Patents

Literature

118 results about "Ethylene glycol diethyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene glycol dimethyl ether (dimethoxyethane, CH3OCH2CH2OCH3), a higher boiling alternative to diethyl ether and THF, also used as a solvent for polysaccharides, a reagent in organometallic chemistry and in some electrolytes of lithium batteries.

Method for promoting light oil yield of atmospheric and vacuum distillation of petroleum oil

InactiveCN1884441AImprove light oil yieldNo need to change the structureHydrocarbon distillationAcetic acidOrganic solvent

The invention relates the method for improving atmospheric and vacuum distillation light oil productivity. The method comprises the following step: adding the 0.001-0.1wt% addition agent with colophony into crude oil in atmospheric and vacuum distillation tower. The addition agent comprises 50-80% colophony and 50-20% organic solvent. The pH is 7.0-7.5. The organic solvent comprises ethanol or cellosolve or ethyl propyl acetone or acetate cellosolve. The method can be used in oil-extraction plant, and the light oil productivity is improved by 1.5-2.3wt%.

Owner:SHANGHAI JIAO TONG UNIV

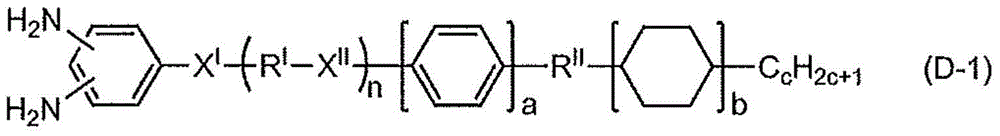

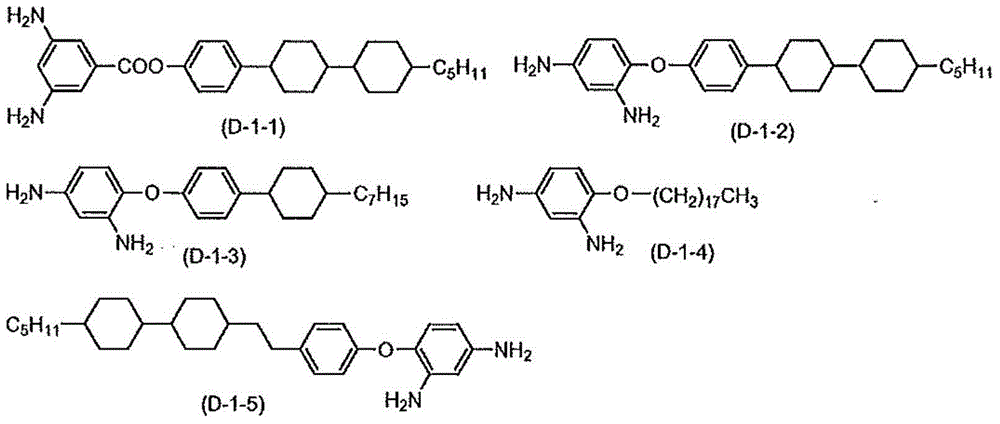

Liquid crystal orientation agent, liquid crystal orientation film, manufacturing method of liquid crystal orientation film, and liquid crystal display element

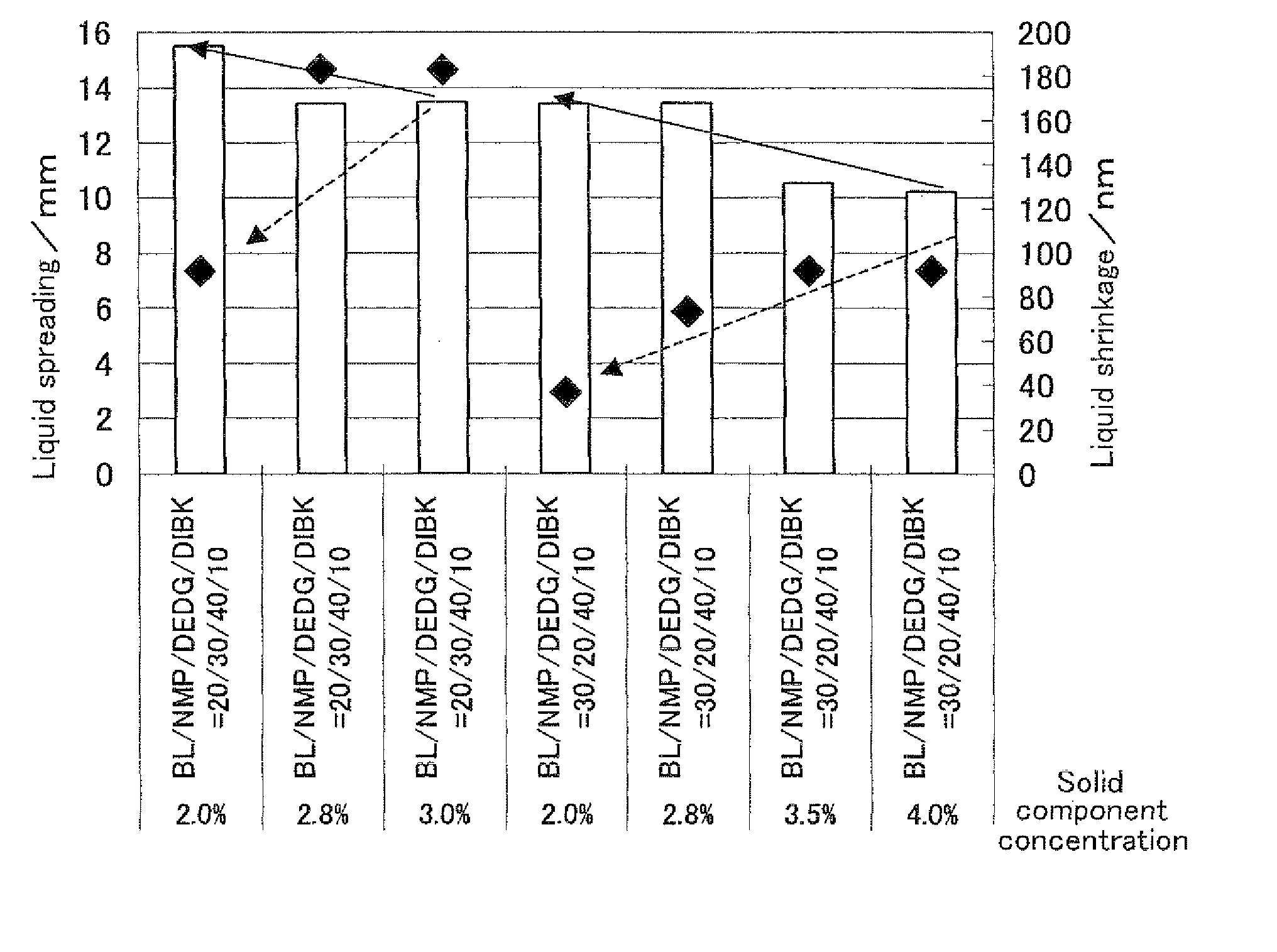

InactiveCN103666486AImprove yieldUniform coatingLiquid crystal compositionsNon-linear opticsDiacetone alcoholDiethylene glycol diethyl ether

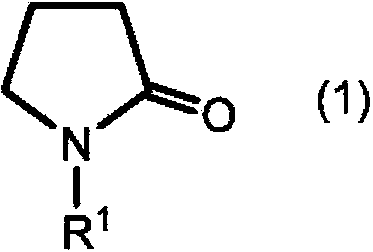

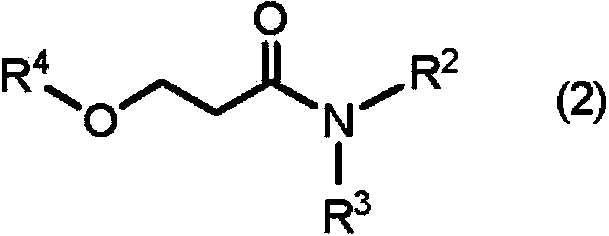

The invention relates to a liquid crystal orientation agent, a liquid crystal orientation film, a manufacturing method of the liquid crystal orientation film, and a liquid crystal display element. The liquid crystal orientation agent has good printing performance with respect to a substrate and good continuous printing performance and prevents swelling of printing plates. The liquid crystal orientation agent contains at last one polymer (A) selected from the group formed by polyamide acid, polyimide, polyamide acid ester and polysiloxane, a first solvent containing more than one of N-ethyl-2-pyrrolidone, 1,3-dimethyl-2-imidazolone, 3-methoxy-N, N-dimethylpropionamide and so on, and a second solvent containing more than one of propylene glycol diacetate, diethylene glycol diethyl ether, diisoamyl ether diacetone alcohol and so on.

Owner:JSR CORPORATIOON

Nanometer polysiloxane nontoxic low-surface-energy ship antifouling coating and preparation method thereof

ActiveCN102618165ALower surface energyImprove corrosion resistanceAntifouling/underwater paintsPaints with biocidesGas phaseSlurry

The invention relates to the field ship antifouling coatings, in particular to a nanometer polysiloxane nontoxic low-surface-energy ship antifouling coating for sea ships and a preparation method thereof, which are used for solving the problem of long-term nontoxicity, antifouling and corrosion on the outer bottom surface of a ship. The nanometer polysiloxane nontoxic low-surface-energy ship antifouling coating comprises the following components in parts by weight: 50-55 parts of polysiloxane resin, 1-5 parts of nanometer slurry, 5-8 parts of dimethylbenzene, 6-10 parts of butyl ester; 2.0-3.0 parts of ethylene glycol diethyl ether acetic ester, 0.3-0.5 part of a dispersing agent, 0.3-0.5 part of an antifoaming agent, 0.1-0.3 part of a flatting agent, 0.5-0.8 part of an anti-settling agent, 0.4-0.7 part of gas phase white carbon black, 15-22 parts of a pigment and 3-6 parts of a filler. The preparation method comprises the following steps of: proportionally preparing, dispersing, and grinding till the fineness is below 30 micros to obtain a component A; and mixing the component A and the component B for curing to obtain the nontoxic long-term ship sea antifouling coating. The nanometer polysiloxane nontoxic low-surface-energy ship antifouling coating is a surface protection material with extreme low surface energy, and plays roles in preventing fouling and scaling, and marine organisms are prevented from being adhered to the antifouling coating easily.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Method for jointly producing glycol ether and ethylene glycol diethyl ether by adopting ethylene glycol as raw material

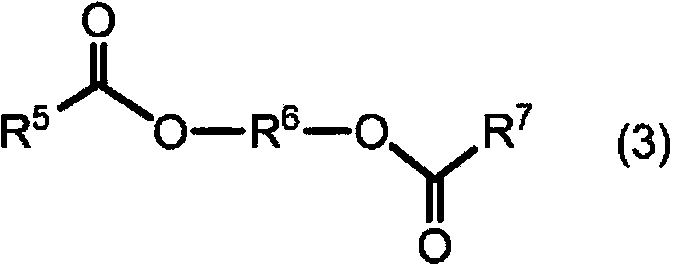

InactiveCN103641695AHigh activityHigh selectivityEther preparation by compound dehydrationMolecular sieveAlcohol

The invention discloses a method for jointly producing glycol ether and ethylene glycol diethyl ether by adopting ethylene glycol as a raw material and belongs to the technical fields of fine chemicals and catalysis. According to the method, the ethylene glycol and ethyl alcohol or ethylene glycol and diethyl ether or ethylene glycol and ethyl alcohol as well as a diethyl ether mixture are adopted as raw materials, one or more than one of substances adopting H<+1>, Al<3+>, B<3+> as positive ions and adopting SO4<2->, NO3<-1>, NO2<-1>, PO4<3-> and X<-1> (X=F, Cl, Br and I) as negative ions is adopted as a modifier and a substance for modifying a molecular sieve or a metallic oxide is adopted as a catalyst to synthetize the glycol ether and the ethylene glycol diethyl ether. The method has the advantages that the problem of reactant generating of ethylene glycol per se in the reaction of the ethylene glycol and the ethyl alcohol is solved; the glycol ether and the ethylene glycol diethyl ether can be jointly produced at the same time; the generating proportion of the glycol ether and the ethylene glycol diethyl ether can be controlled within a certain range.

