Antibacterial coating layer and preparation technology thereof

An antibacterial coating and preparation process technology, applied in the field of antibacterial coating and its preparation process, can solve the problems of dead corners of hygiene, weak absorption, weak activity, etc., and achieve the effects of strong bacteriostatic and sterilizing activity, saving raw materials, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

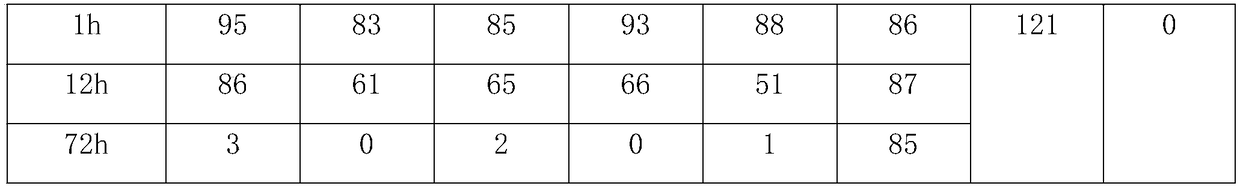

Embodiment 1

[0026] A kind of antibacterial coating, described antibacterial coating comprises Fe 3 o 4 Doped with TiO2 nanoparticles, the antibacterial coating also includes the following components by weight, 20 parts of fluorine-containing acrylic emulsion, 20 parts of epoxy resin emulsion, 0.1 part of melamine, 0.1 part of carbodiimide, 20 parts of talcum powder, 1 part of sodium polymethacrylate, 8 parts of water-based color paste, 1 part of trimethylhydroxypentyl isobutyrate, 0.5 parts of high-carbon alcohol fatty acid ester complex, 20 parts of titanium dioxide, polyoxyethylene alkylphenol 0.2 part of ether, 0.4 part of 1,2-benzisothiazolin-3-one, 0.5 part of alkanolamine, 40 parts of water.

[0027] The Fe 3 o 4 Fe doped TiO2 nanoparticles 3 o 4 The mass percentage is 0.03%.

[0028] Fe in the antibacterial coating 3 o 4 doped TiO 2 The mass percentage of nanoparticles is 0.01%.

[0029] The Fe 3 o 4 doped TiO 2 Nanoparticles made of Ti(SO 4 ) 2 , Fe 3 o 4 , ammoni...

Embodiment 2

[0042] A kind of antibacterial coating, described antibacterial coating comprises Fe 3 o 4 doped TiO 2 Nanoparticles, the antibacterial coating also includes the following components by weight, 40 parts of fluorine-containing acrylic emulsion, 40 parts of epoxy resin emulsion, 1.5 parts of melamine, 1.5 parts of carbodiimide, 40 parts of talcum powder, polymethyl 3 parts of sodium acrylate, 55 parts of water-based color paste, 3 parts of trimethylhydroxypentyl isobutyrate, 2 parts of propylene glycol, 1.0 part of high-carbon alcohol fatty acid ester compound, 40 parts of titanium dioxide, polyoxyethylene alkylphenol 0.4 parts of base ether, 0.6 parts of 1,2-benzisothiazolin-3-one, 0.7 parts of alkanolamine, and 60 parts of water.

[0043] The Fe 3 o 4 doped TiO 2 Fe in nanoparticles 3 o 4 The mass percentage is 0.04%.

[0044] Fe in the antibacterial coating 3 o 4 doped TiO 2 The mass percentage of nanoparticles is 0.02%.

[0045] The Fe 3 o 4 doped TiO 2 Nanopa...

Embodiment 3

[0058] A kind of antibacterial coating, described antibacterial coating comprises Fe 3 o 4 doped TiO 2 Nanoparticles, the antibacterial coating also includes the following components by weight, 25 parts of fluorine-containing acrylic emulsion, 28 parts of epoxy resin emulsion, 0.8 part of melamine, 0.8 part of carbodiimide, 25 parts of talcum powder, polymethyl 1.5 parts of sodium acrylate, 12 parts of water-based color paste, 2 parts of trimethylhydroxypentyl isobutyrate, 0.5 parts of propylene glycol, 0.8 parts of high-carbon alcohol fatty acid ester complex, 26 parts of titanium dioxide, polyoxyethylene alkylphenol 0.25 parts of base ether, 0.45 parts of 1,2-benzisothiazolin-3-one, 0.55 parts of alkanolamine, and 45 parts of water.

[0059] The Fe 3 o 4 doped TiO 2 Fe in nanoparticles 3 o 4 The mass percentage content is 0.05%.

[0060] Fe in the antibacterial coating 3 o 4 doped TiO 2 The mass percentage of nanoparticles is 0.03%.

[0061] The Fe 3 o 4 doped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com