Clutch slave cylinder for hybrid electric vehicles

A technology for clutch cylinders and hybrid vehicles, applied in fluid-driven clutches, non-mechanical-driven clutches, clutches, etc., can solve the problems of increased vehicle operating costs, waste of manpower and material resources, and low reliability of vehicles, and improve reliability , fast conversion, and compact control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

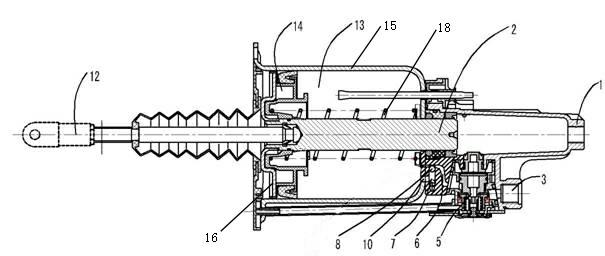

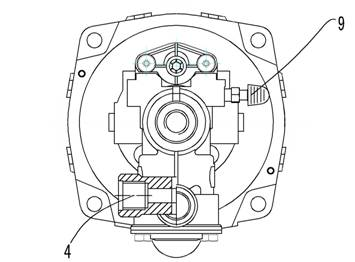

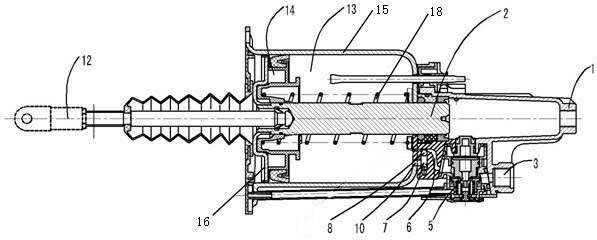

[0013] A kind of embodiment of hybrid vehicle clutch cylinder, such as figure 1 , 2 As shown, it includes the master cylinder 1 and the booster cylinder 15 coaxially connected with the master cylinder 1, the booster cylinder 15 is provided with a booster cylinder piston 16, the rear side of the booster cylinder piston 16 and the rear wall of the booster cylinder A return spring 18 is arranged between them, and the booster cylinder piston 16 divides the booster cylinder body into a front chamber 14 and a rear chamber 13. The master cylinder body 1 is provided with a master cylinder piston 2 connected with the booster cylinder piston 16, and the master cylinder piston 2 The front end is fixedly connected with a clutch push rod 12, and the sub-cylinder is also provided with a booster air inlet and a booster air circuit 6 connected between the booster air inlet and the booster cylinder. Control the booster air inlet and the booster air circuit On-off control valve 5, the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com