Owner:HENAN COAL CHEM IND GROUP INST +1

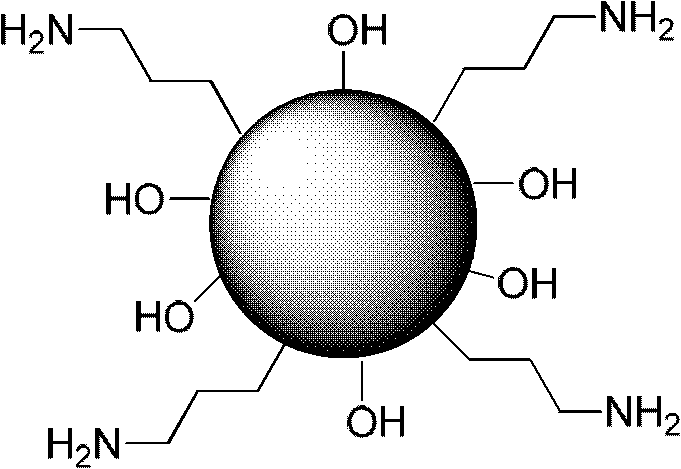

Material adsorbing heavy metal in water solution and method

ActiveCN103157440AOther chemical processesSolid sorbent liquid separationAqueous solutionCadmium Cation

The invention relates to material absorbing heavy metal in water solution and a method. The material is made through the fact that functional perssad is modified on the surface of various kinds of immobilized material, and the functional perssad is in covalent bonding with ethylene glycol tetraacetic acid (EGTA). The material can be used for remove of lead, mercury, cadmium, arsenic and other poisonous metal in the water solution, cannot change an adsorbing effect along with change of the immobilized material, and cannot change other components in the water solution. The material and the method have the advantages of being low in cost, wide in application range, strong in removing performance, good in selectivity, capable of being reproducible, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Liquid crystal aligning agent, liquid crystal aligning film and liquid crystal display element

ActiveCN105001881AReduce non-display areaAchieve narrow frameLiquid crystal compositionsNon-linear opticsDiethylene glycol diethyl etherDiacetone alcohol

The invention provides a liquid crystal aligning agent, a liquid crystal aligning film and a liquid crystal display element. The liquid crystal aligning agent contains at least one polymer (A) selected from the group consisting of polyamic acid, polyamic acid ester and polyimide, and solvents. The solvents contain a specific solvent (X) and a specific solvent (Y). The specific solvent (X) is 1-butoxy-2-propanol; and the specific solvent (Y) contains at least one of the group consisting of diethylene glycol diethyl ether, diacetone alcohol, propylene glycol diacetate and dipropylene glycol monomethyl ether. According to the invention, undesirable film thickness of the end of the coating area of the liquid crystal aligning agent is limited.

Owner:JSR CORPORATIOON

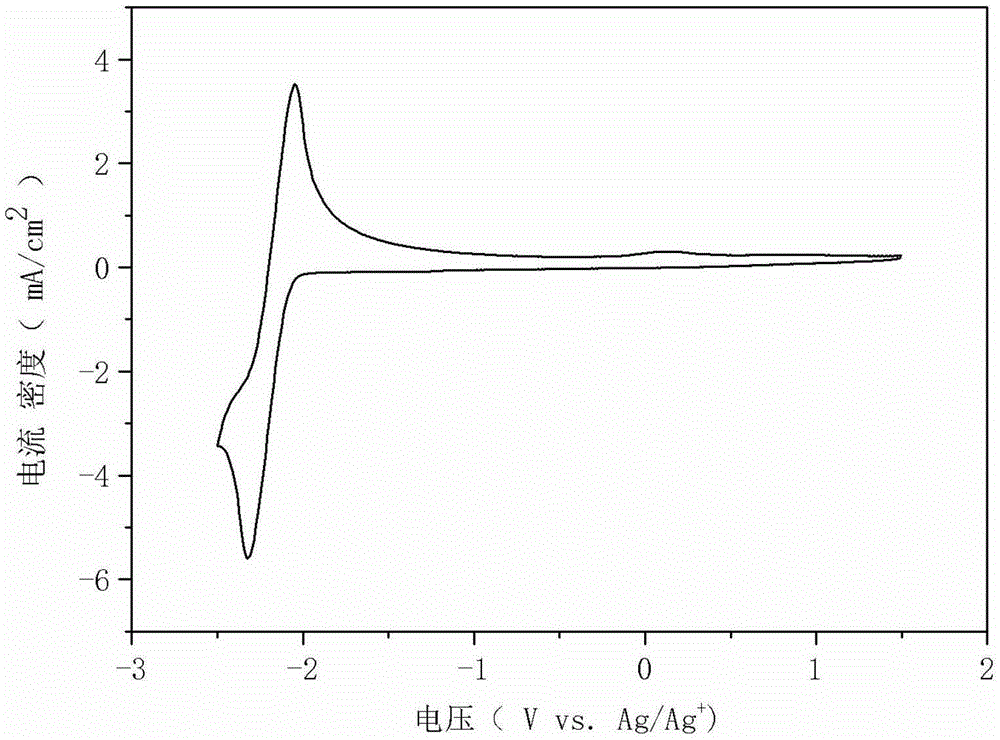

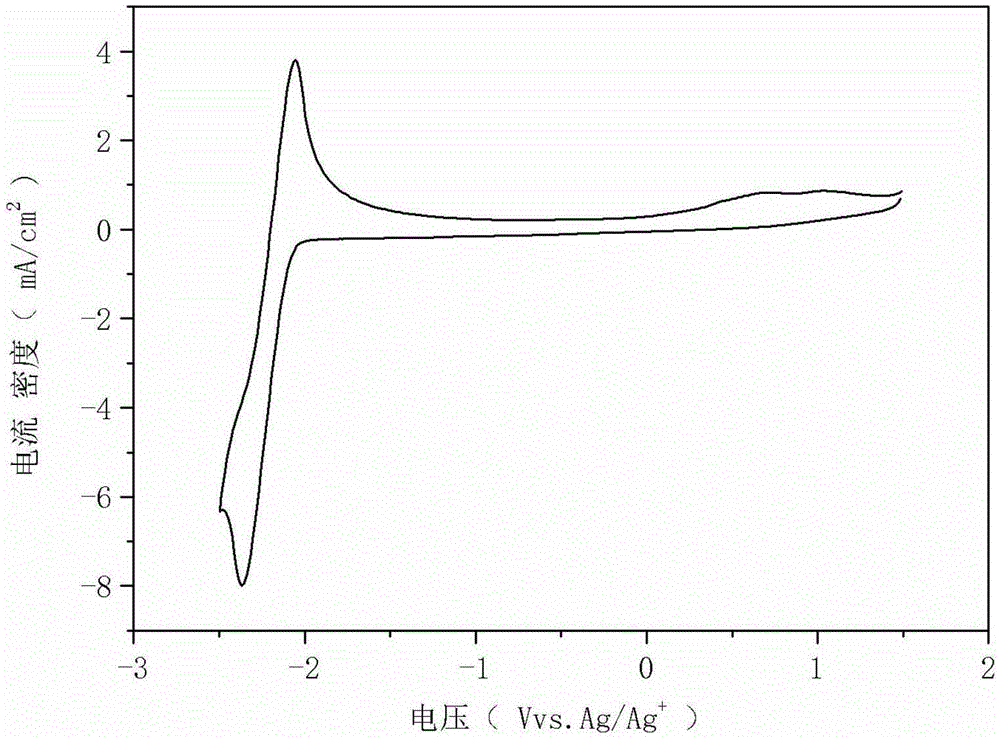

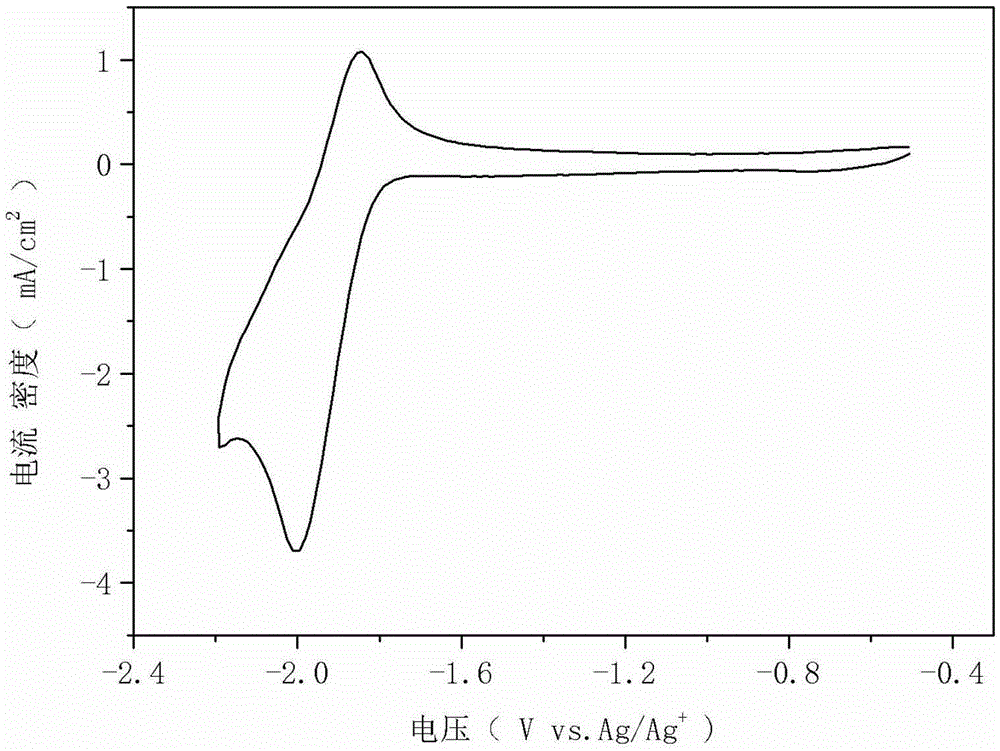

Organic phase electrolyte and application thereof in negative electrode of redox flow battery

InactiveCN106654332ALow electrochemical potentialImprove electrochemical performanceRegenerative fuel cellsTetrafluoroborateDiethyl ether

The invention discloses an organic phase electrolyte and an application thereof in a negative electrode of a redox flow battery. The organic phase electrolyte consists of active materials, a supporting electrolyte and an organic solvent, wherein the active materials are diphenyl ketone and a derivative thereof, anthrone and a derivative thereof, or dibenzoyl methane and a derivative thereof; the supporting electrolyte is selected from tetraethylammonium hexafluorophosphate, tetraethylammonium tetrafluoroborate, tetrabutylammonium hexafluorophosphate or tetrabutylammonium tetrafluoroborate; and the organic solvent is selected from acetonitrile, tetrahydrofuran, propylene carbonate, ethylene carbonate, dimethyl sulfoxide, dimethylformamide, glycol dimethyl ether or ethylene glycol diethyl ether. The organic phase electrolyte disclosed by the invention has relatively low electrochemical potential and high electrochemical property; when the organic phase electrolyte is used as the negative electrode electrolyte of the redox flow battery for assembling an organic phase redox flow battery, relatively high open-circuit voltage can be realized, so that the energy density of the battery can be improved; and meanwhile, the capacity fading of the battery can be lowered, so that the cycle life of the battery can be prolonged.

