A preparing method of chlorinated polyethylene

A technology of chlorinated polyethylene and high-density polyethylene, applied in the field of plastic products, can solve the problems of product performance gap, carbon tetrachloride residue, limited application field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

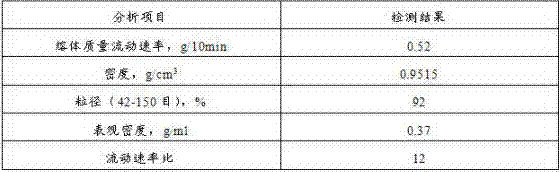

[0018] The embodiment of the present invention discloses a preparation method of chlorinated polyethylene, which includes the following steps: step a) under stirring conditions, add high-density polyethylene powder into 600-1000 parts by weight of hydrochloric acid solution, add 1-5 parts by weight Surfactant, heat up to 50-60°C and stir for 10-30 minutes; step b) add 1-3 parts by weight of sodium polymethacrylate and 0.5-1.8 parts by weight of sodium tripolyphosphate to the product obtained in step a, and peroxide 0.4-1.2 parts by weight of benzoyl, stirring, continue to heat up to 65-70°C; step c) pass chlorine gas into the mixture obtained in step b to carry out chlorination reaction, continue to heat up to 120-140°C to stop the reaction, and control the reaction pressure 0.4-0.45MPa, and then deacidification by filtration, neutralization, centrifugal dehydration, and drying to obtain chlorinated polyethylene.

[0019] As a preferred version, the mass concentration of the h...

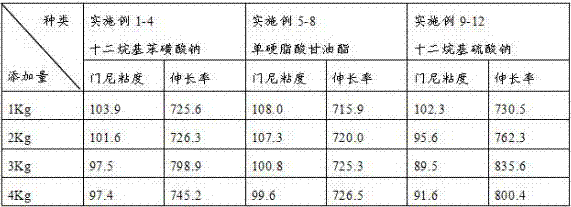

Embodiment 1

[0028] 1. Prepare 800Kg of hydrochloric acid solution with a concentration of 22%, slowly start stirring, add 100Kg of high-density polyethylene powder, add 1 Kg of surfactant, heat up to 55°C and stir for 20 minutes, and perform surface pretreatment on the polyethylene powder to improve its Active, the surfactant is sodium dodecylbenzenesulfonate;

[0029] 2. Then add 1.3Kg of sodium polymethacrylate, 0.98Kg of sodium tripolyphosphate, and 0.6Kg of benzoyl peroxide, stir and mix thoroughly, and then continue to heat up.

[0030] 3. Raise the temperature to 65°C, start to feed chlorine gas into the reactor for chlorination reaction, continuously raise the temperature to 130°C to stop the reaction, control the pressure of the reactor to 0.4-0.45MPa, and feed 60Kg of chlorine gas at 65-110°C for 2- For 3 hours, 60Kg of chlorine gas is introduced at 110-130°C for 2-3 hours;

[0031] 4. After the chlorination is completed, the modified chlorinated polyethylene is obtained through...

Embodiment 2-4

[0033] Adopt the preparation method of embodiment 1, the quality of sodium dodecylbenzenesulfonate is respectively 2Kg, 3Kg, 4Kg;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com