Patents

Literature

179 results about "Barium peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium peroxide is the inorganic compound with the formula BaO₂. This white solid (gray when impure) is one of the most common inorganic peroxides, and it was the first peroxide compound discovered. Being an oxidizer and giving a vivid green colour upon ignition (as do all barium compounds), it finds some use in fireworks; historically, it was also used as a precursor for hydrogen peroxide.

Exhaust gas catalyst

InactiveUS6180075B1Favorable degree of conversionExceptional heat and aging resistanceNitrogen compoundsInternal combustion piston enginesZirconium hydrideCerium(IV) oxide

A single-layered three-way catalytic converter containing palladium as the only catalytically active noble metal, with high activity and heat resistance. The catalyst contains, in addition to finely divided, stabilized aluminum oxide, at least one finely divided cerium / zirconium mixed oxide and optionally finely divided nickel oxide as well as highly dispersed amounts of cerium oxide, zirconium oxide and barium oxide. The palladium is distributed largely uniformly throughout the entire catalyst.

Owner:DMC2 DEGUSSA METALS +1

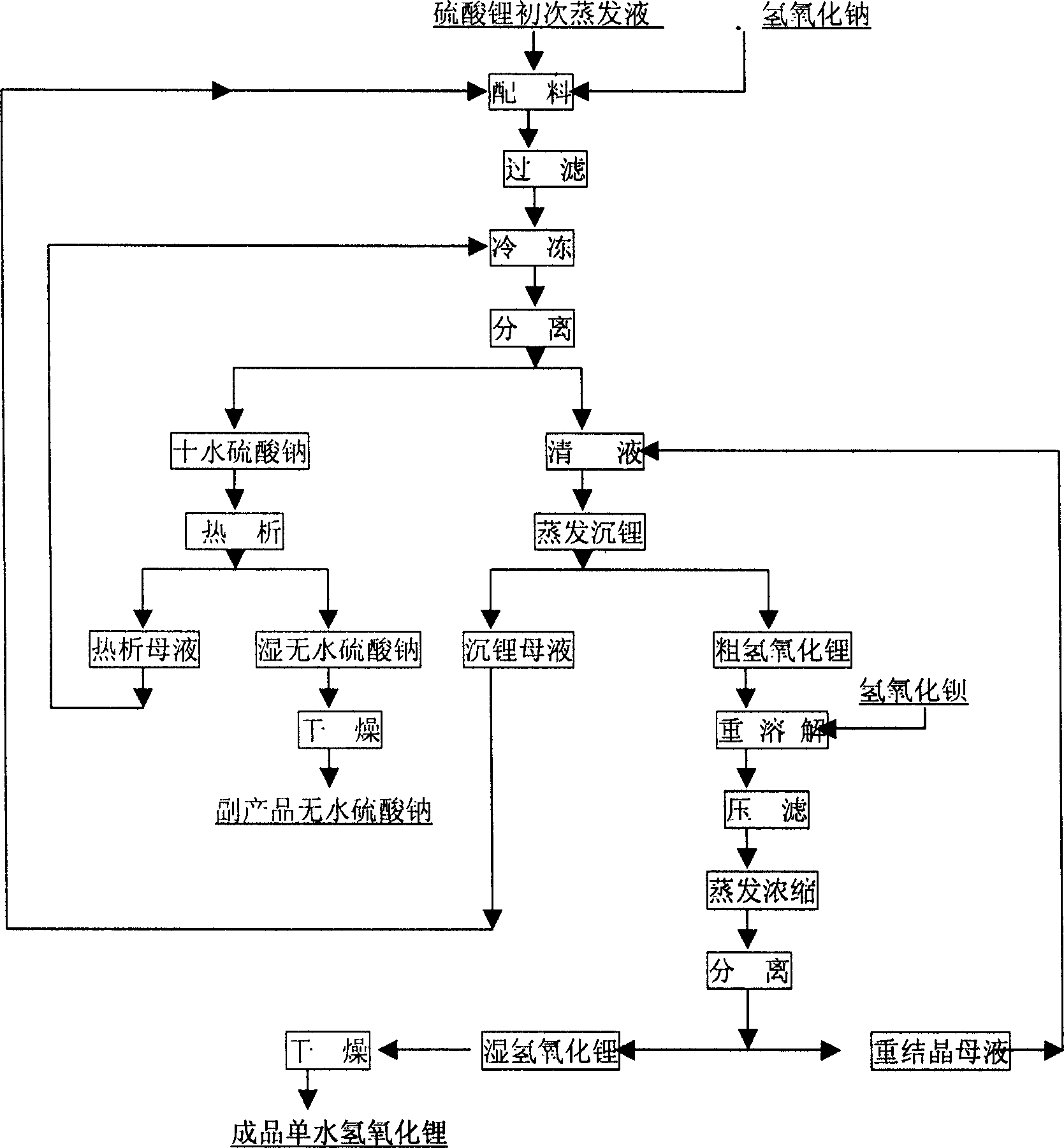

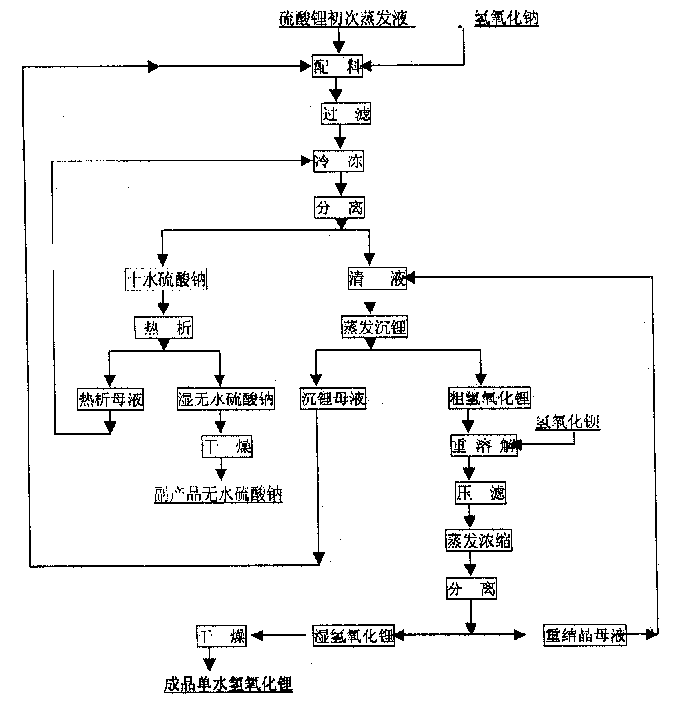

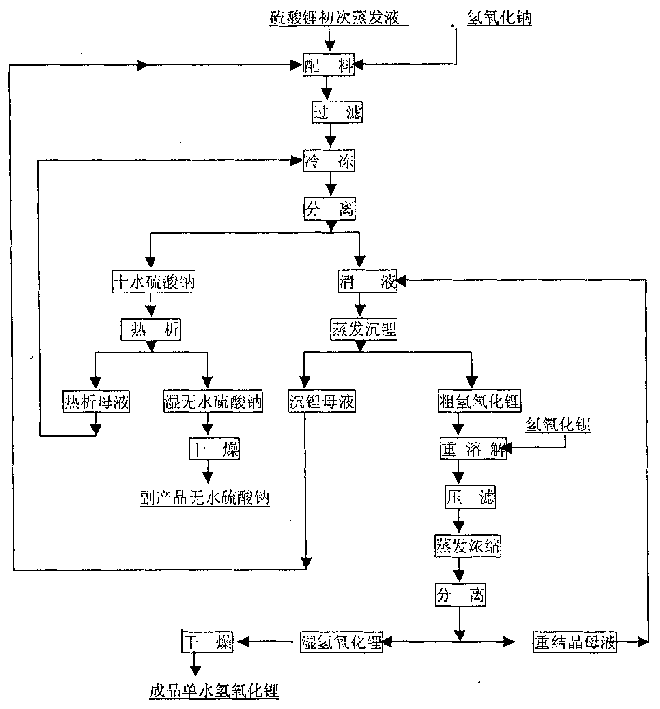

Production process of lithium hydroxide monohydrate

InactiveCN1486931AShort process routeHigh yieldSulfate/bisulfate preparationLithium oxides/hydroxidesSolubilityStrontium hydroxide octahydrate

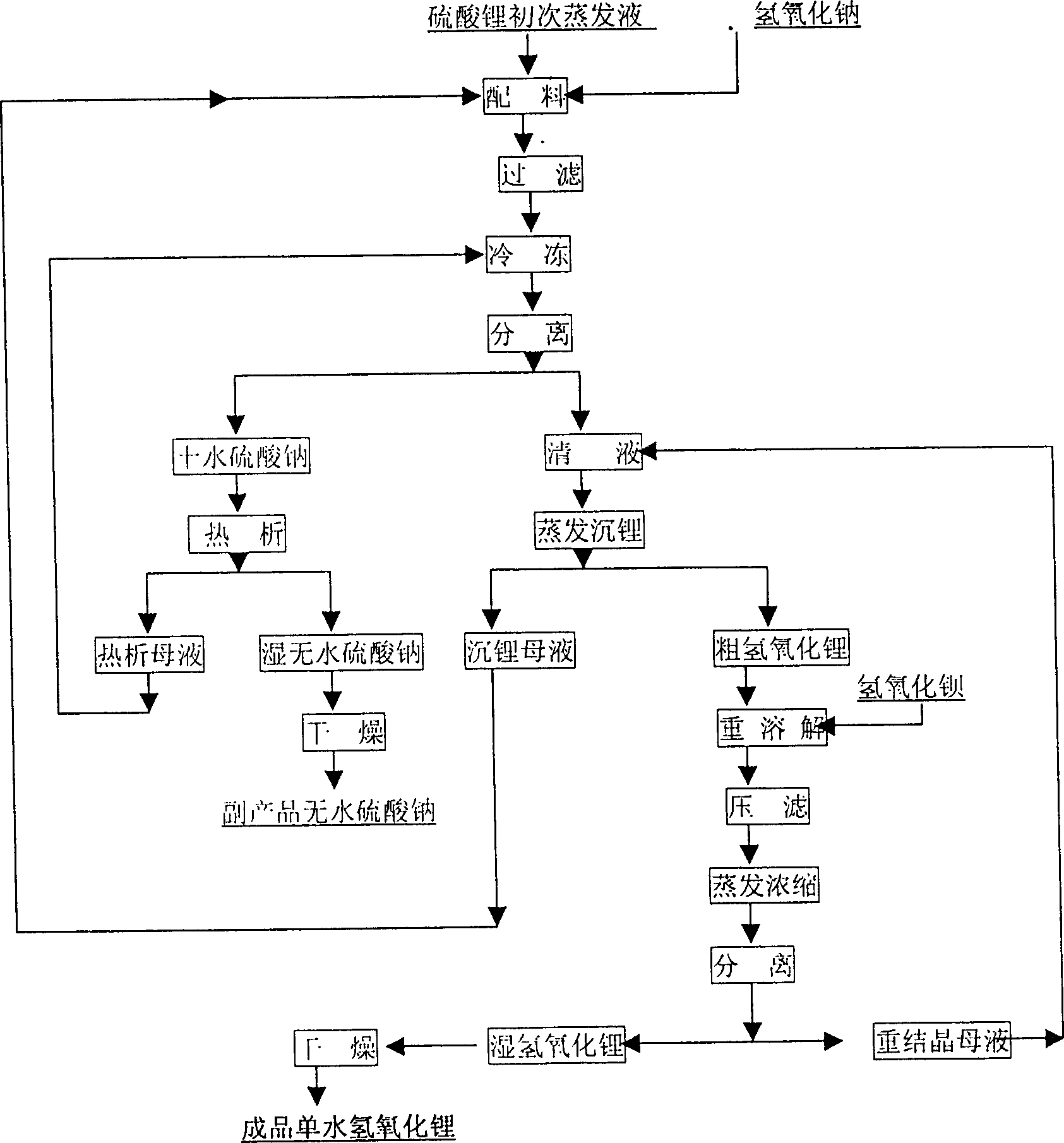

In the production process of lithium hydroxide monohydrate, lithium sulfate solution and caustic soda are made to produce metathetic reaction to form mixture solution of sodium sulfate and lithium hydroxide, and sodium sulfate and lithium hydroxide monohydrate are then separated by means of the obvious difference in low temperature solubility. The production process includes the following steps: adding sodium hydroxide into lithium sulfate solution obtained through serial production steps to obtain mixture solution of sodium sulfate and lithium hydroxide; cooling to minus 10 deg.c to 5 deg.c for the crystallization and separation of sodium sulfate; heating to concentrate the separated clear liquid; crystallization and separation to obtain coarse lithium hydroxide monohydrate product; water dissolving coarse lithium hydroxide monohydrate, adding barium hydroxide to form insoluble barium sulfate, filtering, concentrating filtrate, crystallizing to separate wet lithium hydroxide monohydrate; and drying.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

