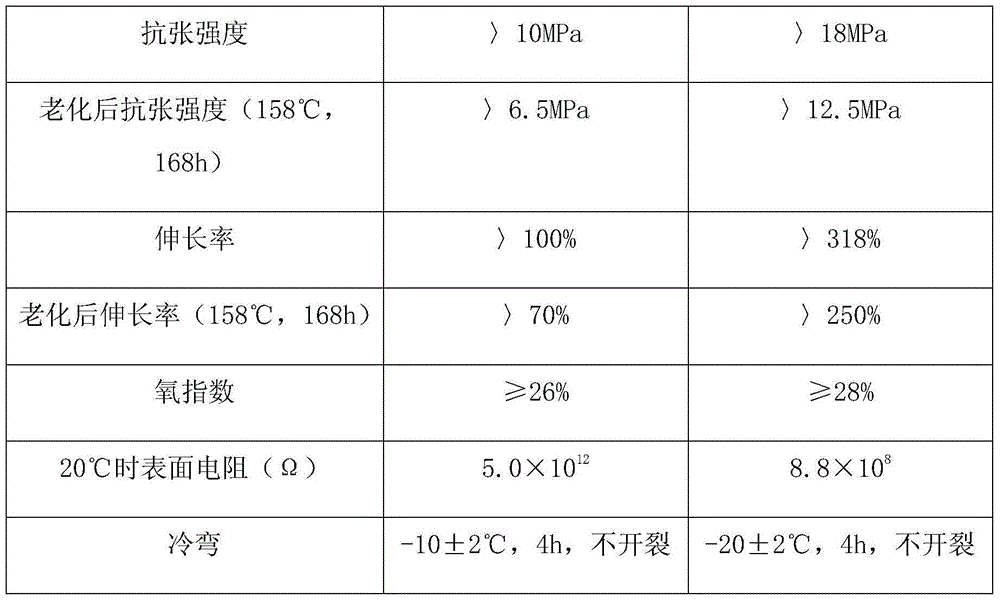

Multi-polymer modified PVC (polyvinyl chloride) cable material and preparation method thereof

A polyvinyl chloride cable, polyvinyl chloride technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of insufficient surface hardness, easy to wear, large shrinkage, etc., to achieve good processing performance, Enhanced thermal stability, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below through specific examples.

[0014] A polyvinyl chloride cable material modified by a variety of polymers, made of the following raw materials in parts by weight (kg): carbon nanotube 13, neopentyl glycol diacrylate 13, dimethyl terephthalate 10, 0.02 tert-butyl peroxy tert-valerate, 5 titanium dioxide, 1 polysodium methacrylate, 68 polyvinyl chloride, 7 polyurethane prepolymer, 3 cellulose acetate, 2 microcrystalline paraffin, 7 additives;

[0015] The auxiliary agent comprises the following raw materials in parts by weight (kg): rapeseed oil 6, aluminum nitride powder 2, titanium dioxide 4, calcium zinc stabilizer DA-9202, trimethylolpropane triacrylate 2, polyimide Amine 3, brucite fiber 1, anti-aging agent TPPD 0.3, castor oil 3, ferrocene 2, dibutyl phthalate 1; the preparation method is that the preparation method is to put aluminum nitride powder and titanium dioxide into the dish Grind in seed oil and cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com