Owner:TIANJIN UNIV

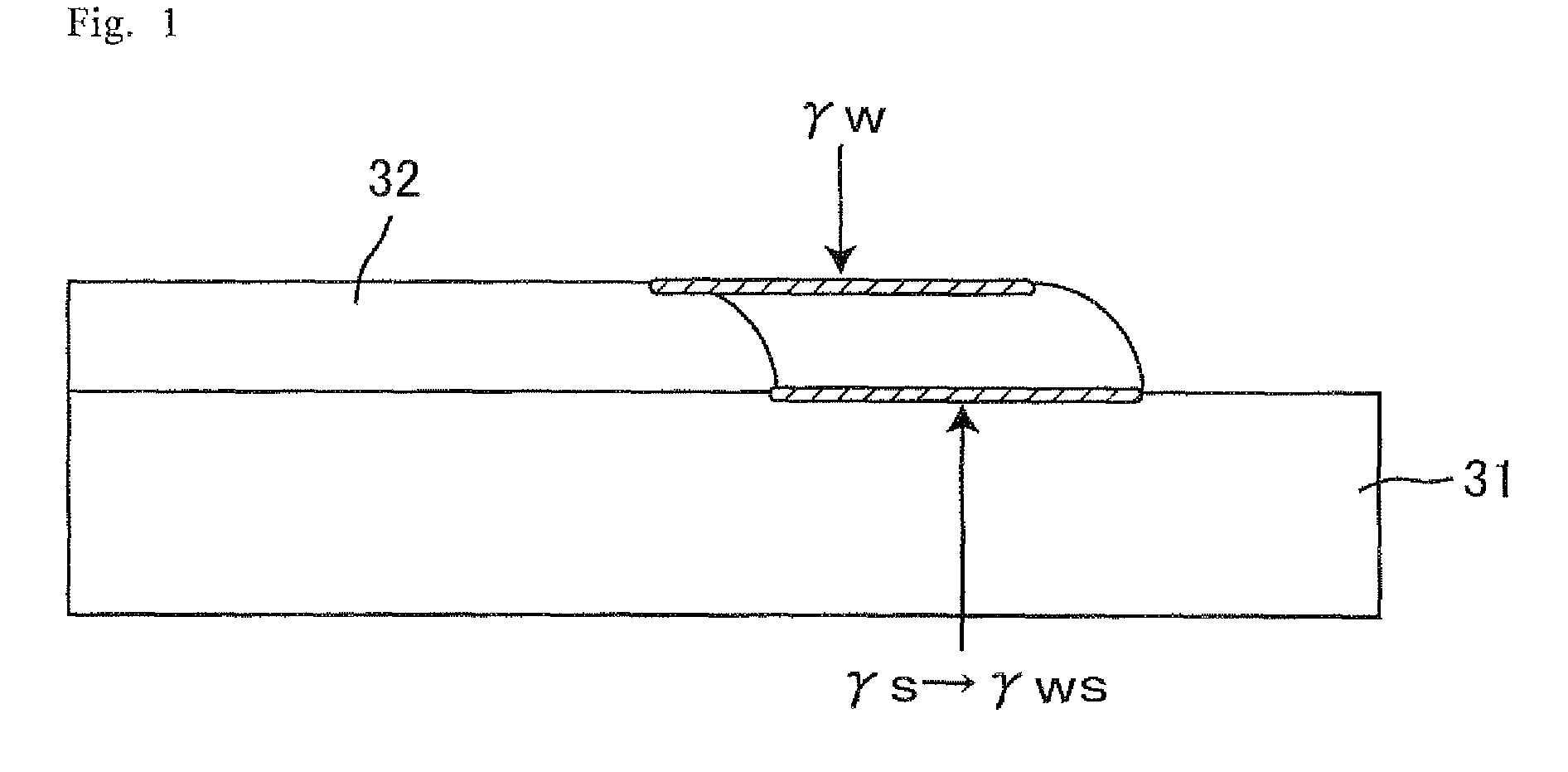

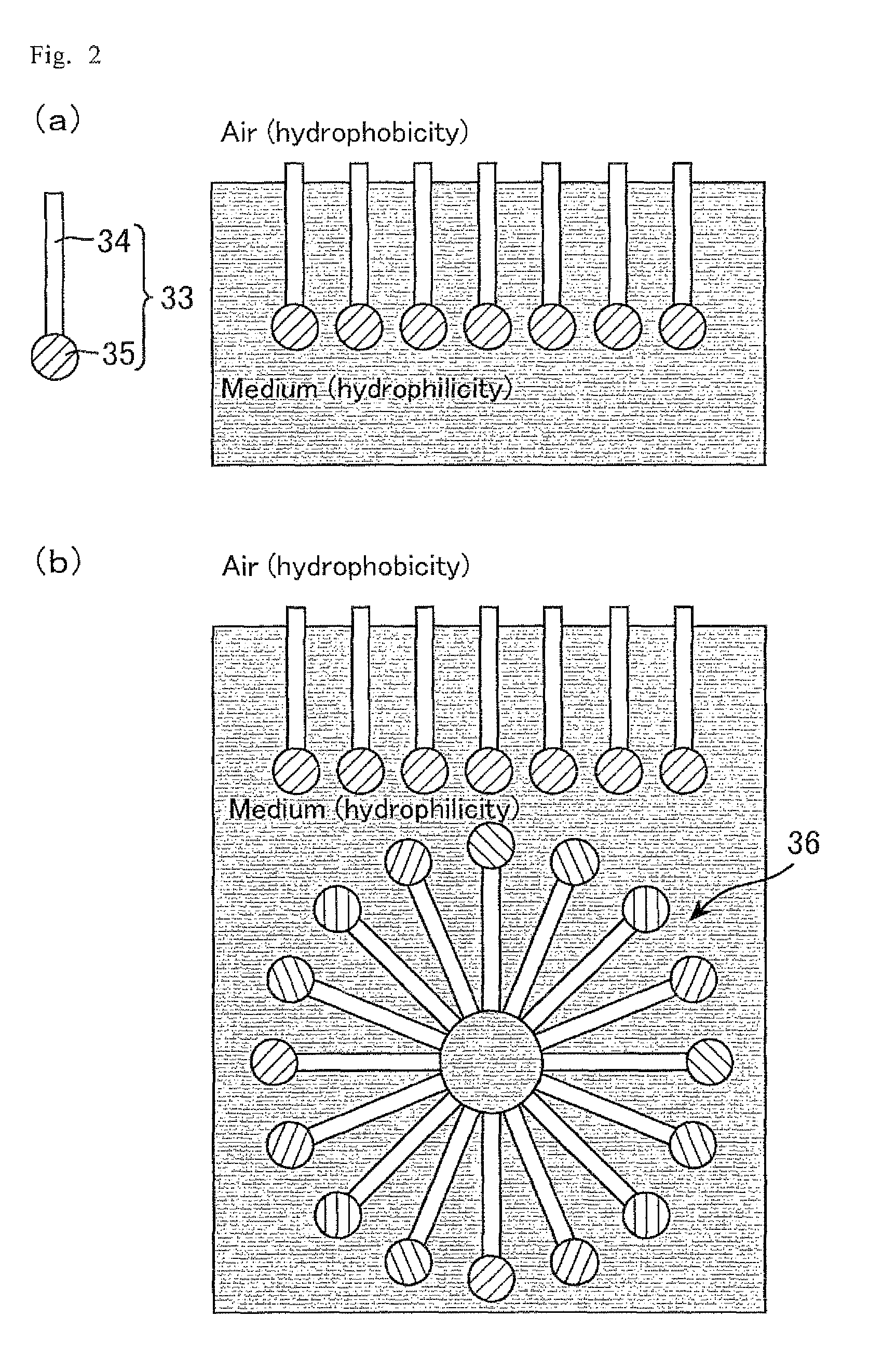

Aligning agent for liquid crystal and liquid-crystal alignment film obtained with the same

ActiveUS7537812B2Good film uniformityLiquid crystal compositionsThin material handlingCrystallographyDiethylene glycol diethyl ether

To provide a liquid crystal aligning agent which gives a coating film with good uniformity regardless of drying temperature after coating, and a liquid crystal alignment film having good coating film uniformity.A liquid crystal aligning agent comprising at least one polymer selected from a polyamic acid and a soluble polyimide, diethylene glycol diethyl ether, and dipropylene glycol monomethyl ether, and a liquid crystal alignment film obtained by printing this liquid crystal aligning agent by a flexographic printing method.

