Nanometer barium titanate powder preparation method based on ball milling

A kind of barium titanate and nanotechnology, which is applied in the direction of nanotechnology, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of difficult purification and many impurities in nanobarium titanate powder, and achieve short process and dispersion Good performance and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Fully mix barium oxide and titanium oxide powder in a certain proportion, the molar ratio of barium oxide and titanium oxide is 1:1, and the diameter of zirconia grinding ball is: 10mm;

[0026] (2) the above-mentioned mixture, zirconia grinding balls, and ball milling fluid are placed in a ball mill jar in a mass ratio of 30:1:15;

[0027] (3) Start the ball mill for ball milling for 6 hours, and the ball mill rotating speed is 240r / min;

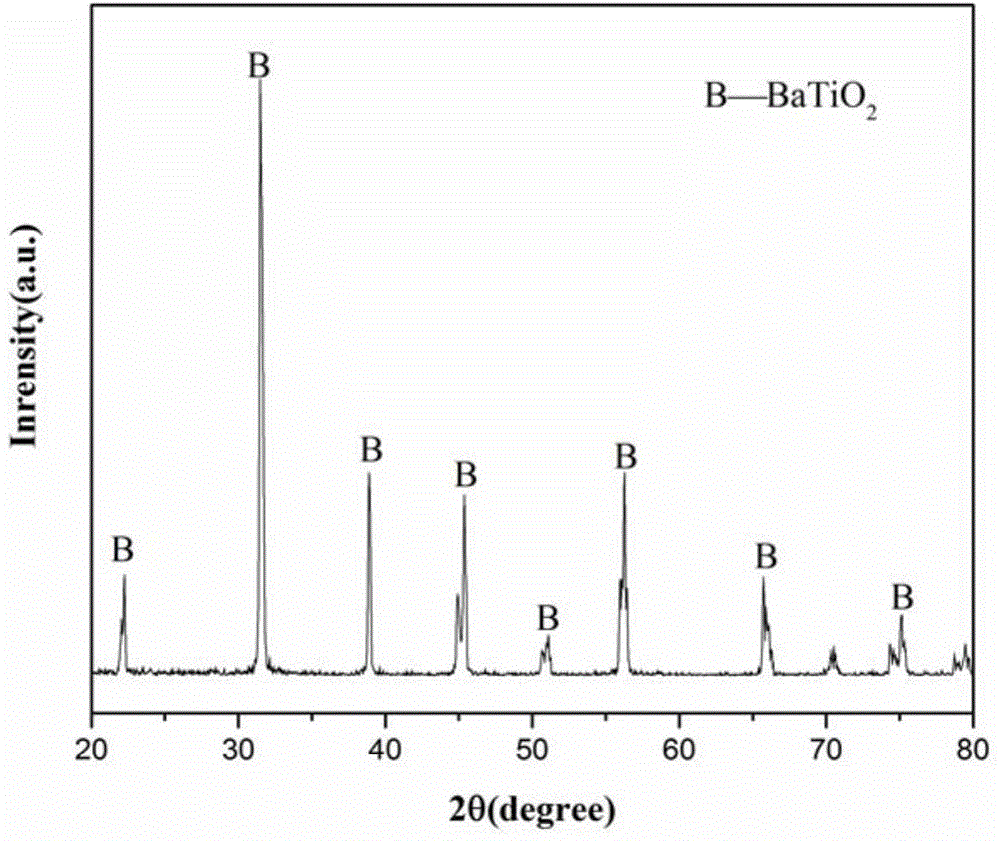

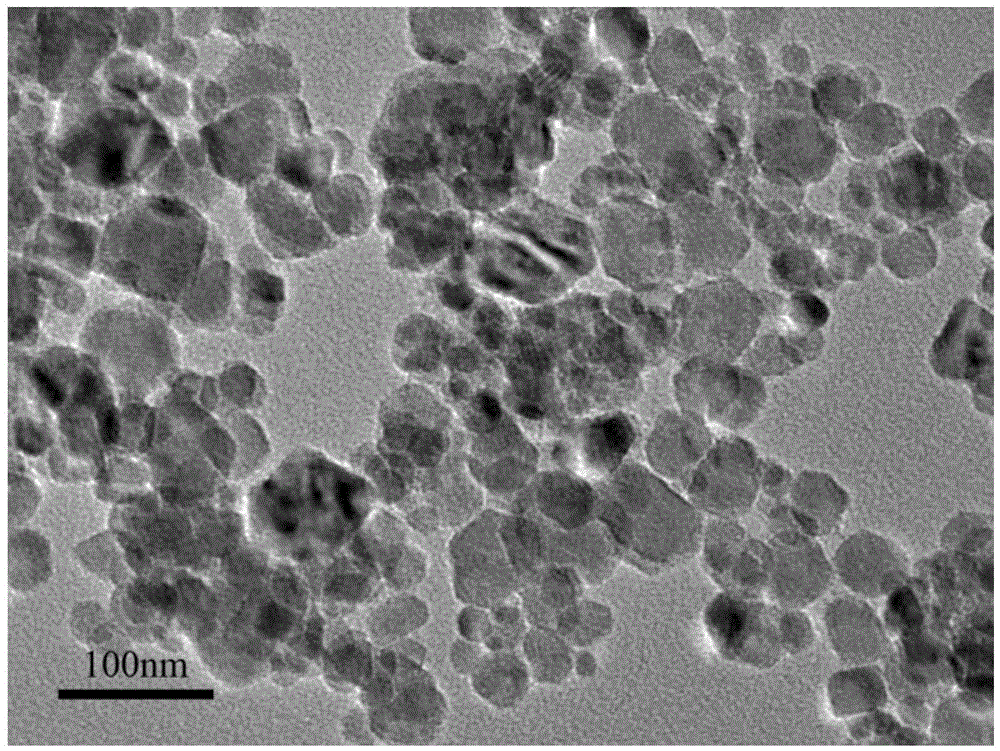

[0028] (4) Filtrating the ball milling solution after ball milling, washing several times, drying, and then crushing and nano-grinding to obtain barium titanate nanopowder. Through product testing, the TEM figure ( figure 1 ), it can be seen from the figure that the average particle size of the barium titanate nanopowder is about 70 nanometers, and the particles are uniform spherical, with good dispersion and no massive agglomerates. Then from its XRD figure ( figure 2 ), it can be seen that no impurity peaks have been detect...

Embodiment 2

[0035] (1) Fully mix barium oxide and titanium oxide powder in a certain proportion, the molar ratio of barium oxide and titanium oxide is 1:1, and the diameter of the grinding ball is: 15mm;

[0036] (2) placing the above-mentioned mixture, zirconia grinding balls, and ball milling liquid in a ball milling jar at a mass ratio of 40:1:20;