Barium metaphosphorate production process

InactiveCN1800000ASimple production processLow costPhosphorus compoundsManufacturing technologyPhosphate

The invention discloses a manufacturing technology of barium metaphosphate, which comprises the following steps: putting barium hydroxide in the container; adding the deionized water and active carbon to stir and heat with 1.05-1.10 specific gravity until the barium hydroxide is dissolved completely; stewing; filtering; obtaining fine barium hydroxide with iron, bronze, nickel, manganese and cobalt less than 0.0003 percent; putting the barium hydroxide in another container to stir and add high-quality phosphate; adjusting the pH value at 9-11 to obtain the deposition of barium hydrophosphate; adding the deionized water to dilute; obtaining the mixing paste of barium hydrophosphate; drying and condensing into barium metaphosphate by centrifugal spray. The technology is easy to adjust and control, whose production impurity content is low and recovery rate is high.

Owner:SHANXI SUPERNEW METAL MATERIAL

Preparation method of leadless glass powder for electronic slurry

A process for preparing lead-free glass powder used for electronic paste, which comprises: firstly uniformly mixing silicon dioxide or sodium silicate, barium oxide or barium carbonate, boron oxide or boric acid, bismuth oxide or bismuth sulfate, aluminum oxide, aluminum sulfate or aluminum silicate, zinc oxide or zinc carbonate, sodium oxide, sodium carbonate or sodium bicarbonate, potassium oxide or potassium carbonate and titanium dioxide, then heating the mixed raw materials to melt, cooling the melted mixture, then grinding into power by a ball grinder, sieving by a sieve of 100-400 eye and lastly drying glass powder to obtain the lead-free glass powder. Because the glass power of the invention does not contain lead oxide (PbO) or compounds of lead oxide (PbO), the invention is harmless in the manufacture process of paste, simultaneously is beneficial for environmental protection, and is convenient for recycling and reusing electronic product modules containing the electronic paste.

Owner:IRICO

Method for recycling platinum and rhodium from binary aqua regia insoluble slag

InactiveCN101476044AEmission reductionImprove protectionProcess efficiency improvementIsolation effectRecovery method

The invention relates to a precious-metal recovery method, specifically relates to a method of recovering platinum / rhodium from insoluble residue of dualistic royal water for solving problems of the existing platinum / rhodium recovering method that the process flow is lengthy and complicated, operational process is dangerous, the isolation effect is bad, and the like. The method comprises steps of preprocessing the insoluble residue of royal water by using barium superoxide, oxidizing the platinum and rhodium thereof, dissolving the oxidized platinum and rhodium in hydrochloric acid; using ammonium chloride to deposit platinum after being converted to a sodium type, adding hydrazine hydrate for recovering the spongy platinum, complexing by adding sodium nitrite into the filter liquor after platinum deposition, depositing rhodium by using ammonium chloride, adding hydrochloric acid for dissolving and sodium type conversion, eliminating base metal in the liquid by using ion exchange resin, finally using hydrazine hydrate and hydrogen gas flame for recovering rhodium powder. The method is a precious-metal-resource secondary recovery utilization and purification method, and has advantages of simple technique, short purification period, convenient operations, high coefficient of recovery, little discharging of waste gas and waste matter, and environment protection, and the like.

Owner:CNOOC TAIYUAN PRECIOUS METALS

Method for removing chloro-olefin in water through strengthening activating calcium peroxide

InactiveCN104692515ALow priceImprove stabilityWater treatment compoundsWater contaminantsBiological activationEthyl Chloride

The invention relates to a method for removing chloro-olefin in water through strengthening activating calcium peroxide, for removing the chloro-olefin contaminant existed in the underground water by using the oxidation of the calcium peroxide (CaO2), and belongs to the technical field of environmental management. In the treating process, in the existence of the calcium peroxide, the ferric ion is added for activating the oxidizing agent, the citric acid is added for reinforcing the activation effect and then the chloro-olefin contaminant is oxidized. The method has the advantages that the calcium peroxide is used as a novel green oxidizing agent and has the characteristics of strong oxidizing ability, high stability and long oxidizing effect; by adopting the ferric ion and the citric acid, the calcium peroxide can be continuously and effectively activated and the timeliness of the oxidation can be increased; the pollution of the underground water caused by the chloro-olefin can be effectively green repaired and treated without intermediate product accumulation or secondary pollution.

Owner:EAST CHINA UNIV OF SCI & TECH

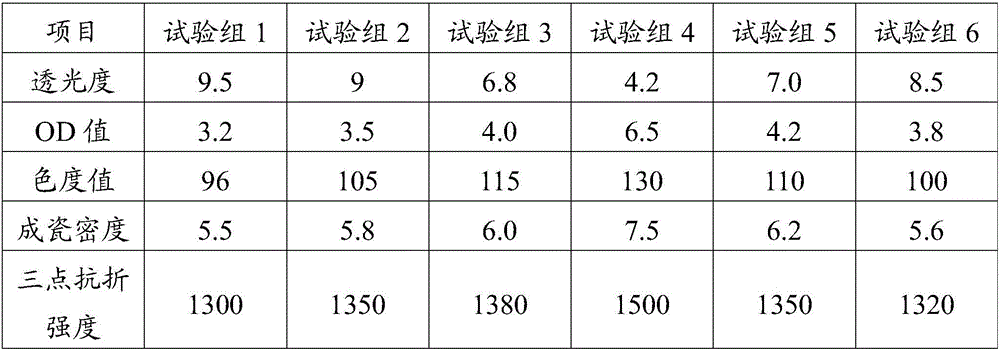

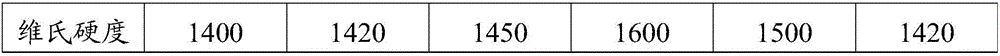

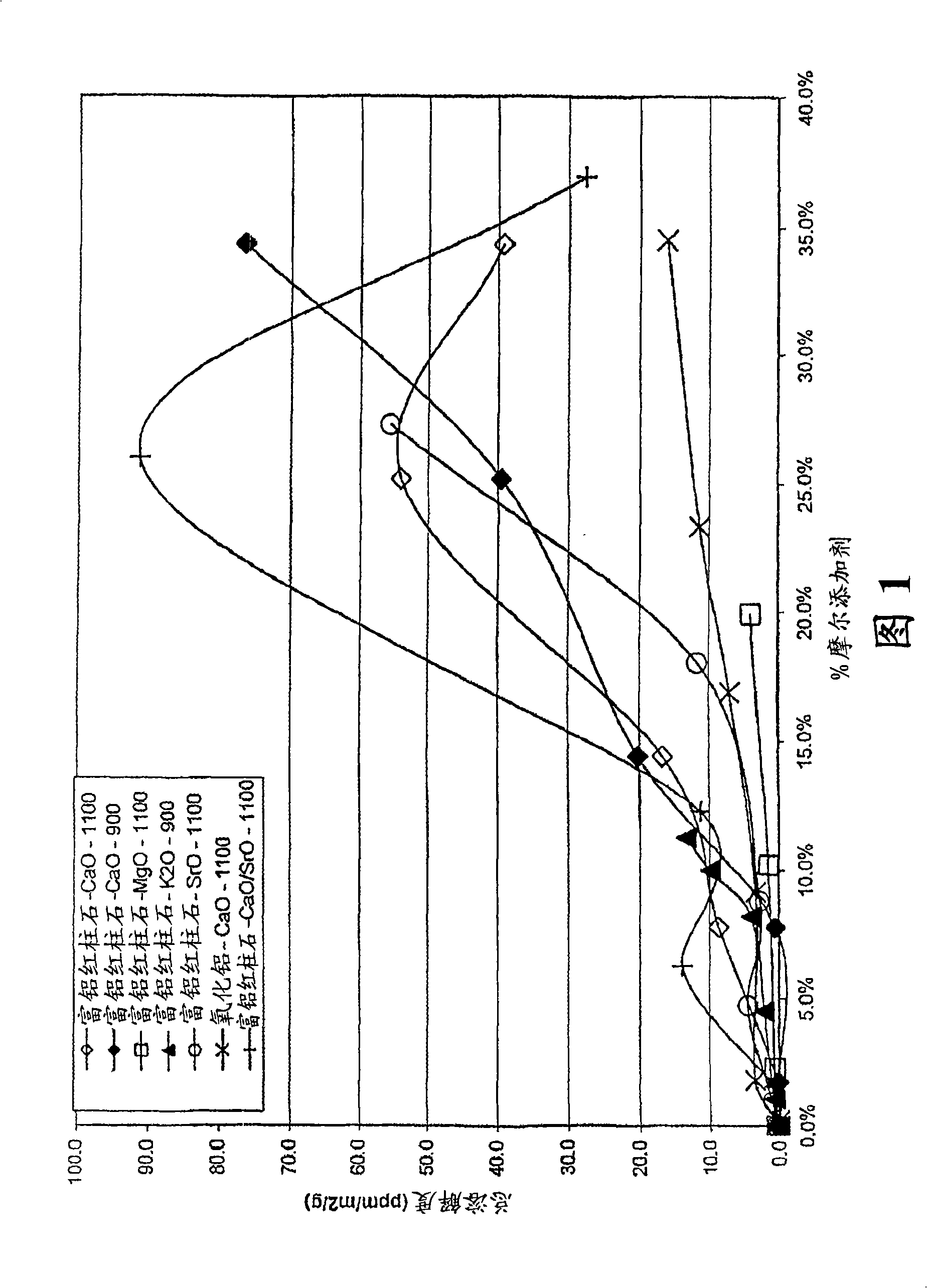

Preparation method of white zirconia ceramic

The invention discloses a white zirconia ceramic material composition. The composition includes: by weight, aluminium oxide 0.01-35%, magnesium oxide 0-20%, calcium oxide 0-20%, strontium oxide 0-20%, barium oxide 0-20%, yttrium oxide 1.5-8%, and balance zirconium oxide containing hafnium oxide. The white zirconia ceramic material composition has small powder granularity and uniform dispersion, and the white zirconia ceramic containing the composition has high whiteness and light-proofness, and low transmissivity. Moreover, the invention also discloses white zirconia ceramic prepared from the white zirconia ceramic material composition and a preparation method of the white zirconia ceramic.