Owner:NISSAN CHEM CORP

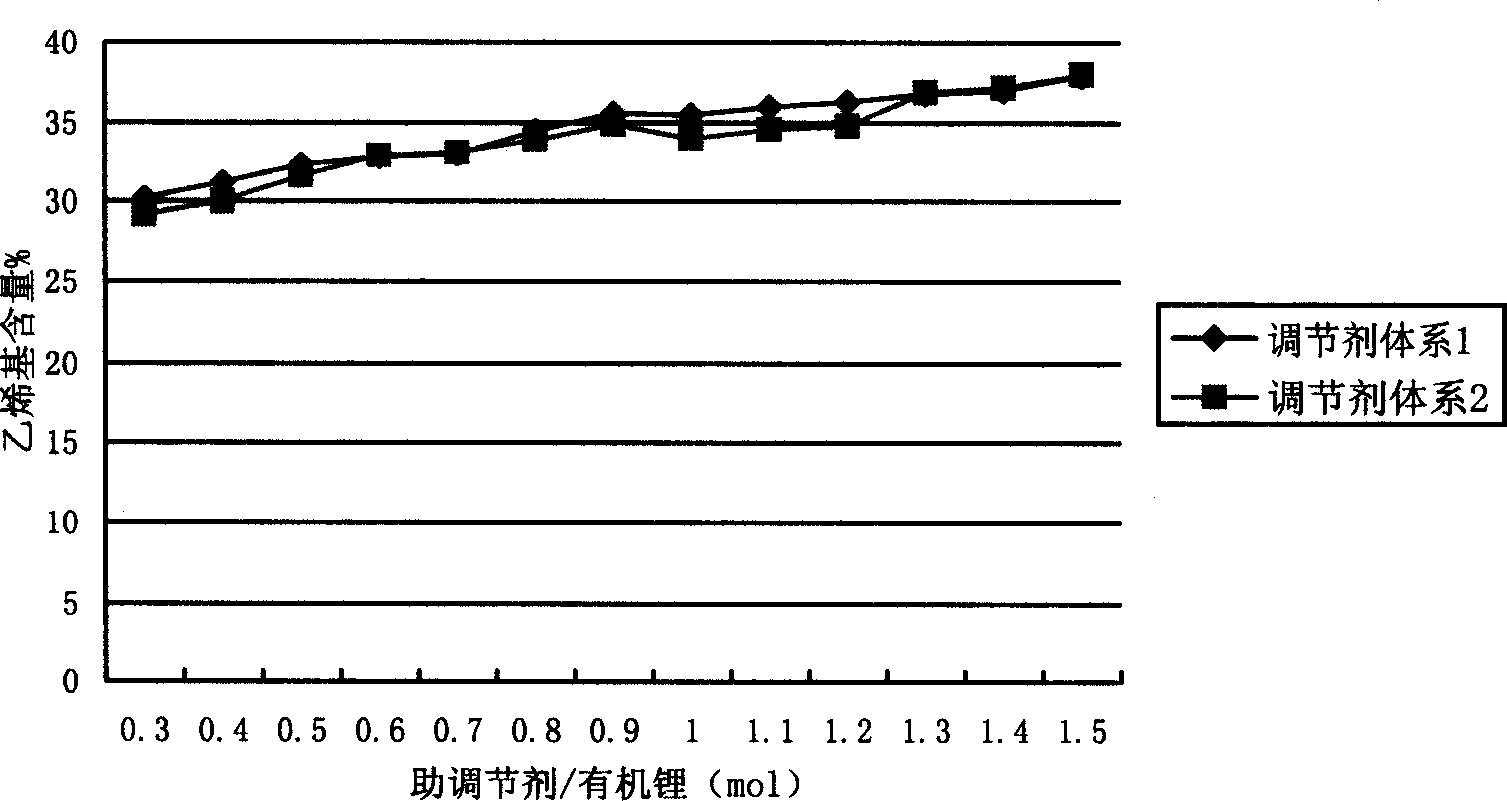

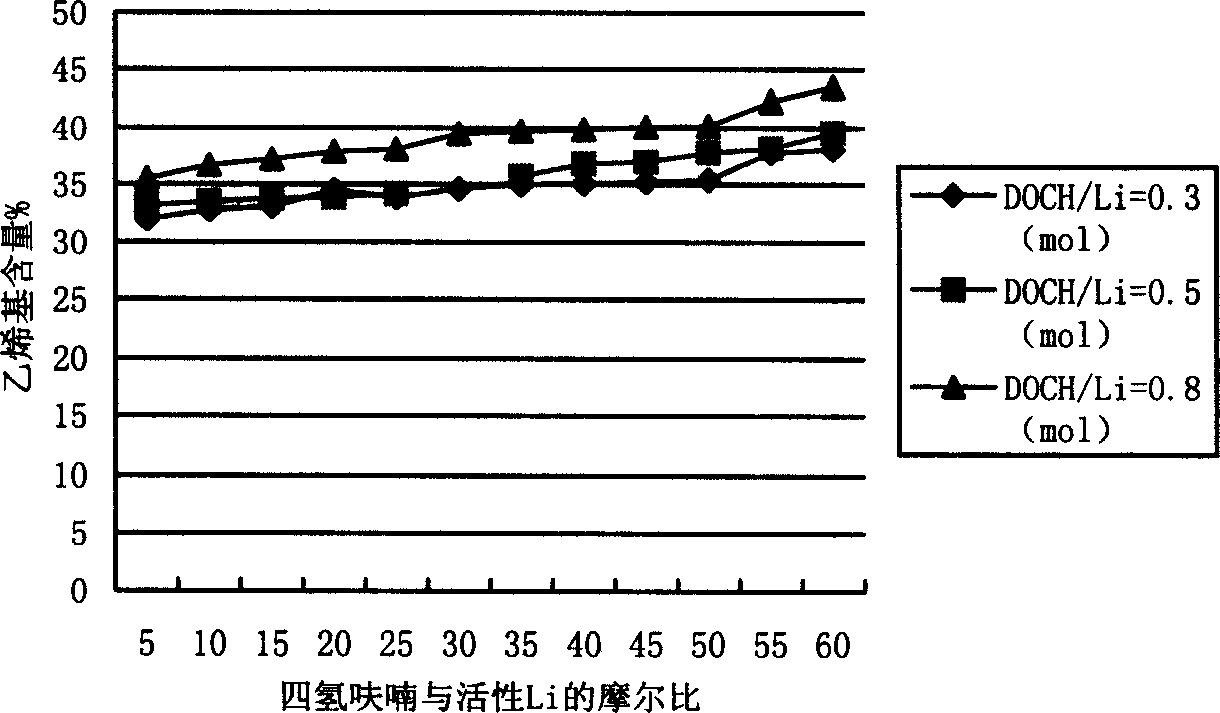

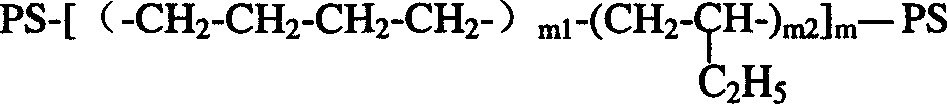

Process of controlling 1.2-structure content and distribution in polybutyldiene

ActiveCN1861651AEvenly distributedStable within a certain range and evenly distributedPolybutadieneImpurity

A process for controlling the content and distribution of 1,2-structure in polybutadiene features use of a tetrahydrofuran / ethanediol diether (or dibutylether) as its regulation system to make the content of 1,2-structures in 33-37% range and the uniform distribution of 1,2-structures in molecular chain.

