Patents

Literature

95 results about "Sodium polymethacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method of methacrylate or acrylate industrial wastewater

ActiveCN101786742AEmission reductionMultistage water/sewage treatmentNature of treatment waterUltrafiltrationReducing agent

The invention discloses a treatment method of methacrylate or acrylate industrial wastewater. The method comprises the following steps: adjusting the pH value of methacrylate or acrylate industrial wastewater to 6-8, ensuring the wastewater to pass through an activated carbon layer for filtering and pretreatment, adding chain transfer agent in the pretreated wastewater, stirring to dissolve solids, heating to 40-90 DEG C; dropping an aqueous solution dissolved with initiator, keeping temperature for 1-10 hours to perform polymerization reaction; cooling the reacted wastewater to the room temperature, and passing through a nanofiltration membrane and / or ultrafiltration membrane separating component to remove partial water and small molecule salts and obtain a sodium polymethacrylate or sodium polyacrylate aqueous solution. By using the method of the invention, the wastewater discharge is reduced during the production process of methacrylate or acrylate; the sodium methacrylate or sodium acrylate in wastewater is recycled, and the byproduct low molecular weight sodium polymethacrylate or sodium polyacrylate aqueous solution can be used as the dispersant, antisludging agent and water reducing agent of cement.

Owner:GUANGDONG RITOP FINE CHEM

Composite fine particles of forward osmosis driving solution system and application thereof

