Method for utilizing template to prepare silicon dioxide hollow microspheres

A silica and hollow technology, which is applied in the field of preparation of template particles and hollow nano-microspheres, can solve problems such as difficult operation in industrial production, influence of polyelectrolyte concentration, slow drop rate, etc., achieve simple and effective dispersion, and short experiment cycle , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0032] Take 3ml of PAANa aqueous solution with a mass percentage concentration of 4%, add it to 50ml of absolute ethanol under stirring, and stir at a constant speed for 30min; add 1ml of ammonia solution with a mass percentage concentration of 25% into the system, stir and disperse evenly; finally add 1ml of Tetraethyl silicate, sealed container, stirring reaction for 12h. After the reaction, the template was removed by washing with water, and the product was collected and dried.

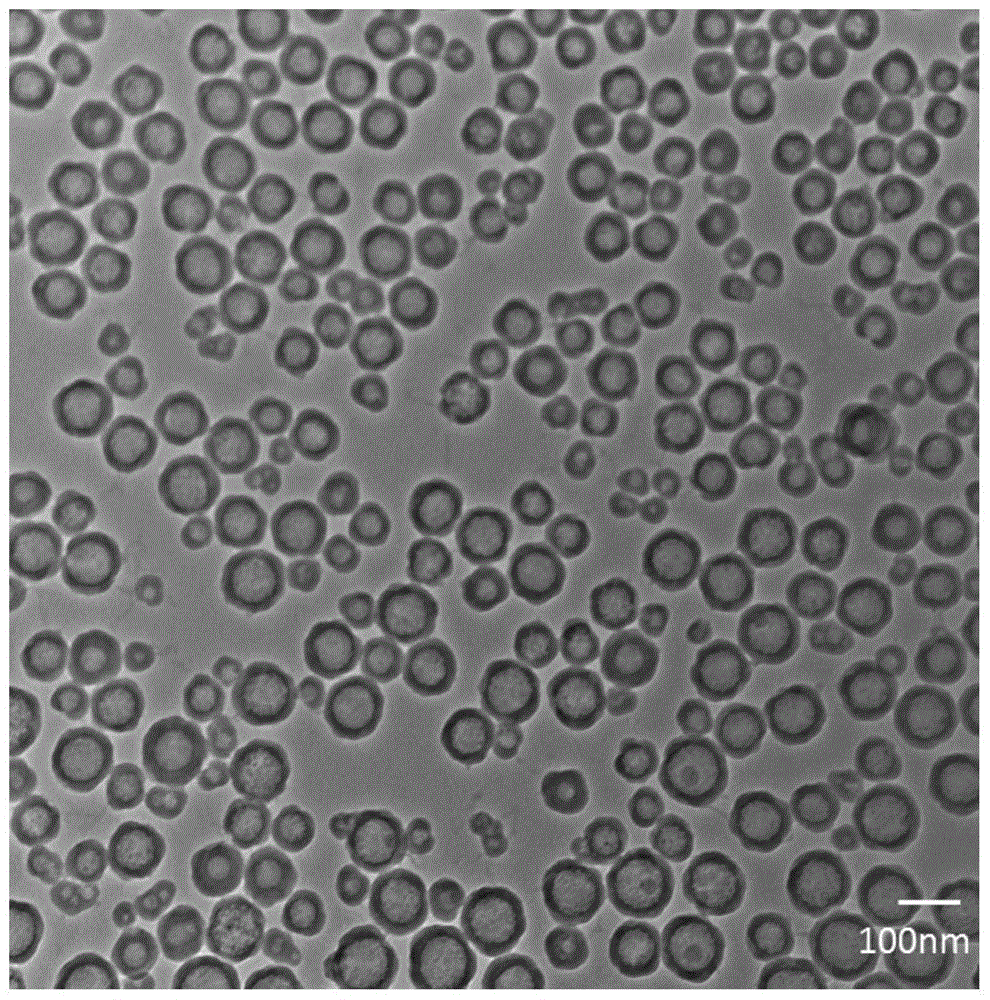

[0033] figure 1 It is the TEM picture of the product in Example 1. From figure 1 It can be seen that the coating has been successfully achieved, and silica microspheres without a solid structure have been obtained. The size of the hollow spheres is about 100nm, the thickness of the shell layer is 20-30nm, and the dispersion is good.

