Magnetic nano ferrum-carrying ordered mesoporous carbon and preparation method and application thereof

A magnetic nano and mesoporous carbon technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve problems such as easy agglomeration, easy oxidation and deactivation, and achieve difficult agglomeration and adsorption capacity Large, not easy to block the effect of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

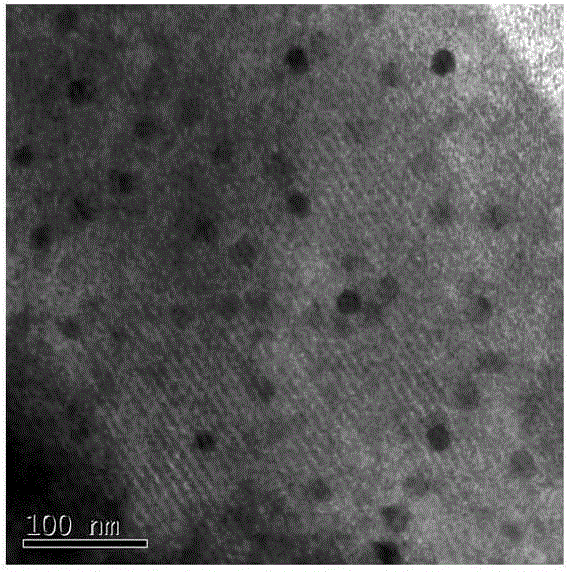

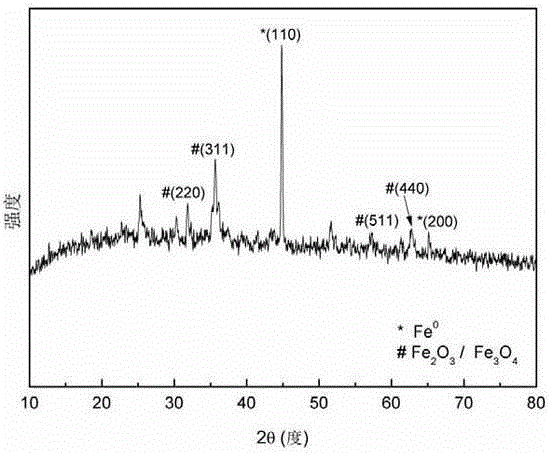

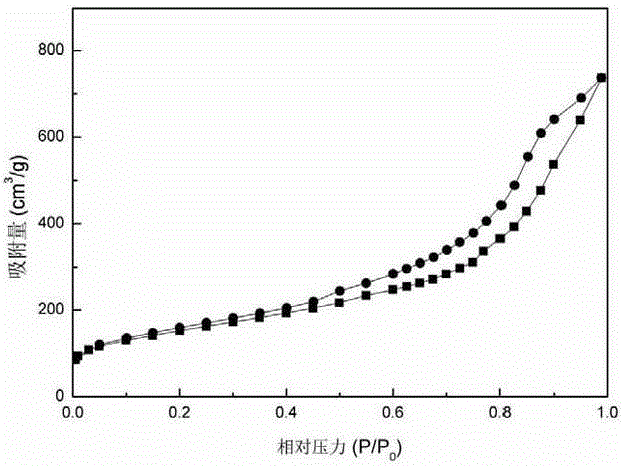

[0044] A magnetic nanometer iron-loaded ordered mesoporous carbon of the present invention, the magnetic nanometer iron-loaded ordered mesoporous carbon uses ordered mesoporous silicon SBA-15 as a template, sucrose as a carbon source, and ferric chloride hexahydrate as an iron source , prepared by nano-co-casting one-step method; the specific surface area of magnetic nanometer iron-loaded ordered mesoporous carbon is 536m 2 / g, the pore size is 3.5nm~4.3nm.

[0045] In this embodiment, the magnetic nanoparticles in the magnetic nano-iron-loaded ordered mesoporous carbon are zero-valent iron and iron oxides, and the iron oxides are triiron tetroxide and ferric oxide; Prepared by reduction method.

[0046] A method for preparing the magnetic nanometer iron-loaded ordered mesoporous carbon in the above-mentioned embodiment, comprising the following steps:

[0047] (1) Preparation of ordered mesoporous silicon SBA-15 template:

[0048] (1.1) Add 8.0g of block copolymer P123 t...

Embodiment 2

[0077] An application of the magnetic nanometer iron-loaded ordered mesoporous carbon of the present invention in the removal of bisphenol A in water comprises the following steps:

[0078] Get 6 parts of the magnetic nanometer iron-loaded ordered mesoporous carbon in Example 1, the quality of each part is 0.005g, add respectively in the bisphenol A solution that 10mL concentration is 200mg / L, adjust the pH value to be 5, 7, 9, 10, 11, 12, at a temperature of 25°C and a rotational speed of 150rpm, the oscillation adsorption reaction was carried out for 6 hours, and then the magnetic nanometer iron-loaded ordered mesoporous carbon adsorbed with bisphenol A was magnetically separated from water for 5 minutes to complete the adsorption process. Treatment of bisphenol A in water.

[0079]Utilize the ultraviolet spectrophotometer to measure the amount of unadsorbed bisphenol A in the solution, the result is as follows Figure 8 shown. Depend on Figure 8 It can be seen that the ...

Embodiment 3

[0081] An application of the magnetic nanometer iron-loaded ordered mesoporous carbon of the present invention in the removal of bisphenol A in water comprises the following steps:

[0082] Get 12 parts of magnetic nano iron-loaded ordered mesoporous carbon in Example 1, the quality of each part is 0.005g, join 10mL concentration respectively in the bisphenol A solution that is 200mg / L, adjust the pH value of bisphenol A solution 9, at a temperature of 25°C and a rotational speed of 150rpm, carry out an oscillating adsorption reaction for 5min, 10min, 15min, 20min, 25min, 30min, 60min, 120min, 180min, 240min, 300min, 360min, and the magnetic nanometer adsorbed with bisphenol A Iron-loaded ordered mesoporous carbon is magnetically separated from water for 5 minutes to complete the treatment of bisphenol A in water.

[0083] Utilize the ultraviolet spectrophotometer to measure the amount of unadsorbed bisphenol A in the solution, draw the schematic diagram of adsorption time and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com