Heavy-load high-temperature-resistant precision grinding abrasive cloth primer and coating adhesive and preparation method thereof

A technology of precision grinding and high temperature resistance, which is applied in the direction of abrasives, adhesives, manufacturing tools, etc. It can solve the problems of reduced bonding performance, easy detachment of abrasives, low bonding strength, etc., and achieves excellent heat resistance, uniform coating, The effect of high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

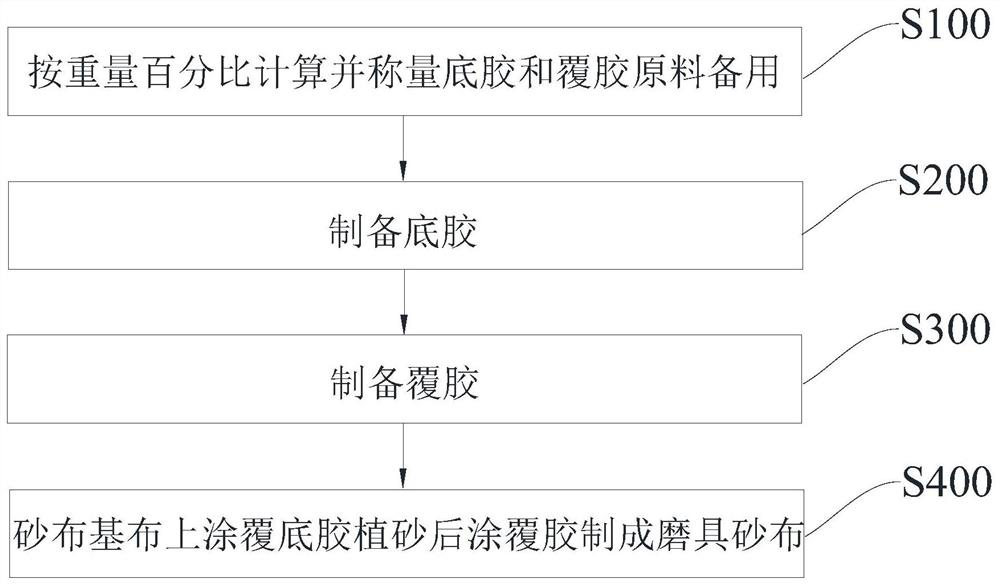

[0025] Such as figure 1 Shown, a kind of preparation method of heavy-duty high-temperature resistant precision grinding emery cloth base glue and covering glue, comprises the following steps:

[0026] S100. Calculate and weigh the raw materials for the base rubber and the coating rubber according to the weight percentage, wherein the base rubber is 34.72% and the coating rubber is 65.28%;

[0027] S200, preparing a primer, which is composed of the following components according to weight percentage: first phenolic resin: 30-40%, second phenolic resin: 20-35%, ethylene glycol diethyl ether: 2.8-5%, coupling agent : 0.1-0.3%, wollastonite: 35-45%, penetrant: 0.2-0.5% and defoamer: 0.2-0.8%, wherein the first phenolic resin is phenolic resin 9600, and the second phenolic resin is water-soluble phenolic resin Resin 1100, penetrating agent is silicone grease, defoaming agent is silicone, coupling agent is silane coupling agent,

[0028] The preparation process of the primer is as...

Embodiment 1

[0034] Grinding abrasive cloth consists of a base cloth and a primer and a cover rubber coated on the base cloth. According to the percentage by weight, it is composed of 34.72% primer, 65.28% cover rubber and an appropriate amount of abrasives.

[0035] Among them, the formula of primer components is: phenolic resin 9600: 34%, phenolic resin 1100: 22.6%, coupling agent: 0.20%, ethylene glycol diethyl ether: 2.94%, wollastonite: 39.50%, penetrating agent: 0.20% , Defoamer: 0.56%, 100% in total, the viscosity is adjusted to 3000cps by water;

[0036] The formula of the coating component is: phenolic resin 1900: 24%, phenolic resin 9600: 17.3%, cryolite: 53.00%, titanium dioxide: 3.40%, blue pigment: 1.91%, Siben: 0.15%, coupling agent: 0.16%, thickener: 0.08%, 100% in total, the viscosity is adjusted to 2000cps by ethylene glycol diethyl ether.

[0037] Preparation method: take the weight percentage of the above formula to prepare 200m 2 Heavy-duty high-temperature resistant ...

Embodiment 2

[0042] Grinding abrasive cloth consists of a base cloth and a primer and a cover rubber coated on the base cloth. According to the percentage by weight, it is composed of 34.72% primer, 65.28% cover rubber and an appropriate amount of abrasives.

[0043] Among them, the formula of primer components is: phenolic resin 9600: 32%, phenolic resin 1100: 24.6%, coupling agent: 0.19%, ethylene glycol diethyl ether: 3.09%, wollastonite: 39.38%, penetrating agent: 0.19% , Defoamer: 0.55%, 100% in total, the viscosity is adjusted to 3000cps by water;

[0044] The formula of the coating component is: phenolic resin 1900: 29%, phenolic resin 9600: 12.3%, cryolite: 52.69%, titanium dioxide: 3.66%, blue pigment: 1.91%, Siben: 0.14%, coupling agent: 0.20%, thickener: 0.10%, 100% in total, the viscosity is adjusted to 2000cps by ethylene glycol diethyl ether.

[0045] Preparation method: take the weight percentage of the above formula to prepare 200m 2 Heavy-duty high-temperature resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com