Anticorrosive agent for concrete and anticorrosive concrete

A concrete and anti-corrosion agent technology, which is applied in the field of building materials and anti-corrosion agents, can solve the problems that the sulfate corrosion cannot be completely cured and has little effect, so as to improve the strength, impermeability and corrosion resistance, and alleviate the intractable corrosion. Corrosion resistance, non-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

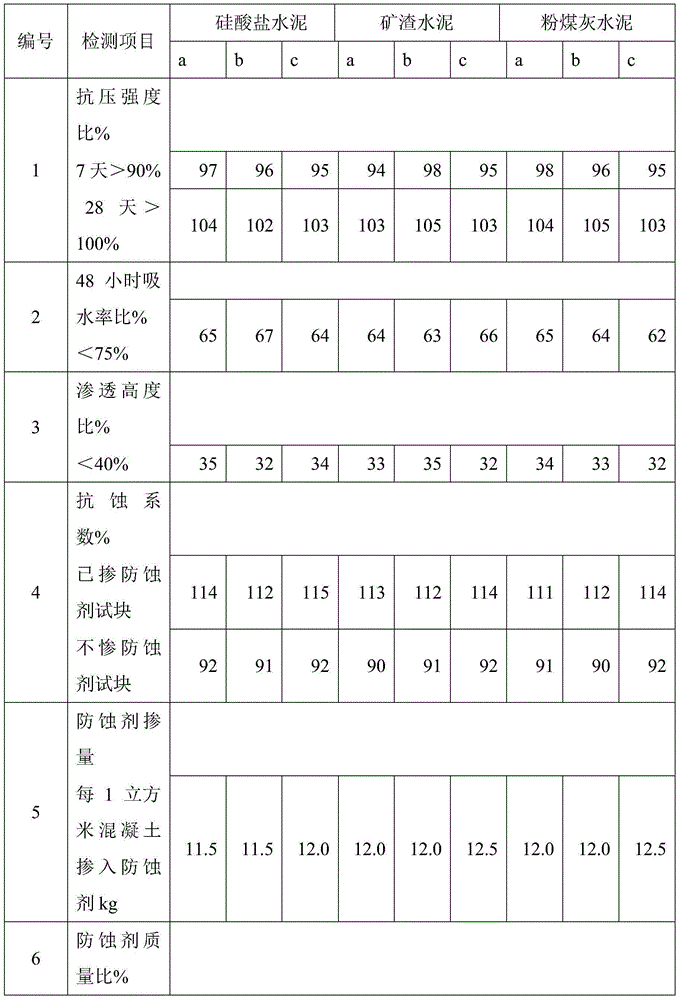

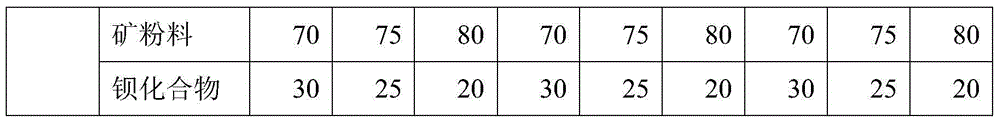

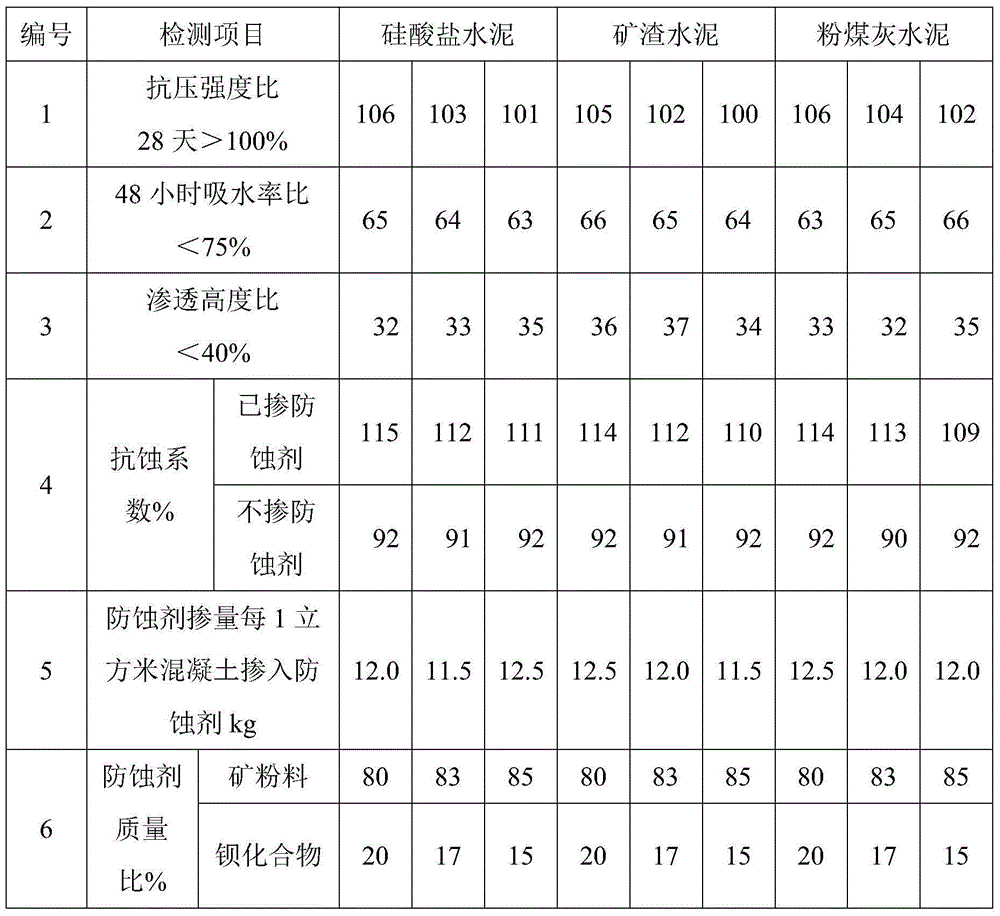

Examples

Embodiment Construction

[0046] The fineness of fly ash, blast furnace water-quenched slag powder, silica fume, light-burned metakaolin powder, phosphorus slag powder, alum slag powder and natural zeolite powder used in the corrosion inhibitor provided by the present invention is 2500 pores / cm 2 All through the sieve.

[0047] ●The barium sulfide used in the corrosion inhibitor provided by the present invention has a fineness of 2500 holes / cm 2 All through the sieve.

[0048] ●Preparation of corrosion inhibitor:

[0049] The anticorrosion agent of the present invention is obtained by mixing the barium sulfide and the powder evenly in proportion.

[0050] ●Preparation of anti-corrosion concrete:

[0051] At the concrete construction site or ready-mixed concrete station and concrete prefabricated component factory, when mixing the anti-corrosion agent provided by the present invention in the concrete, after mixing 12kg anti-salt corrosion agent per cubic meter of concrete, it is stirred, transported,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com