Owner:CHAOZHOU THREE CIRCLE GRP

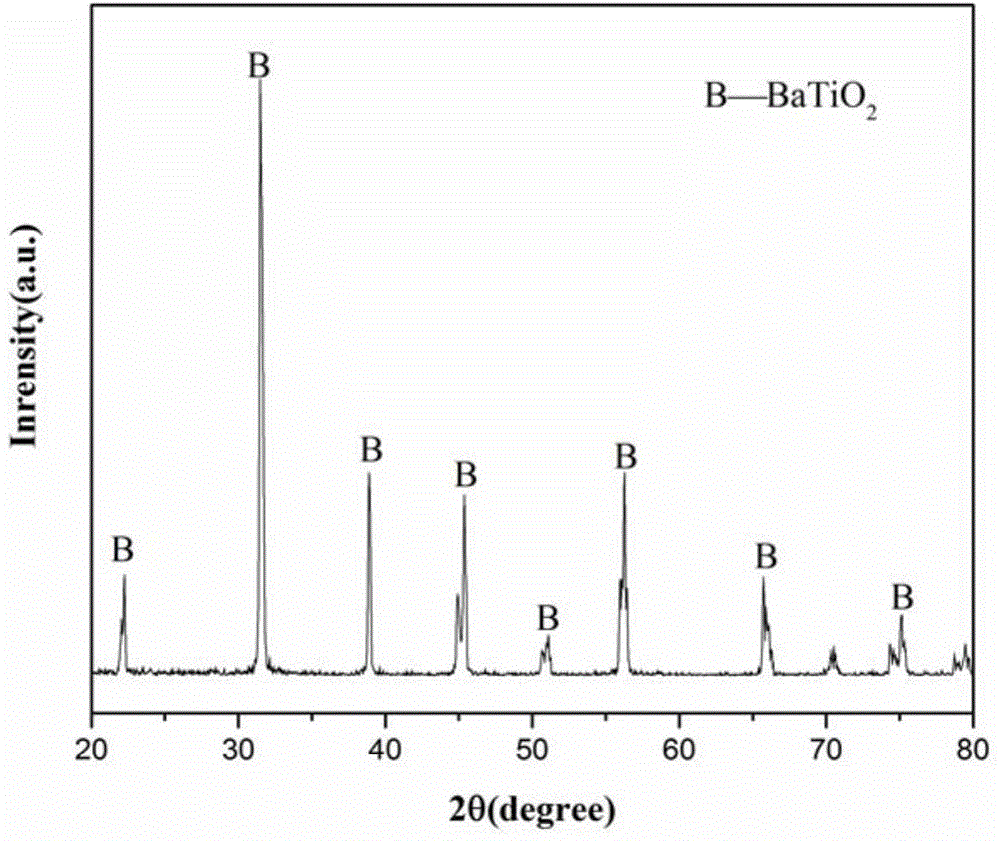

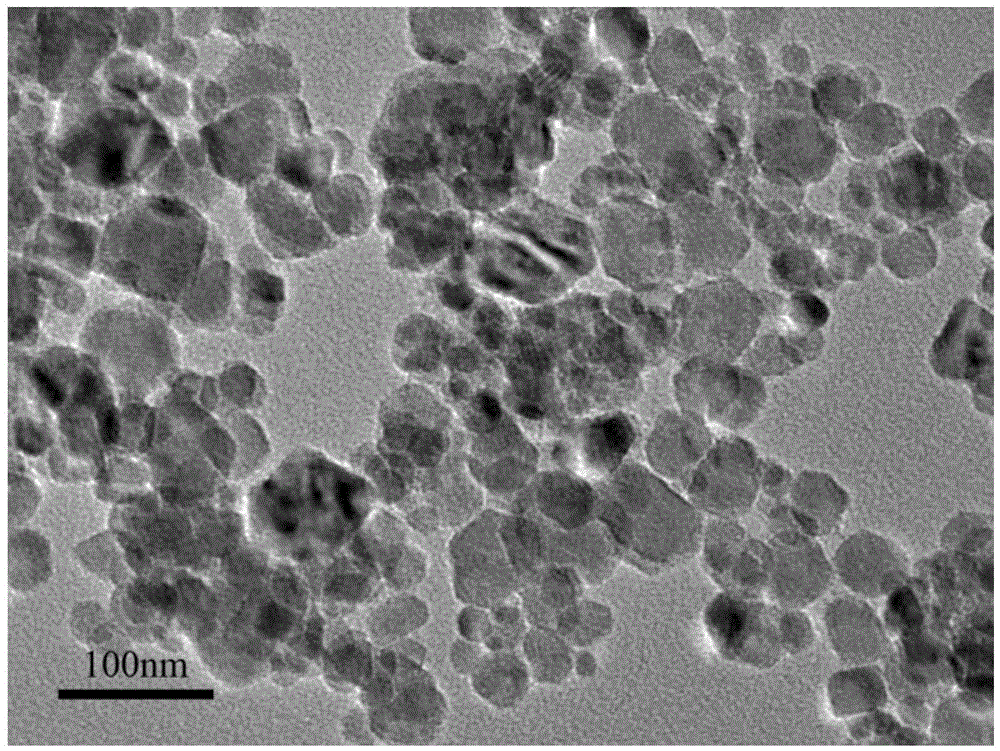

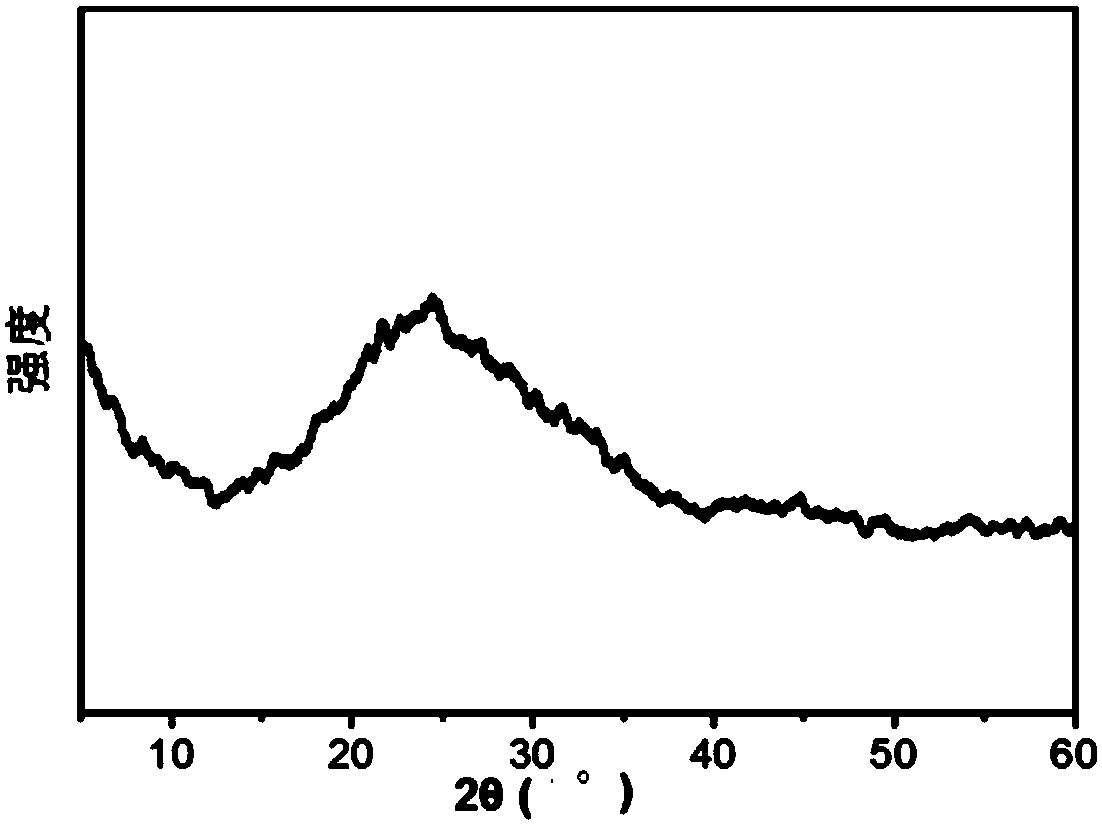

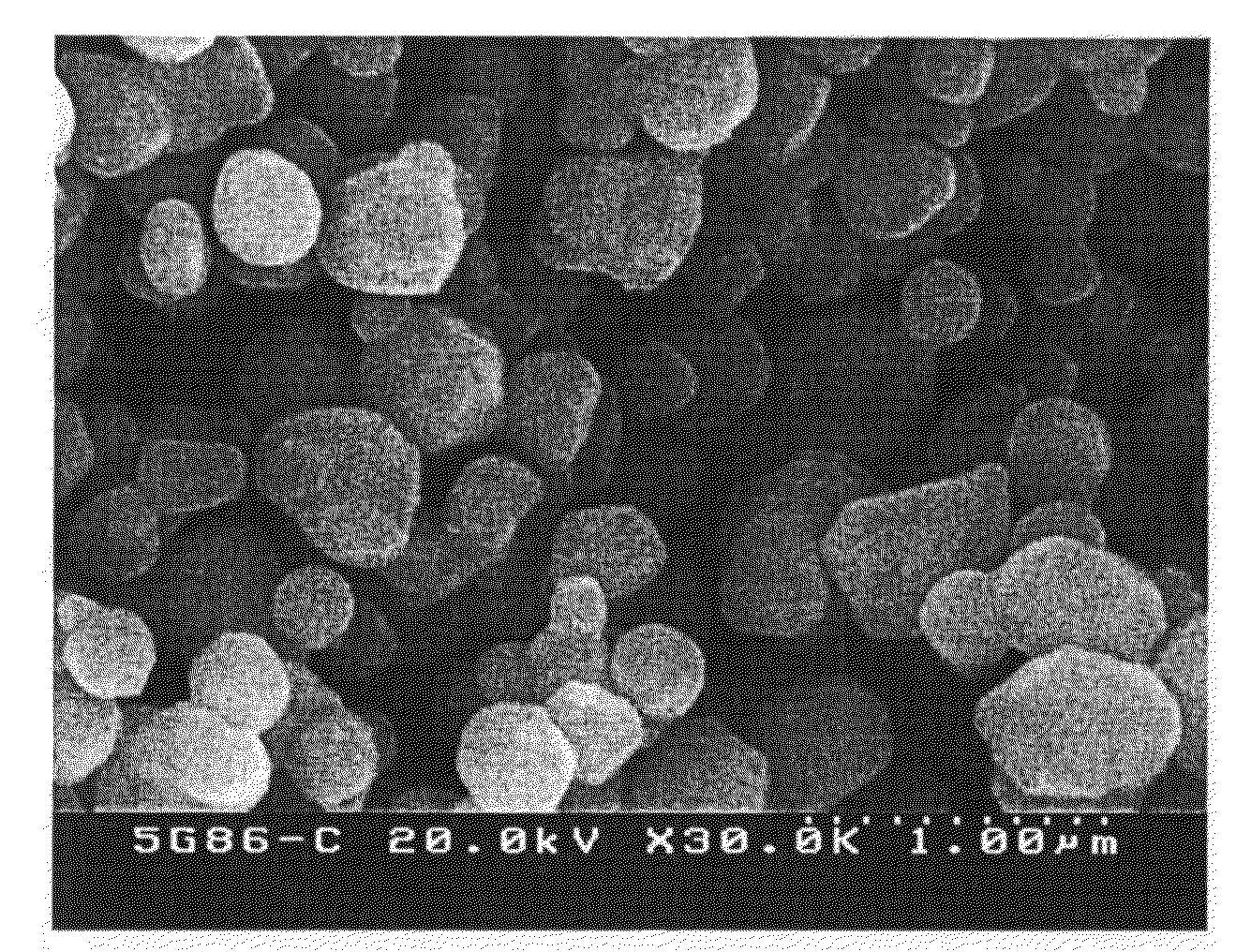

Nanometer barium titanate powder preparation method based on ball milling

ActiveCN104828858AMild reaction conditionsShort processMaterial nanotechnologyTitanium compoundsChemical reactionFiltration