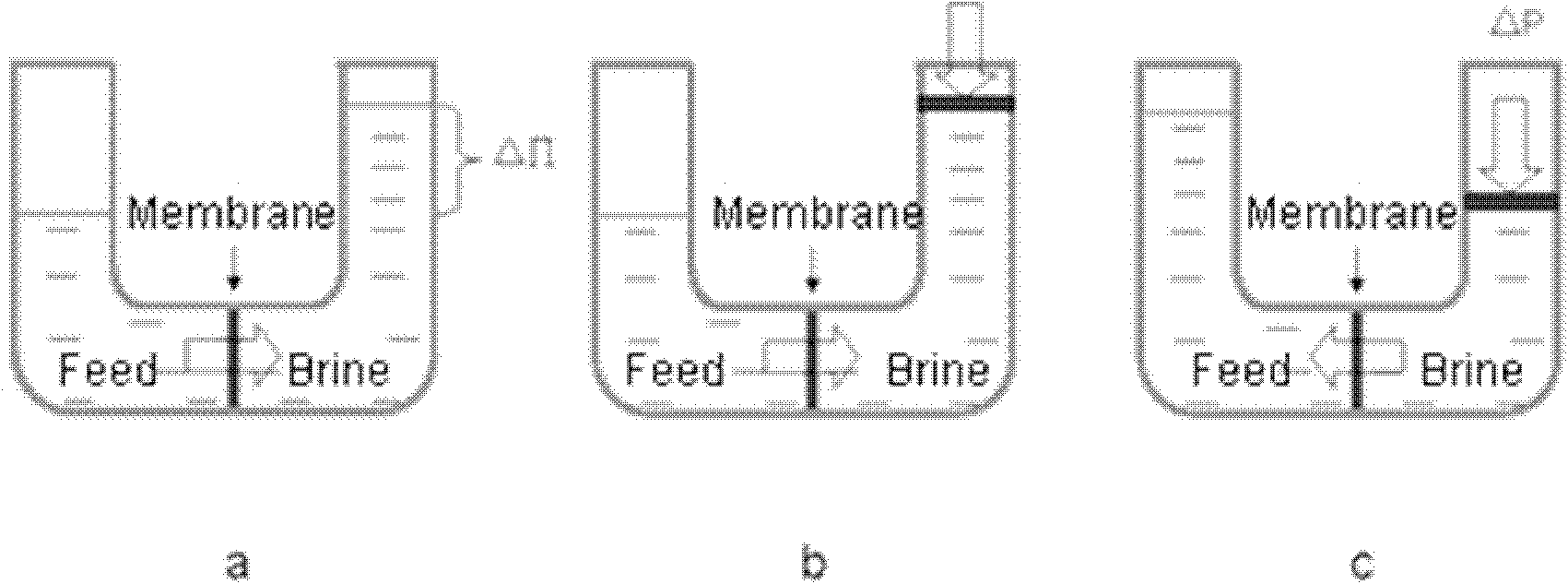

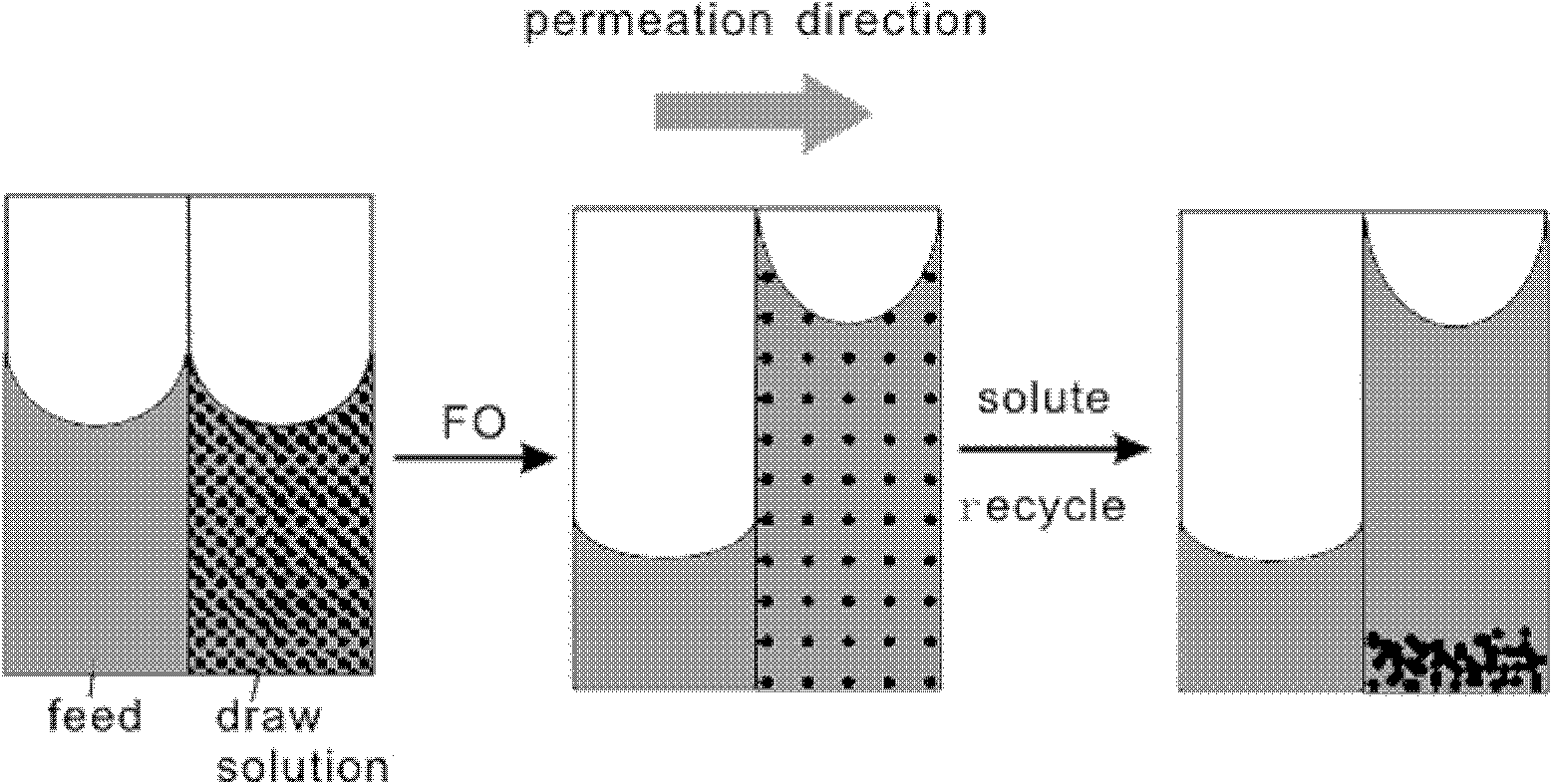

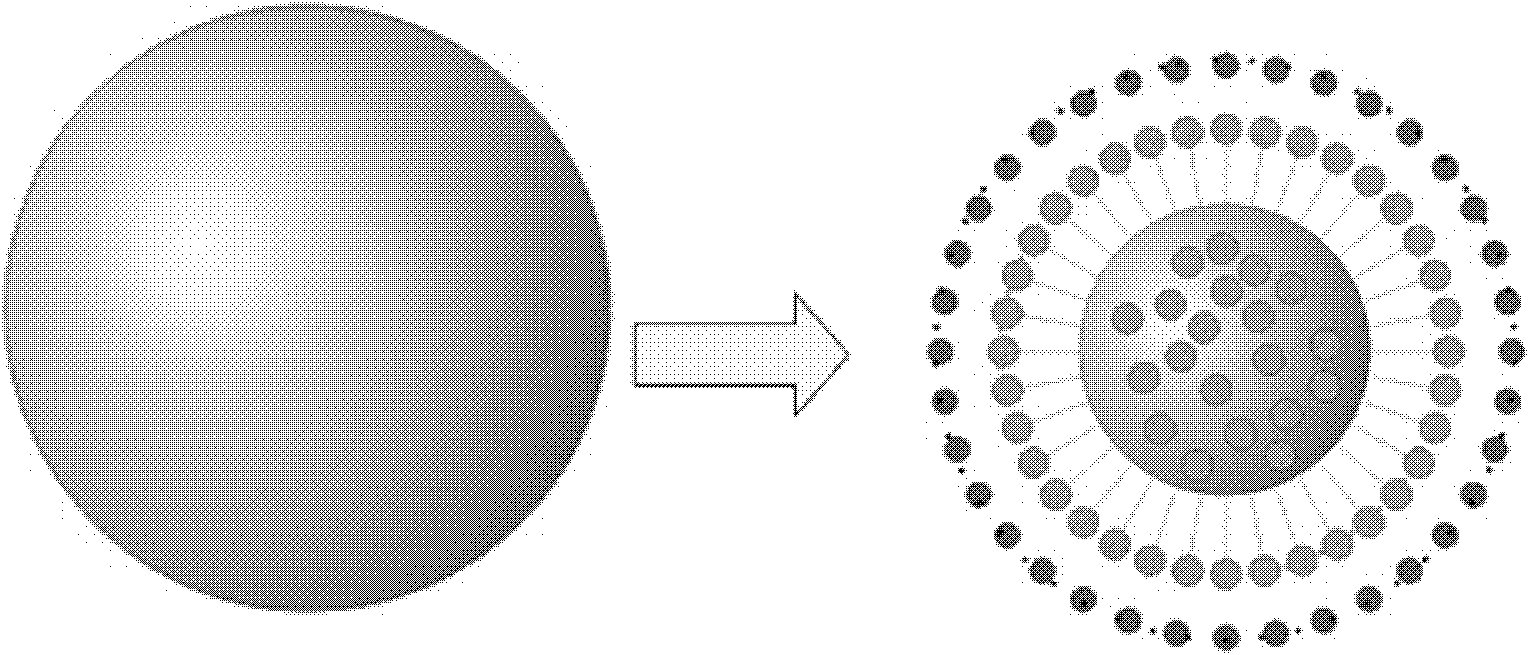

InactiveCN101891281AAchieve fadeReduce energy consumptionWater/sewage treatment bu osmosis/dialysisChemical structurePolyvinyl alcohol

The invention relates to composite fine particles of a forward osmosis driving solution system. Fine particle cores are fully or partially coated by a separable outer layer; an outer layer shell provides an osmotic pressure; and the cores provide a separable characteristic. The solution system has the characteristics that: (1) the system has the composite fine particles having core-shell structures; (2) the diameters of the composite fine particles are less than 500 microns; and (3) the cores of the fine particles comprise particle cores of polymer particles, chitosan, nonmetal particles, metal or alloy; the shells of the fine particles comprise sodium polystyrene sulfonate, polyvinylamine hydrochloride, polyacrylic acid sodium salt, sylvite, calcium salt, polymethylacrylic acid sodium salt or sylvite, polyvinyl alcohol or polyaniline hydrochloride; the surfaces of the fine particle shells are provided with grafted groups, namely, chemical substances having ionization performance are grated on the surfaces of the particle shells by a chemical method; chemical structures having ionization performance are selected from the following chemical substances: Cl<->, COO<-> or SO<3->; and corresponding counter ions are H<+>, Na<+>, K<+>, Ca<2+> or quaternary ammonium salt according to the properties of the groups.

Owner:NANJING UNIV OF TECH +1

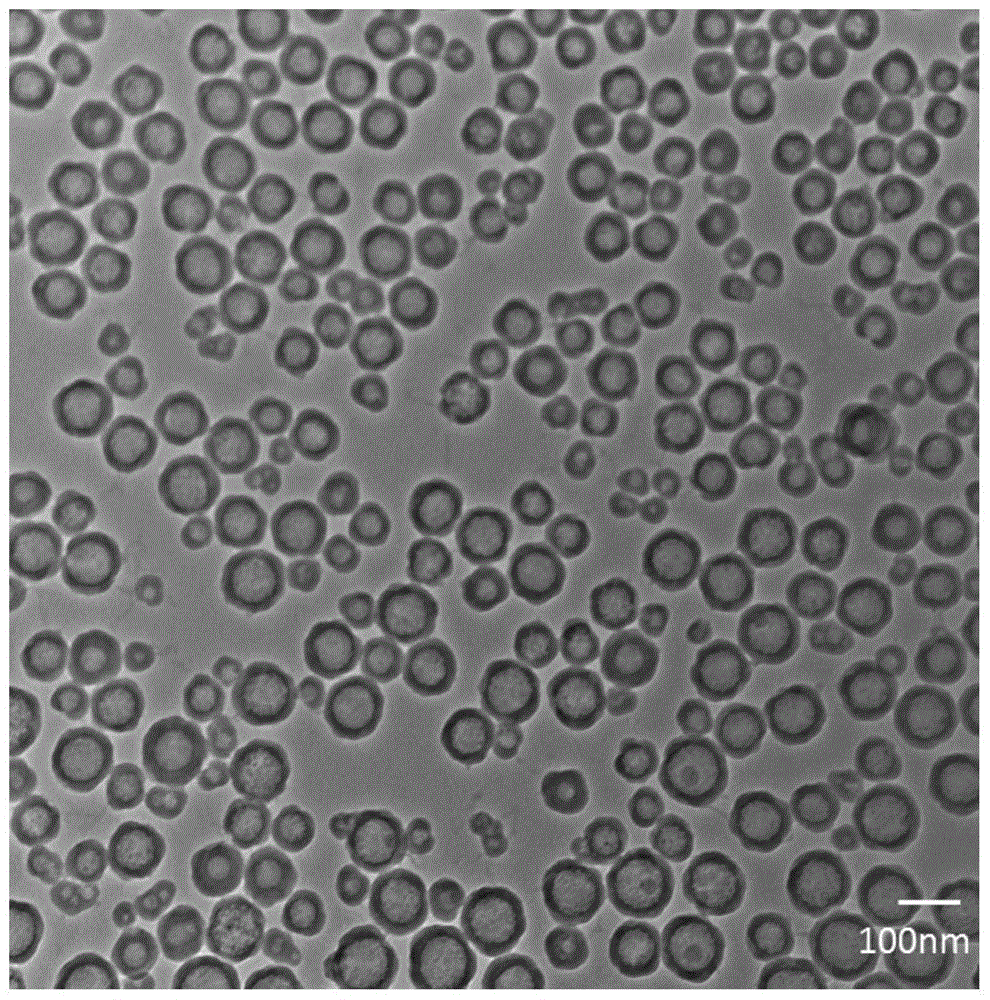

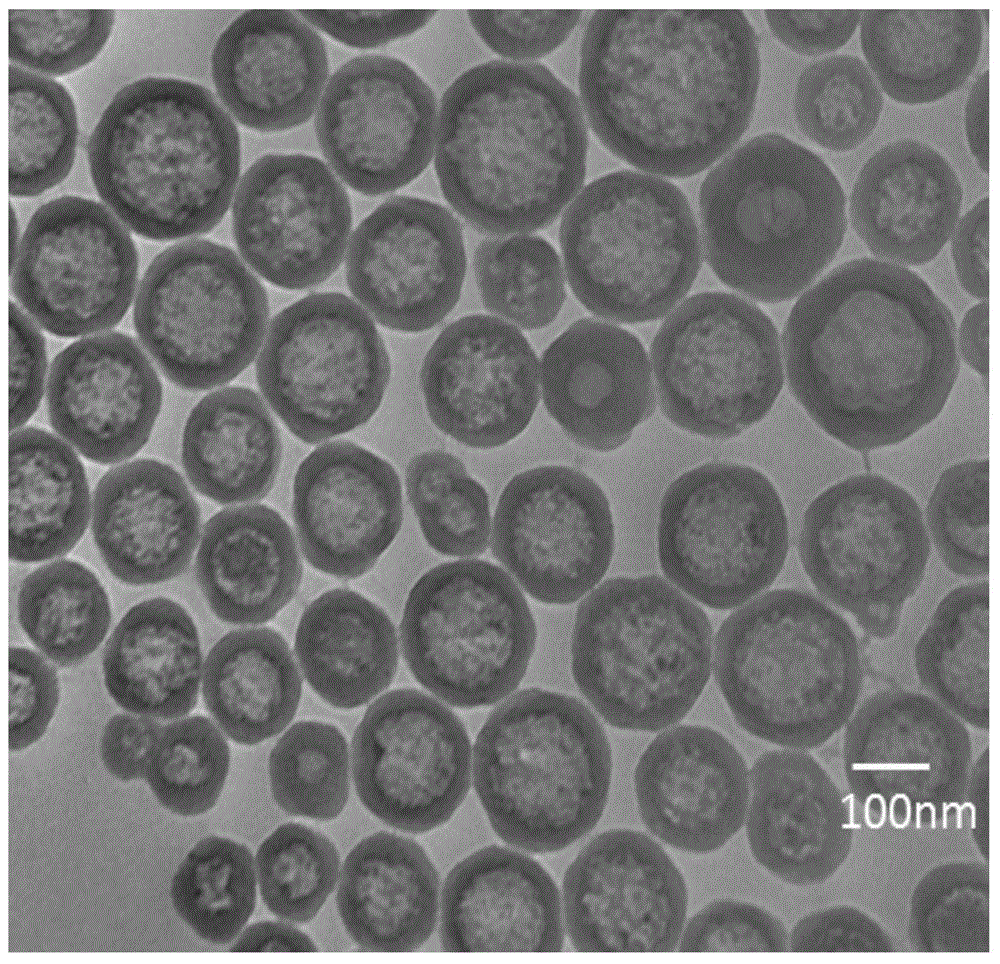

Method for utilizing template to prepare silicon dioxide hollow microspheres

InactiveCN104787769AGood dispersionGood size controlMaterial nanotechnologySilicaMicrosphereSolid particle

