Patents

Literature

70results about How to "Production safety and environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforcing agent of amphoteric polyacrylamide cardboard paper

ActiveCN101666059AProduction safety and environmental protectionEnhancement effect is goodReinforcing agents additionPaper/cardboardCardboardPolyacrylamide

The invention discloses a reinforcing agent of amphoteric polyacrylamide cardboard paper. In the existing reinforcing agents, some have unobvious reinforcing effect, and some have extremely great pollution and damage to the environment. The reinforcing agent is prepared by deionized water, anion monomer, cation monomer, non-ion monomer, pH adjusting agent and an initiating system, and is characterized in that: the anion monomer selects the mixture of carboxylic group unsaturated monomer and sulfonic group unsaturated monomer for use; and the non-ion monomer selects the mixture of acrylamide or acrylamide derivative and methyl methacrylate or methyl methacrylate derivative for use. The reinforcing agent has favorable reinforcing effect and greatly improves the safety and environment protection of production.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

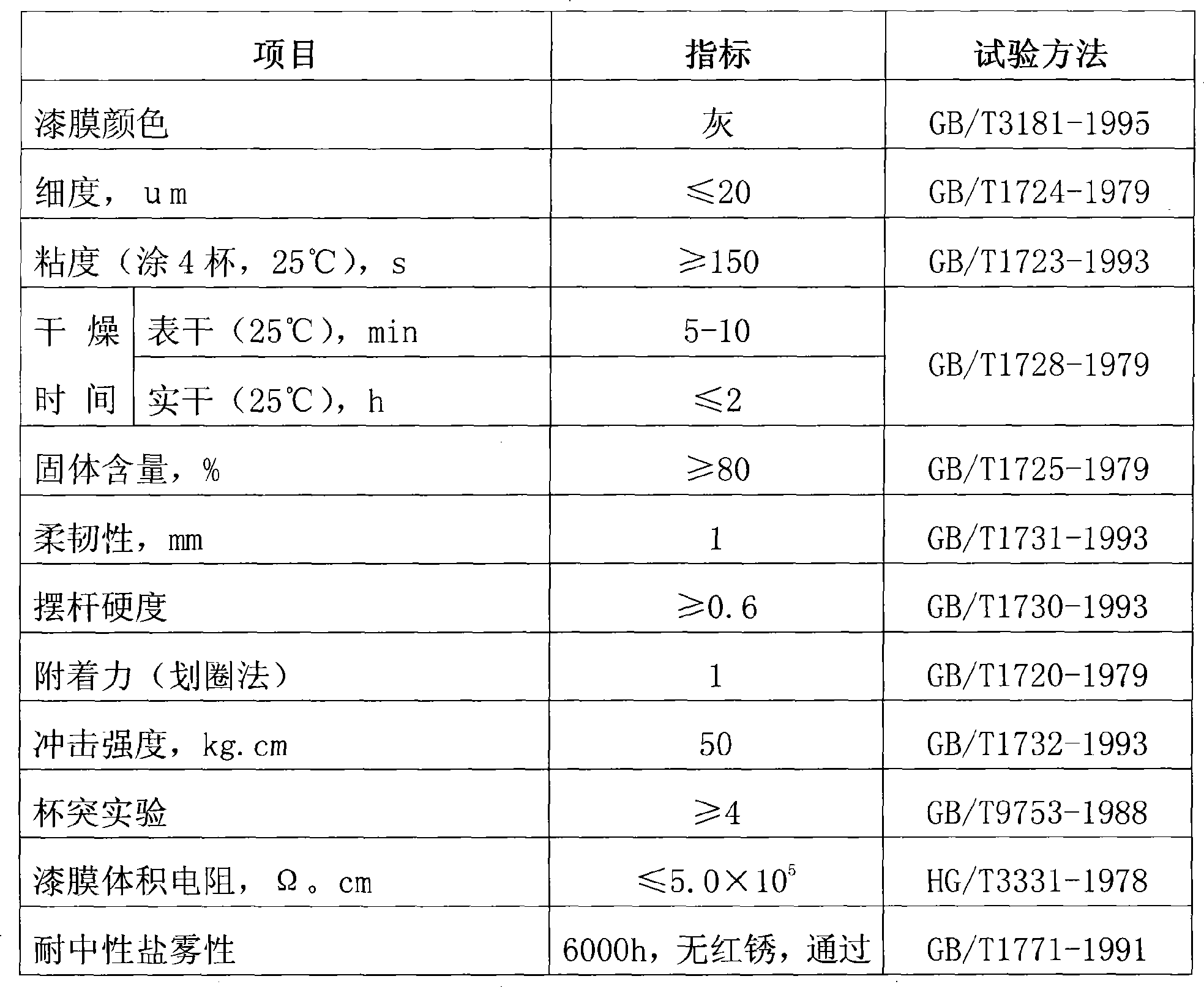

High-efficient zinc-rich anti-corrosive paint and preparation method thereof

InactiveCN101445676AImprove anti-corrosion performanceMeet protectiveAnti-corrosive paintsElectrically-conductive paintsCoated surfaceSalt spray test

The invention relates to a high-efficient zinc-rich anti-corrosive paint and a preparation method thereof. Components of the paint according to parts by weight are as below: 2.0-2.6 parts of ethylene resin, 75.0-86.0 parts of zinc powder, 11.0-24.0 parts of solvent and 0.1-0.5 part of addition agent. The invention is characterized in that the ordinary active zinc powder is used; zinc content in a dried film is greater than 96.5 percent so as to solve a present technical problem that only the use of high-purity zinc powder can lead to the zinc content of 96 percent in the dried film. A high-efficient zinc-rich anti-corrosive paint coating has excellent physical and mechanical performance and excellent anti-corrosive performance, and no red rust is generated during a 6000h neutral salt spray test. The surface of the coating can be used together with anti-corrosive finish paint of various types, and the requirement of various long-term heavy anti-corrosion constructions can be satisfied; the paint system is of single component which can be used at the temperature of -25 DEG C-80 DEG C; the construction is convenient, and the range of use environment temperature is wide; and the invention has good antistatic performance and can be used for an antistatic coating.

