Preparation method and application of high-efficiency calcium carbonate dispersing agent

A dispersant, calcium carbonate technology, applied in chemical instruments and methods, dyed polymer organic compound treatment, fibrous fillers, etc., can solve the problems of lower utilization efficiency of dispersant and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

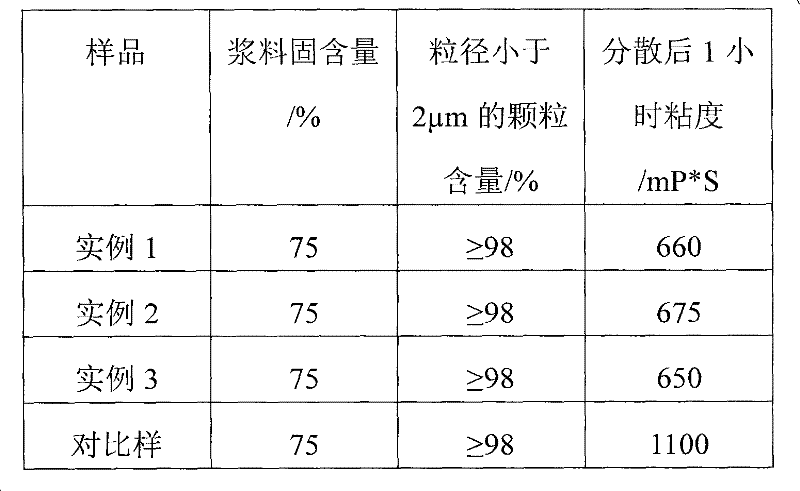

Examples

Embodiment 1

[0024] Add CuCl to the reaction kettle 2 6.02g, add 300.20g of toluene after sufficient nitrogen to expel oxygen, stir and mix, continue to pass nitrogen for 30 minutes, then add 14.03g of 2,2′-bipyridine, raise the temperature to 50°C under the protection of nitrogen and react for 1 hour to obtain a homogeneous complex solution.

[0025] Adjust the temperature to 100° C., and add 320.52 g of tert-butyl acrylate monomer that has been driven by nitrogen to drive oxygen. Within 3 hours, 100 mL of a toluene solution containing 4.06 g of azobisisobutyronitrile was slowly added dropwise, and then reacted with constant temperature and nitrogen flow for 5 hours. After passing through an alumina column to remove transition metals, the resulting solution was mixed with 70.16 g of sodium hydroxide solution (32% by weight), and then heated and hydrolyzed at 120° C. for 3 hours to convert tert-butyl polyacrylate into sodium polyacrylate.

Embodiment 2

[0028] Add CuCl to the reaction kettle 2 10.91g, add 350.30g of toluene after sufficient nitrogen to drive away oxygen, stir and mix, continue to pass nitrogen for 30 minutes, then add 25.20g of 2,2′-bipyridine, raise the temperature to 50°C under the protection of nitrogen and react for 1 hour to obtain a homogeneous complex solution.

[0029] The temperature was raised to 95°C, and 355.24 g of tert-butyl methacrylate monomer that had been driven by nitrogen to drive oxygen was added. Within 3 hours, 100 mL of a toluene solution containing 7.80 g of azobisisobutyronitrile was slowly added dropwise, and then reacted with constant temperature and nitrogen for 5 hours. After passing through an alumina column to remove transition metals, mix the resulting solution with 70.05 g of sodium hydroxide solution (weight concentration 32%), and then hydrolyze at 130° C. for 4 hours to convert poly-tert-butyl methacrylate into poly-sodium methacrylate .

[0030] The solvent and tert-bu...

Embodiment 3

[0032] Preparation of low molecular weight narrow distribution poly(sodium acrylate-co-sodium methacrylate):

[0033] Add CuCl to the reaction kettle 2 8.03g, add 350.20g of toluene after sufficient nitrogen to drive oxygen, stir and mix, continue to pass nitrogen for 30 minutes, then add 18.60g of 2,2′-bipyridine, raise the temperature to 50°C under the protection of nitrogen and react for 1 hour to obtain a homogeneous complex solution.

[0034] Adjust the temperature to 90° C., and add 337.52 g of a monomer mixture of tert-butyl methacrylate and tert-butyl acrylate that has been driven through nitrogen to drive oxygen. Within 3 hours, 100 mL of a toluene solution containing 5.37 g of azobisisobutyronitrile was slowly added dropwise, and the mixture was reacted with nitrogen at constant temperature for 5 hours. After passing through the alumina column to remove transition metals, the resulting solution was mixed with 70.05 g of sodium hydroxide solution (32% by weight), an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com