The invention discloses a method for utilizing a template to prepare silicon dioxide hollow microspheres, and belongs to the field of inorganic nanometer materials. The silicon dioxide hollow microspheres are prepared from the following raw materials in parts by volume: 100 parts of alcohol, 0.5-5 parts of ammonia water (the concentration in mass percent is 25-28%), 1-30 parts of a silicon source precursor, and 1-15 parts of a template aqueous solution (the concentration in mass percent is 1-8%). The method is characterized by comprising the following steps: using water-soluble anionic sodium polyacrylate or sodium polymethacrylate, using aggregates separated out in the poor solvent alcohol as the template, adding ammonia water as a catalyst, at last, adding the silicon source precursor, enabling a hermetic reaction for 5-24 hours under the stirring condition at the temperature of 5-50 DEG C, after the reaction, washing out the template with water, and collecting the dried product, so as to obtain the nano-scale hollow structure microspheres. According to the method disclosed by the invention, the size of the product is adjusted by changing the feeding ratio of the raw materials; the method has the advantages of being simple and easy to operate, good in morphology of the product, free of solid particles and the like; furthermore, the manner of removing the template with water is mild, free of pollution and low in energy consumption.

Owner:BEIJING UNIV OF CHEM TECH

Demoulding agent

The invention discloses a demoulding agent. The demoulding agent is prepared from, by weight, 12%-18% of organic dibasic acid, 7%-16% of sodium hydroxide, 2%-6% of sodium polymethacrylate, 0.2%-0.8% of isodecanol polyoxyethylene ether, 0.1%-0.5% of polyacrylamide, 0.5%-4% of polyisobutylene succinic anhydride, 1%-7% of organic silicon resin, 0.1%-0.2% of defoamer and the balance water, wherein the organic dibasic acid adopts phthalandione or isophthalic acid or hexanedioic acid. The demoulding agent does not contain graphite and has excellent high-temperature adhesion property, lubricating property and cooling property, the demoulding effect is good, the compatibility with water is excellent, removing through water washing is facilitated, an extremely strong protective effect is exerted on a mold, and it can be guaranteed that residues of the mold are less, the surface is bright and smooth, and the service life of the mold is greatly prolonged.

Owner:JIANGSU HANDEFU IND GOODS SCI & TECH

Novel tunnel shield machine main bearing sealing material

InactiveCN105176635AIncrease in sizeImprove mechanical propertiesLubricant compositionCross-linkFiber

The invention discloses a novel tunnel shield machine main bearing sealing material, which comprises the following components: 27-59% of basic grease, 5%-10% of lubricating grease, 5-20% of a tackifier, 20%-60% of powder filler, 1%-5% of natural degradable fiber, 0.5%-5% of a water absorption material particle, 1-10% of an anti-extrusion agent, and the balance other auxiliary materials. The water absorption material particle involved in the invention includes one of the following raw materials: 1) a cross-linked sodium polyacrylate salt; 2) a cross-linked potassium polyacrylate salt; 3) a crosslinked sodium polymethacrylate salt; 4) a crosslinked potassium polymethacrylate salt; and 5) other high polymer materials with similar structure and properties. The material can absorb a large amount of water when encountering water so as to play multiple roles that: 1) it can serve as normal powder, 2) it can absorb water directly so as to play a waterproof role, 3) the volume increases after water absorption so as to further enhance the material volume and mechanical properties, thereby improving the waterproof performance, and 4) after expansion, the material can block permeable holes and gaps.

Owner:东莞市明洁隧道建设材料有限公司

Acid-proof latex paint

InactiveCN107629565AImprove acid resistanceQuality improvementAnti-corrosive paintsEmulsion paintsPolystyrenePolyethylene glycol

The invention relates to an acid-proof latex paint, belonging to the technical field of coating. The latex paint contains the following components: polystyrene latex, polyvinyl acetate-ethylene emulsion, dispersing agent (sodium polymethacrylate), FCCHA, preservative (sodium pentachlorophenate), polyethylene glycol, polyurethane, hexanediol, diethylene glycol, pyrethroid, deionized water, titaniumdioxide and wollastonite in powder. The quality of the latex paint is improved, and the acid-proof property is better improved, so that the latex paint can completely resist the erosion of acidic substances of acid rain and the like.

Owner:王渊明

Multi-polymer modified PVC (polyvinyl chloride) cable material and preparation method thereof

InactiveCN104893182AHigh strengthIncrease elasticityPlastic/resin/waxes insulatorsPolymer modifiedMicrocrystalline wax

The invention discloses a multi-polymer modified PVC (polyvinyl chloride) cable material which is prepared from raw materials in parts by weight as follows: 13-15 parts of carbon nano tubes, 13-14 parts of neopentyl glycol diacrylate, 10-12 parts of dimethyl terephthalate, 0.02-0.04 parts of tert-butyl peroxy pivalate, 5-7 parts of titanium dioxide, 1-1.5 parts of sodium polymethacrylate, 68-72 parts of PVC, 7-9 parts of a polyurethane prepolymer, 3-5 parts of cellulose acetate, 2-3 parts of microcrystalline wax and 7-9 parts of an auxiliary. The polymers such as the polyurethane prepolymer, sodium polymethacrylate and the like are added to the PVC cable material with a special process, the carbon nano tubes are further added according to the formula, so that the composite material has good strength, elasticity, fatigue resistance, wear resistance and flexibility, the thermal stability of the product is enhanced by the aid of the auxiliary, the processability is good, and the service life is prolonged.

Owner:HEFEI HEAN MACHINERY MFG

Nano bacteria-killing paint

InactiveCN1515637AMake up for the singularityImprove securityAntifouling/underwater paintsPaints with biocidesCarboxymethyl celluloseWhite powder

The present invention relates to a nano bactericidal environment-protecting type paint. It is made up by using (wt%) 33%-38% of water-soluble latex using polyacrylic ester resin as base material, 4%-6% of microporous silver-carried bactericidal material, 21%-27% of superfine filling material, 9%-13% of rutile titanium white powder, 0.08%-0.2% of carboxymethyl cellulose, 0.05%-0.1% of sodium polymethacrylate, 0.1%-0.18% of sodium hexametaphosphate, 0.2%-0.4% of sodium pentachlorophenate and the rest water. It has fungusproof and antibacterial function.

Owner:SHANGHAI MINTAO IND DEV

Spinning oil and preparation method thereof

ActiveCN104032570AImprove performanceHigh elongation at breakFibre treatmentPhosphatePolyethylene glycol

The invention discloses spinning oil and a preparation method thereof. The spinning oil is prepared from the following components in parts by weight: 50-60 parts of dodecyl trimethyl ammonium chloride, 10-20 parts of dodecyl oleate, 10-20 parts of polyoxyethylene oleate, 1-4 parts of lauroyl diethanolamide, 1-5 parts of sodium dodecyl benzene sulfonate, 0.5-2 parts of octyl phosphate, 15-25 parts of dodecyl oleate, 2-8 parts of polyethylene glycol 600, 16-30 parts of dimethyl siloxane, 2-7 parts of sodium polymethacrylate and 3-8 parts of dioctyl phthalate. The preparation method of the spinning oil comprises the steps of adding dodecyl oleate, polyoxyethylene oleate, octyl phosphate, dodecyl oleate, polyethylene glycol 600 and dioctyl phthalate into a reaction kettle, heating and stirring for reaction, adding the remaining components, stirring for reaction at high temperature under a vacuum condition, and then carrying out low-temperature normal-pressure reaction. Compared with the existing spinning oil, the spinning oil has excellent performances which are remarkably improved.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

Dyeing method for polysulfonamide yarns

ActiveCN102720076AImprove cleanlinessShort lifeFibre typesDry-cleaning apparatus for textilesYarnWater baths

The invention discloses a dyeing method for polysulfonamide yarns, comprising: 1, inverting yarns; 2, processing before dyeing: placing a cylinder yarn into a pretreatment water bath, then heating the water to a temperature between 50 DEG C and 60 DEG C at a speed of 2 DEG C to 3 DEG C per minute, washing the yarn for 5 to 10 minutes, then washing the yarn with clear water, and drying the yarn; Dissolvability of a detergent is 0.8 to 1.2 grams per litter, and the detergent is composed of the following compositions: 3-5 parts of castor oil ethylene oxide condensation products; 15-20 parts of laurinol polyoxyethylene ether; 15-20 parts of sodium dodecyl sulfate; 3-6 parts of dodecyl dimethyl betaine; 3-6 parts of coconut oil amide propyl group hydroxyl sulfobetaines, 3-6 parts of sodium polymethacrylate, 3-5 parts of polyvinylpyrrolidone; 2-4 parts of sodium citrate; 1-2 parts of sodium silicate; 2-4 parts of bentonite; and 50-80 parts of water; 3, dyeing; 4, processing after dyeing. The production process of the invention produces less foam, is easy to operate, has a high color fastness, and the dyed polysulfonamide yarns possess a soft hand feeling.

