Liquid barium/zinc thermal stabilizer, preparation method therefor and equipment for implementing method

A heat stabilizer, liquid technology, applied in the field of liquid barium/zinc heat stabilizer, can solve the problems of long production time period, great harm to operators, troublesome manual transfer, etc., and achieves simplified production process, short production period, acid mist small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

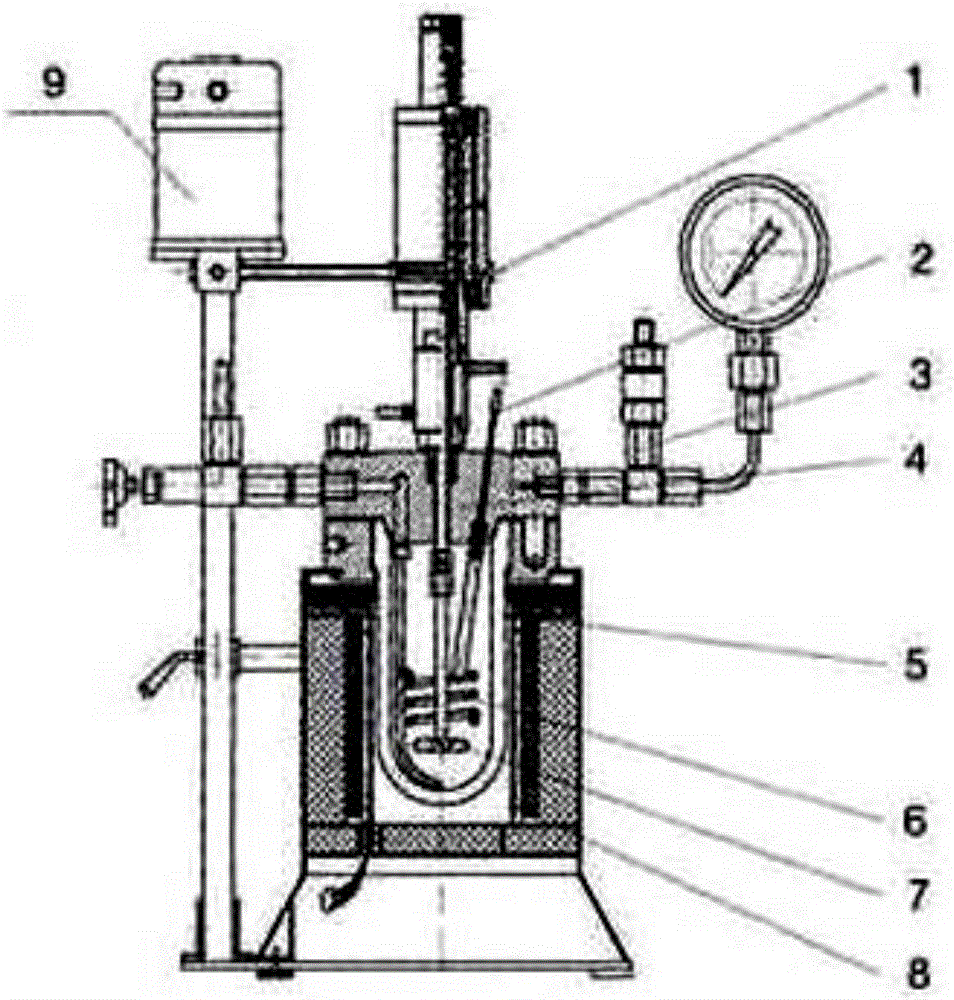

Image

Examples

Embodiment 1

[0054] A liquid barium / zinc heat stabilizer, comprising the following preparation raw materials in parts by weight: 28 parts of barium hydroxide monohydrate, 15 parts of zinc oxide, 33 parts of acid solution, 1 part of catalyst, 2 parts of water-carrying agent, saturated cycloalkane solvent 18 parts, 10 parts of heat-resistant additive;

[0055] Among them, the acid solution is a mixture of 5 parts of isooctanoic acid, 10 parts of octanoic acid, 5 parts of oleic acid, 10 parts of p-tert-butylbenzoic acid and 3 parts of benzoic acid, the catalyst is a mixture of 0.3 parts of acetic acid and 0.7 parts of formic acid, and the water carrier It is a mixture of 1 part of ethylene glycol and 1 part of methanol, the saturated naphthenic solvent is a mixture of 3 parts of glycerin, 2 parts of methyl ethyl ketone, 8 parts of odorless kerosene and 5 parts of albino oil, and the heat-resistant additive is 5 parts of soybean oil and a mixture of 5 parts phosphite.

[0056] A preparation m...

Embodiment 2

[0063] A liquid barium / zinc heat stabilizer, comprising the following preparation raw materials in parts by weight: 30 parts of barium hydroxide monohydrate, 17 parts of zinc oxide, 38 parts of acid solution, 1 part of catalyst, 1 part of water-carrying agent, saturated cycloalkane solvent 5 parts, 5 parts of heat-resistant additive;

[0064] Among them, the acid liquid is 38 parts of oleic acid, the catalyst is 1 part of propionic acid, the water-carrying agent is 1 part of ethylene glycol, the saturated naphthenic solvent is 5 parts of deodorized kerosene, and the heat-resistant additive is 2 parts of SBM and 3 parts of DBM. mixture.

[0065] A preparation method of liquid barium / zinc heat stabilizer, comprising the following steps:

[0066] 201. Pre-heat the oil bath temperature of the reactor to 140°C, add 38 parts of acid solution into the reactor, cover the lid of the reactor, start stirring and heat the temperature to 95°C, and the stirring frequency is 18Hz per minute...

Embodiment 3

[0072] A liquid barium / zinc heat stabilizer, comprising the following preparation raw materials in parts by weight: 30 parts of barium hydroxide monohydrate, 15 parts of zinc oxide, 40 parts of acid solution, 1 part of catalyst, 1 part of water-carrying agent, saturated cycloalkane solvent 8 parts, 5 parts heat-resistant additive;

[0073] Among them, the acid liquid is a mixture of 18 parts of isooctanoic acid and 22 parts of p-tert-butylbenzoic acid, the catalyst is a mixture of 0.5 parts of acetic acid, 0.2 parts of formic acid and 0.3 parts of propionic acid, and the water carrier is 1 part of methanol, saturated naphthenic solvent It is a mixture of 3 parts of triethylene glycol and 5 parts of cyclohexanone, and the heat-resistant additive is a mixture of 2 parts of soybean oil, 2 parts of phosphite ester and 1 part of antioxidant.

[0074] A preparation method of liquid barium / zinc heat stabilizer, comprising the following steps:

[0075] 301. Pre-heat the oil bath temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com