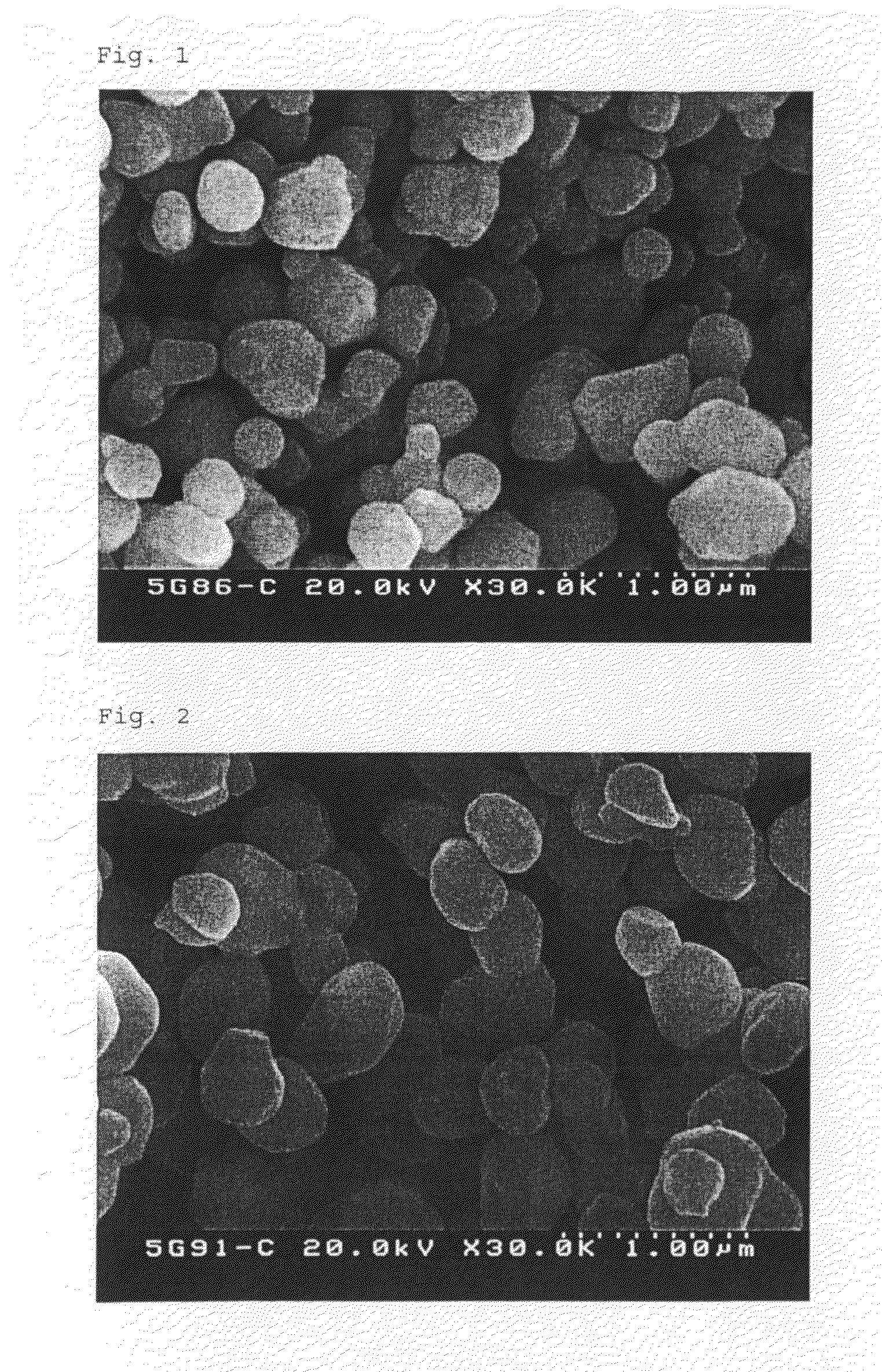

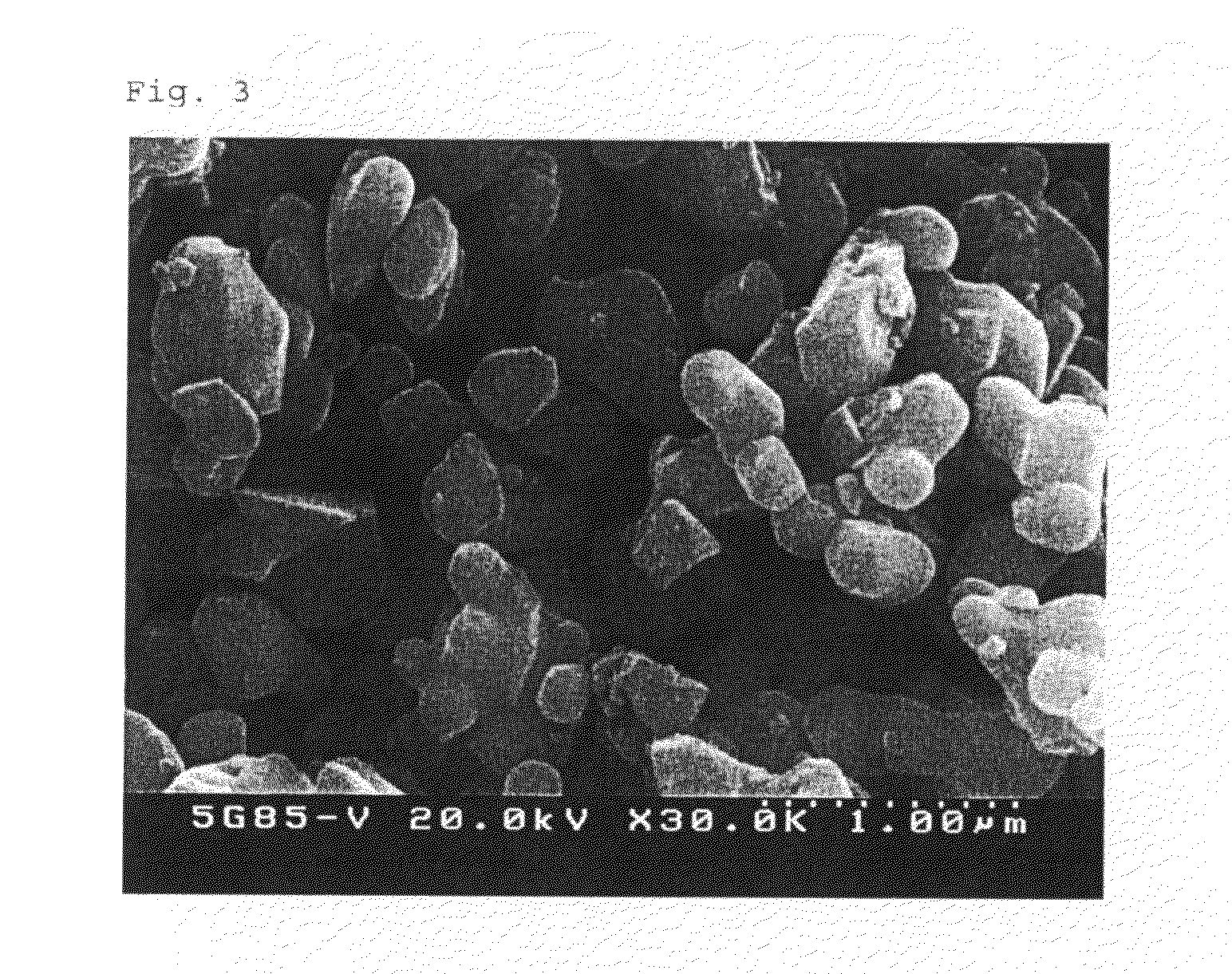

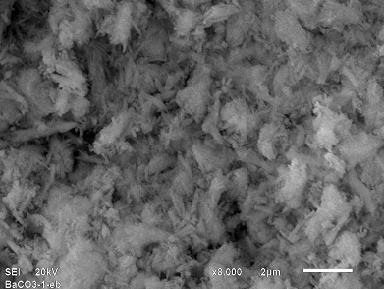

The present invention discloses a nanometer barium titanate powder preparation method based on ball milling. According to the method, barium oxide, titanium oxide, zirconium oxide grinding ball, and deionized water are added to a ball mill to carry out a chemical reaction under a ball milling condition, and the mixture obtained from the reaction is sequentially subjected to filtration separation, drying, and grinding crushing to obtain the tetragonal phase nanometer barium titanate powder. According to the present invention, the tetragonal phase nanometer barium titanate powder prepared through the method has characteristics of high purity, small particle size, uniform particle, and good dispersion, wherein the average particle size of the powder is within 60-80 nm; and the preparation process does not require the addition of any other chemical solvents, has advantages of no requirement of calcining, simple process, inexpensive equipment, easy operation, low energy consumption, and the like, and provides good industrial prospects in the field of electronic ceramic material preparation.

Owner:HUNAN SEEDER ELECTRONICS CERAMIC TECH IND PARK DEV CO LTD

Composite cerium-zirconium-barium oxides and preparing method thereof

The invention provides a kind of super tiny cerium-zirconium-barium compound oxide and the manufacturing method. The molecular formula is CexZr1-xBayOz, the mol proportion of cerium, zirconium and barium is: Ce=X(X=0.1í½1) : Xr=1-X: Ba=Y(Y=0.1í½0.5), it uses metal nitrate such as cerium nitrate, zirconium nitrate, barium nitrate as materials, through polyglycol high molecular surface decorating agent, uses butyl alcohol azeotropy distillation. The baked temperature is 600 deg.C í½700 deg.C, the time is 3í½4 hours.

Owner:ZHEJIANG UNIV

Leadless cadmium-free glass enamel and preparation method thereof

The invention relates to a lead and cadmium free glass glaze, which is characterized in that the glass glaze consists of the following raw materials: zinc oxide, barium oxide, silicon dioxide, titanium dioxide, potassium nitrate, lithium carbonate, stannic oxide, boric acid, alumina, and zirconium dioxide. The preparation method includes: all the raw materials are put in a mixer to stir, then the uniformly stirred powder is added to a converter to be heated and melt until the powder is completely fused; the fused melt is poured into a normal-temperature pool to be cooled and condensed to half-boiled crystals; then the crystals are put into a ball mill to be milled; the milled half-boiled glass powder is poured into a dryer to be dried and then obtains glass glaze after breaking and filtering. The glass glaze is lead and cadmium free and beneficial to environment protection.