Owner:SHANGHAI NEW UNION TEXTRA IMPORT & EXPORT

Super-micro-montmorillonite hand-washing liquid

InactiveCN101040826AEasy to cleanReduce pollutionCosmetic preparationsToilet preparationsBrickManufacturing technology

A ultra-fine montmorillonite hand cleanser belongs to washing product technique, which uses alta-mud to process ultra-fine treatment to prepare ultra-fine montmorillonite slurry, adds methylol cellulose, polymethyl sodium polyacrylate and surface activator to be mixed. The inventive hand cleanser is an emulsifier with hydrophilic, lipophilic, neutral, nontoxic, asepsis, non phosphorus-containing, de-oil, and beauty functions, while it can effectively reduce pollution, to be used to wash hand and clean dishware, in particular to be used by machine workers, clean brick, metal element and furs.

Owner:杨遇霄

Concrete synergist with strong workability and bleeding resistance and concrete

The invention discloses a concrete synergist with strong workability and bleeding resistance. Raw materials of the synergist comprise the following ingredients (by weight): 8-15 parts of allyl polyoxyethylene ether, 5-10 parts of maleic anhydride, 10-16 parts of polyacrylamide, 3-8 parts of polyvinyl alcohol, 2-6 parts of methyl methacrylate, 4-8 parts of fiber, 2-5 parts of polystyrene microspheres, 1-5 parts of polypropylene glycol, 4-9 parts of polysodium methacrylate, 5-10 parts of isobutenol polyoxyethylene ether, 1-5 parts of rice bran, 0.1-2 parts of a foam stabilizer, 30-50 parts of water and 1-3 parts of sodium tripolyphosphate. The concrete synergist has good workability with a concrete mixture, and has good fluidity and strong bleeding resistance. Through coordination and promotion effects between all components, slurry structure is more compact, and more chemical bonds with stronger binding force are generated between cement hydration particles so as to replace Van der Waals' force. Cementing force of a cementing material is raised, strength of cement and concrete is increased, quality and performance of a concrete material are enhanced, and cohesiveness and pumpability of the concrete mixture are improved.

Owner:CHONGQING TECH & BUSINESS INST

A preparing method of chlorinated polyethylene

A preparing method of chlorinated polyethylene is provided. The method includes, under stirring, adding high-density polyethylene powder into a hydrochloric acid solution, adding a surfactant into the mixture, heating the mixture to 50-60 DEG C, stirring the mixture for 10-30 min, then adding sodium polymethacrylate, sodium tripolyphosphate and benzoyl peroxide, stirring the mixture, heating the mixture to 65-70 DEG C, feeding chlorine to perform a chlorination reaction, continuously heating the mixture, then terminating the reaction, controlling reaction pressure, and performing filtration for acid removing, neutralization, centrifugal dehydration and drying to obtain the chlorinated polyethylene. Compared with the prior art, the surfactant is utilized to modify the high-density polyethylene powder in the method, and the chlorinated polyethylene can have low Mooney viscosity and a high elongation through ratio adjustment and can be applied in the rubber and plastic fields so that the application range of chlorinated polyethylene modified products is wider. Process water used in production is recycled and zero emission of water is achieved largely so that the method is energy-saving and environmentally friendly.

Owner:河北泰纳新材料科技有限公司

Vinyl acetate-acrylic emulsion, synthesis method thereof and electrical steel coating

InactiveCN103881002ANarrow particle size distributionLarge particle sizeCoatingsIsooctyl acrylateSynthesis methods

The invention discloses vinyl acetate-acrylic emulsion, a synthesis method thereof and an electrical steel coating. The vinyl acetate-acrylic emulsion comprises the following components by weight percent in terms of the total weight of the emulsion: 20.0-45.0% of vinyl acetate, 1.0-10.0% of butyl acrylate, 1.0-10.0% of 2-ethylhexyl acrylate, 1.0-10.0% of methyl methacrylate, 0.2-2.0% of methacrylic acid, 0.2-1.0% of alkylphenol polyoxyethylene ether OP-10, 0.4-2.0% of alkylphenol ether sulfosuccinate sodium salt MS-1, 40.0-65.0% of water, 0.2-1.2% of sodium polymethacrylate, 0.1-1.0% of sodium hydrogen phosphate and 0.2-1.0% of ammonium persulfate. The preparation method is characterized by firstly preparing pre-emulsion and an initiator water solution, mixing the pre-emulsion with the initiator water solution in batches and emulsifying the mixture, thus obtaining pure acrylic emulsion. The pure acrylic emulsion is narrow in particle size distribution and is fine in particle size. The prepared electrical steel coating has good resin dispersibility and long shelf life and is suitable for high-speed roller coating.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