Owner:贵阳神迪科技有限公司

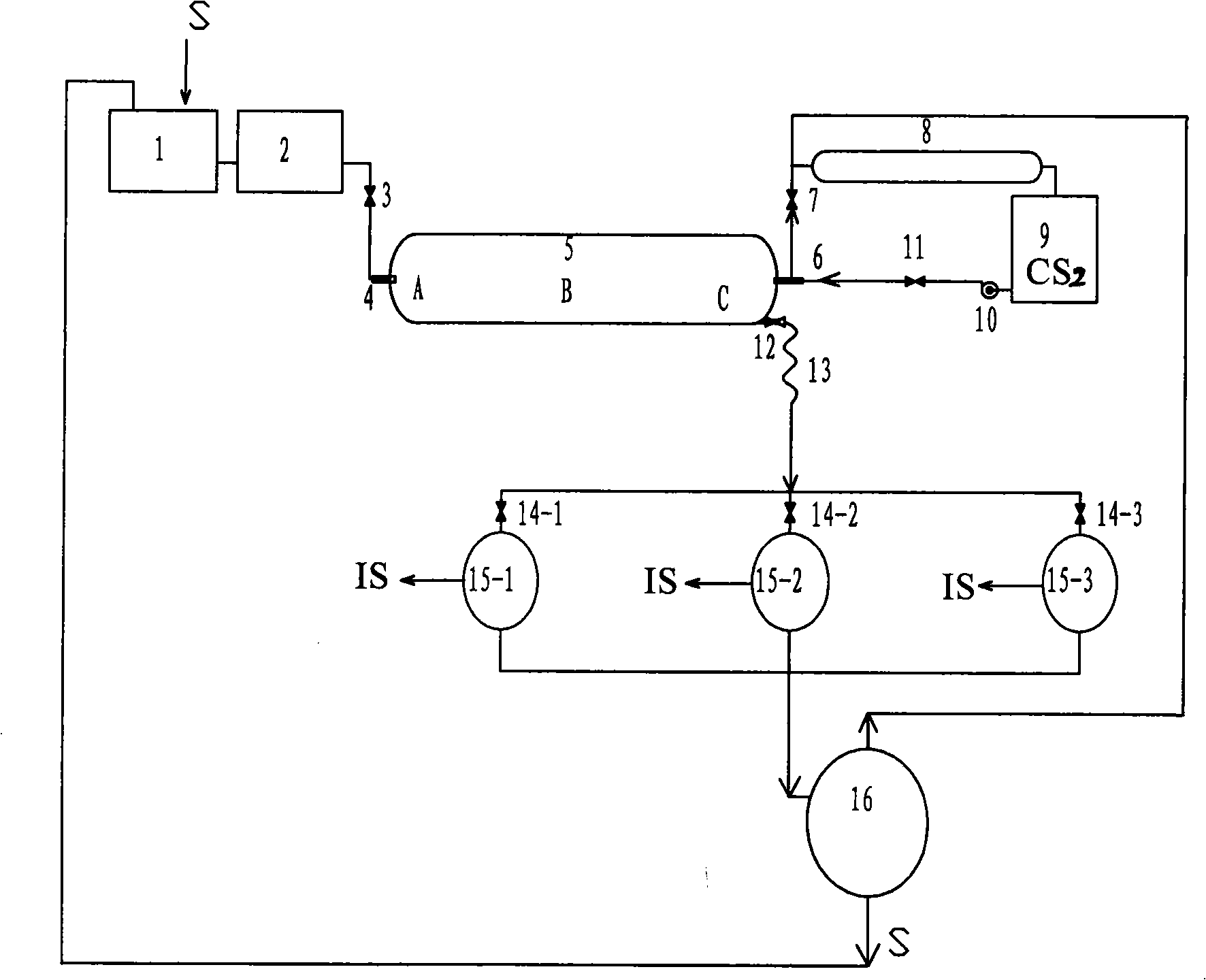

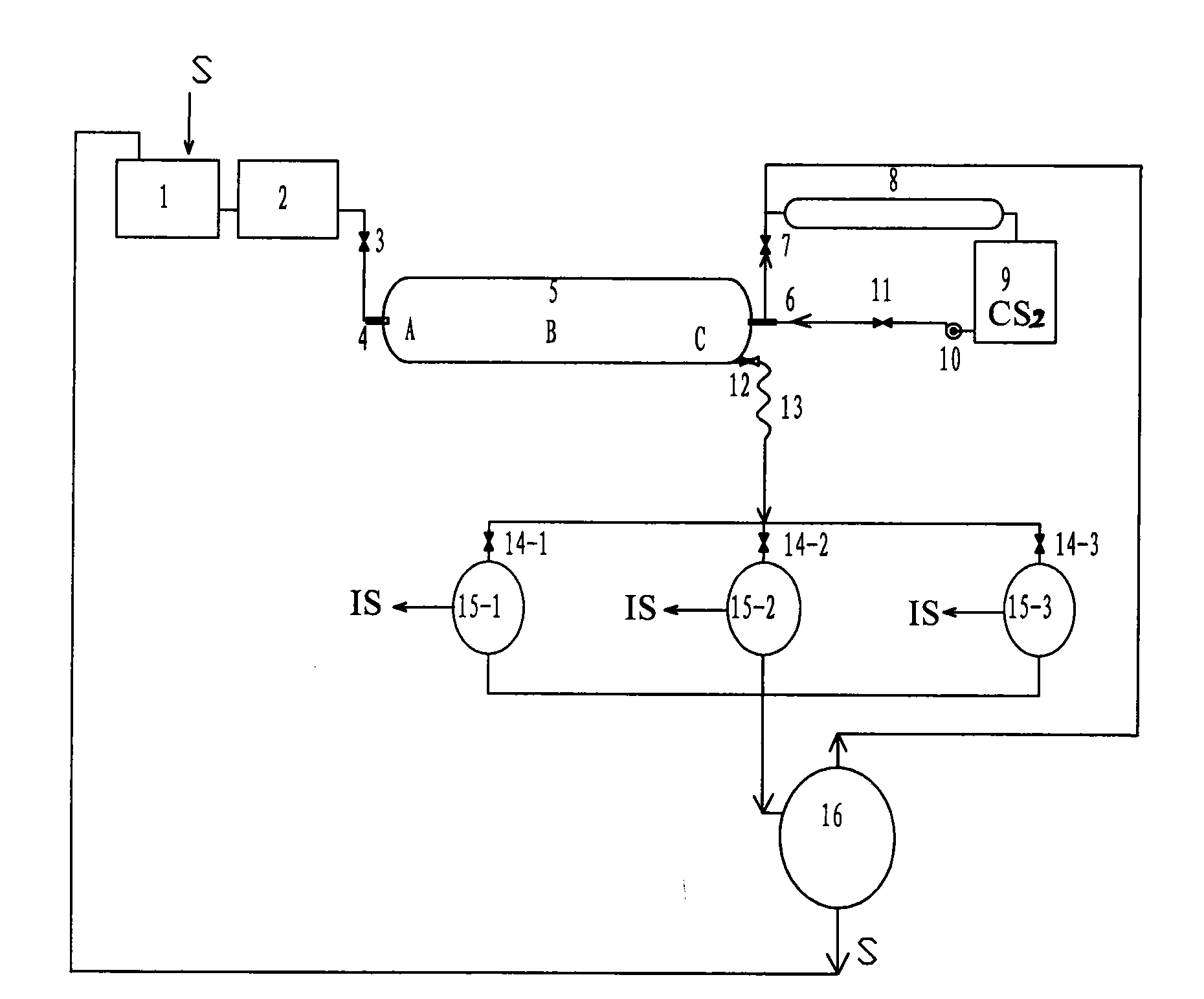

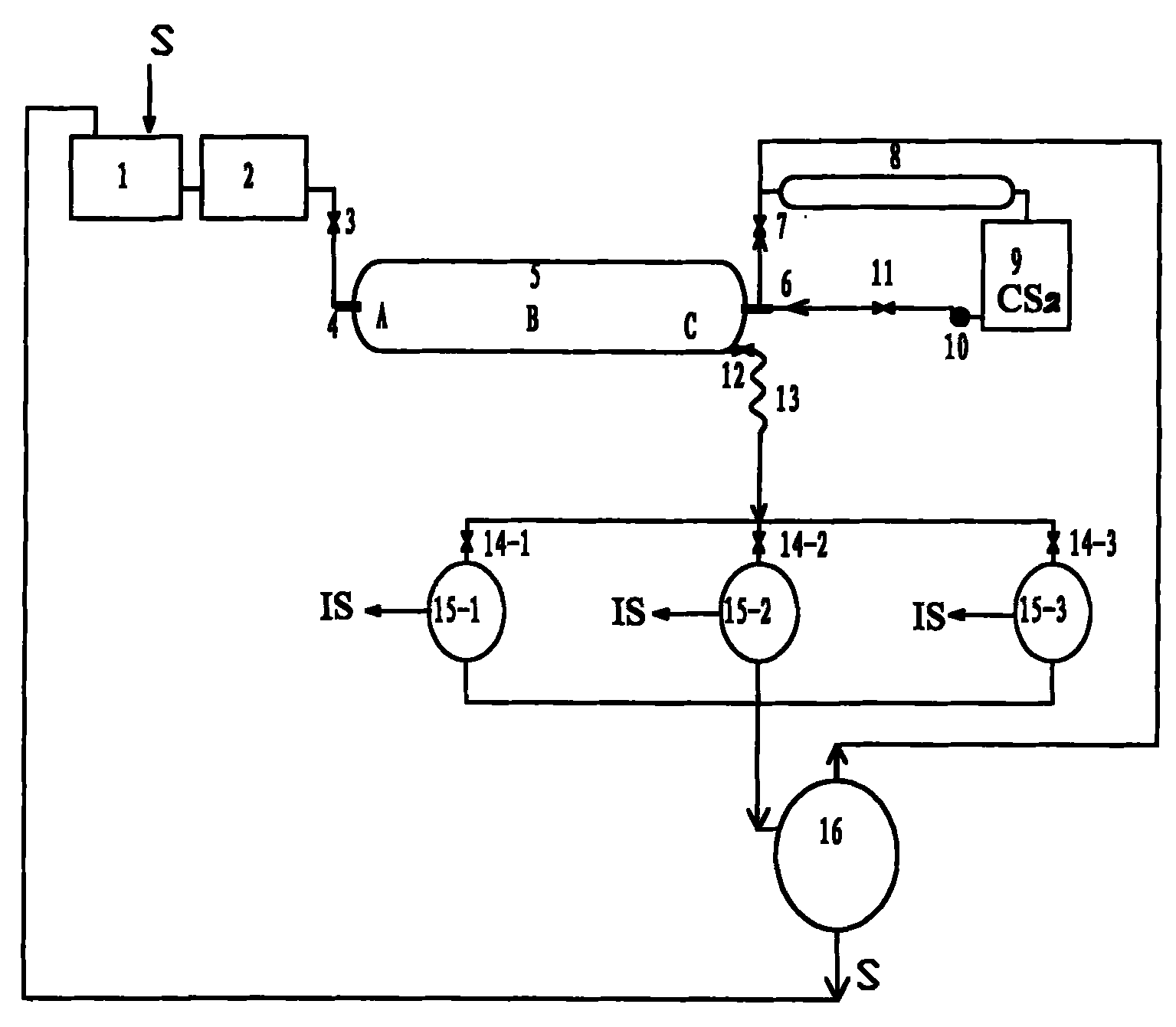

Method for producing insoluble sulfur

InactiveCN101337660AProduction safety and environmental protectionAvoid pollutionSulfur preparation/purificationSulfurNitrogen

The invention discloses a method for producing insoluble sulfur, which comprises the steps of melting sulfur, extracting, drying and pulverizing. By using the method, the insoluble sulfur is continuously produced under the totally-enclosed condition of normal pressure, nitrogen of normal pressure is used for sealing a heating groove, and the extracting step and the pulverizing step are completed in the same reactor. The specific operation steps are as follows in sequence: (1) melting the sulfur and heating up; (2) extracting and pulverizing; and (3) drying to obtain products produced through the method. The method has the advantages that: (1) the insoluble sulfur is continuously produced under the totally-enclosed condition of the normal pressure, and nitrogen is used for sealing the upper space of the sulfur heating groove, thereby resulting in no oxide leakage of carbon bisulfide and sulfur, and achieving safe and environmental-friendly production; (2) the pulverizing and quenching processes are finished in the same multifunctional rotary reactor, thus saving pulverizing devices, avoiding dust pollution when pulverizing, and protecting production environment.

