Calcium peroxide oxygenating agent particles and manufacturing method thereof

A technology of calcium peroxide and oxygenation agent, which is applied in chemical instruments and methods, water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve problems such as human injury, large specific surface area, and oxygen waste, Achieve the effect of low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

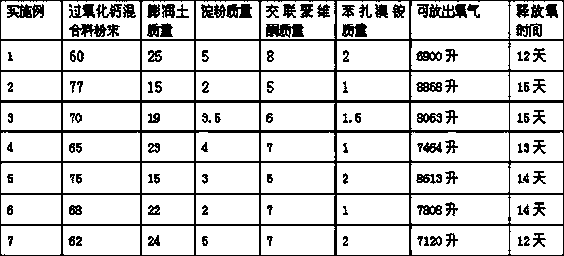

[0017] The calcium peroxide oxygenator particles of the present invention contain 60%-77% by mass of calcium peroxide mixture, 15%-25% by mass of bentonite, and 5%-8% by mass of cross-linked Povidone, starch at 2%-5% by mass, and benzalkonium bromide at 1-2% by mass. The calcium peroxide mixture contains calcium peroxide and calcium hydroxide, and the mass percentage of calcium peroxide in the calcium peroxide mixture is 65%-75%.

[0018] The raw materials adopted in the present invention are introduced below:

[0019] 1, calcium peroxide mixture powder: calcium peroxide mixture of the present invention contains calcium peroxide and calcium hydroxide, wherein the amount percentage composition of calcium peroxide is 65%-75%, can be 65%, 75%, 68%, 72%, 70%, etc.

[0020] Calcium peroxide is obtained by the reaction of sodium hydroxide and hydrogen peroxide, and only part of calcium peroxide and unreacted calcium hydroxide can be generated during the reaction process, so the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com