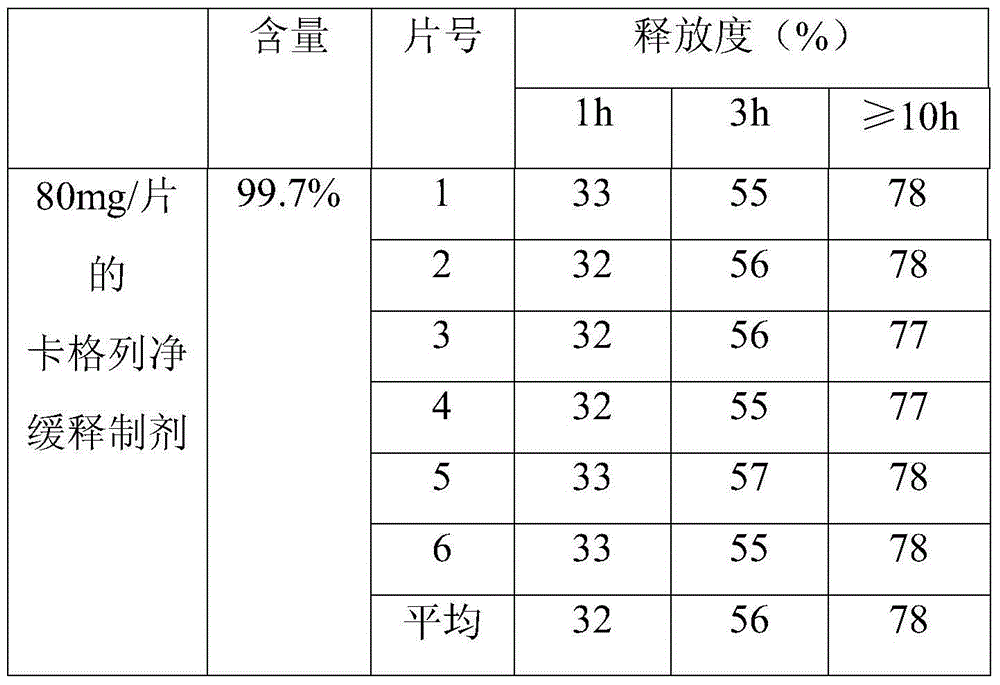

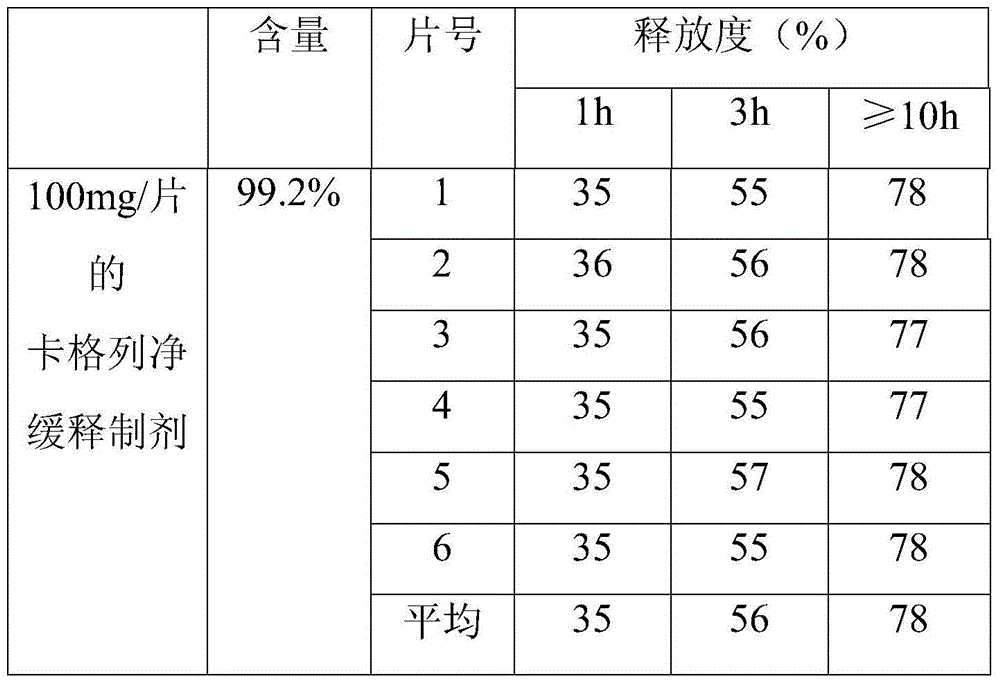

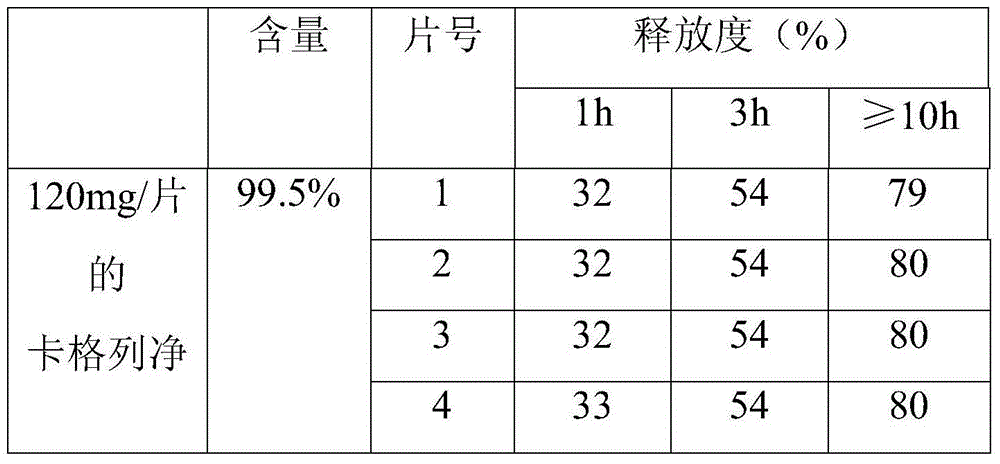

Invokana sustained release preparation and preparation method thereof

ActiveCN104688670AReduce the number of dosesReduce adverse reactionsOrganic active ingredientsMetabolism disorderSide effectMedicine

The invention discloses an invokana sustained release preparation and a preparation method thereof. The invokana sustained release preparation is composed of the following raw materials in parts by weight: 40-60 parts of invokana, 8-30 parts of polymethacrylate, 5-30 parts of sodium polymethacrylate, 5-60 parts of lactose and 1-5 parts of aerosil. The invokana sustained release preparation prepared according to the invention reduces the administration frequency, lowers the untoward effect of drugs on gastrointestinal tracts, reduces the side effect of drugs on the human body, and can achieve the maximum drug efficacy with the minimum dose of drugs; and the preparation method disclosed by the invention is simple in process and can be put into industrial production easily.

Owner:CHENGDU HENGRUI PHARMA

Aqueous ceramic tile bonding agent and preparation method thereof

InactiveCN107488426AStrong two-way permeabilityImprove adhesionEster polymer adhesivesDivinyl benzeneAmmonium sulfate

The invention discloses an aqueous ceramic tile bonding agent. The aqueous ceramic tile bonding agent comprises the following components in percent by weight: 20 to 35 percent of butyl acrylate, 20 to 30 percent of methyl methacrylate, 0.1 to 0.5 percent of ammonium persulfate, 1 to 4 percent of divinyl benzene, 0.1 to 0.5 percent of an emulgator OP-10, 0.5 to 2 percent of acrylic acid, 0.5 to 3 percent of sodium polymethacrylate, and water for the surplus. The aqueous ceramic tile bonding agent is simple and easy to operation in preparation technology, has high bidirectional permeability, is high in bonding power, and can effectively solve the problems of hollowing and dropping of ceramic tiles and marbles after the ceramic tiles and marbles are bonded to walls.

Owner:武汉市华林粘合剂有限公司

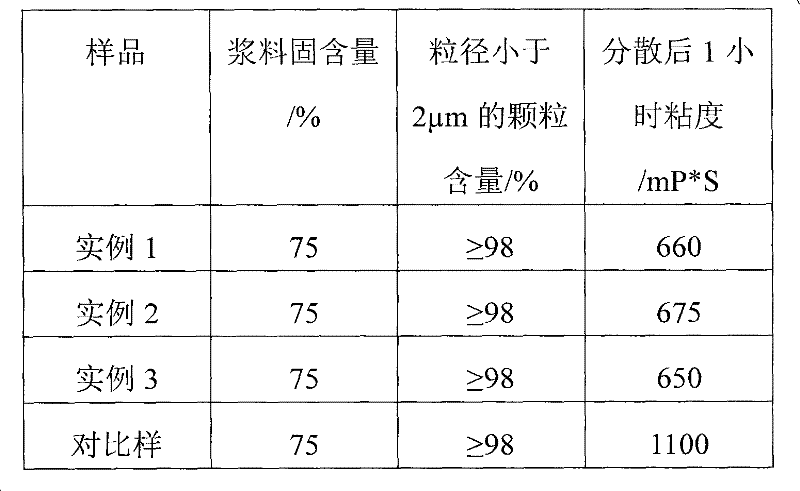

Preparation method and application of high-efficiency calcium carbonate dispersing agent

The invention discloses a preparation method of a high-efficiency calcium carbonate dispersing agent, which comprises the following steps of: (1) reacting transition metal halides with 2,2'-dipyridyl in solvent under inert atmosphere to obtain complex solution; (2) mixing the complex solution and a vinyl carboxylate monomer, adding initiator solution, reacting, treating by column chromatography on a reaction product to remove transition metal, and collecting solution obtained after treatment by the column chromatography; and (3) mixing the obtained solution and solution of sodium hydroxide, distilling to remove a solvent and an alcohol by-product, regulating the pH value by adding an alkaline substance, and regulating solid content by adding water to obtain the dispersing agent. In the method, ester monomers such as acrylates, methacrylates and the like are subjected to reverse atom transfer radical polymerization to prepare polyacrylate or polymethacrylate with narrow molecular weight distribution, and the polyacrylate or the polymethacrylate is hydrolyzed in the solution of the sodium hydroxide to prepare a sodium polyacrylate or sodium polymethacrylate dispersing agent with high dispersing efficiency.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Low-noise flame-retardant automobile rubber material

InactiveCN105440357AWide variety of sourcesEasy to produceArtifical filament manufactureLow noiseRubber material

The invention discloses a low-noise flame-retardant automobile rubber material which is prepared from, by weight parts, 0.8-1 part of anti-aging agent BLE, 5-7 parts of zinc oxide, 1-2 parts of polysodium methacrylate, 5-7 parts of ammonium polyphosphate, 24-27 parts of polyacrylonitrile, 12-13 parts of graphite, 3-4 parts of fly ash microsphere, 0.7-1 part of sodium dodecyl sulfate, 42-55 parts of liquid acrylonitrile butadiene rubber, 0.6-1 part of methacrylic acid, 52-60 parts of butadiene acrylonitrile rubber, 20-25 parts of butadiene styrene rubber, 7-9 parts of nanometer diamond powder, 5-7 parts of polyvinyl acetate emulsion, 14-16 parts of magnesia powder, 0.4-0.5 part of scorch retarder CTP, 7-9 parts of talc powder and 2-3 parts of calcium hydroxide. By optimizing the ratio of the components, the prepared rubber material has good damping, sound-insulating and flame-retardant performance and is extensive in material source and easy to produce.

Owner:安徽创奇乐智能游乐设备有限公司

Novel heat-insulating coating for buildings

ActiveCN104194525AReduce transmissionImprove reflectivityReflecting/signal paintsCis-Butenedioic AcidPolytetramethylene glycol

The invention discloses a novel heat-insulating coating for buildings, which consists of the following components in parts by weight: 0.1-0.3 part of sodium polymethacrylate, 0.3-0.6 part of terpineol, 40-60 parts of vinyl acetate-dibutyl maleate copolymer emulsion, 3-5 parts of methyl methacrylate, 10-20 parts of titanium dioxide, 10-20 parts of talcum powder, 10-20 parts of nano ceramic heat-insulating powder, 2-6 parts of polytetramethylene glycol, 0.1-0.3 part of an emulsifier OP-10, 1-3 parts of tributyl phosphate, 0.3-0.6 part of sodium hexametaphosphate, 10-20 parts of barium sulfate, 0.1-0.3 part of hydroxymethyl cellulose, and 30-50 parts of water. The invention also discloses a preparation method of the heat-insulating coating. The heat-insulating coating provided by the invention is good in heat insulation performance, and widely applied.

