Soluble-insoluble UCST type PMAAc vector as well as immobilized enzyme and application thereof

A carrier and soluble technology, applied in soluble-insoluble UCST type PMAAc carrier, its immobilized enzyme and its application field, can solve the problems of low cellulose hydrolysis efficiency, difficult recovery, etc., to achieve full contact, improved stability, Excellent acid and alkali resistance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

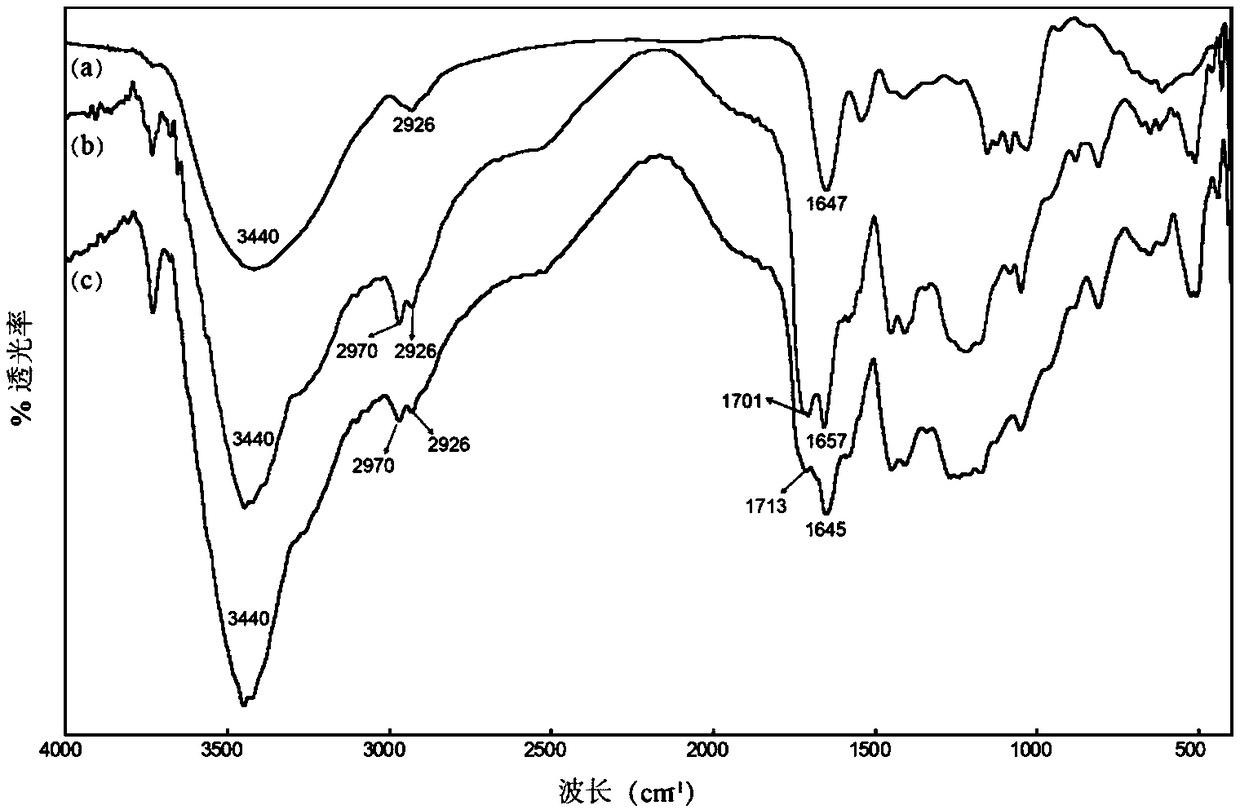

[0050] Embodiment 1: the preparation of soluble-insoluble UCST type PMAAc carrier and the immobilization of enzyme

[0051] (1) Preparation of soluble-insoluble UCST PMAAc carrier:

[0052] At room temperature, dissolve 1 g of acrylic acid (AAc) and 0.022 g of ammonium persulfate (APS) in 10 mL of deionized water, then transfer them to a three-necked flask, and slowly add 0.32 g of methacrylamide dissolved in 10 mL of deionized water dropwise. (MAA), after shaking well, bubbling with nitrogen gas for about half an hour, then transfer to a single-necked flask, vacuumize under nitrogen protection, magnetically stir at 60 °C for 3.5 hours, take it out, cool and centrifuge, remove the supernatant, and use deionized water The temperature was raised to resuspend the material, and the product was obtained after repeated three times. After drying in a vacuum oven at 40° C. overnight, a transparent gel-like product was obtained. Next, lead an appropriate amount of PMAAc solution into ...

Embodiment 2

[0057] Embodiment 2: the preparation of soluble-insoluble UCST type PMAAc carrier and the immobilization of enzyme

[0058] (1) Preparation of soluble-insoluble UCST PMAAc carrier:

[0059] At room temperature, dissolve 1.88 g of acrylic acid (AAc) and 0.042 g of ammonium persulfate (APS) in 10 mL of deionized water, then transfer them to a three-necked flask, and slowly add 0.52 g of methacrylic acid dissolved in 10 mL of deionized water dropwise. Amide (MAA), after shaking well, bubbling with nitrogen gas for about half an hour, then transferred to a single-necked flask, vacuumed under nitrogen protection, magnetically stirred at 60 °C for 4.5 hours, then taken out, cooled, centrifuged, supernatant removed, and deionized The material was resuspended in water, and the product was obtained after repeated three times. After drying in a vacuum oven at 40° C. overnight, a transparent gel-like product was obtained. Next, lead an appropriate amount of PMAAc solution into a glass t...

Embodiment 3

[0064] Embodiment 3: the preparation of soluble-insoluble UCST type PMAAc carrier and the immobilization of enzyme

[0065] (1) Preparation of soluble-insoluble UCST PMAAc carrier:

[0066] At room temperature, 1.44 g of acrylic acid (AAc) and 0.032 g of ammonium persulfate (APS) were dissolved in 10 mL of deionized water, then transferred to a three-necked flask, and slowly added dropwise with methacrylamide dissolved in 10 mL of deionized water ( MAA, 0.42 g), shake well, then bubble with nitrogen for about half an hour, then transfer to a single-necked flask, vacuumize under nitrogen protection, stir magnetically at 60°C for 4 hours, take it out, cool and centrifuge, remove the supernatant, and use The material was resuspended in deionized water, and the product was obtained after repeated three times. After drying overnight in a vacuum oven at 40°C, a transparent gel-like product was obtained. Next, lead an appropriate amount of PMAAc solution into a glass test tube, hang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com