Concrete synergist with strong workability and bleeding resistance and concrete

A concrete synergist and water-bleeding technology, applied in the field of building materials, can solve the problems of insignificant reduction in the amount of cementitious materials, uneven product quality, poor workability of concrete, etc., so as to improve the efficiency of cement hydration reaction. , Improve the strength of concrete, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

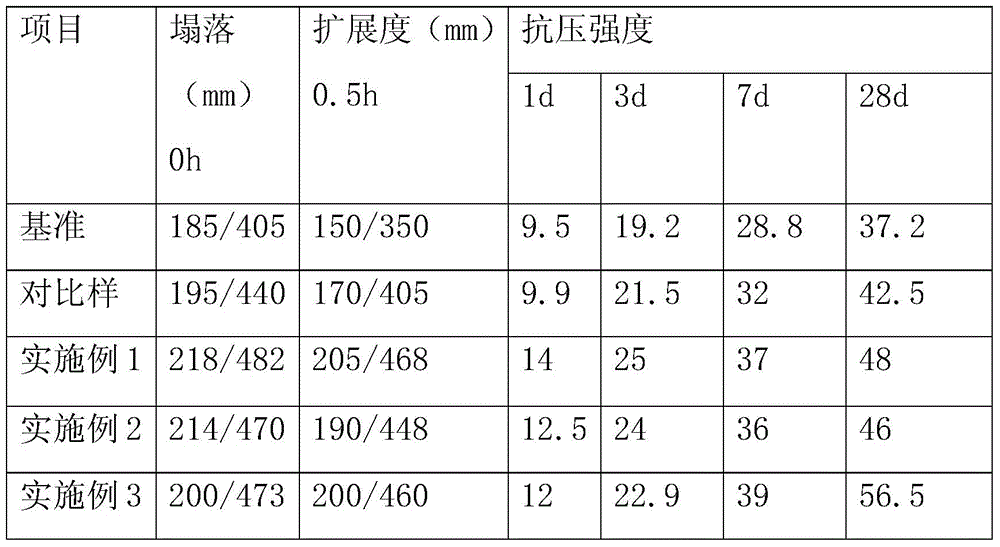

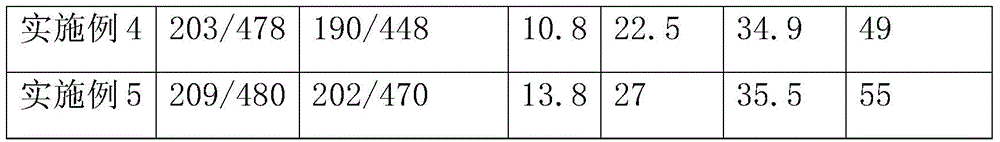

Examples

Embodiment 1

[0017] The concrete synergist with strong workability and bleeding resistance of the present embodiment, the synergist raw material comprises the following components by weight: 8-15 parts of allyl polyoxyethylene ether, 5-10 parts of maleic acid Anhydride, 10-16 parts of polyacrylamide, 3-8 parts of polyvinyl alcohol, 2-6 parts of methyl methacrylate, 4-8 parts of fiber, 2-5 parts of polystyrene microspheres, 1-5 parts of polypropylene glycol , 4-9 parts of emulsion sodium polymethacrylate, 5-10 parts of isobutylene alcohol polyoxyethylene ether, 1-5 parts of rice bran, 0.1-2 parts of foam stabilizer, 30-50 parts of water, 1-3 parts of tripolyphosphoric acid sodium.

[0018] In this embodiment, the fibers are carbon fibers, and the carbon fibers are replaced with one or more mixtures of steel fibers, nylon fibers, and polypropylene fibers in equal parts by weight; all qualified products are obtained.

[0019] The concrete synergist with strong workability and bleeding resist...

Embodiment 2

[0021] The concrete synergist with strong workability and bleeding resistance of the present embodiment, the synergist raw material comprises the following components by weight: 8-15 parts of allyl polyoxyethylene ether, 5-10 parts of maleic acid Anhydride, 10-16 parts of polyacrylamide, 3-8 parts of polyvinyl alcohol, 2-6 parts of methyl methacrylate, 4-8 parts of fiber, 2-5 parts of polystyrene microspheres, 1-5 parts of polypropylene glycol , 4-9 parts of emulsion sodium polymethacrylate, 5-10 parts of isobutylene alcohol polyoxyethylene ether, 1-5 parts of rice bran, 0.1-2 parts of foam stabilizer, 30-50 parts of water, 1-3 parts of tripolyphosphoric acid sodium.

[0022] In this embodiment, the fibers are steel fibers, and the carbon fibers are replaced with one or more mixtures of carbon fibers, nylon fibers, and polypropylene fibers in equal parts by weight; all qualified products are obtained.

[0023] The concrete synergist with strong workability and bleeding resist...

Embodiment 3

[0027] The concrete synergist with strong workability and bleeding resistance of the present embodiment, the synergist raw material comprises the following components by weight: 8-15 parts of allyl polyoxyethylene ether, 5-10 parts of maleic acid Anhydride, 10-16 parts of polyacrylamide, 3-8 parts of polyvinyl alcohol, 2-6 parts of methyl methacrylate, 4-8 parts of fiber, 2-5 parts of polystyrene microspheres, 1-5 parts of polypropylene glycol , 4-9 parts of emulsion sodium polymethacrylate, 5-10 parts of isobutylene alcohol polyoxyethylene ether, 1-5 parts of rice bran, 0.1-2 parts of foam stabilizer, 30-50 parts of water, 1-3 parts of tripolyphosphoric acid sodium.

[0028] In this embodiment, the fibers are nylon fibers, and the carbon fibers are replaced with one or more mixtures of steel fibers, carbon fibers, and polypropylene fibers in equal parts by weight; all qualified products are obtained.

[0029]The concrete synergist with strong workability and bleeding resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com