Bridge connection rail surface environmental protection coating for civil and architectural engineeringroad and bridge construction

A technology for civil construction, road and bridge, which is applied in the field of environmental protection coating on the surface of bridge connecting railings in civil construction, road and bridge construction, which can solve the problems of poor application effect of coating materials, achieve superior flame retardancy and improve product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

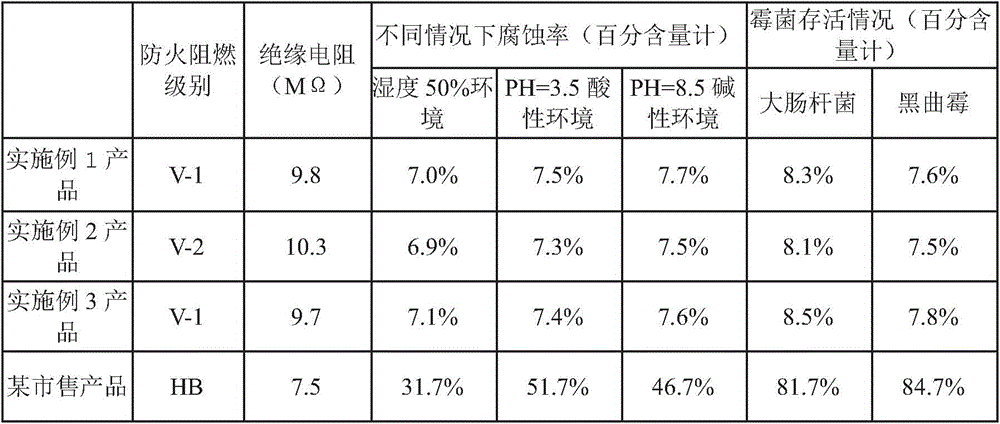

Examples

Embodiment 1

[0016] The environmental protection coating on the surface of the bridge connecting railings for civil engineering construction, road and bridge construction in this embodiment is composed of the following components in parts by mass: 10 parts of PVC resin powder, 8 parts of styrene-butadiene rubber, 8 parts of hexamethylene diisocyanate, 6 parts of propargyl chloride 8 parts, 8 parts of isothiazolone, 8 parts of glass powder, 6 parts of soda ash, 8 parts of lead iodate powder, 8 parts of chrome green, 6 parts of zinc chromate, 6 parts of magnesium silicate powder, 8 parts of magnesium methacrylate, 8 parts of sodium polymethacrylate, 6 parts of spodumene powder, 4 parts of zinc sulfide powder, 8 parts of asbestos powder, 6 parts of argan oil, 4 parts of methyl acetate, 8 parts of soybean oil, 6 parts of ethylene glycol diethyl ether, acrylic acid 6 parts of isobutyl ester, 6 parts of tripropylene glycol diacrylate, 6 parts of dibasic lead sulfate, 6 parts of dioctyl sodium sul...

Embodiment 2

[0022] The environmental protection coating on the surface of the bridge connecting railings for civil engineering construction, road and bridge construction in this embodiment is composed of the following components in parts by mass: 12 parts of PVC resin powder, 10 parts of styrene-butadiene rubber, 10 parts of hexamethylene diisocyanate, and 8 parts of propargyl chloride 10 parts, 10 parts of isothiazolone, 10 parts of glass powder, 8 parts of soda ash, 10 parts of lead iodate powder, 10 parts of chrome green, 8 parts of zinc chromate, 8 parts of magnesium silicate powder, 10 parts of magnesium methacrylate, 10 parts of sodium polymethacrylate, 8 parts of spodumene powder, 6 parts of zinc sulfide powder, 10 parts of asbestos powder, 8 parts of argan oil, 6 parts of methyl acetate, 10 parts of soybean oil, 8 parts of ethylene glycol diethyl ether, acrylic acid 8 parts of isobutyl ester, 8 parts of tripropylene glycol diacrylate, 8 parts of dibasic lead sulfate, 8 parts of dio...

Embodiment 3

[0028] The environmental protection coating on the surface of the bridge connecting railing for civil engineering construction, road and bridge construction in this embodiment is composed of the following components in parts by mass: 14 parts of PVC resin powder, 12 parts of styrene-butadiene rubber, 12 parts of hexamethylene diisocyanate, and 10 parts of propargyl chloride 12 parts, 12 parts of isothiazolinone, 12 parts of glass powder, 10 parts of soda ash, 12 parts of lead iodate powder, 12 parts of chrome green, 10 parts of zinc chromate, 10 parts of magnesium silicate powder, 12 parts of magnesium methacrylate, 12 parts of sodium polymethacrylate, 10 parts of spodumene powder, 8 parts of zinc sulfide powder, 12 parts of asbestos powder, 10 parts of argan oil, 8 parts of methyl acetate, 12 parts of soybean oil, 10 parts of ethylene glycol diethyl ether, acrylic acid 10 parts of isobutyl ester, 10 parts of tripropylene glycol diacrylate, 10 parts of dibasic lead sulfate, 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com