Integral running castings mold device of large-sized steel ingot clamp

An integral casting and ingot mold technology, applied in the field of steel ingot molds, can solve the problems of falling off or loosening, long ingot firing time and high cost, avoiding falling off or loose points, saving money and man-hours, and simple assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

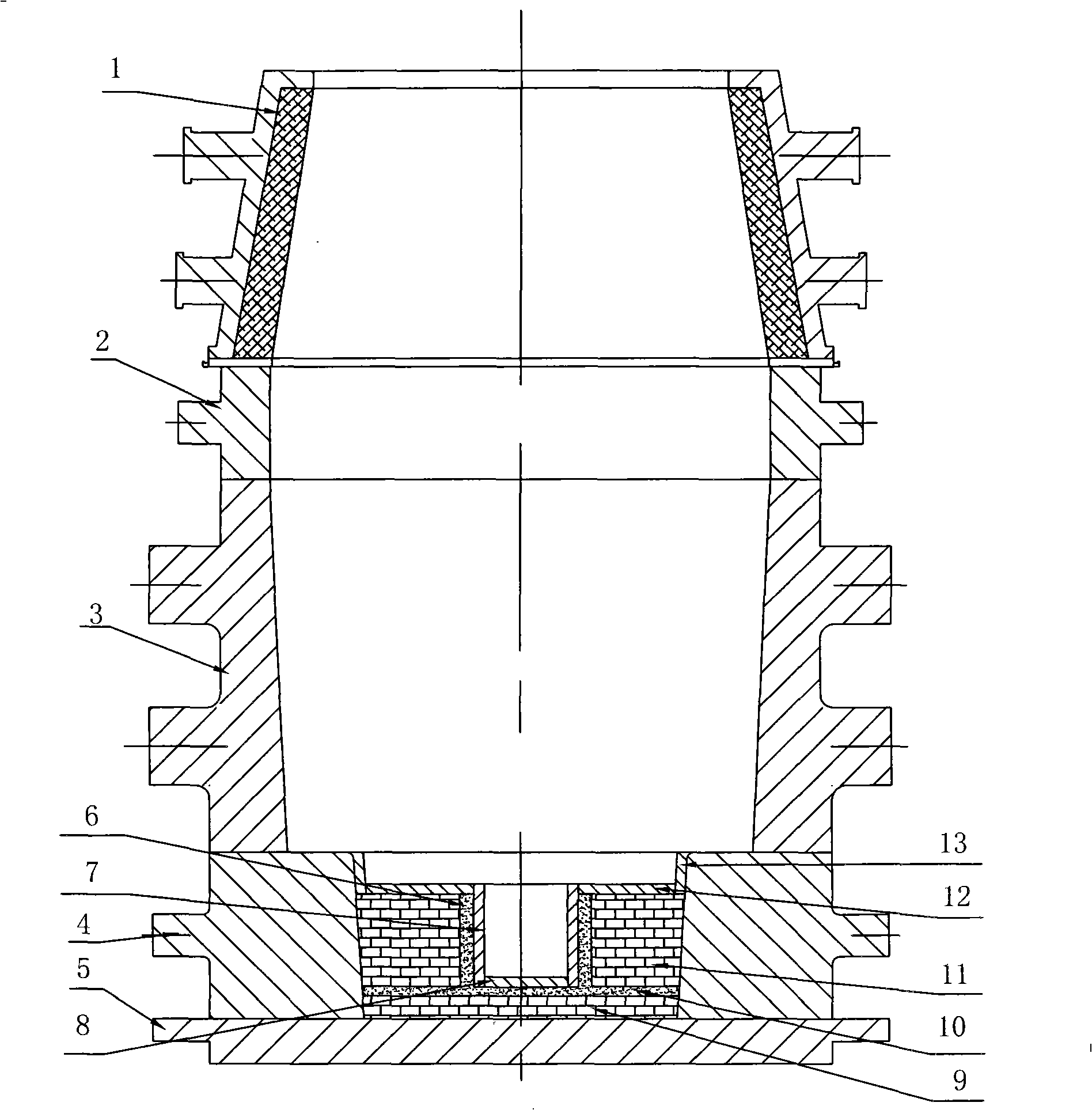

[0009] exist figure 1 In the middle, the lower chassis seat 5 is flatly laid on the ground plane, the upper chassis retainer 4 is placed on the lower chassis seat 5, and several layers of refractory brick cushion 9 are built in the upper chassis retainer 4, and the refractory brick cushion 9 is laid Sand-covered lining 10, a circular refractory brick wall 11 is built on the sand lining 10, and the facade resin sand lining 6 is laid on the inner ring of the circular refractory brick wall 11. The facade resin sand lining 6 and the nozzle sleeve steel cylinder 7 Bonding, the circular steel plate pad 8 is placed in the nozzle sleeve steel cylinder 7, the bottom is attached to the sand lining 10, the chassis cover 13 is placed on the top of the circular refractory brick wall 11, and the circular steel plate pad 12 is installed in the chassis cover 13; Steel ingot mold 3 is installed on upper chassis retaining ring 4, heightening ring 2 is installed on steel ingot mold 3, and therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com