Owner:SHANGHAI WENGAO COLORGLASS

High temperature resistant fibres

Thermal insulation comprises sol-gel formed fibres comprising 10 to 99mol% of a refractory base composition, and 1 to 90mol% of a component selected from alkaline earth metal oxides, alkali metal oxides, and mixtures thereof, and wherein said alkaline earth metal oxides if present comprise one or more of calcium oxide, strontium oxide, barium oxide or a mixture thereof. The refractory base comprises SiO2 and A12O3.

Owner:THE MORGAN CRUCIBLE CO PLC

Method for remediating PAEs polluted soil by using microwave enhanced calcium peroxide

InactiveCN106493162AStay acidicPromote degradationContaminated soil reclamationSlurryBarium peroxide

The invention belongs to the technical field of organic polluted soil remediation and discloses a method for remediating phthalic acid esters (PAEs) polluted soil by using microwave enhanced calcium peroxide. The method comprises the steps of preparing a slurry soil mixed solution from the PAEs polluted soil according to a certain liquid-solid ratio; adding a certain quantity of citric acid, ferrous sulfate and calcium peroxide into the solution; and carrying out microwave treatment and standing to enable the degradation rate of PAEs in the soil to reach more than 80%. The method has the advantages of simple process condition, low operation requirement, high treatment efficiency, low oxidizing agent waste and the like and is suitable for remediating the PAEs polluted soil.

Owner:CHANGZHOU UNIV

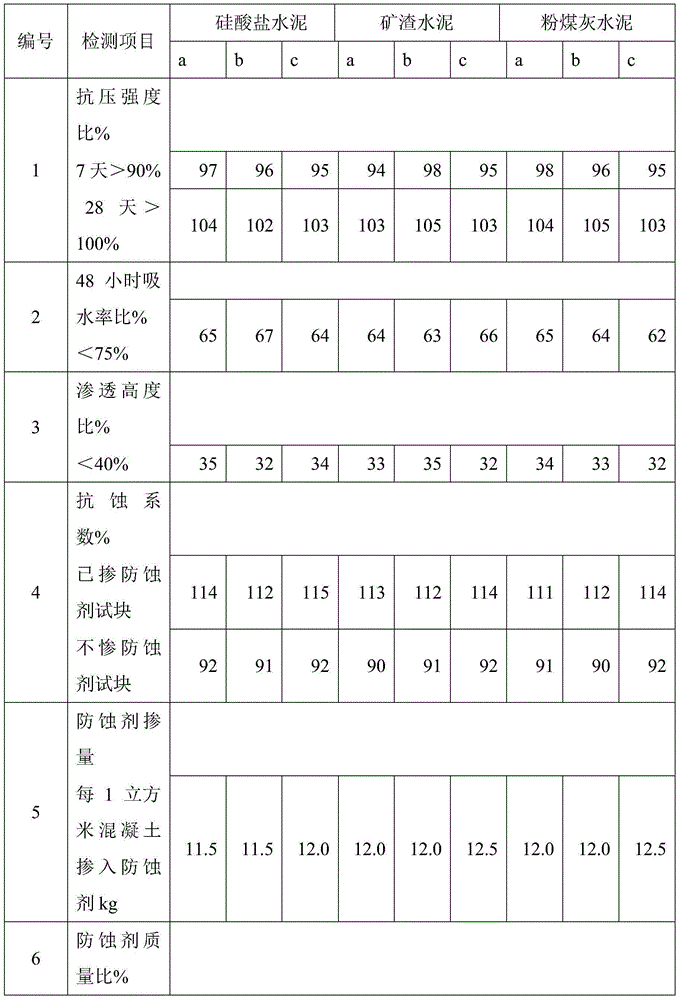

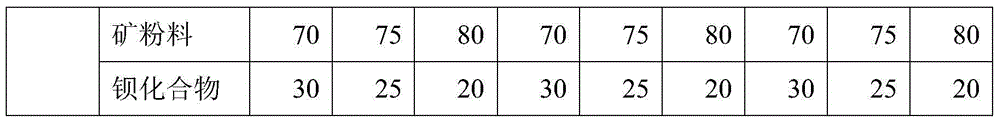

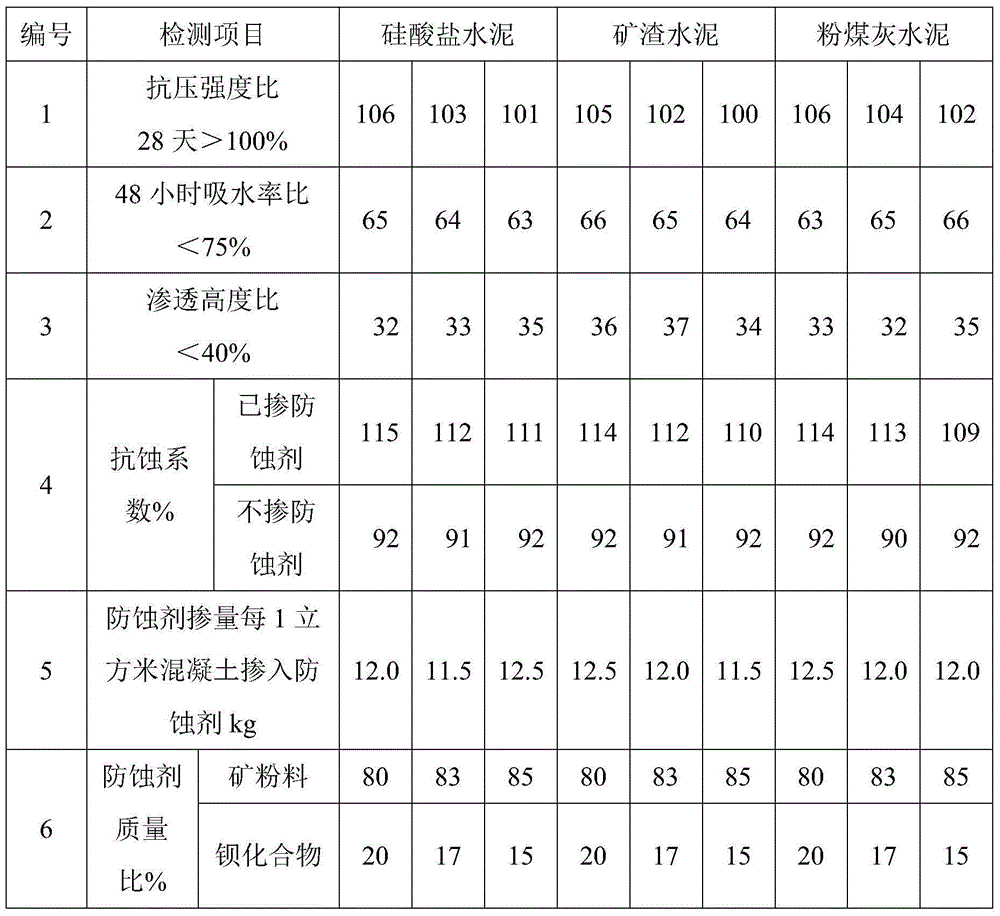

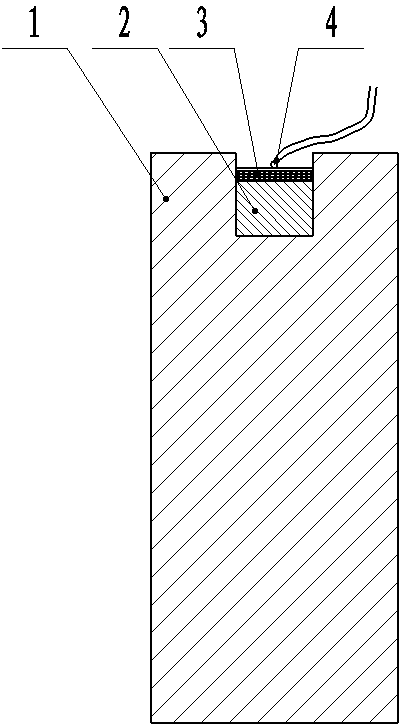

Anticorrosive agent for concrete and anticorrosive concrete

The invention provides an anticorrosive agent for concrete. The anticorrosive agent is a mixture of powder selected from the group consisting of fly ash, blast-furnace water-quenched slag powder, silica fume, light-burnt metakaolin powder, phosphorus slag powder, alum slag powder, natural zeolite powder and the like and a barium compound selected from the group consisting of barium chloride, barium nitrate, barium acetate, barium hydroxide, barium sulfide and the like. The anticorrosive agent for concrete provided by the invention enables Ca(OH)2 by-produced in hydration of cement to bond with SiO2 included in cement so as to produce secondary hydrated calcium silicate, so the strength and impermeability of concrete are improved; barium ions doped into concrete reacts with SO4<2-> from the outside in time to produce inertial and stable secondary barite, so deionization of SO4<2-> is realized and corrosivity of SO4<2-> is eradicated; the secondary barite forms a stable mineral inorganic protection film on the surface layer of concrete, so further invasion of external harmful ions is prevented, the strength, impermeability and corrosion resistance of concrete are further improved, the service life of concrete is substantially prolonged, and economic benefits are increased.

Owner:李亚铃

Porous carbon material and preparation method thereof

InactiveCN108069410ALarge specific surface areaIncrease the active siteCarbon preparation/purificationPore distributionChemical reaction

The invention discloses a natural wood porous carbon material and a preparation method thereof. The porous carbon material is prepared by: heating natural wood cut into pieces in air for the purpose of pretreatment, soaking in a strong base solution, drying, and performing high temperature pyrolysis under protective gas; a strong base herein is one of sodium hydroxide, potassium hydroxide, lithiumhydroxide, calcium hydroxide and barium hydroxide. The porous carbon material has large specific surface area, good uniformity of pore distribution and good conductivity, as well as improved chemicalreaction activity; the porous carbon material prepared herein is widely applicable and is suitable for use in energy storage, adsorption, water treatment and other aspects. The porous carbon materialis prepared by means of physical soaking; the preparation method is simple and feasible; the porous carbon material is green; the materials are widely resourceful and low in cost.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Ignition drug for lifesaving solid oxygen and preparation method thereof

ActiveCN103204755AReliable ignitionHigh energyExplosive working-up apparatusPerchlorate saltSodium chlorate

The invention provides an ignition drug for lifesaving solid oxygen and a preparation method thereof. The ignition drug is prepared from the following raw materials by mass percent by using a compacting technology: 32-44 % of sodium chlorate, 20-30 % of potassium perchlorate, 14-18 % of iron powder, 4-8 % of titanium powder, 5-12 % of cobalt chloride, 3-7 % of ferric oxide, 0.5-5 % of barium peroxide and 0.1-1.5 % of mica powder. The method solves problems of poor technology quality and low efficiency existing in prior art. According to the invention, electric igniter or ignition by mechanically knocking primer is employed, and thus energy is relatively high, impact force is large and solid-oxygen columns can be reliably ignited; residues do not flow after the ignition drug burns, thereby ensuring product safety; both high and low temperature performances satisfy corresponding product technology standards, remote automatic control is realized to start solid oxygen, and production quality and production efficiency of the ignition drug can be improved.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

