Full-automatic lock body

A fully automatic, lock body technology, applied in the field of locks, can solve the problems of trouble, the key cannot be turned to unlock, and the lock body is difficult to install universally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

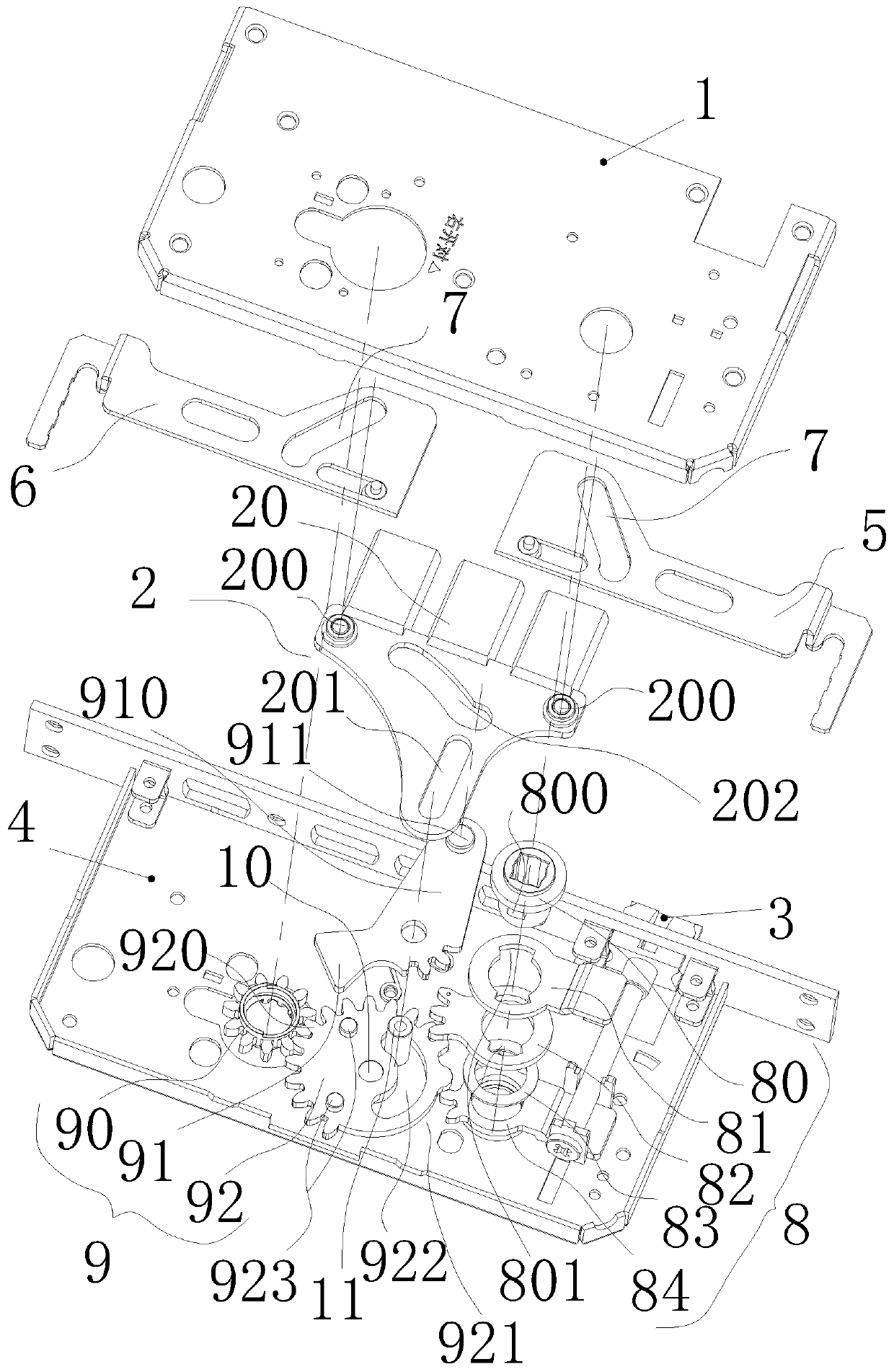

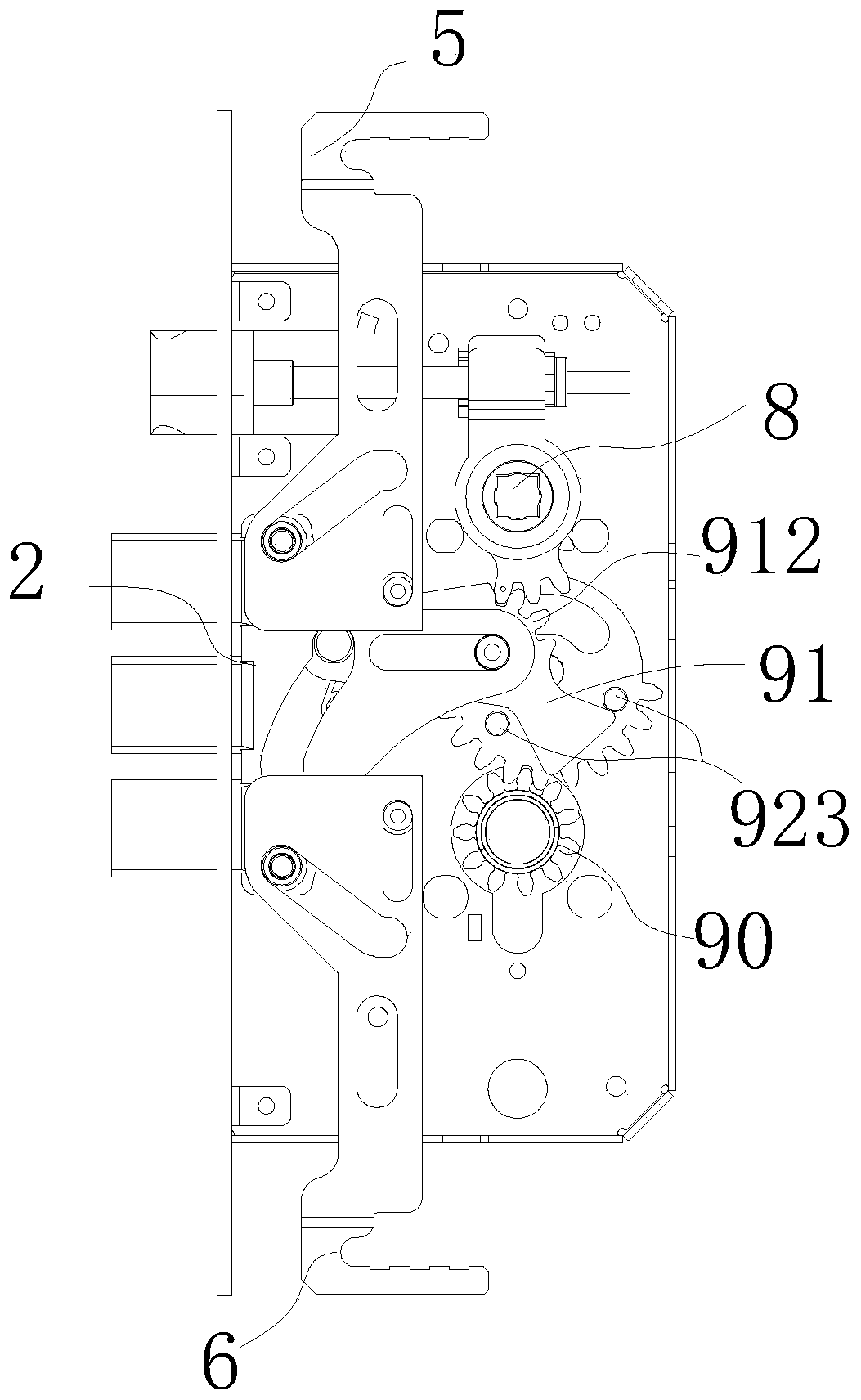

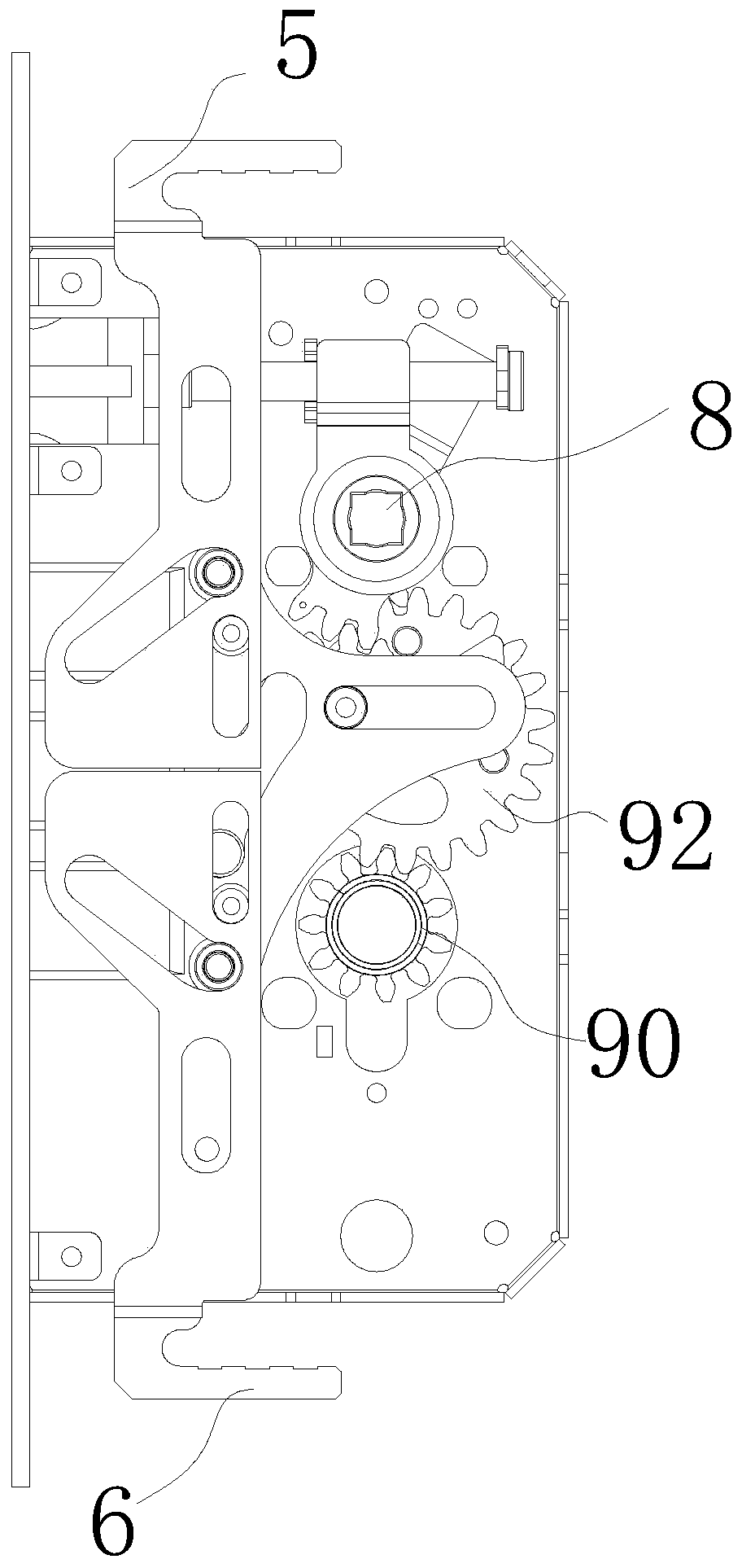

[0032] Fully automatic lock body, such as Figure 1 to Figure 5 As shown, it includes upper cover plate 1, square tongue assembly 2, oblique tongue assembly 3, lock body shell 4, upper heaven and earth hook 5 and lower heaven and earth hook 6, square tongue assembly 2 and oblique tongue assembly 3 are telescopically installed on the lock body respectively Inside the shell 4 and covered by the upper cover plate 1 on the side; the upper sky hook 5 and the lower sky hook 6 are installed in the lock body shell 4, and are driven, stretched out or retracted by the square tongue plate 20 on the square tongue assembly 2 On both sides of the lock body shell 4, the corresponding upper and lower heaven and earth hooks 5 and 6 are respectively provided with oblique pull grooves 7 that cooperate with the push block 200 installed on the square tongue plate 20, and are also provided in the lock body shell 4. There is a shift fork device 8 that drives the latch tongue assembly 3 to retract in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com