Owner:CHINA PETROCHEMICAL CORP +1

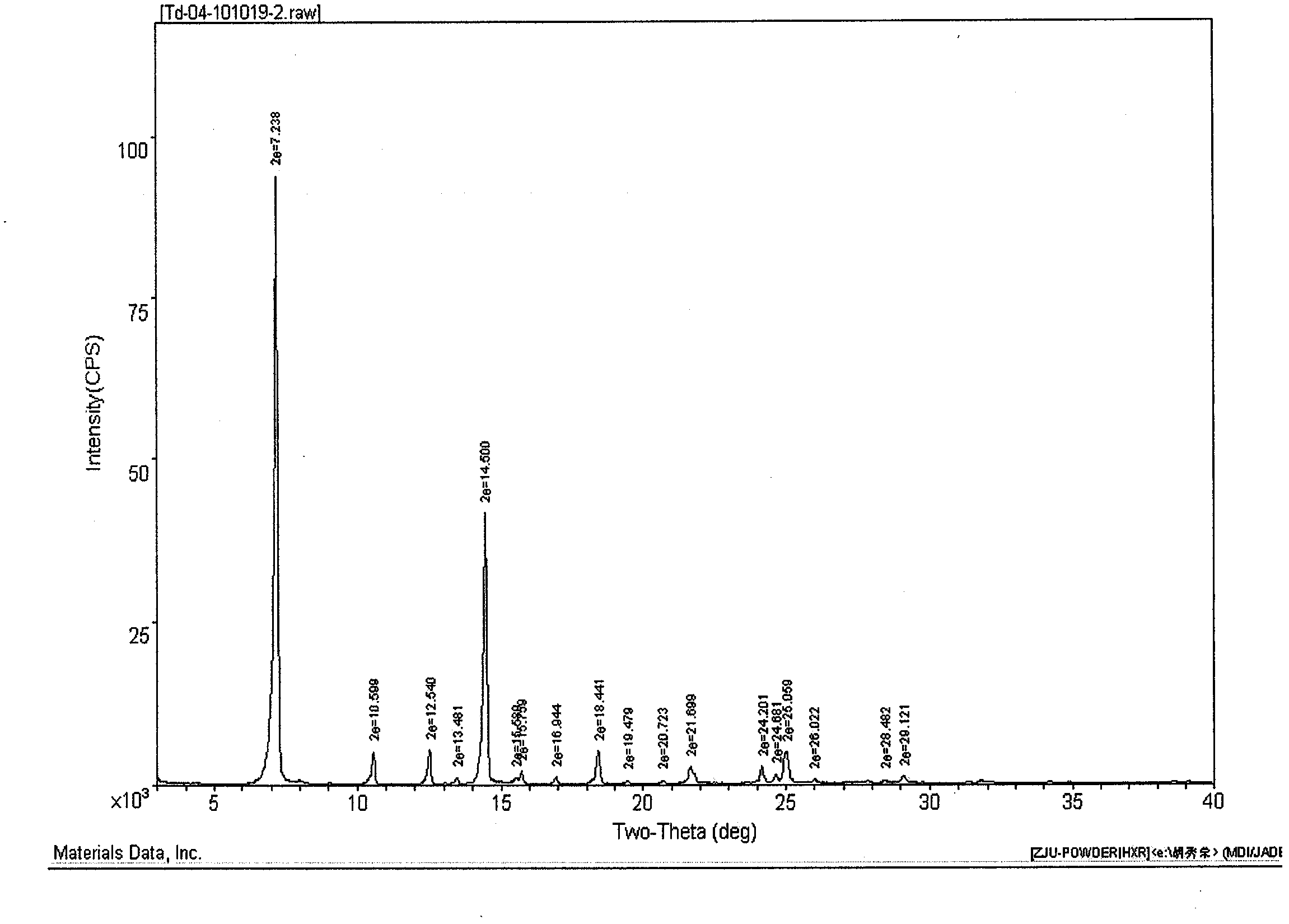

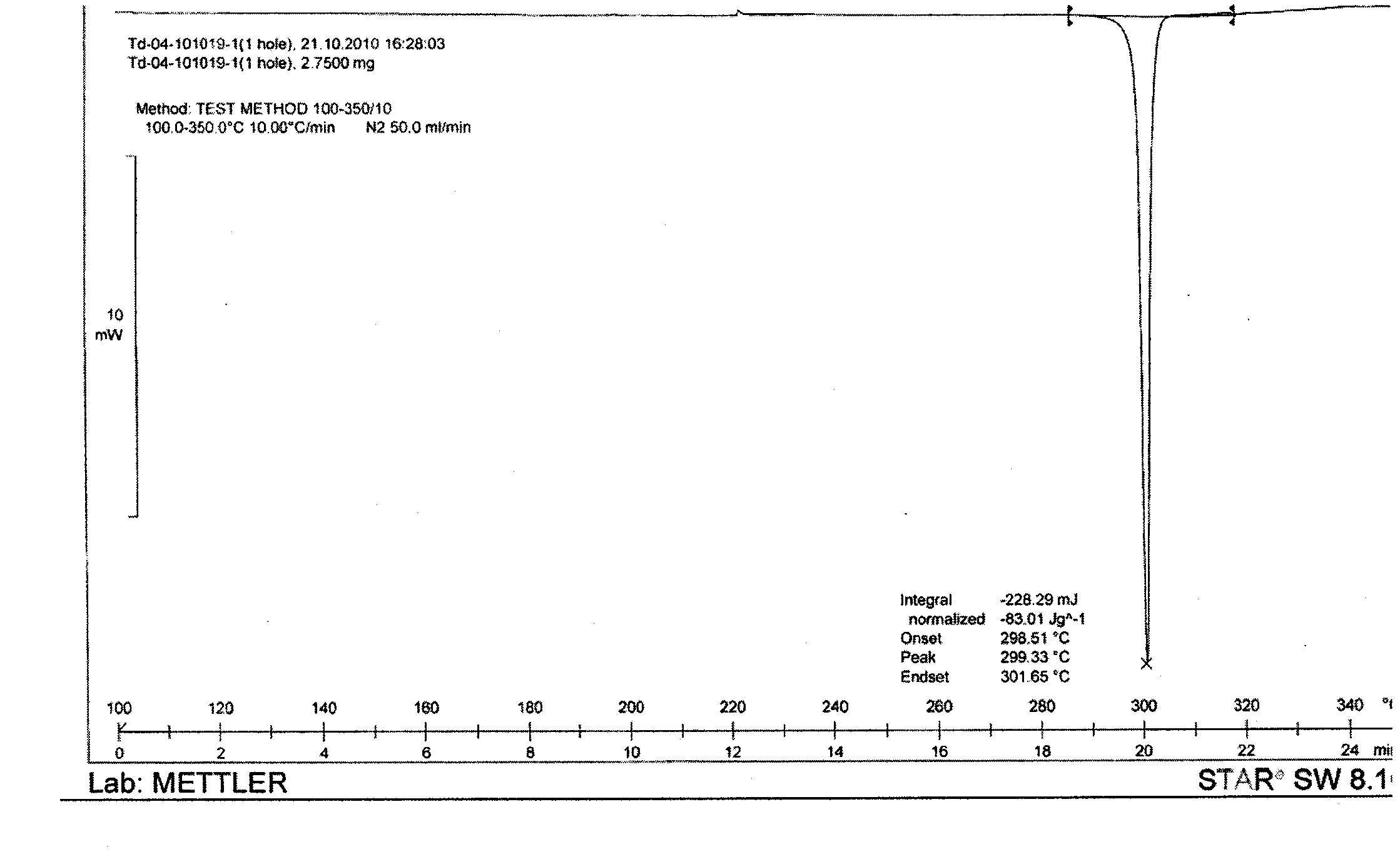

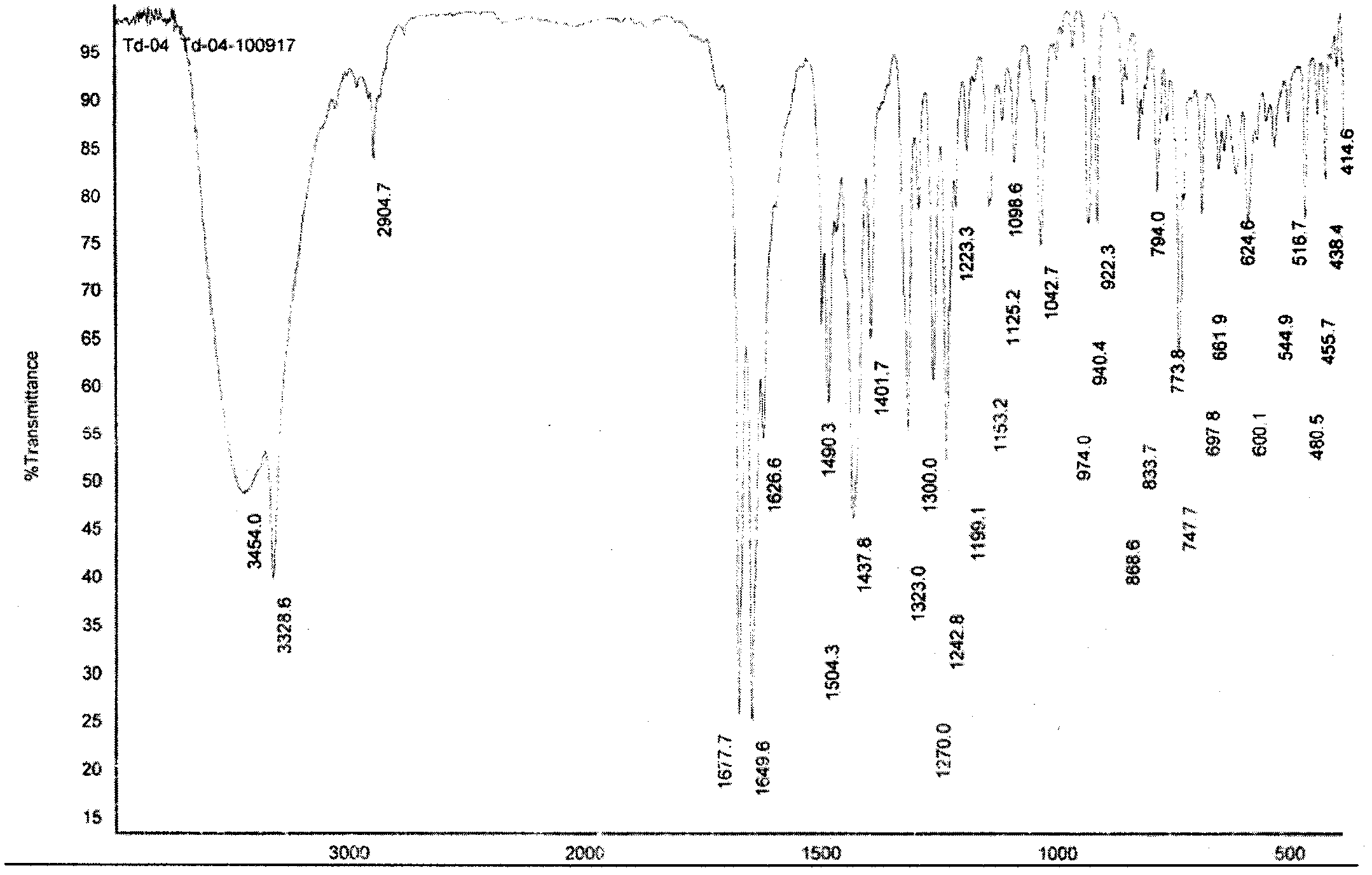

New preparation method for Tadalafei crystal form I

The invention provides a preparation method for Tadalafei I type. The preparation method comprises the following steps of: heating a Tadalafei crude product to the temperature of between 50 and 140 DEG C; dissolving the Tadalafei crude product in ethylene glycol monoethyl ether, ethylene glycol diethyl ether, ethylene glycol monomethyl ether, 1,3-dioxolane or a mixed solvent of two or three thereof; cooling a system to obtain a crystal; and separating to obtain a precipitate. The preparation method has the characteristics of low solvent consumption and high yield. By the method, a pure I type Tadalafei crystal can be obtained; and by the crystallization method, the product can be purified and optical purity can be improved.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD

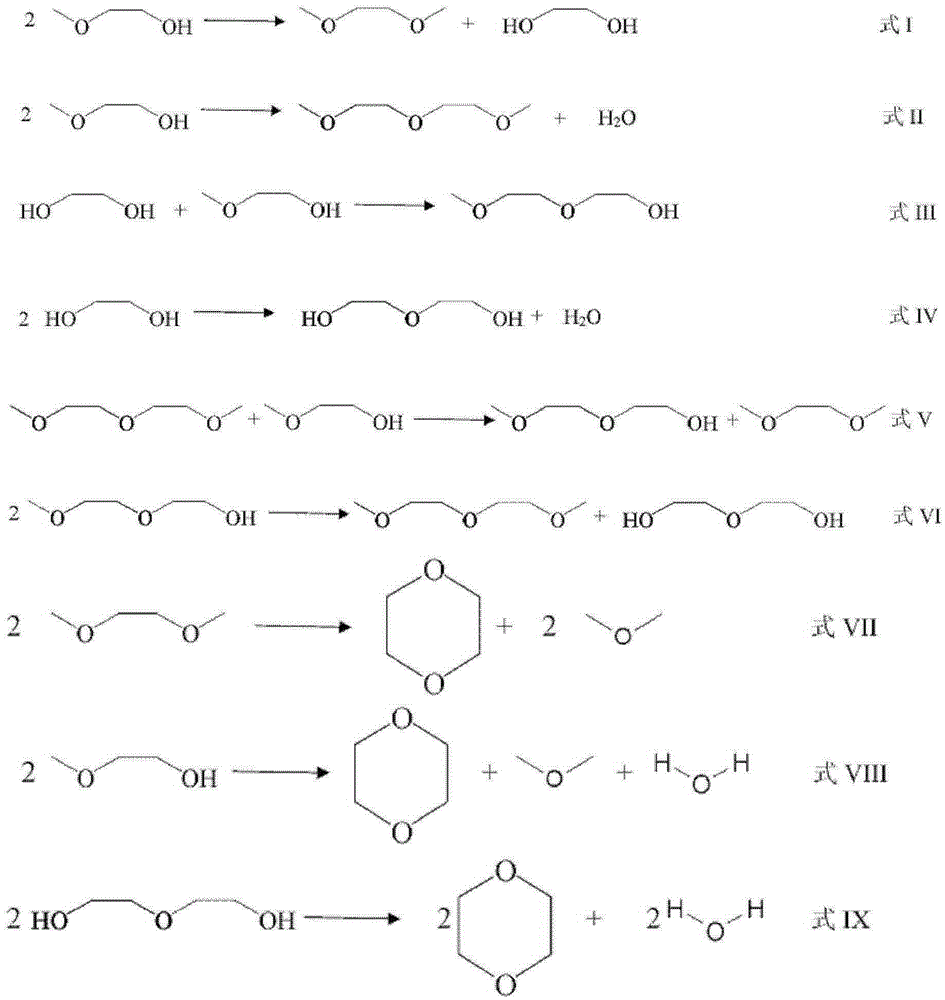

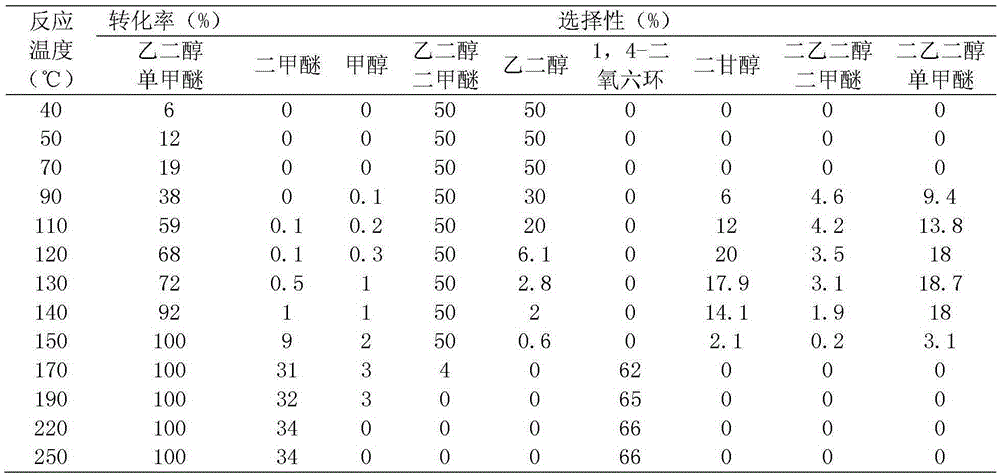

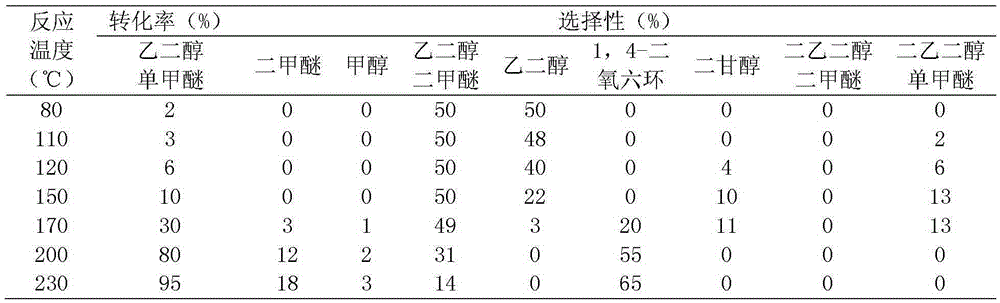

Method for directly co-preparing glycol dimethyl ether and ethylene glycol from ethylene glycol monomethyl ether

ActiveCN106554258ALess side effectsMolecular sieve catalystsBulk chemical productionPolyethylene glycolReaction temperature

The invention provides a method for directly co-preparing glycol dimethyl ether and ethylene glycol from ethylene glycol monomethyl ether. The method specifically comprises the following steps: enabling a raw material ethylene glycol monomethyl ether and optional inert gas which is taken as carrier gas to pass through a reactor loaded with a solid acid catalyst; reacting under conditions with a reaction temperature ranging from 40 DEG C to 150 DEG C and reaction pressure ranging from 0.1 Mpa to 15.0 Mpa to generate glycol dimethyl ether and ethylene glycol, wherein mass space velocity of the raw material ethylene glycol monomethyl ether ranges from 0.05 h<-1> to 5.0 h<-1>; and volume concentration of the raw material ethylene glycol monomethyl ether is 1-100%, and volume concentration of the carrier gas is 0-99%. Under a low-temperature condition, the method takes solid acid as a catalyst and takes ethylene glycol monomethyl ether as the raw material to prepare glycol dimethyl ether and ethylene glycol with high selectivity; and meanwhile, formation of a byproduct 1,4-dioxane which pollutes the environment or damages a human body or an animal body is basically or completely avoided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

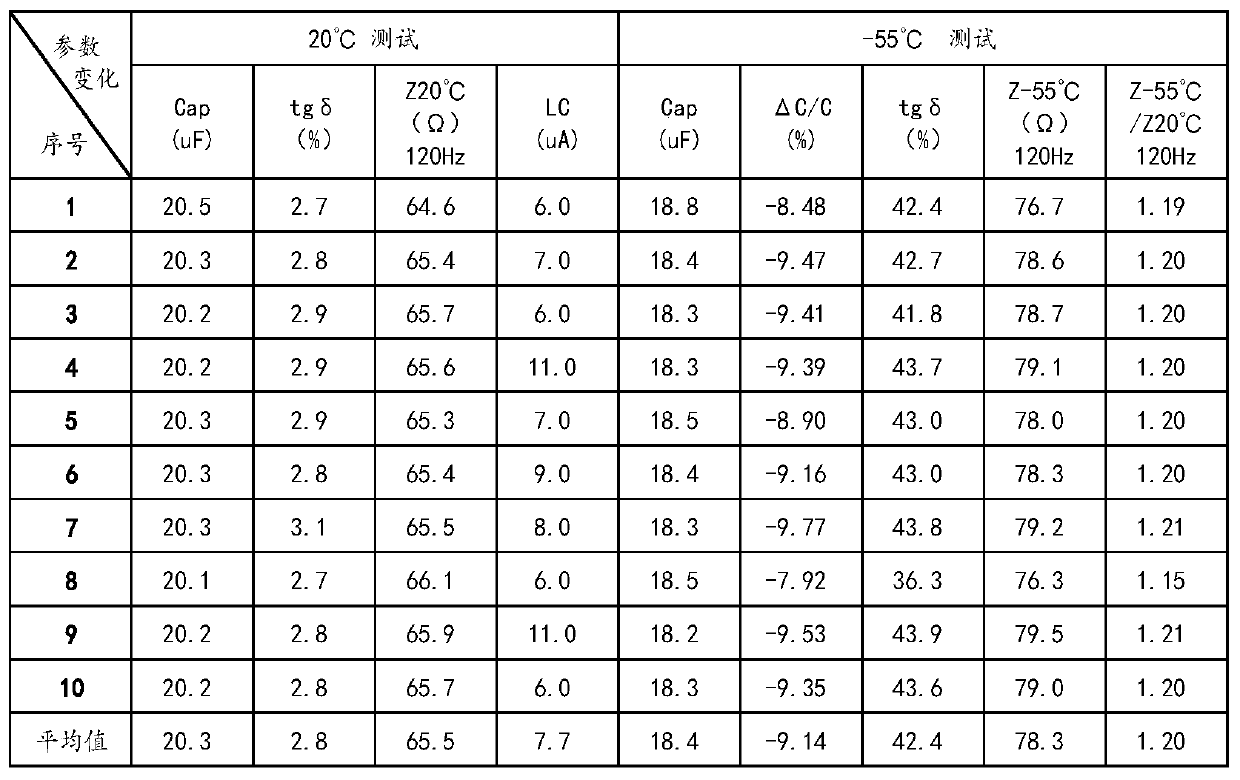

Ultralow-temperature high-voltage chip aluminum capacitor-used electrolyte and preparation method thereof

ActiveCN109935468AGood negative thermoelectric propertiesEffective series resistance (ESR) reductionLiquid electrolytic capacitorsDiethylene glycol monobutyl etherSulfolane

The invention provides an ultralow-temperature high-voltage chip aluminum capacitor-used electrolyte, which comprises 32% to 58% of a main solvent, 5% to 34% of an auxiliary solvent, 5.2% to 21.4% ofa solute, 2.5% to 8.5% of a flash fire booster, 0.7% to 2.5% of a hydrogen scavenger and 1% to 10% of a modified synthetic additive, wherein the main solvent is one or multiple selected from ethyleneglycol, diethylene glycol, triethylene glycol, ethylene carbonate, propylene carbonate, gamma-butyrolactone and the like; and the auxiliary solvent is one or multiple selected from diethylene glycol mono-methyl ether, diethyl carbitol, diethylene glycol ethyl methyl ether, diglycol dimethyl ether, triethylene glycol dimethyl ether, diethylene glycol monobutyl ether, dimethyl sulfoxide, sulfolane and the like. The ultralow-temperature high-voltage electrolyte has good negative temperature electric performance, higher stability and stronger applicability.