Owner:BAOYE HUBEI CONSTR ENG GRP

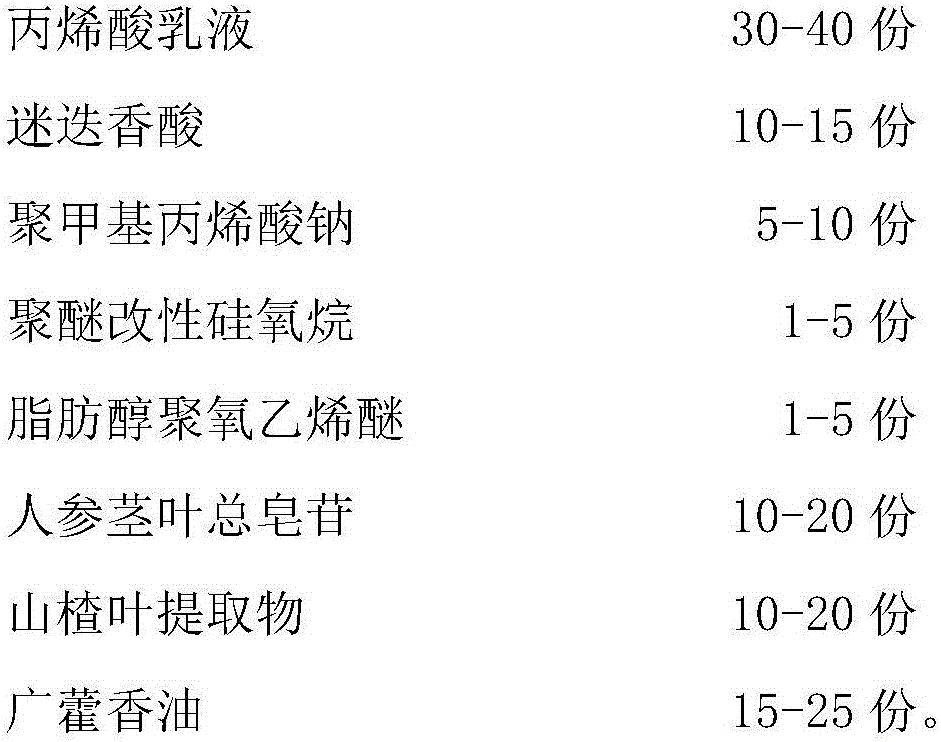

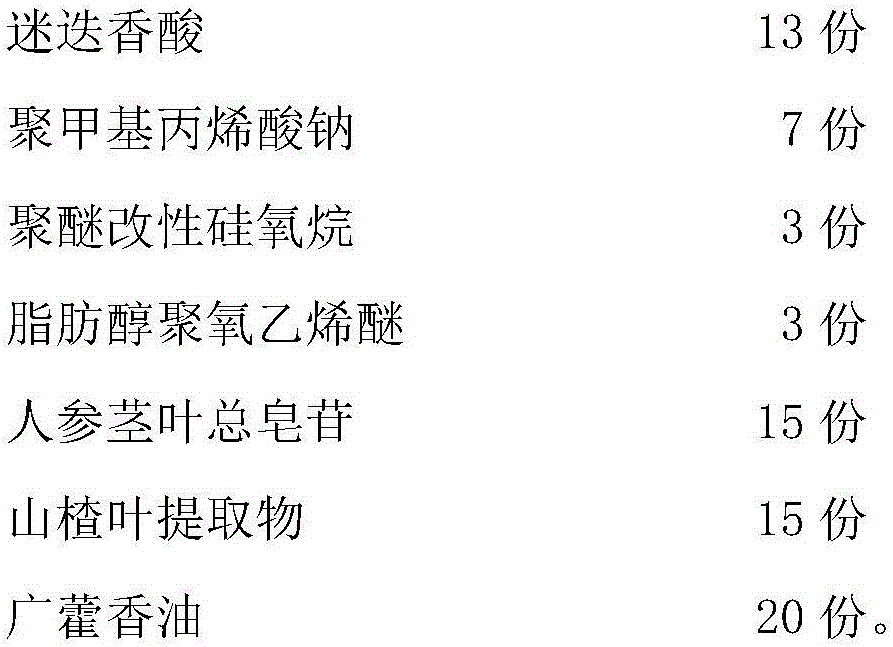

Efficient environment-friendly textile dye

The invention belongs to the technical field of textile materials, and particularly relates to an efficient environment-friendly textile dye. The efficient environment-friendly textile dye mainly comprises acrylic emulsion, rosmarinic acid, sodium polymethacrylate, polyether siloxane, fatty alcohol-polyoxyethylene ether, ginseng-stem-leaf total saponin, Chinese hawthorn leaf extract and patchouli oil. The rosmarinic acid has the bacteriostatic effect, the anti-inflammatory effect, the antiviral effect, the anti-tumor effect, the anti-allergic effect, the antioxidant effect, the anti-thrombus and anti-platelet-aggregation effects, the radiation protection effect and the immunosuppressive effect, and has quite good stability. The polyether siloxane has the foam-eliminating and foam-suppressing effects, is free of toxic and side effects and is good in stability. Meanwhile, the ginseng-stem-leaf total saponin has high moisture absorption performance, and the Chinese hawthorn leaf extract has high moisture guiding performance. The patchouli oil has specific aromatic odor, the specific smell of the ginseng-stem-leaf total saponin and the specific smell of the Chinese hawthorn leaf extract can be covered, certain potential safety hazards of the health of the human body can be avoided, and the environment can be protected.

Owner:RUIAN AOYA CLOTHING CO LTD

Coating for concrete wall surface

The invention belongs to the technical field of coatings and relates to a coating for a concrete wall surface. The coating comprises the following raw materials in parts by weight: 20-30 parts of emulsion binder, 6-16 parts of titanium dioxide, 4-8 parts of talcum powder, 10-15 parts of barium sulfate, 2-3 parts of glycol, 0.3-0.5 part of tributyl phosphate, 0.1-0.3 part of sodium hexametaphosphate, 0.15-0.25 part of emulsifier OP-10, 0.1-0.2 part of carboxymethylcellulose, 0.1-0.3 part of sodium polymethacrylate, 0.2-0.4 part of phenyl mercuric acetate, 0.1-0.3 part of terpilenol, 3-6 parts of zinc oxide, 5-15 parts of calcium carbonate, 3-5 parts of environment-friendly glue with a market sold number 805, 20-30 parts of tap water, purified water or distilled water and the balance of ammonia water. The coating has the major advantages of wide raw material source, simple and convenient formulation and firm binding to the concrete wall surface.

Owner:中釉彩涂釉股份有限公司

High-performance nanocrystalline magnetic core preparation method for high-frequency electronic transformer

ActiveCN103700481ASignificant rise in temperatureImprove qualityInductances/transformers/magnets manufactureTransformerSilanes

The invention discloses a high-performance nanocrystalline magnetic core preparation method for a high-frequency electronic transformer. The method specifically comprises the following steps of performing vacuum isothermal annealing on an iron-based amorphous thin strip to obtain a nanocrystalline thin strip; crushing the obtained nanocrystalline thin strip to obtain nanocrystalline metal powder; classifying the nanocrystalline metal powder into unequal parts of materials A and B; treating the material A by using sodium alcohol ether sulphate, sodium polymethacrylate and sodium hexametaphosphate, and treating the material B sequentially by using vinyl trimethoxy silane, kaolin, polyisobutylene, phytic acid, nanocarbon and polyacrylic acid; uniformly mixing the treated materials A and B, adding a sodium silicate aqueous solution, performing compression molding, coating the surface of a molded magnetic core with magnetic core glue G500, and performing curing to obtain a finished product. According to the method, the prepared magnetic core has the advantages of excellent high-temperature and high-frequency characteristics, low loss value and the like, and is high in comprehensive performance.

