Vinyl acetate-acrylic emulsion, synthesis method thereof and electrical steel coating

A vinegar-acrylic emulsion and a synthesis method technology, applied in the coating and other directions, can solve the problems affecting the long-term storage and use of the coating, and achieve the effects of good surface quality, long storage period and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

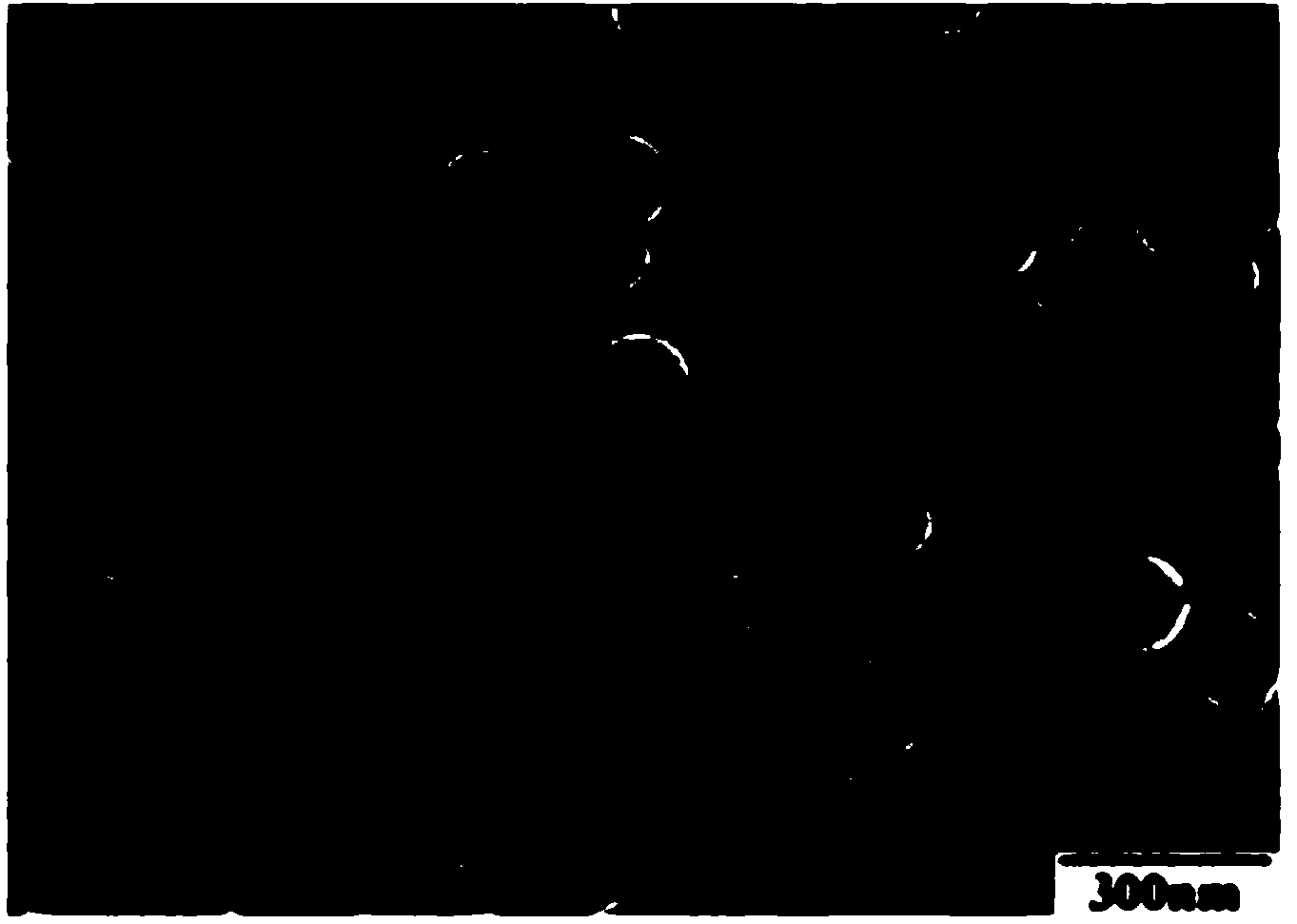

Image

Examples

Embodiment 1

[0029] A kind of vinegar acrylic emulsion, each component accounts for the weight ratio of emulsion total amount:

[0030] 35.0% vinyl acetate, 5.0% butyl acrylate, 2.0% isooctyl acrylate, 5.0% methyl methacrylate, 0.5% methacrylic acid, 0.3% alkylphenol polyoxyethylene ether OP-10, 1.0% alkyl Phenyl ether sulfosuccinate sodium salt MS-1, 49.6% water, 0.5% sodium polymethacrylate, 0.4% disodium hydrogen phosphate and 0.8% ammonium persulfate.

[0031] A kind of synthetic method of vinegar-acrylic emulsion:

[0032] A, take by weighing each component according to the weight ratio that each component of the above-mentioned vinegar-acrylic emulsion accounts for the total amount of the emulsion;

[0033] B. The weighed vinyl acetate, butyl acrylate, isooctyl acrylate, methyl methacrylate, methacrylic acid, alkylphenol polyoxyethylene ether OP-10, alkylphenol ether sulfosuccinate sodium Salt MS-1, sodium polymethacrylate, disodium hydrogen phosphate and part of the water weighed,...

Embodiment 2

[0042] A kind of vinegar acrylic emulsion, each component accounts for the weight ratio of emulsion total amount:

[0043] 20.0% vinyl acetate, 10.0% butyl acrylate, 5.0% isooctyl acrylate, 10.0% methyl methacrylate, 1.0% methacrylic acid, 0.6% alkylphenol polyoxyethylene ether OP-10, 1.2% alkyl Phenyl ether sulfosuccinate sodium salt MS-1, 51.2% water, 0.2% sodium polymethacrylate, 0.2% disodium hydrogen phosphate and 0.6% ammonium persulfate.

[0044] A kind of synthetic method of vinegar-acrylic emulsion:

[0045] A, take by weighing each component according to the weight ratio that each component of the above-mentioned vinegar-acrylic emulsion accounts for the total amount of the emulsion;

[0046] B. Vinyl acetate, butyl acrylate, isooctyl acrylate, methyl methacrylate, methacrylic acid, alkylphenol polyoxyethylene ether OP-10 alkylphenol ether sulfosuccinate sodium salt MS-1 , sodium polymethacrylate, disodium hydrogen phosphate and part of the water weighed, stirred, ...

Embodiment 3

[0055] A kind of vinegar acrylic emulsion, each component accounts for the weight ratio of emulsion total amount:

[0056] 45.0% vinyl acetate, 7.8% butyl acrylate, 10.0% isooctyl acrylate, 8.0% methyl methacrylate, 1.8% methacrylic acid, 1.0% alkylphenol polyoxyethylene ether OP-10, 1.7% alkyl Phenyl ether sulfosuccinate sodium salt MS-1, 54.3% water, 1.2% sodium polymethacrylate, 1.0% disodium hydrogen phosphate and 0.2% ammonium persulfate.

[0057] A kind of synthetic method of vinegar-acrylic emulsion:

[0058] A, take by weighing each component according to the weight ratio that each component of the above-mentioned vinegar-acrylic emulsion accounts for the total amount of the emulsion;

[0059] B. The weighed vinyl acetate, butyl acrylate, isooctyl acrylate, methyl methacrylate, methacrylic acid, alkylphenol polyoxyethylene ether OP-10, alkylphenol ether sulfosuccinate sodium Salt MS-1, sodium polymethacrylate, disodium hydrogen phosphate and part of the water weighed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com