Owner:湖州新江浩电子有限公司

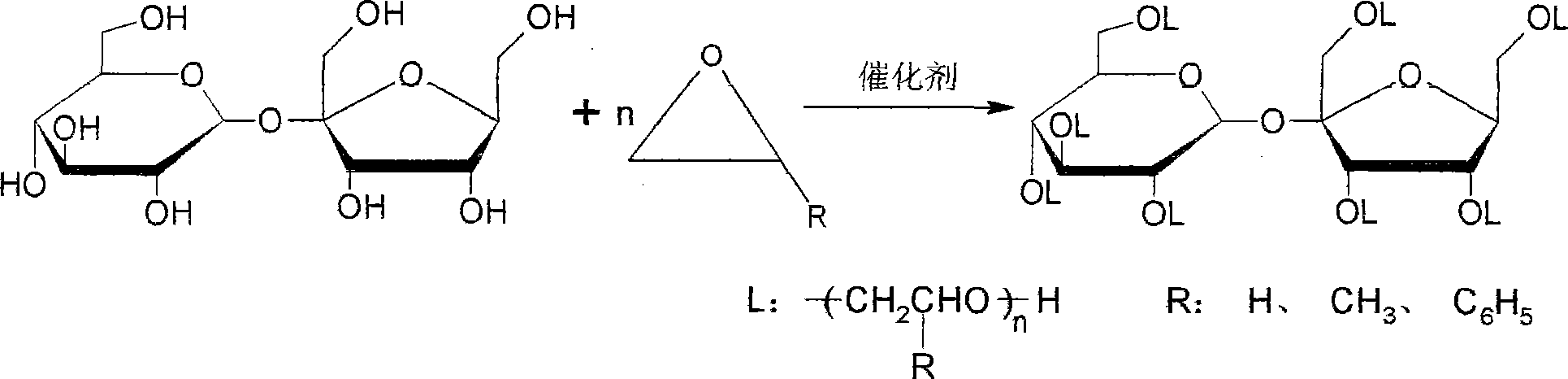

Catalyst for synthesizing polyether glycol from sucrose and oxidized olefin and preparation method thereof

The invention discloses a kind of bimetal complex cyanide solid catalyst, belonging to chemical industrial catalyst preparation field. The chemical formula of it is Zn3[Co(CN)5(A)]2.wZnA2.xH2O.yL.zL1: A is Cl-, Br-, I-, CNS-, NCO-; L is organic alcohol, such as dimethyl carbinol, tert-butanol, amyl alcohol; L1 is organic ether, such as dioxide hexacyclic ring, dioxide pentacyclic ring, butyl ether, ethyl ether, propyl ether, diethylene glycol; factor are: w (0.01- 0.1), x (0.1- 1), y (1-4), z (1- 4). The product can catalyze polymerization of sucrose with olefin to produce polyether polyol, and the process is characterized by low reaction temperature and pressure, less catalytic consumption high molecular weight, narroe distribution and low degree of unsaturation for produced polyether.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Methanol gasoline for vehicle

InactiveCN1743432AReduce consumptionAdequate resource guaranteeLiquid carbonaceous fuelsIsobutanol1-Propanol

This invention relates to a car-used methyl alcohol gasoline and its preparation method. The gasoline is composed of following raw materials in terms of weight proportion: methyl alcohol 10-80%, alcohol 2-15%, basic oil 5-30% lead-free gasoline 10-80%, ethylene glycol diethyl ether 0.1-2.0%, ethylene glycol diethyl ether 0.1-2.0%, ethylene glycol monomethyl ether 0.1-2.0%, isobutanol 0.1-2.0%, isopropanol 0.1-2.0%, 1-propanol 0.1-2.0% and 2.6-2-tert-butyl-p-cresol 0.1-2.0%.

Owner:姜彬

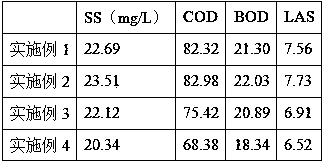

Preparation and application of printing and dyeing sewage treatment agent

InactiveCN107758789ASustainable processingSafe handlingWater contaminantsWaste water treatment from textile industrySodium acetatePolyacrylamide

The invention discloses preparation and application of a printing and dyeing sewage treatment agent. The preparation steps are follows: adding a coconut shell powder into a phosphoric acid solution for soaking, calcinating for activation, and then adding a copper nitrate solution and an yttrium nitrate solution for modification, and calcinating to obtain modified coconut shell activated carbon; adding an organic modifier and aluminum chloride into deionized water, then adding bentonite, reacting, and grinding to obtain modified bentonite; taking modified coconut shell activated carbon powder,polymeric ferric trichloride, polyaluminum chloride, modified bentonite, corn starch, sodium acetate, polyacrylamide, polysorbate, plant fiber and ethylene glycol-bis(beta-aminoethyl ether)-N,N,N',N'-tetraacetic acid, uniformly mixing, and granulating to obtain the sewage treatment agent. The invention has the beneficial effects as follows: by the preparation method, raw materials are compounded to play a coordinated role, and printing and dyeing sewage with relatively high chroma and concentration can be continuously treated, and the treated water can be reused repeatedly; a technology for treating the dyeing and dyeing sewage by using the water treatment agent is simple, efficient, low in treatment cost and free of side effects on operators.

Owner:ZHEJIANG OCEAN UNIV

Method for promoting light oil yield of atmospheric and vacuum distillation of petroleum oil

InactiveCN100348695CImprove light oil yieldNo need to change the structureHydrocarbon distillationAcetic acidOrganic solvent

The invention relates the method for improving atmospheric and vacuum distillation light oil productivity. The method comprises the following step: adding the 0.001-0.1wt% addition agent with colophony into crude oil in atmospheric and vacuum distillation tower. The addition agent comprises 50-80% colophony and 50-20% organic solvent. The pH is 7.0-7.5. The organic solvent comprises ethanol or cellosolve or ethyl propyl acetone or acetate cellosolve. The method can be used in oil-extraction plant, and the light oil productivity is improved by 1.5-2.3wt%.

Owner:SHANGHAI JIAO TONG UNIV

Composition for forming a liquid crystal alignment film, and liquid crystal display device

ActiveUS8057868B2Good coating performanceSuppress display unevennessLiquid crystal compositionsPlastic/resin/waxes insulatorsDiethylene glycol diethyl etherLiquid-crystal display

The present invention provides: a composition for forming a liquid crystal alignment film capable of forming a liquid crystal alignment film excellent in evenness; and a liquid crystal display device. The present invention provides a composition for forming a liquid crystal alignment film, wherein the composition comprises: a material for forming a liquid crystal alignment film; diethylene glycol diethyl ether; diisobutyl ketone; and at least one of γ-butyrolactone and N-methyl-2-pyrrolidone as solvents.

Owner:SHARP KK +1

Non-aqueous inkjet ink and ink set

Owner:GENERAL CO LTD

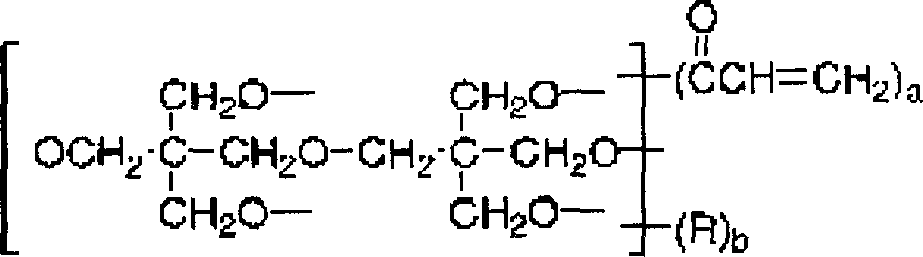

Light sensitive resin composition

ActiveCN1702554AHigh light sensitivityImprove transmittanceStatic indicating devicesPhotosensitive materials for photomechanical apparatusDiethylene glycol diethyl etherCarboxylic acid

The photosensitive resin composition comprises (a) an acrylic copolymer obtained by copolymerizing (i) an unsaturated carboxylic acid, an unsaturated carboxylic acid anhydride or a mixture of them, (ii) an epoxy-containing unsaturated compound and (iii) an olefinically unsaturated compound, (b) a 1,2-quinonediazido compound and (c) one or more solvents selected from the group consisting of benzyl alcohol, hexyl alcohol, diethylene glycol dimethyl ether, diethylene glycol methylethyl ether, diethylene glycol diethyl ether, dipropylene glycol diethyl ether, dipropylene glycol dimethyl ether and dipropylene glycol methylethyl ether. So this invention provides a photosensitive resin composition which is excellent in performances such as sensitivity transmittance, insulation and chemical resistance, remarkably improves flatness and coating property in particular, and is suitable for forming an interlayer insulating film in a process for fabricating LCD, etc.

