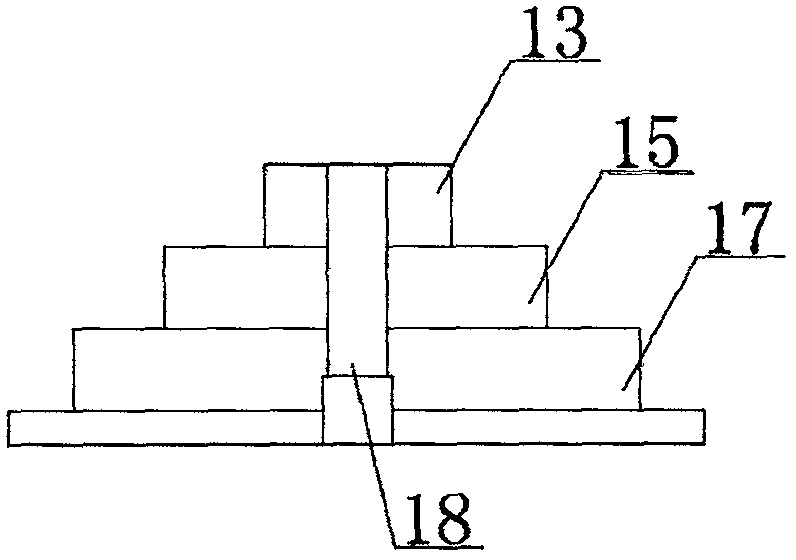

[0024] The present invention will be described in detail below with reference to the accompanying drawings. As shown in the drawings, the structure of the present invention includes tubular electrode A No. 1, tubular electrode B No. 2, tubular electrode C No. 3, tubular electrode D No. 4, tubular electrode E No. 5, and electrode fixing plate A6 , Electrode fixing plate B7, sleeve barrel 8, sleeve cover A9, sleeve cover B10, terminal A11, terminal B12, step A13, step B14, step C15, step D16, step E17, water inlet 18, water outlet 19, and It is characterized in that the electrode fixing plate A6 is provided with tubular electrode A No. 1, tubular electrode C No. 3 and tubular electrode E No. 5, and the electrode fixing plate B7 is equipped with tubular electrode B No. 2 and tubular electrode D No. 4 , the electrode fixing plate A6 and the electrode fixing plate B7 are combined to form a body in an up-and-down structure, the outside of the electrode fixing plate A6 and the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com