Method and device for detecting quality defects of mark on glass fuse tube products

A technology for fuse tubes and quality defects, which is applied to the field of quality defect detection on glass fuse tube products, can solve the problems of complicated and unpopular defects to be detected, improve detection speed and detection accuracy, ensure reliability, and realize automation The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

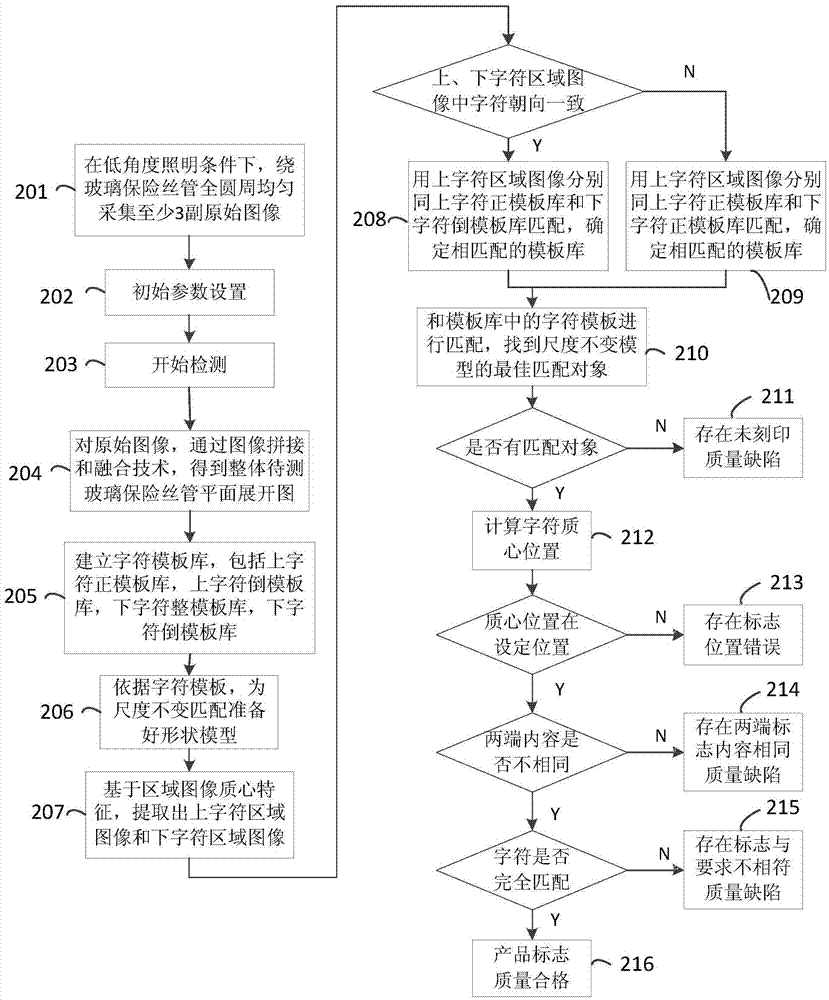

[0041] The present invention will be further elaborated below in conjunction with the accompanying drawings.

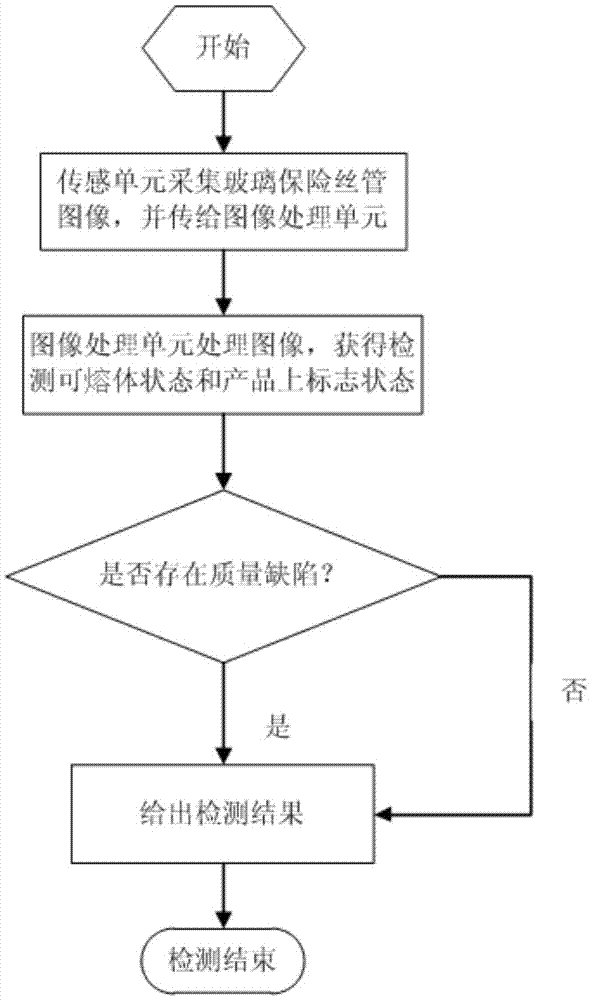

[0042] Such as figure 1 Shown, the mark quality defect detection method on the glass fuse tube product of the present invention comprises the following steps:

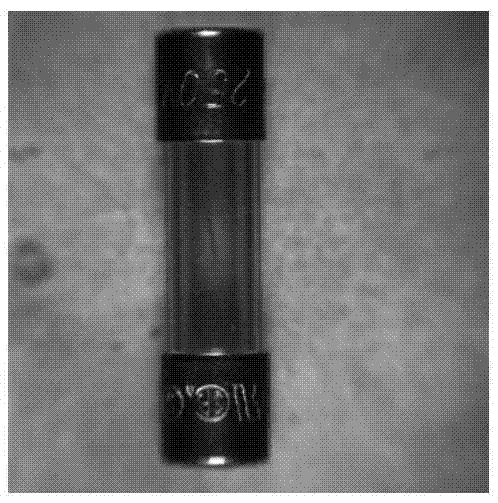

[0043] Acquire the original image of the glass fuse tube to be tested by the sensing unit, and send the collected original image to the image processing unit;

[0044] The image processing unit processes and analyzes the collected original image of the glass fuse tube to be tested, and detects the quality defects of the marks on the product, that is, the mark is not engraved, the position of the mark is on the top, the content of the marks at both ends is the same, and the mark does not meet the requirements, so as to distinguish The appearance quality of the glass fuse tube.

[0045] The method of the present invention passes through Figure 4 The device shown is realized, and the glass fuse tube melt qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com