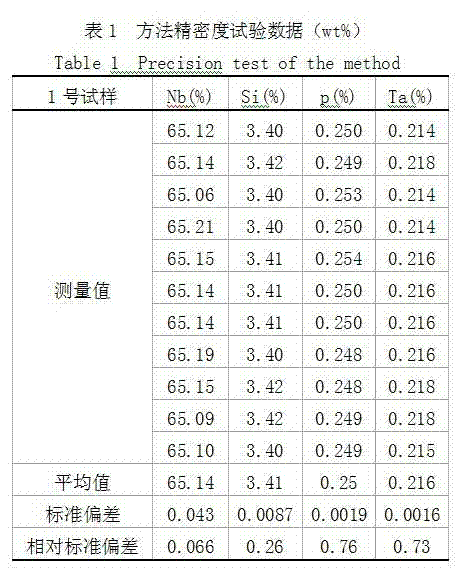

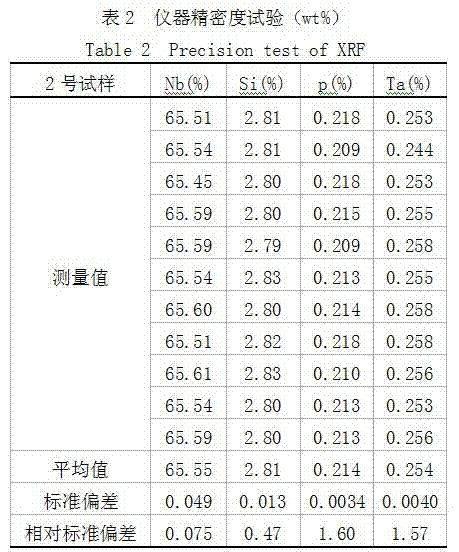

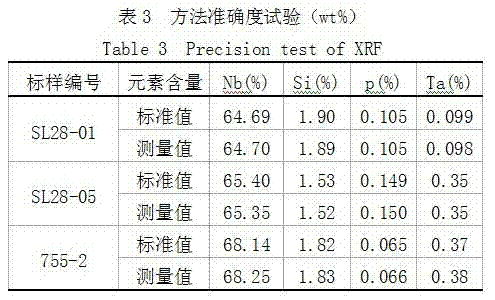

Method for measuring element content in ferrocolumbium alloy by X-fluorescence

InactiveCN102359973AImprove oxidation effectFast analysisMaterial analysis using wave/particle radiationAlloyBarium peroxide

The invention discloses a method for measuring an element content in a ferrocolumbium alloy by X-fluorescence. The method comprises the following steps of: (1) hanging on a wall; (2) oxidizing; (3) smelting; (4) measuring fluorescence intensity and drawing a calibration curve; and (5) preparing a glass sample sheet to be sampled, measuring the spectral line intensity of columbium, thallium, silicon and phosphorus in the glass sample sheet to be sampled, and determining the percentage content of the columbium, thallium, silicon and phosphorus in a ferroniobium sample to be tested according to the calibration curve of the step (4). The ferroniobium glass sheet is successfully prepared by hanging lithium tetraborate on the wall and selecting barium peroxide as an oxidant for high-temperature fusion under the condition of no corrosion damage to a platinum crucible and provides a proper sample for measuring by using an X-fluorescence method. After an oxidization process of raising temperature gradually is adopted in particular, a very good oxidization effect can be achieved. The method can effectively improve the analysis speed of the element content in ferroniobium and the accuracy of analysis data and has the characteristics of simple operation and practicability.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

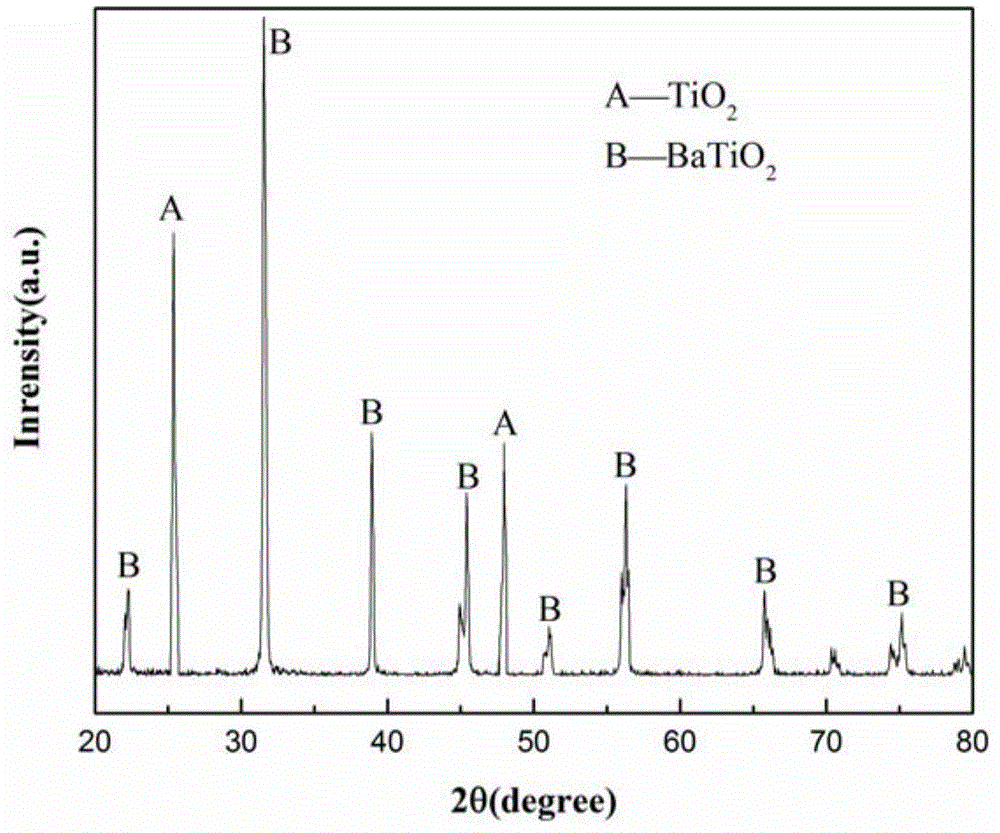

Process for preparing barium titanate

InactiveUS7854916B2High crystallinityHigh purityAlkaline earth titanatesTitanium oxides/hydroxidesBarium titanateCeramic capacitor

Owner:HANWHA CHEMICAL CORPORATION

Liquid barium/zinc thermal stabilizer, preparation method therefor and equipment for implementing method

ActiveCN105218967AProduction safety and environmental protectionTakes a long timeChemical/physical/physico-chemical stationary reactorsZinc hydroxideSolvent

The invention discloses a liquid barium / zinc thermal stabilizer. The liquid barium / zinc thermal stabilizer is prepared from the following raw materials in parts by weight: 20-30 parts of barium oxide and / or hydroxide of barium, 15-20 parts of zinc oxide and / or zinc hydroxide, 30-40 parts of acid liquor, 1-2 parts of water carrying agent, 5-20 parts of saturated cyclane solvent and 5-15 parts of heat-resistant assistant, wherein the hydroxide of barium is at least one of anhydrous barium hydroxide, barium monohydrate and barium octahydrate. The invention also discloses a preparation method for the liquid barium / zinc thermal stabilizer and equipment for implementing the method. The liquid barium / zinc thermal stabilizer product disclosed by the invention is stable in property, is free of irritant odors and cannot harm bodies of operating workers; and the preparation method for the liquid barium / zinc thermal stabilizer disclosed by the invention adopts a one-step method, so that the production process is simplified, unsafe factors in a production process are reduced, and the production efficiency and yield rate are increased.

Owner:GUANGZHOU YINGSU NEW MATERIAL TECH CO LTD

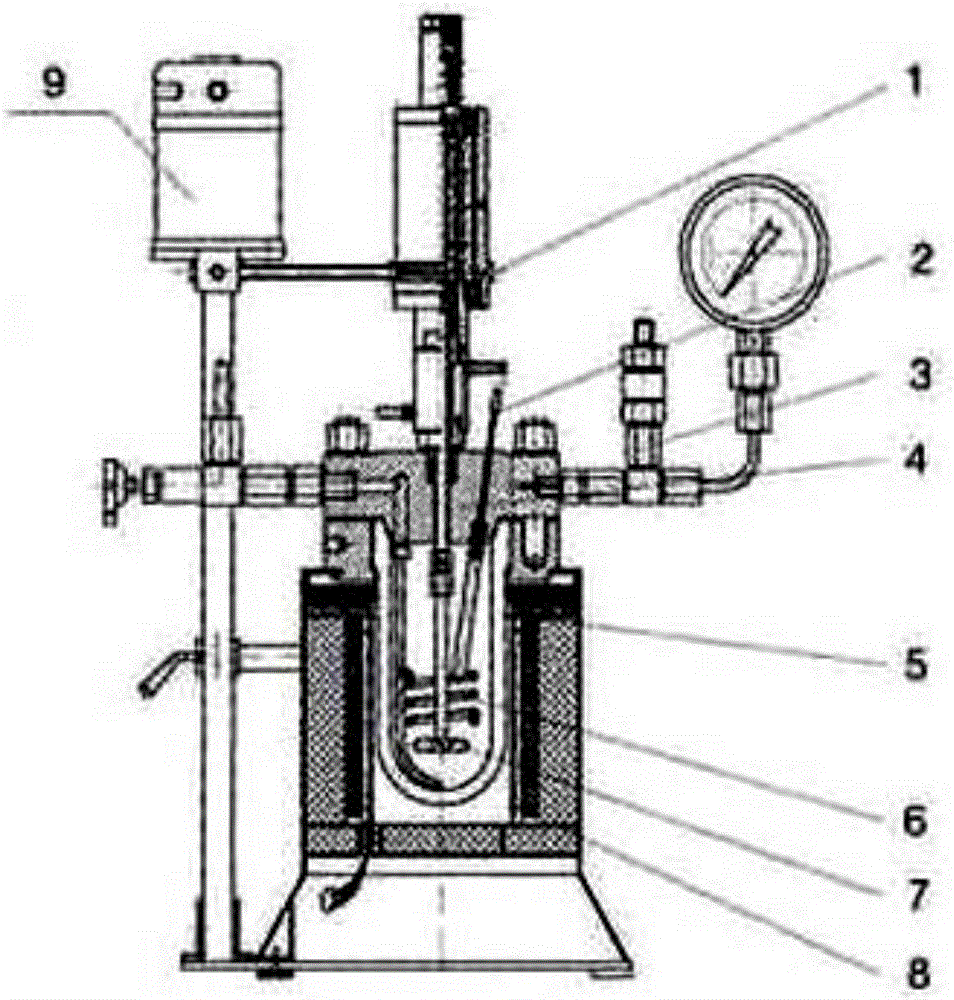

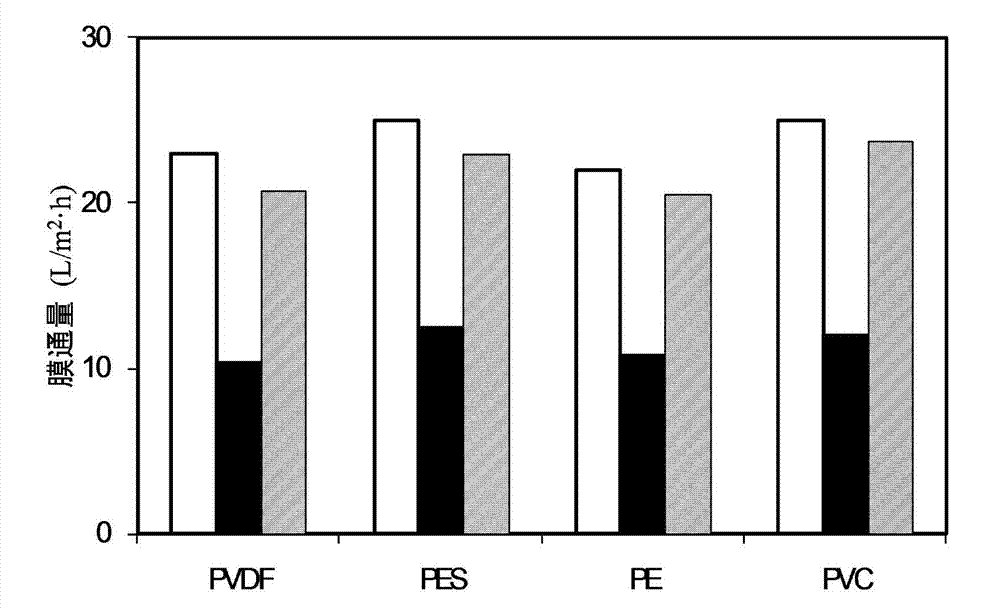

Method for cleaning membrane pollution with high-activity singlet oxygen

InactiveCN103521081AEasy to cleanAccelerated destructionSemi-permeable membranesSinglet oxygenPotassium