Owner:TONGLING SANJIA TRANSFORMER

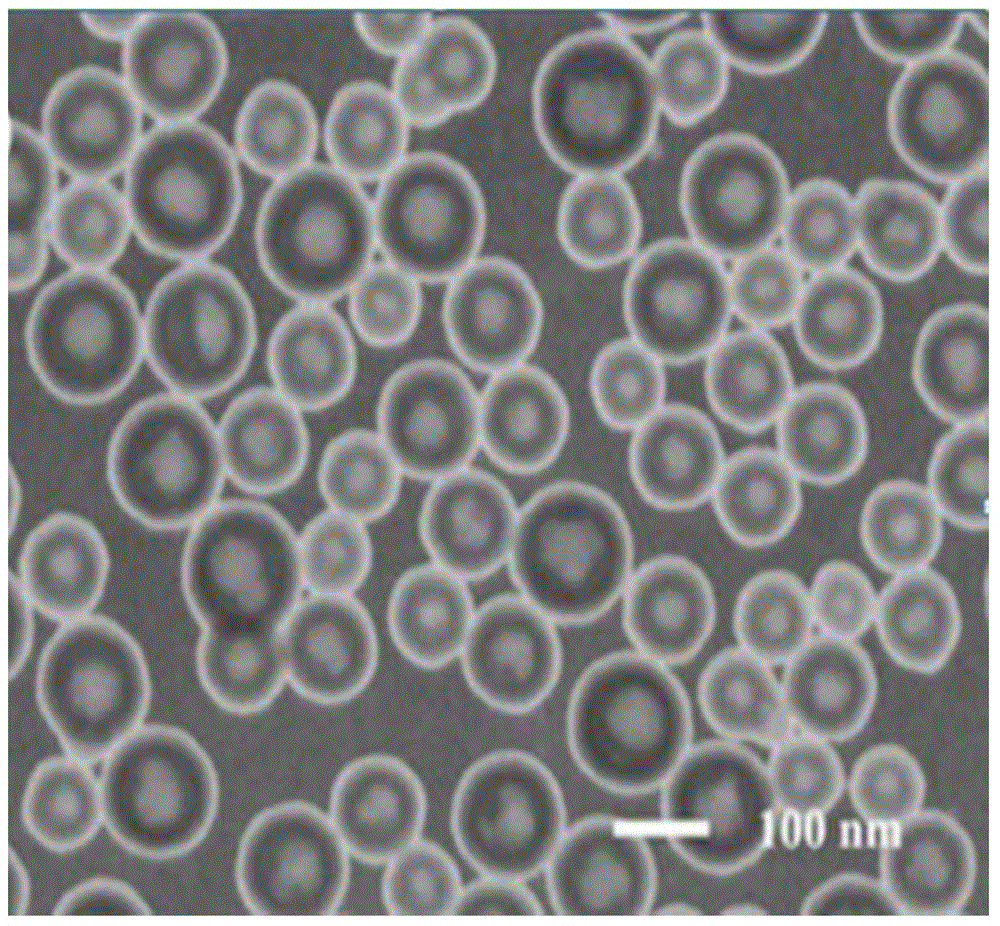

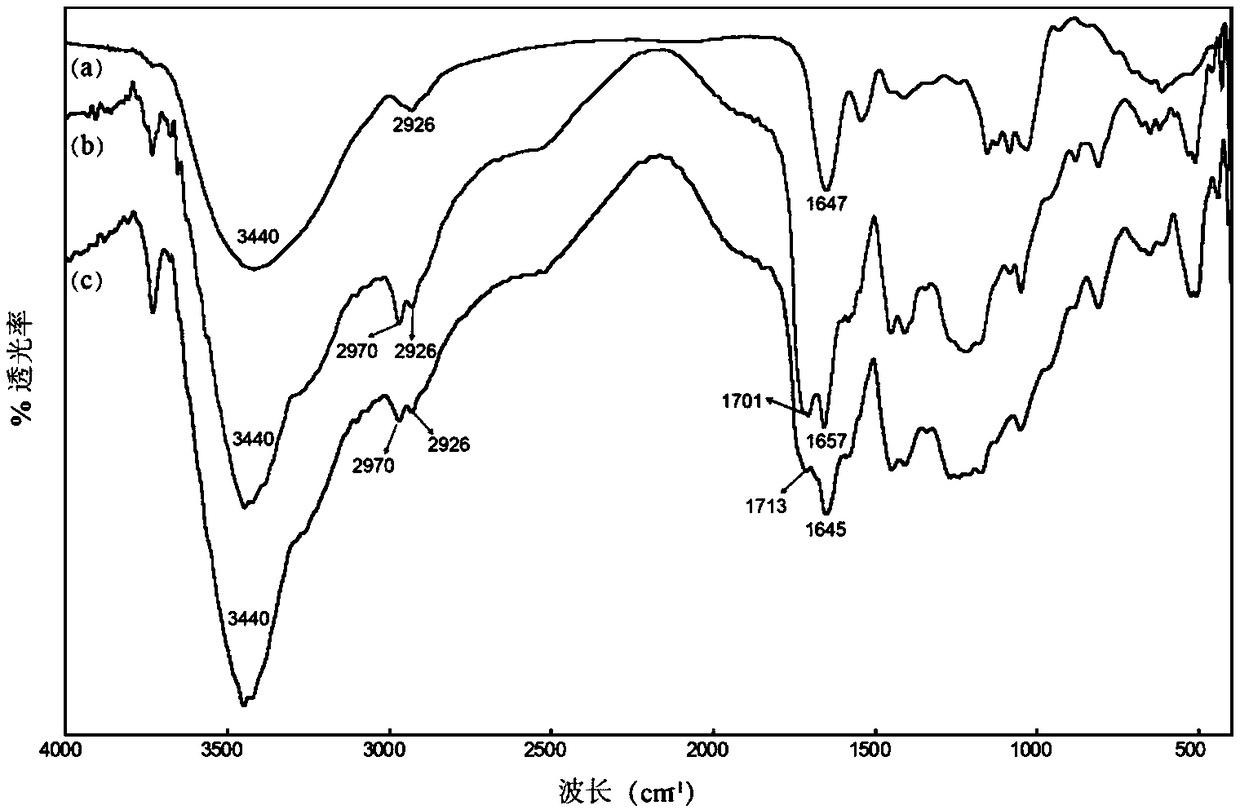

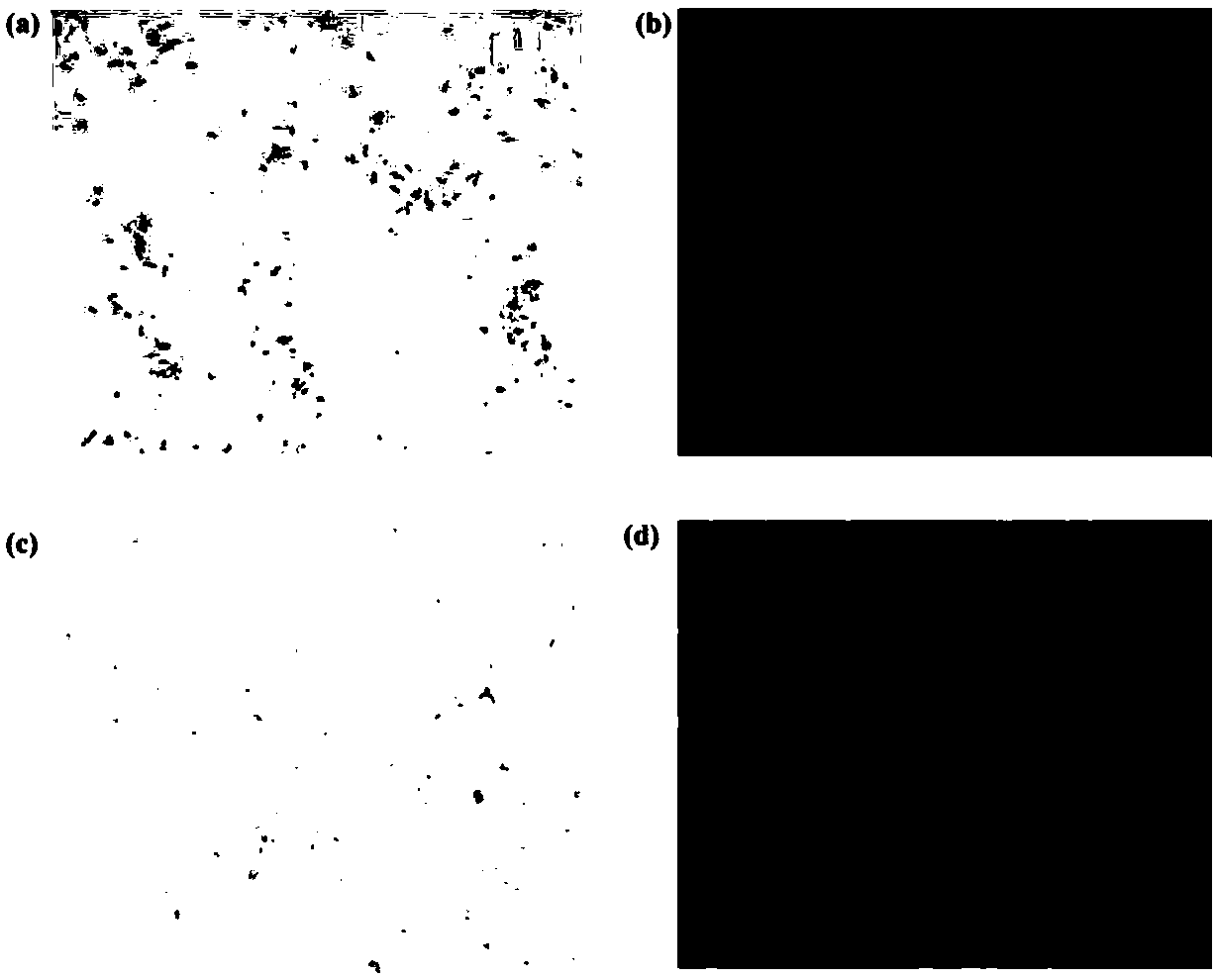

Soluble-insoluble UCST type PMAAc vector as well as immobilized enzyme and application thereof

