Method for cleaning membrane pollution with high-activity singlet oxygen

A singlet oxygen and membrane fouling technology, applied in the field of membrane cleaning, can solve the problems of inconvenient transportation and storage, complex process operation and safety hazards, etc., and achieve the effect of easy acquisition, low price and strong oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

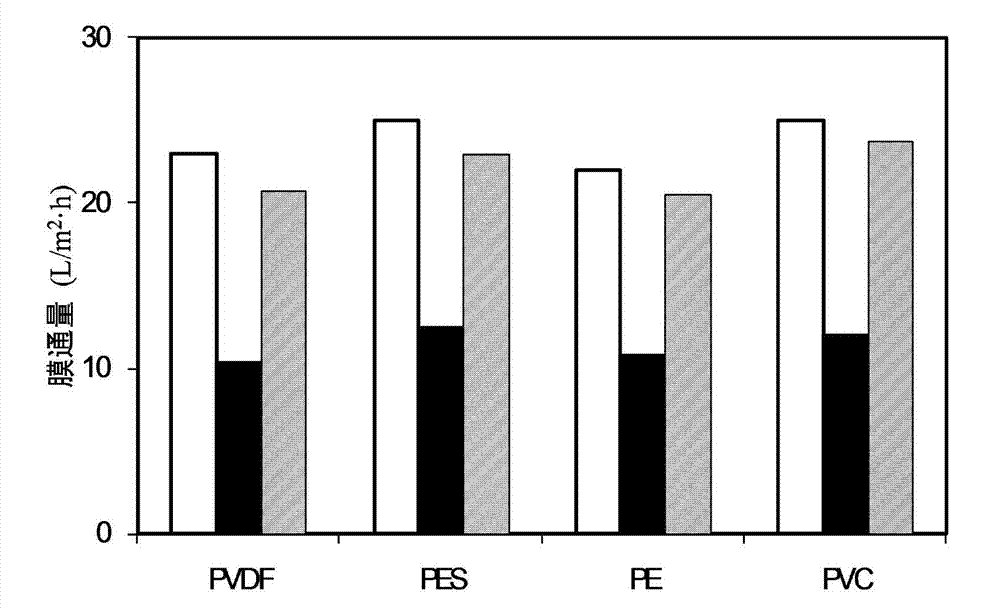

[0019] Specific Embodiment 1: This embodiment is a method for cleaning membrane fouling by using highly active singlet oxygen, which is achieved through the following steps: a. Putting the polluted membrane module to be cleaned into a pool filled with tap water; b. Add solid bleaching powder and inorganic solid peroxide into the pool in step 1 according to the mass ratio of (1-10):1, and stir evenly. When the peroxide concentration is 50-1000mg / L, the soaking time of the membrane module is Under the condition of 10 to 180 minutes, the membrane module is cleaned; c. Put the cleaned membrane module into another pool filled with tap water for rinsing, that is, the cleaning of membrane pollution by using highly active singlet oxygen is completed.

[0020] The membrane material of the contaminated membrane module described in this embodiment is polyvinylidene fluoride (PVDF), polyethersulfone (PES), polyethylene (PE) or polyvinyl chloride (PVC).

[0021] The solid bleaching powder ...

specific Embodiment approach 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of solid bleaching powder to inorganic solid peroxide is (2-9):1. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass ratio of solid bleaching powder to inorganic solid peroxide is (3-8):1. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com