The invention discloses a method for cleaning membrane pollution with high-activity singlet oxygen, and relates to methods for cleaning membranes. The method for cleaning the membrane pollution with the high-activity singlet oxygen comprises the steps that solid bleaching powder and inorganic solid peroxide are added to a pool with a polluted membrane component, and the polluted membrane component is stirred, soaked and then bleached. The peroxide is calcium peroxide, magnesium peroxide, barium peroxide, sodium percarbonate and potassium percarbonate. Hypochlorite ions provided by the bleaching powder in the method for cleaning a membrane fast react with hydrogen peroxide released after the peroxide is dissolved in water to generate the high-activity singlet oxygen, the high-activity singlet oxygen directly acts on biological cells with the membrane pollution, the enzymatic structure is fast damaged, and the membrane cleaning effect is good. The high-activity singlet oxygen is an environment-friendly reagent, poisonous and harmful by-products cannot be generated in the cleaning process, and waste liquid can be directly discharged after the cleaning. The high-activity singlet oxygen can be directly added for use as a solid reagent, equipment does not need to be additionally arranged, the operation is simple and easy to carry out, the agents are convenient to transport and store, the price is low, and the agents are easy to obtain.

Owner:HARBIN INST OF TECH

Chlorate oxygen column as ignitor and production thereof

ActiveCN1817824AIncrease oxygen contentMature and stable manufacturing processExplosivesOxygenPotassium perchlorate

An ignition medicine with chlorate oxygen column and its production are disclosed. The ignition medicine consists of sodium chlorate 30~50% with grain size 60~300 meshes, lithium hyperchlorate or sodium perchlorate 10~30% with grain size 60~300 meshes, barium dioxide 0.1~6% with grain size 80~200 meshes, metal oxide ironic oxide or cuprous oxide 5~9% with grain size 20~200 meshes, metal powders 15~25% with grain size 100~300 meshes and cobalt salt 5~15% with grain size 40~200 meshes. It has shorter gas-take time and higher starting success probability of engine.

Owner:中国航天科技集团公司第四研究院第四十二所

Super-smooth glaze and preparation method therefor

InactiveCN104892031AThe glaze is as bright as a mirrorSmooth and delicate glazeClaywaresCalciteSilicon oxide

The invention relates to a super-smooth glaze and a preparation method therefor, and belongs to the technical field of ceramic processing. The super-smooth glaze is prepared from the following the components in parts by weight: potassium feldspar, quartz, kaolin, calcite, dolomite, boric acid, aluminum oxide, silicon oxide, calcium oxide, potassium oxide, sodium oxide, zinc oxide and barium oxide. The preparation method comprises: placing mixed materials which are weighed in proportion into a planetary type rapid ball mill, adding pure water of which the weight accounts for 30-40% of the total weight of the mixed materials, and performing ball milling on the mixture until the particle diameter is 0.5-1.0 [mu] m so as to obtain the super-smooth glaze. By adopting the method, the the surface of a glaze layer is highly smooth, and the glaze surface roughness of the glaze is greatly reduced in comparison with that of common ceramic glazes.

Owner:DA HAN INT HLDG LTD

Flux-cored cutting wire for underwater wet-type arc cutting and preparation method thereof

The invention discloses a flux-cored cutting wire for underwater wet-type arc cutting and a preparation method thereof. The flux-cored cutting wire is composed of a flux core and an outer layer steel belt, and is characterized in that the flux core is prepared from the following flux powder components in percentage by mass: 8-24% of dolomite, 0.5-4% of quartz sand, 0.1-3% of cesium carbonate, 0.1-3% of potassium carbonate, 0.6-2.4% of cerium oxide, 2.4-4.8% of manganese peroxide and the balance of calcium peroxide or barium peroxide. The preparation method comprises the following steps: evenly mixing the prepared flux powder; preparing the outer layer steel belt into a U-shaped slot by using a forming machine; filling the evenly mixed flux powder into the U-shaped slot, and closing the slot notch; and finally, gradually drawing by using a drawing machine to obtain the flux-cored cutting wire. The flux-cored cutting wire is used for cutting underwater low-carbon steel and low-alloy steel, and does not need additional gas shielding or excess oxygen supply.

Owner:JIANGSU UNIV OF SCI & TECH

Fire coal desulfurization and denitrification decoking additive and preparation process thereof

The invention provides a fire coal desulfurization and denitrification decoking additive and a preparation process thereof. The fire coal desulfurization and denitrification decoking additive comprises a coal dust additive, which is added to the fire coal, and a catalytic activator, which is added to a slurry tank of a desulfurization system; and the preparation process comprises the following steps of: first, adding sodium carbonate, magnesium oxide, silicon dioxide, zinc oxide, manganese dioxide, copper oxide and barium oxide in sequence and stirring the mixture for 20 minutes; and then adding active calcium oxide and ammonium bicarbonate, and stirring the mixture for 10 minutes; uniformly mixing the mixture to obtain the coal dust additive; first stirring the active calcium oxide, active aluminum oxide and caustic calcined magnesite for 15 minutes; and then adding active carbon and calcium ammonium nitrate, and uniformly stirring the mixture to obtain the catalytic activator. According to the invention, without changing the traditional boiler and desulfurization equipment as well as the process thereof, the user selects corresponding additive and catalytic activator provided by the invention according to physical and chemical indexes of the coal so as to produce coal-saving, desulfurization, denitrification and decoking effects. During using high sulfur coals, the desulfurization efficiency is obviously increased and the SO2 emission reduction reaches the standard.

Owner:窦崇庆 +2

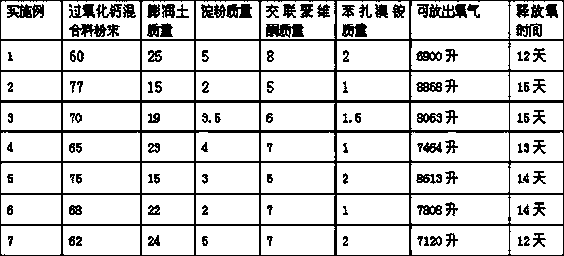

Calcium peroxide oxygenating agent particles and manufacturing method thereof

InactiveCN103435111ADisintegrates quicklySimple processWater/sewage treatment using germicide/oligodynamic-processCalcium hydroxideSodium Bentonite

The invention discloses calcium peroxide oxygenating agent particles. The calcium peroxide oxygenating agent particles comprise the following components in percentage by mass: 60-77 percent of calcium peroxide mixture, 15-25 percent of bentonite, 5-8 percent of polyvinylpolypyrrolidone, 2-5 percent of dry starch and 1-2 percent of benzalkonium bromide, wherein the calcium peroxide mixture contains calcium peroxide and calcium hydroxide, and the percentage composition of calcium peroxide is 65-75 percent. A manufacturing method comprises the following steps: uniformly mixing the calcium peroxide mixture powder, bentonite, polyvinylpolypyrrolidone and the dry starch to obtain an oxygenating agent mixture; adding water and benzalkonium bromide into the oxygenating agent mixture to obtain an oxygenating agent mixed wet material; granulating and polishing the oxygenating agent mixed wet material to obtain the calcium peroxide oxygenating agent particles. The calcium peroxide oxygenating agent particles can quickly sink to the bottom of a pool and can be quickly disintegrated to form calcium peroxide suspension, and then oxygen is gradually released and is absorbed by the water. The manufacturing method has the characteristics of simple process, low production cost and the like.

Owner:SHANGYU JIEHUA CHEM

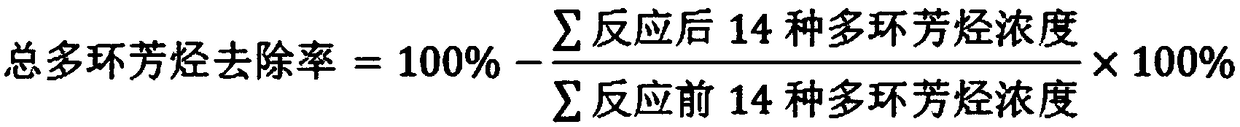

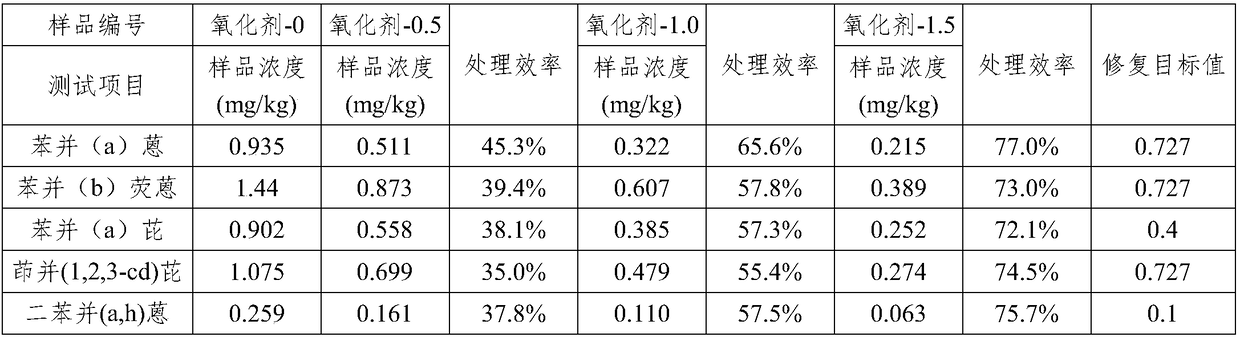

Method of using persulfate-calcium peroxide to remove polycyclic aromatic hydrocarbons in soil to repair soil through composite oxidation

InactiveCN109382405ARetentive pHEfficient removalContaminated soil reclamationBenzenePolycyclic aromatic hydrocarbon

The invention relates to the technical field of environmental governance, and especially relates to a method of using persulfate-calcium peroxide to remove polycyclic aromatic hydrocarbons in soil torepair soil through composite oxidation. The method comprises following steps: drying soil to be tested in the air; sieving the soil; evenly mixing the soil with calcium peroxide; adding distilled water into the mixture to prepare slurry; adding oxalate ions, ferrous ions, and persulfate ions into the slurry in sequence; evenly stirring to obtain a slurry reaction solution; placing the slurry reaction solution in a dark place, and allowing the slurry reaction solution to stand still to carry out reactions. After reactions, polycyclic aromatic hydrocarbons in the soil can be removed. The provided method can effectively remove polycyclic aromatic hydrocarbons (benzanthracene (a), benzofluoranthrene (b), benzoapyrene (a), indenopyrene (1,2,3-cd), and dibenzanthracene (a,h)) in soil; the removal rate of polycyclic aromatic hydrocarbons is high, and the neutral property (pH) of the soil is maintained.

