Clutch and reversing device

A reversing device and gear technology, applied in the field of clutches, can solve problems such as large radial and axial dimensions, inability to rotate by hand, unsuitable for clutches, etc., and achieve long service life, ensure safety, and have no joint noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

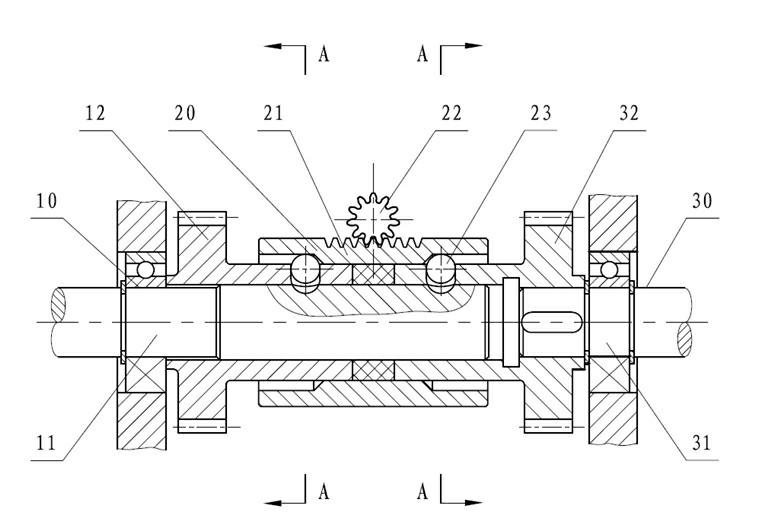

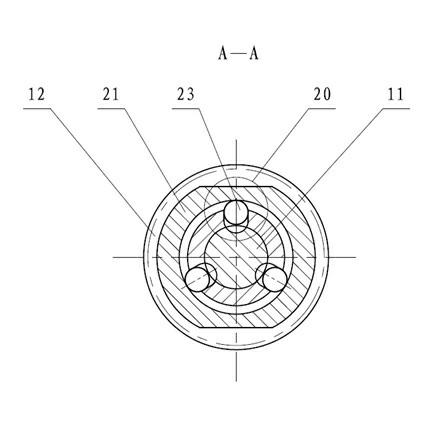

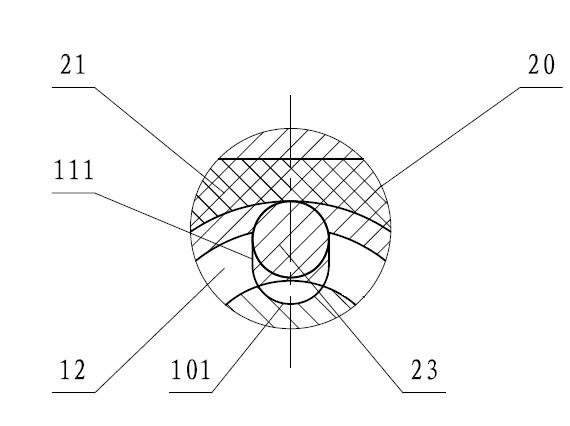

[0036] Such as Figure 1-7 As shown, the device includes an input shaft component 10, a clutch and reversing component 20, and an output shaft component 30. A clutch and reversing component 20 is installed between the input shaft component 10 and the output shaft component 30 to form a clutch and reversing device, wherein The bridge shaft component connected with the input shaft component 10 and the output shaft component 30 is not shown in the figure; the input shaft component 10 is composed of an input shaft 11 and an input shaft gear 12, and the output shaft component 30 consists of an output shaft 31 and an output shaft gear 32 The clutch and reversing part 20 is composed of a sliding sleeve 21, a gear shaft 22, and a steel ball 23. The input shaft gear 12 and the output shaft gear 32 are sleeved on the input shaft 11, and the output shaft gear 32 is connected to the output shaft with a flat key 31 is connected as a whole, the input shaft 11 and the output shaft 31 are coax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com