[0037] (3) start ball mill ball mill for 7 hours, and the ball mill rotating speed is 350r / min;

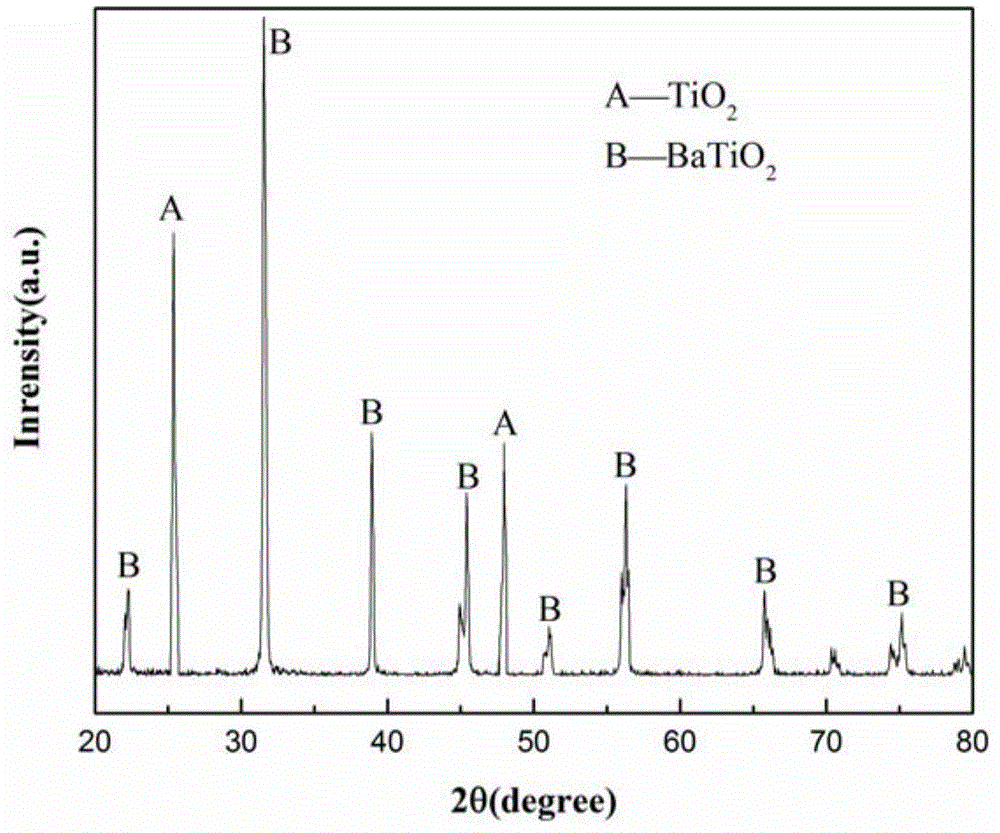

[0038](4) Filtrating the ball milling solution after ball milling, washing several times, drying, and then crushing and nano-grinding to obtain barium titanate nanopowder. According to product testing, the average particle size of the prepared barium titanate nanopowder is about 60 nanometers, and the particles are uniform spherical, with good dispersibility and no massive agglomerates. From its XRD detection, it can be seen that no impurity peaks are detected, all are peaks of tetragonal phase barium titanate nanopowder, and the purity reache...

Embodiment 3

[0040] (1) Fully mix barium oxide and titanium oxide powder in a certain proportion, the molar ratio of barium oxide and titanium oxide is 1:1, and the diameter of the grinding ball is: 15mm;

[0041] (2) the above-mentioned mixture, zirconia grinding balls, and ball milling fluid are placed in a ball mill jar in a mass ratio of 50:1:25;

[0042] (3) Start the ball mill for ball milling for 8 hours, and the ball mill rotating speed is 450r / min;

[0043] (4) Filtrating the ball milling solution after ball milling, washing several times, drying, and then crushing and nano-grinding to obtain barium titanate nanopowder. According to product testing, the average particle size of the prepared barium titanate nanopowder is about 80 nanometers, and the particles are uniform spherical, with good dispersibility and no massive agglomerates. From its XRD detection, it can be seen that no impurity peaks are detected, all are peaks of tetragonal phase barium titanate nanopowder, and the pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com