Owner:SHANGHAI ENERGY CONSERVATION OF ENVIRONMENT

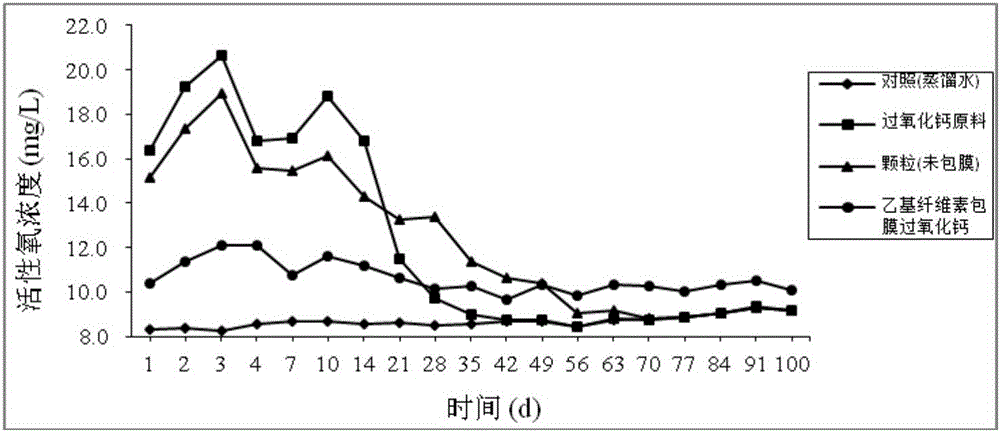

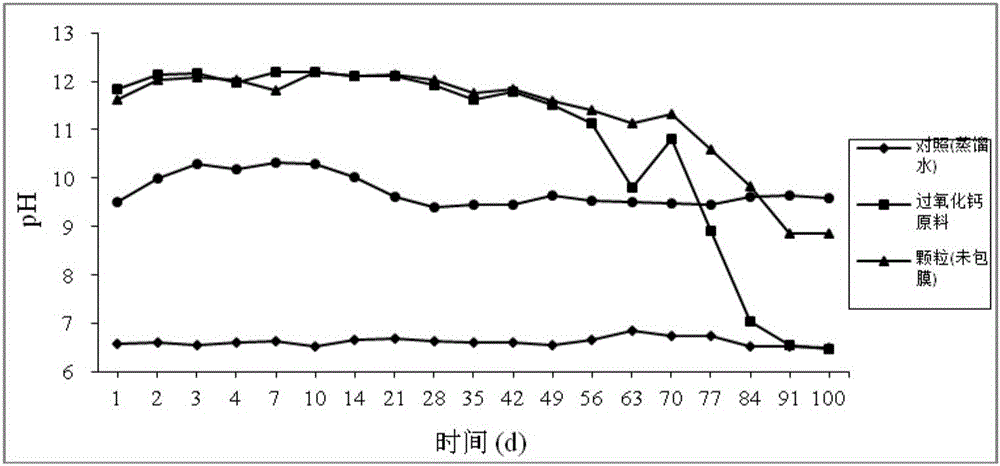

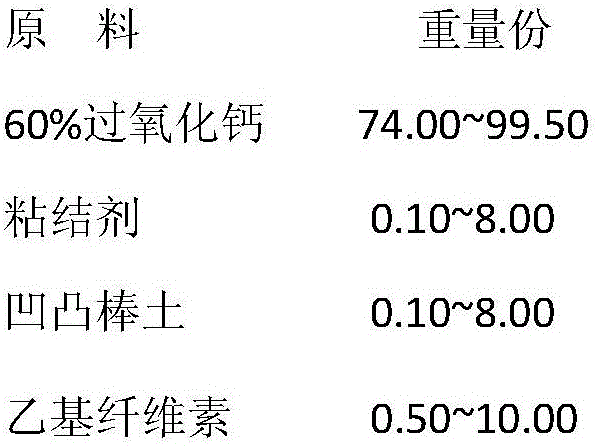

Sustained-release oxidizing agent taking calcium peroxide as matrix and ethyl cellulose as coating and preparation method thereof

InactiveCN105925267ASolve the problem of oxygen release timeRaise the pHAgriculture tools and machinesOther chemical processesRelease timePaddy field

The invention discloses a sustained-release oxidizing agent taking calcium peroxide as the matrix and ethyl cellulose as the coating and a preparation method thereof. The oxidizing agent is prepared from calcium peroxide (60%), a binding agent, attapulgite, and ethyl cellulose according to a certain ratio. The preparation method comprises the following steps: step A, evenly mixing calcium peroxide (60%), a binding agent, and attapulgite, and granulating the mixture to obtain particles with a size of 3 to 5 mm; step B, according to the weight of particles obtained in the step A, supplying enough ethyl cellulose, coating particles by ethyl cellulose, and drying to obtain the sustained-release oxidizing agent. The formula is reasonable, the method is feasible, and the operation is simple. The problem that calcium peroxide releases oxygen in gleying paddy fields in a short period is solved, the growth environment for paddy rice in gleying paddy fields is improved; after calcium peroxide is coated by ethyl cellulose, the oxygen release time is prolonged to 100 days or more, and, compared with that of calcium peroxide powder, the oxygen release time is prolonged by 58 days or more, in other words 1.4 times or more. The oxidizing agent has a great popularization and application value in the middle and lower reaches, which have many glyeing paddy fields, of Changjiang River.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

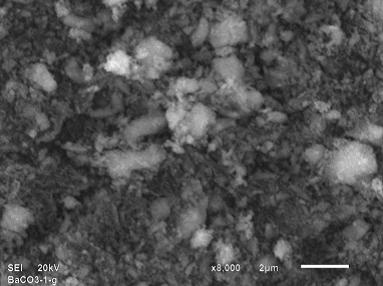

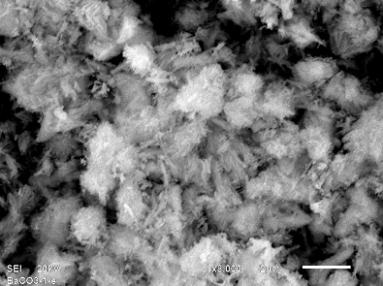

Production method for high-purity electronic-grade barium carbonate

InactiveCN102649578AReduce adsorptionAvoid generatingCalcium/strontium/barium carbonatesNanotechnologyMicrowaveBarium peroxide

The invention relates to a production method for high-purity electronic-grade barium carbonate. The production method comprises the following steps: adding barium hydroxide into deionized water, heating the barium hydroxide in the stirring process and preparing into a barium hydroxide solution; adding polyacrylamide into the barium hydroxide solution and introducing carbon dioxide into the barium hydroxide solution by using a disc type microporous aerator; heating the barium hydroxide solution until the barium hydroxide solution is boiled; cooling and filtering the precipitate to obtain the barium carbonate precipitate; and drying the barium carbonate precipitate in a microwave dryer to obtain the high-purity electronic-grade barium carbonate. The polyacrylamide serves as a dispersing agent and has a good dispersing effect, so the production cost is reduced. The carbon dioxide is introduced by the disc type microporous aerator and is mixed with the barium hydroxide completely and uniformly, so the specific area of the produced barium carbonate is large, the production time is shortened, and the production efficiency is improved.

Owner:SHANDONG YINBEI TECH

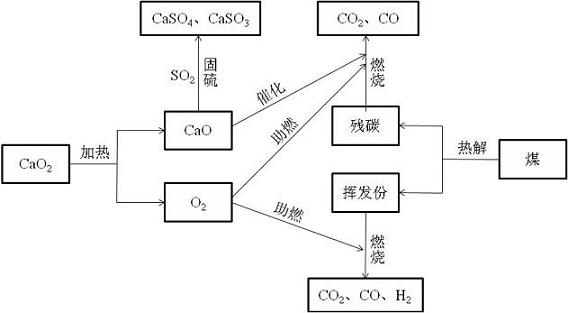

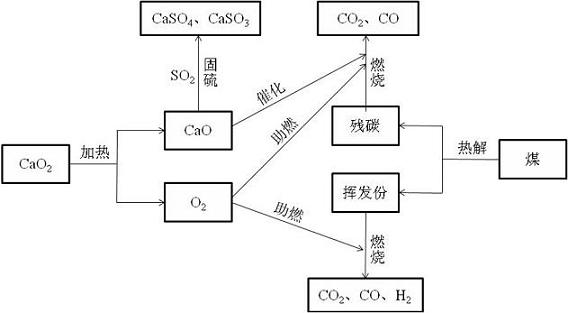

New application of calcium peroxide and fire coal combustion-supporting solid sulfide additive

The invention discloses a new application of calcium peroxide and a fire coal combustion-supporting solid sulfide additive. The calcium peroxide is taken as a fire coal combustion-supporting catalyzer which is added to the fire coals to be subject to even physical mixing together with the fire coals, thereby being used for improving combustion performance and combustion efficiency of the fire coals. The fire coal combustion-supporting solid sulfide additive is composed of the calcium peroxide and sulfur fixing agent, wherein the calcium peroxide accounts for 4.8%-9.1% and the sulphur fixing agent accounts for 90.9%-95.2%. In the invention, application fields and utilization occasions of the calcium peroxide are broadened and the calcium peroxide and the obtained combustion-supporting solid sulfide additive are added with a small additive amount, thus being capable of reducing addition cost. The invention can be applied to various coals and equipment, is in no need of special equipment and has wide applicable range. The physical mixing is adopted for the addition, thereby having simple technology and generating no secondary pollution. The calcium peroxide is used flexibly, not only being capable of being used independently, but also assisting other sulphur fixing agents to improve solid sulfur effect.

Owner:CHONGQING UNIV

Production process of lithium hydroxide monohydrate

InactiveCN1214981CShort process routeHigh yieldSulfate/bisulfate preparationLithium oxides/hydroxidesSolubilityStrontium hydroxide octahydrate

In the production process of lithium hydroxide monohydrate, lithium sulfate solution and caustic soda are made to produce metathetic reaction to form mixture solution of sodium sulfate and lithium hydroxide, and sodium sulfate and lithium hydroxide monohydrate are then separated by means of the obvious difference in low temperature solubility. The production process includes the following steps: adding sodium hydroxide into lithium sulfate solution obtained through serial production steps to obtain mixture solution of sodium sulfate and lithium hydroxide; cooling to minus 10 deg.c to 5 deg.c for the crystallization and separation of sodium sulfate; heating to concentrate the separated clear liquid; crystallization and separation to obtain coarse lithium hydroxide monohydrate product; water dissolving coarse lithium hydroxide monohydrate, adding barium hydroxide to form insoluble barium sulfate, filtering, concentrating filtrate, crystallizing to separate wet lithium hydroxide monohydrate; and drying.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com