ActiveCN108642040AHigh yieldVerify covalent bindingOn/in organic carrierFermentationCelluloseNitrogen

The invention belongs to the technical field of immobilized enzymes, relates to a soluble-insoluble UCST type PMAAc vector as well as an immobilized enzyme and an application thereof, and in particular to a preparation method of the soluble-insoluble high critical solution temperature (UCST) type sodium polymethylacrylate (PMAAc) vector, an application of the immobilized enzyme and an applicationof an immobilized enzyme degraded cellulose material thereof. The preparation method comprises the following steps: dissolving acrylic acid and ammonium persulfate through de-ionized water; slowly dropping methacrylamide which is dissolved by de-ionized water; uniformly shaking an obtained solution, filling nitrogen until bubbling and transferring an obtained solution into a single-mouth flask; implementing vacuumizing in nitrogen protection; conducting a reaction under magnetic stirring; implementing centrifuging after conducting cooling; discarding supernatant liquid; and heating up a resuspended material via de-ionized water, so that the finished product (the PMAAc vector) is obtained. The vector provided by the invention is applicable to immobilized cellulase, and the vector is used for degrading cellulose materials; the immobilized enzyme prepared by the invention is excellent in storage stability and reuse effect; and efficiency of hydrolyzing and catalyzing the cellulose materials is also obviously improved.

Owner:JIANGSU UNIV

Polyvinyl acetate emulsion paint and preparation method thereof

The invention relates to a polyvinyl acetate emulsion paint and a preparation method thereof, and belongs to the technical field of emulsion paints. The polyvinyl acetate emulsion paint disclosed by the invention is prepared from the following raw materials in parts by weight: 40-50 parts of a polyvinyl acetate emulsion, 0.05-0.1 part of sodium polymethacrylate, 0.3-0.5 part of a dispersing agent, 0.2-0.4 part of sodium pentachlorophenate, 5-7 parts of carboxymethyl cellulose thickener, 1-2 parts of ethylene glycol, 2-3 parts of propylene glycol, 0.05-0.20 part of a defoaming agent, 15-20 parts of deionized water, 15-25 parts of titanium dioxide, 5-10 parts of charlton white, 10-15 parts of light calcium carbonate and 5-10 parts of talcum powder. Compared with an existing polyvinyl acetate emulsion paint, the polyvinyl acetate emulsion paint disclosed by the invention has the advantages that the production cost is low; the paint has good adhesive property with the coated surface; and a coating is durable in use.

Owner:CHENGDU JINHUI TECH

Antibacterial coating layer and preparation technology thereof

InactiveCN108864880ABroad absorption spectrumHigh bactericidal activityAntifouling/underwater paintsPaints with biocidesKetoneDodecylbenzene

Owner:太仓斯迪克新材料科技有限公司

Bridge connection rail surface environmental protection coating for civil and architectural engineeringroad and bridge construction

InactiveCN106084940AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsDiethylene glycol diethyl etherMaterials science

The invention relates to a bridge connection rail surface environmental protection coating for civil and architectural engineeringroad and bridge construction. The bridge connection rail surface environmental protection coating comprises the following components: PVC resin powder, butadiene-styrene rubber, hexamethylenediisocyanate, propargyl chloride, isothiazolinone, glass powder, soda ash, lead iodide powder, chrome green, zinc chromate, magnesium silicate powder, magnesium methacrylate, sodium polymethacrylate, spodumene powder, zinc sulfide powder, asbestos powder, nut oil, methyl acetate, soya oil acid, diethylene glycol diethyl ether, isobutyl acrylate, tripropylene glycol diacrylate, dibasyl lead sulfate, sodium diethylhexyl sulfosuccinate, epoxy silane crosslinker, sodium dioctylsulfosuccinate, sorbitol, sodium dodecyl sulfonate, alkyl diphenyl phosphate, and ethoxylated lauryl alcohol sulfate. The product provided by the invention has superior flame-retardant, acid and alkali-proof, mildew-proof and antibacterial properties, and the product properties are improved.

Owner:梁方英

Material for multifunctional power maintenance gloves

InactiveCN105907035AExcellent flame retardantGood acid and alkali resistanceGlovesProtective garmentP-tert-octylphenolStyrene maleic anhydride

The invention relates to a material for multifunctional power maintenance gloves. The material comprises the following components: hexaflumuron, Carbomer, pine tar, boiled tung oil, ethylamine, isothiazolinone, styrene-maleic anhydride copolymers, p-tert-octyl phenol formaldehyde resin, methyl MQ silicone resin, polystyrene resin, arabinogalactan, amino-oligosaccharin, acrylic acid-2-ethyl hexyl ester, clove oil, ethyl p-hydroxybenzoate, dimethyl hydroxyl silicone oil, diisoamyl ether, ammonium chromate, barium peroxide, sulfadiazine silver, poly(butylene succinate), sodium polymethacrylate, trimethyl phosphate, sodium hexametaphosphate, chlorinated polyethylene, morpholine, nano-alumina powder, citric acid, glucose, sorbitol and carboxymethylcellulose. The product prepared from material has excellent flame retardance, acid-base resistance, mildew resistance and mold resistance, and the performance of the product is improved.

Owner:王义金

Self-stripping type metal rust remover

The invention discloses a self-stripping type metal rust remover. The self-stripping type metal rust remover consists of the following raw materials in parts by weight: 15-18 parts of n-ethyl maleimide, 15-16 parts of succinimide, 13-14 parts of phthalimide, 12-15 parts of maleimide, 13-16 parts of fumaric acid, 15-18 parts of phthalic anhydride, 18-20 parts of methylhexahydrophthalic anhydride, 15-18 parts of methacrylamide, 13-15 parts of methyl nadic anhydride, 16-18 parts of dimethylacetamide, 13-15 parts of acrylamide, 5-6 parts of methyl methacrylate, 3-4 parts of styrene, 5-6 parts of hydroxyethyl acrylate, 6-8 parts of sodium polyacrylate, 5-6 parts of sodium polymethacrylate, 3-5 parts of lauroamide propyl betaine, 75-80 parts of deionized water and the like. After the self-stripping type metal rust remover is applied to the rust surface of the metal, the rust remover is used for enabling the metal rust to be made into solid flake-shaped substances and automatically stripping the solid flake-shaped substances; the self-stripping type metal rust remover is not required to be dipped in a tank during constructing; the self-stripping type metal rust remover can be applied in a spray coating manner, also can be applied in a brush coating manner and is suitable for a variety of industries for a variety of purposes.

Owner:司徒建辉

Power distribution cabinet body material preparation method

The invention relates to a power distribution cabinet body material preparation method, which specifically comprises: 1, weighing the following raw materials by weight: 30-35 parts of a nickel-based alloy, 10-12 parts of silicon carbide fiber, 12-16 parts of ash calcium powder, 2-8 parts of volcanic ash, 5-18 parts of spinel powder, 10-16 parts of sodium polymethacrylate, 5-9 parts of copper sulfate, 3-9 parts of polyhexamethylene guanidine, 1-5 parts of shellac and 3-23 parts of butyl acrylate; 2, mixing the nickel-based alloy, the silicon carbide fiber, the ash calcium powder, the volcanic ash and the spinel powder, and carrying out ball milling; and 3, adding the sodium polymethacrylate, the copper sulfate, the polyhexamethylene guanidine and the butyl acrylate into the mixture obtainedin the step 2, uniformly stirring, adding the shellac, and carrying out secondary stirring to obtain the cabinet material. According to the invention, the problem of poor performance of the coating layer material of the power distribution cabinet in the prior art is solved.

Owner:西安优信机电工程有限公司

Computer data connecting wire

InactiveCN106046743ASoft textureExcellent flame retardantCommunication cablesInsulated cablesAllyl methyl sulfidePropylamine

The invention relates to a computer data connecting wire, which comprises a plurality of copper alloy conducting wires and protection sheaths, wherein the copper alloy conducting wires are placed in a mutually parallel way; the outer layer of each copper alloy conducting wire is respectively covered by the protection sheaths; each protection sheath is prepared from the following ingredients including bisphenol A type polycarbonate, rosin calcium soap, vinylite, coal tar, tallow di(2-Hydroxyethyl) amine oxide, hydrogenated soybean oil, terpilenol, tung oil, folium artemisiae argyi extracts, garlic extracts, isothiazolinone, cylindrin, ash calcium powder, cinerite, allyl methyl sulfide, flint clay powder, coke, sodium polymethacrylate, sericite powder, tripterygium wilfordii, ammonium polyphosphate, guanyl urea phosphate, triethylene glycol di-2-ethylhexoate, p-cresol, sodium benzoate, ricinate butyl oleate sodium sulfate, ricinate oleate polyoxy acrylic ester, propylamine, allyl glycidyl ether and acrylic acid-hydroxy-propyl acrylate copolymers. The computer data connecting wire has the advantage that the use performance of a product is improved.

Owner:权周越

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com