Owner:DONGJIN SEMICHEM CO LTD

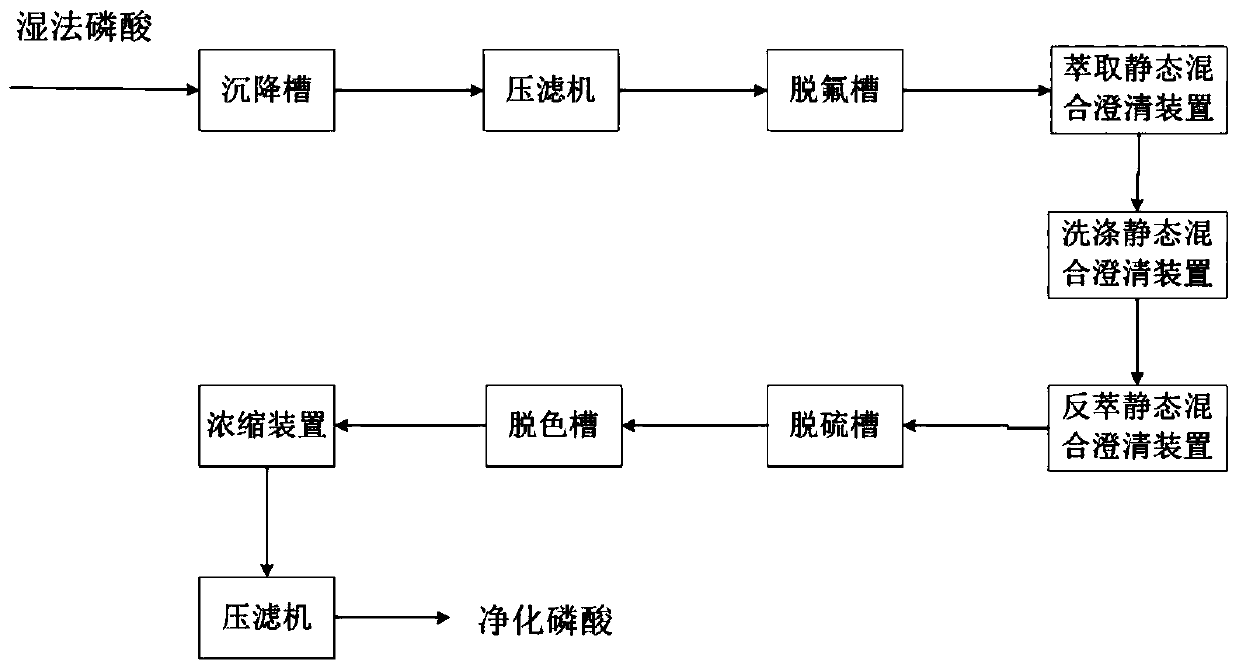

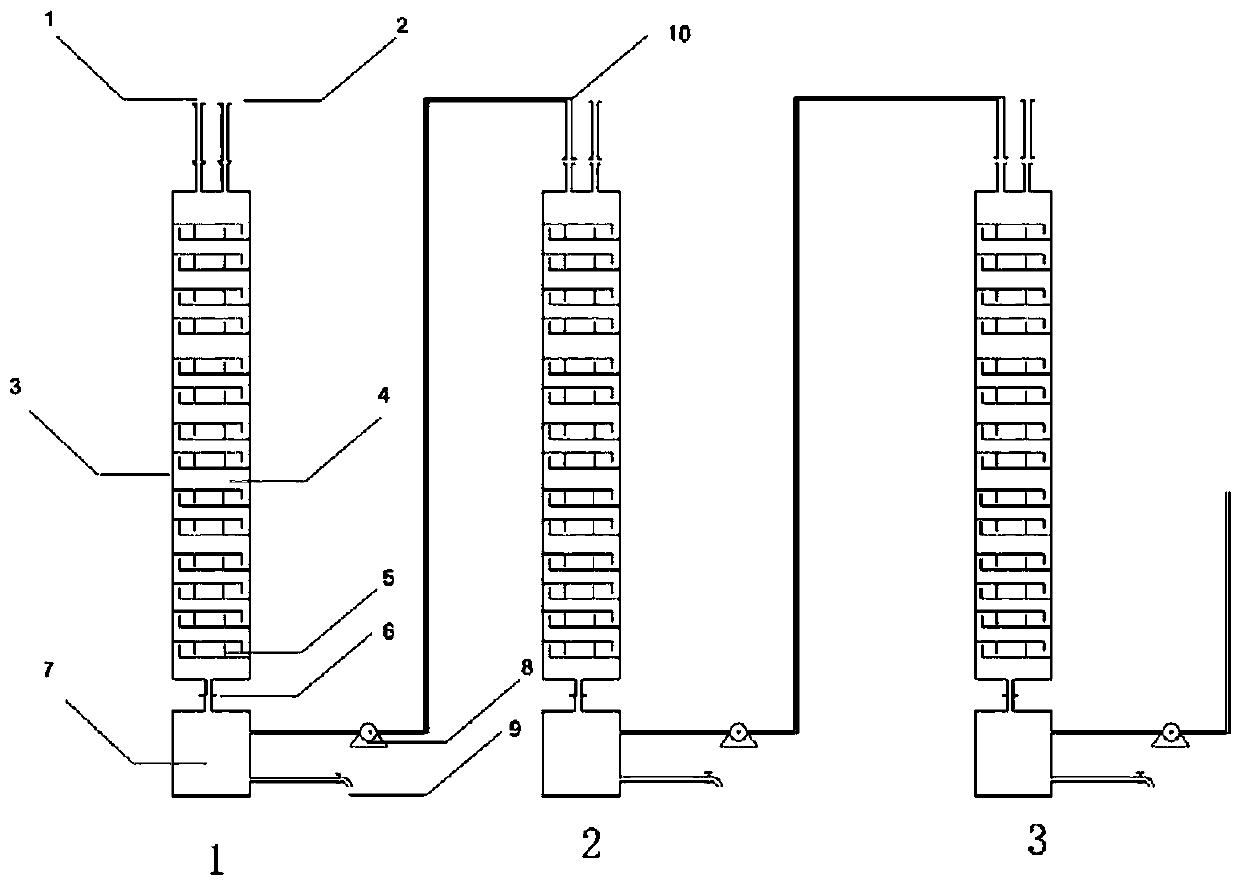

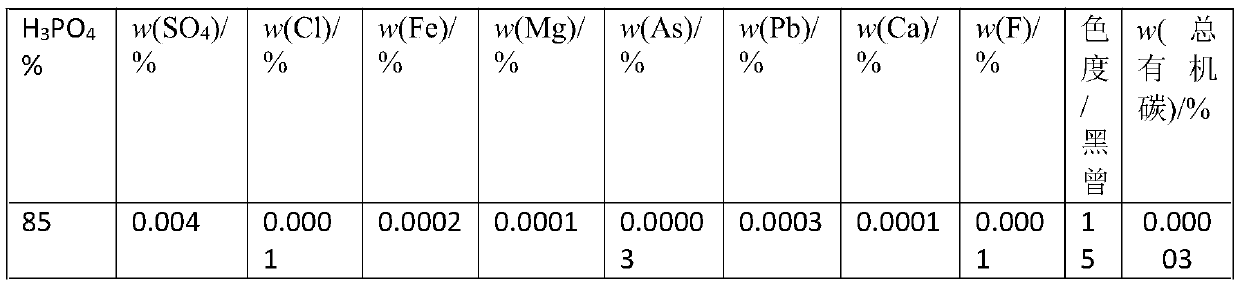

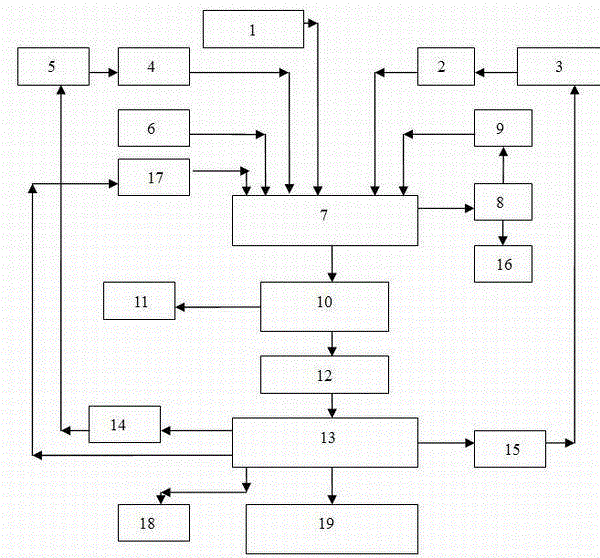

Production method and device for purification of low-concentration wet-process phosphoric acid by solvent extraction

InactiveCN109928373AGood effectIncrease economic value addedPhosphorus compoundsCyclohexanoneIsooctyl alcohol

The invention relates to a production method and device for purification of low-concentration wet-process phosphoric acid by solvent extraction. The technology utilizes solvent extraction to realize preparation of food-grade phosphoric acid from low-concentration wet-process phosphoric acid. The method adopts one or more of trioctyl phosphate, cyclohexanol, isooctyl alcohol, butyl ether, cyclohexanone, isobutyl acetate and ethylene glycol diethyl ether as the extraction agent; extraction, washing and reverse extraction are accomplished by a multistage static mixer; and in the washing process,the quaternary ammonium salt cation [N(CH3)4]<+> is added into a washing solution. The static mixer used in the invention is special equipment designed and developed by self according to the process requirements and practical production practice experience, and is the key production device of the invention. The method and equipment provided by the invention can be applied to the industrial production of food grade phosphoric acid from wet-process phosphoric acid, and can significantly shorten the purification process, reduce consumption and ultimately lower the purification cost of the whole process.

Owner:广西川金诺化工有限公司

Biomass chelated modified heavy metal capturing agent as well as preparation method and application thereof

ActiveCN107744798AEasy to degradeLess prone to secondary pollutionOther chemical processesWater contaminantsChemical industrySide chain

The invention relates to a biomass chelated modified heavy metal capturing agent as well as a preparation method and application thereof. The biomass chelated modified heavy metal capturing agent is characterized by being prepared from konjac glucomannan, water, an initiator azobis(2-methylpropionamidine)dihydrochloride V-50, N-vinylformamide, ethylene glycol-bis-(2-aminoethylether)-N,N,N',N'-tetraacetic dianhydride, potassium hydroxide and carbon disulfide; the biomass chelated modified heavy metal capturing agent is used for treating heavy-metal wastewater discharged by electroplating, smelting, mining, mineral dressing, chemical industry, machines and the like. According to the biomass chelated modified heavy metal capturing agent, complex heavy metal ions can be adsorbed through a synthesized konjac glucomannan macromolecular framework grafted novel chelated functional group; each basic unit can provide hexa-coordinate atoms to carry out strong chelating and adsorption; furthermore, sodium dithiocarbamate of a konjac glucomannan grafted sedimentation-assisting side chain and a sedimentation-assisting agent are subjected to chemical sedimentation reaction and a large aggregate is generated within a few of seconds, so that rapid sedimentation is realized.

Owner:合肥九州龙腾科技成果转化有限公司

Solvent method synthetic process of Si-75

InactiveCN104804032AHigh purityOvercoming steric potentialGroup 4/14 element organic compoundsDistillationImpurity

The invention relates to a solvent method synthetic process of Si-75. Si-75 can be used for radial tyres and other rubber products and belongs to the technical field of coupling agents. The solvent method synthetic process comprises the following steps: adding sodium sulfide containing nine crystal water and powdered sulfur into methylbenzene, heating, dewatering, cooling, adding gamma-chloropropyl triethoxysilane and absolute ethyl alcohol, then adding ethylene glycol diethyl ether, heating, after the reaction, cooling to the room temperature, filtering inorganic salt and impurities for industrial salt application, transferring filtrate to a distiller, distilling solvent and foreshot under reduced pressure for recycling, and performing distillation to obtain the Si-75 when the vacuum degree is greater than or equal to 0.090 Mpa and the temperature is greater than or equal to 150 DEG C, wherein the molar ratio of the sodium sulfide to the powdered sulfur is 1:1, the weight ratio of the methylbenzene to the sodium sulfide is 1.6-2, the weight ratio of the gamma-chloropropyl triethoxysilane to the sodium sulfide is 2.00-2.06, the weight ratio of the absolute ethyl alcohol to the absolute ethyl alcohol is 1:1, and the weight ratio of the ethylene glycol diethyl ether to the methylbenzene is 0.3-0.6.

Owner:NANCHANG GANYU ORGANOSILICONE

Ink composition

An ink composition, contains: an organic solvent, a metal pigment, and a resin, in which the organic solvent contains, based on the total amount of the ink composition, 60% by mass or more of diethylene glycol diethylether, 24 to 37% by mass of γ-butyrolactone and / or tetraethylene glycol dimethyl ether, and more than 1% by mass and lower than 5% by mass of tetraethylene glycol monobutyl ether, and the 50% average particle diameter in terms of sphere determined by a light scattering method of the metal pigment is 0.8 to 1.2 μm.

Owner:SEIKO EPSON CORP

Preparation and applications of aquatic product sewage treatment agent

ActiveCN107892339AGood molding effectEasy to recycleWater contaminantsWaste water treatment from animal husbandryAluminium chlorideSide effect

The invention discloses a preparation method and applications of an aquatic product sewage treatment agent. The preparation method comprises following steps: mussel shell is treated with a diluted acid solution, and then is subjected to high temperature treatment and grinding so as to obtain mussel shell powder; an organic modifying agent and aluminium chloride are dissolved with deionized water,roasted bentonite is added, and stirring, reaction, and grinding are carried out so as to obtain modified bentonite; the mussel shell powder, sodium alginate, polyferric chloride, polymeric aluminium,the modified bentonite, polyacrylamide, vegetable fiber, and ethylene glycol-bis-(2-aminoethylether)-N,N, N', N'-tetraacetic acid (EGTA) are uniformly mixed, are subjected to pelletizing moulding ina pelletizer, and are dried so as to obtain the aquatic product sewage treatment agent. The beneficial effects are that: the advantages of the ingredients are achieved, synergetic effects are achieved, nitrogen, phosphor, and organic pollutants can be removed effectively, the aquatic product sewage treatment agent can be recycled, and can be used for aquatic product sewage treatment, the treatmenttechnology is simple, the operationality is high, efficiency is high, and no side effect on operation personnel is caused .

