Material for multifunctional power maintenance gloves

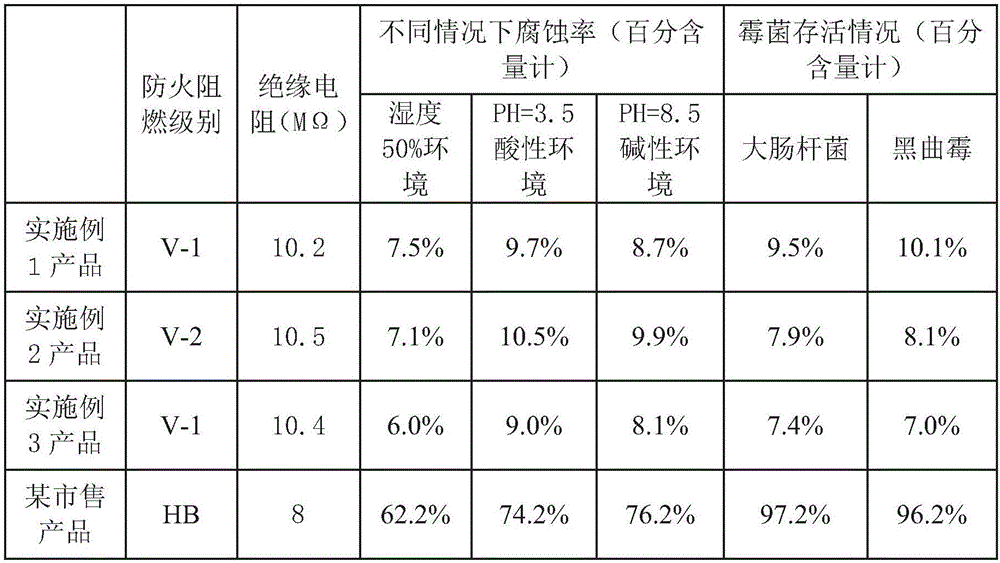

A multifunctional and electric technology, applied in gloves, protective clothing, clothing, etc., can solve the problems of short service life and poor effect of gloves, achieve superior flame retardancy, anti-mildew and antibacterial performance, and improve product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The multifunctional power maintenance glove material in this embodiment is composed of the following parts by mass: 16 parts of hexaflumuron, 18 parts of carbomer, 14 parts of pine tar, 12 parts of cooked tung oil, 18 parts of ethylamine, 14 parts of thiazolinone, 12 parts of styrene-maleic anhydride copolymer, 18 parts of p-tert-octylphenol formaldehyde resin, 14 parts of methyl MQ silicone resin, 12 parts of polystyrene resin, 18 parts of arabinogalactan, 14 parts of amino oligosaccharin, 14 parts of 2-ethylhexyl acrylate, 12 parts of clove oil, 18 parts of ethyl p-hydroxybenzoate, 14 parts of dimethyl hydroxy silicone oil, 12 parts of diisoamyl ether, ammonium chromate 18 parts, 14 parts of barium peroxide, 12 parts of silver sulfadiazine, 18 parts of polybutylene succinate, 14 parts of sodium polymethacrylate, 12 parts of trimethyl phosphate, 18 parts of sodium hexametaphosphate, chlorinated 14 parts of polyethylene, 14 parts of morpholine, 14 parts of nano alumina p...

Embodiment 2

[0022] The multifunctional power maintenance glove material in this embodiment is composed of the following parts by mass: 18 parts of hexaflumuron, 20 parts of carbomer, 16 parts of pine tar, 14 parts of cooked tung oil, 20 parts of ethylamine, 16 parts of thiazolinone, 14 parts of styrene-maleic anhydride copolymer, 20 parts of p-tert-octylphenol formaldehyde resin, 16 parts of methyl MQ silicone resin, 14 parts of polystyrene resin, 20 parts of arabinogalactan, 16 parts of amino oligosaccharin, 16 parts of 2-ethylhexyl acrylate, 14 parts of clove oil, 20 parts of ethyl p-hydroxybenzoate, 16 parts of dimethyl hydroxy silicone oil, 14 parts of diisoamyl ether, ammonium chromate 20 parts, 16 parts of barium peroxide, 14 parts of silver sulfadiazine, 20 parts of polybutylene succinate, 16 parts of sodium polymethacrylate, 14 parts of trimethyl phosphate, 20 parts of sodium hexametaphosphate, chlorinated 16 parts of polyethylene, 16 parts of morpholine, 16 parts of nano alumina p...

Embodiment 3

[0028] The multifunctional power maintenance glove material in this embodiment is composed of the following parts by mass: 20 parts of hexaflumuron, 22 parts of carbomer, 18 parts of pine tar, 16 parts of cooked tung oil, 22 parts of ethylamine, 18 parts of thiazolinone, 16 parts of styrene-maleic anhydride copolymer, 22 parts of p-tert-octylphenol formaldehyde resin, 18 parts of methyl MQ silicone resin, 16 parts of polystyrene resin, 22 parts of arabinogalactan, 18 parts of amino oligosaccharins, 18 parts of 2-ethylhexyl acrylate, 16 parts of clove oil, 22 parts of ethyl p-hydroxybenzoate, 18 parts of dimethyl hydroxy silicone oil, 16 parts of diisoamyl ether, ammonium chromate 22 parts, 18 parts of barium peroxide, 16 parts of silver sulfadiazine, 22 parts of polybutylene succinate, 18 parts of sodium polymethacrylate, 16 parts of trimethyl phosphate, 22 parts of sodium hexametaphosphate, chlorinated 18 parts of polyethylene, 18 parts of morpholine, 18 parts of nano alumina ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com