Embodiment example 2

[0035] Take 3ml of PAANa aqueous solution with a mass percentage concentration of 4%, add it to 50ml of absolute ethanol under stirring, and stir at a constant speed for 30min; add 1m of ammonia solution with a mass percentage concentration of 25% into the system, stir and disperse evenly; finally add 2ml of Tetraethyl silicate, sealed container, stirring reaction for 12h. After the reaction, the template was removed by washing with water, and the product was collected and dried.

Embodiment example 3

[0037] Take 3ml of PAANa aqueous solution with a mass percentage concentration of 5%, add it to 50ml of absolute ethanol under stirring, and stir at a constant speed for 30min; add 1ml of ammonia solution with a mass percentage concentration of 25% into the system, stir and disperse evenly; finally add 1ml of Tetraethyl silicate, sealed container, stirring reaction for 12h. After the reaction, the template was removed by washing with water, and the product was collected and dried.

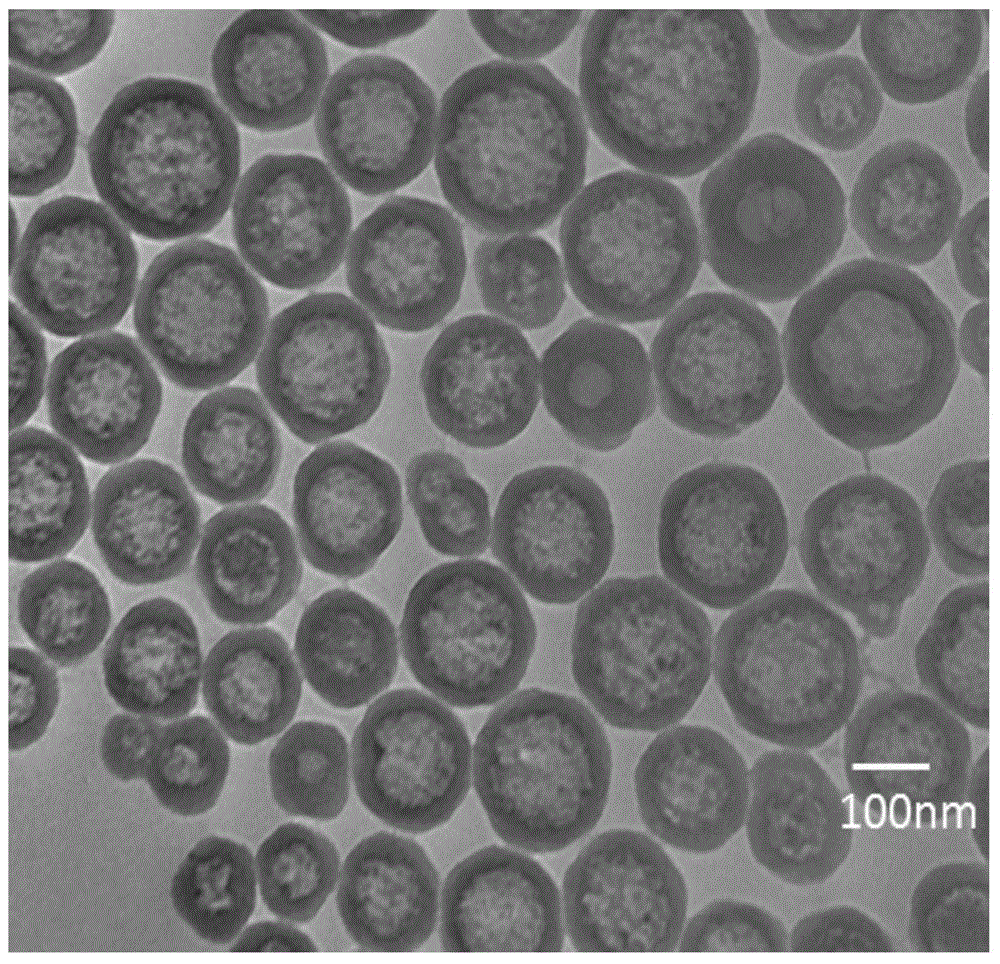

[0038] figure 2 It is the TEM picture of the product in Example 3. The product has good dispersion and no hollow structure, the size of the hollow sphere is about 140nm, and the shell wall thickness is 20-30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com