Owner:江苏金山新材料科技有限公司

Novel sewage treatment agent

InactiveCN102329016AEfficient captureEfficient industrial productionScale removal and water softeningWater/sewage treatmentPhosphateDiethylene triamine

The invention provides a novel sewage treatment agent which comprises the following components in percentage by weight: 0.1-10% of ethylene glycol tetraacetic acid, 1-50% of ethylene diamine, 1-15% of pentasodium diethylene triamine pentaacetate, 1-15% of phosphate and the balance of water. The invention can effectively capture multiple metallic ions in the water body, such as Ca<2+>, Mg<2+>, iron ions, zinc ions, strontium ions and the like, and has obvious corrosion inhibition effect.

Owner:天津市瑞福驰化工有限公司

Commodity theft-proof dye

The invention relates the dyestuff agent used for commodity anti-theft, comprising 8-12% water-based ink, 52-58% deicing fluid, 2-4% auxiliary coloring agent and demineralized water. The water-based ink is made by mixing the water-soluble dye, acrylic resin, acrylic ester emulsion, dispersing agent, defoaming agent and silicone, or by water-soluble acid dye or basic dye direct dyeing. The deicing fluid is ethylene alcohol or ethyl ether or ethylene glycol monobutyl ether or ethylene glycol diethyl ether or glyceryl alcohol or triethanolamine. The auxiliary coloring agent is p-nitrophenol or o-aminoazotoluene or o-phenetidine or orasol. The product can't deposit, differentiate and coagulate for long time, and the method keeps coloring agent effective.

Owner:上海齐林助剂有限公司

Sewage treatment agent for printing and dyeing wastewater as well as preparation method and application of sewage treatment agent

InactiveCN106495257AEasy to handleReduce processing costsWater treatment parameter controlWater treatment compoundsCalcium silicatePhosphate

The invention discloses a sewage treatment agent for printing and dyeing wastewater. The sewage treatment agent is prepared from the following raw materials in parts by weight: 8-11 parts of aluminum sulfate, 10-13 parts of ferric phosphate, 3-6 parts of seaweed mud, 11-15 parts of sea-foam stone powder, 2-5 parts of nano-zinc oxide, 1-3 parts of active calcium silicate, 15-19 parts of trimethylene di(octadecyl dimethyl) ammonium-bentonite, 1-2 parts of ethylene glycol tetraacetic acid, 2-5 parts of a chitosan-graphene composite material, 24-27 parts of polyaluminum ferric chloride and 18-22 parts of polyacrylamide. The invention further discloses a preparation method of the sewage treatment agent for printing and dyeing wastewater. The sewage treatment agent disclosed by the invention is capable of effectively removing pollutants in printing and dyeing wastewater, good in treatment effect, low in treatment cost, free from toxicity and free from secondary pollution.

Owner:ZHENGZHOU ZHANGMENG NETWORK TECH CO LTD

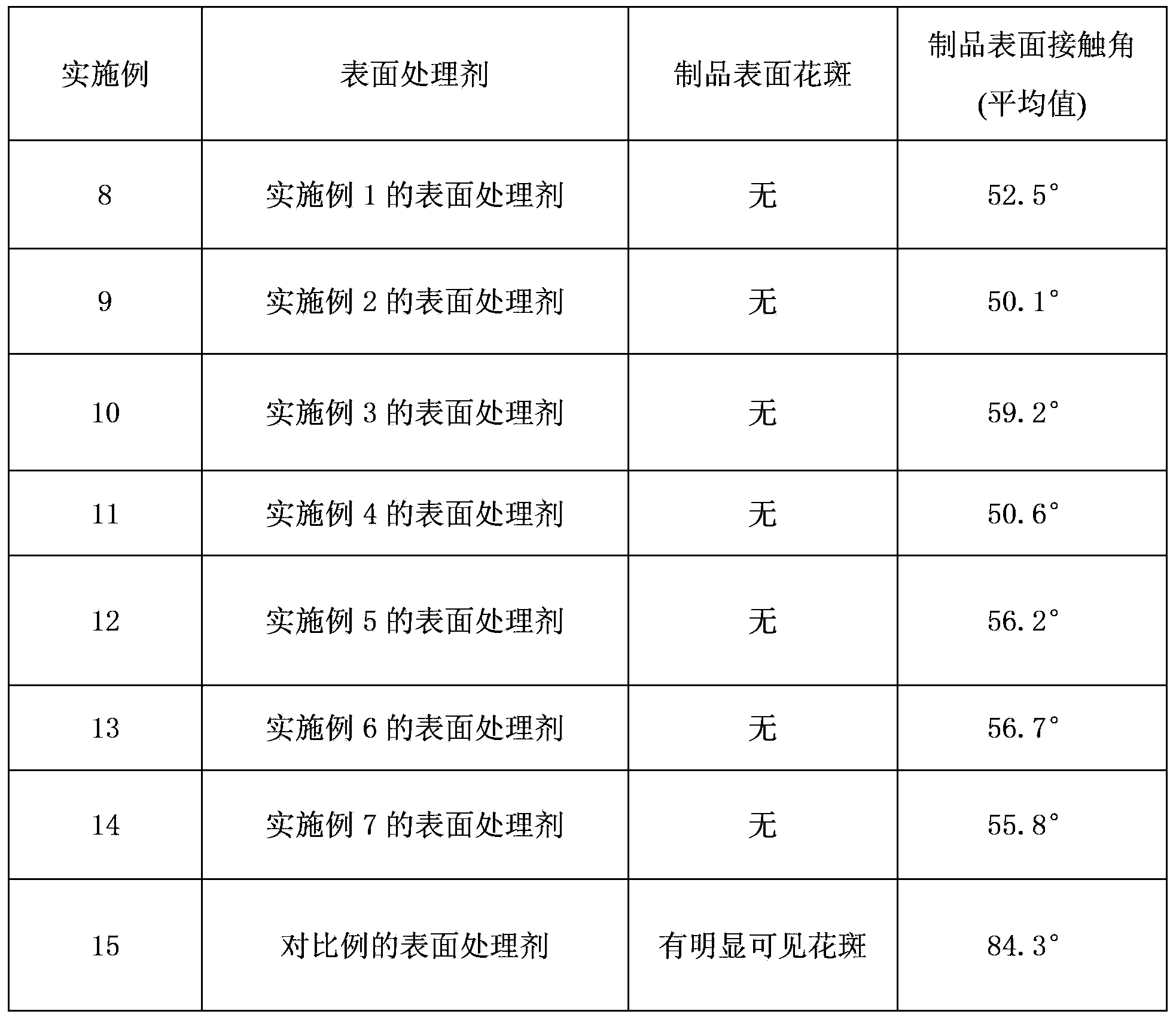

Polytetrafluoroethylene product surface treatment agent and preparation method thereof

ActiveCN103351474AImprove working conditionsSolve the problem of safety productionDiethylene glycol diethyl etherAfter treatment

The invention discloses a polytetrafluoroethylene product surface treatment agent which comprises the following components in parts by weight: 50-280 parts of naphthalene, 10-50 parts of metallic sodium and 600-800 parts of a solvent, wherein the solvent is one of 1,4-dioxane, glycol dimethyl ether, diethylene glycol dimethyl ether, diethylene glycol diethyl ether, ethylene glycol butyl methyl ether, tetraethylene glycol dimethyl ether and diethylene glycol isobutyl ether. The invention further provides a preparation method for the polytetrafluoroethylene product surface treatment agent. The polytetrafluoroethylene product surface treatment agent has the advantages of safety, environmental pollution and high treatment capability; and a polytetrafluoroethylene product obtained after treatment of the surface treatment agent is good in quality and high in qualified rate.

Owner:ZHEJIANG GREEN NEW MATERIALS +1

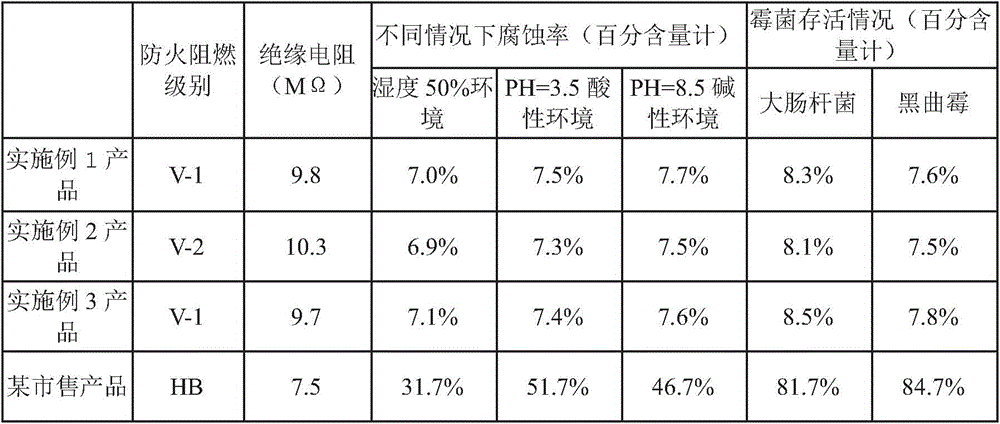

Bridge connection rail surface environmental protection coating for civil and architectural engineeringroad and bridge construction

InactiveCN106084940AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsDiethylene glycol diethyl etherMaterials science

The invention relates to a bridge connection rail surface environmental protection coating for civil and architectural engineeringroad and bridge construction. The bridge connection rail surface environmental protection coating comprises the following components: PVC resin powder, butadiene-styrene rubber, hexamethylenediisocyanate, propargyl chloride, isothiazolinone, glass powder, soda ash, lead iodide powder, chrome green, zinc chromate, magnesium silicate powder, magnesium methacrylate, sodium polymethacrylate, spodumene powder, zinc sulfide powder, asbestos powder, nut oil, methyl acetate, soya oil acid, diethylene glycol diethyl ether, isobutyl acrylate, tripropylene glycol diacrylate, dibasyl lead sulfate, sodium diethylhexyl sulfosuccinate, epoxy silane crosslinker, sodium dioctylsulfosuccinate, sorbitol, sodium dodecyl sulfonate, alkyl diphenyl phosphate, and ethoxylated lauryl alcohol sulfate. The product provided by the invention has superior flame-retardant, acid and alkali-proof, mildew-proof and antibacterial properties, and the product properties are improved.

Owner:梁方英

Highly efficient environment friendly waste water treatment agent

InactiveCN106335946AHigh purityImprove hydrophobicityWater contaminantsWater/sewage treatment by flocculation/precipitationActivated sludgeManganese

The invention discloses a highly efficient environment friendly waste water treatment agent which comprises, by weight, 5 to 10 parts of carboxymethylcellulose, 5 to 15 parts of sodium polyacrylate, 0.1 to 0.3 part of Amino Trimethylene Phosphonic Acid, 0.5 to 2 portions of ethylene glycol diethylether diamine tetraacetic acid, 10 to 25 parts of fly ash, 5 to 10 parts of sodium carbonate, 5 to 7 parts of Ipomoea batatas, 3 to 5 parts of sunflower straw, 10 to 15 parts of activated sludge, 5 to 7 parts of shaddock peel, 5 to 10 parts of Firmiana simplex fallen leaves, 0.5 to 1 part of jasmine straw, 0.1 to 0.5 part of methyl acetate and 50 to 180 parts of distilled water. The highly efficient environment friendly waste water treatment agent provided by the invention has stark decontamination effects to the Zn2 +, Cu2 +, Pd2 +, Cd2 +, chromium and manganese in the waster water polluted by heavy metal. The agent can effectively reduces the content of COD ad SS in the waster water; the treatment results are optimal with easily acquirable and cheap raw materials. The waster water treatment agent is prone to decompose and poses no negative impacts to the environment which make it more economically feasible and environment friendly.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com