Owner:广州市烨荣贸易有限公司

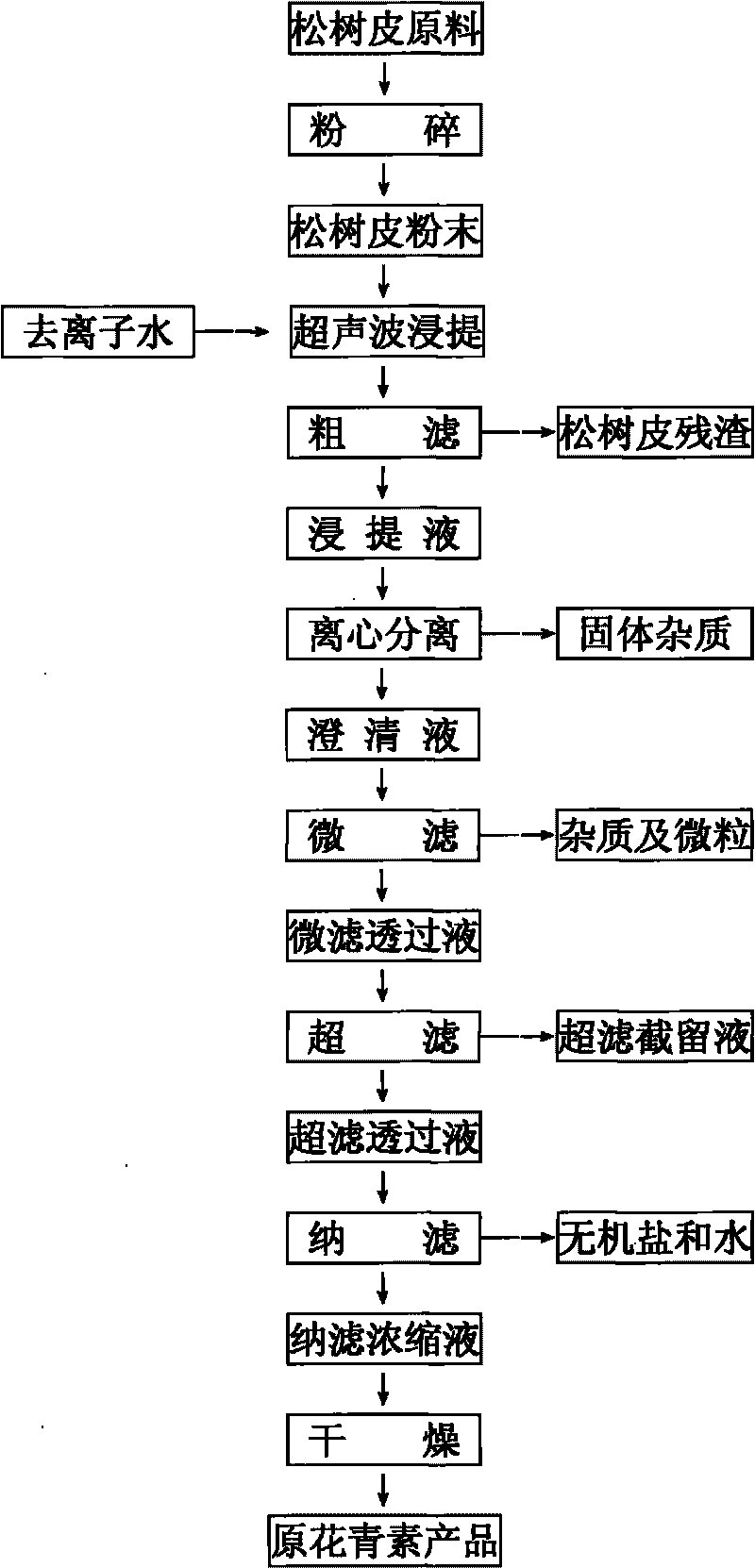

Method for extracting proanthocyanidin from pine bark by taking water as solvent

InactiveCN101701013AReduce energy consumptionImprove extraction efficiencyOrganic chemistrySolventChemistry

The invention discloses a method for extracting proanthocyanidin from pine bark by taking water as solvent. The method takes the pine bark as raw material and water as extraction solvent, utilizes ultrasonic wave technology for enhanced extraction to obtain proanthocyanidin leach liquor, uses the membrane separation technology of microfiltration for removing impurities, ultrafiltration purification and nanofiltration concentration for processing to obtain concentrated proanthocyanidin liquid, and finally obtains the proanthocyanidin product by vacuum or freeze drying. The method only takes the water as the extraction solvent, and utilizes the ultrasonic wave extraction technology and the membrane separation technology, so as to lead the whole technical process to be operated under the low temperature condition, thus not only effectively improving the extraction yield of active ingredients and ensuring bioactive substances not to be damaged, but also being safe and environment-friendly in production and having no residual chemical solvent on the product. Therefore, the proanthocyanidin is a natural and green product in the true sense, and the production method is very environment-friendly.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

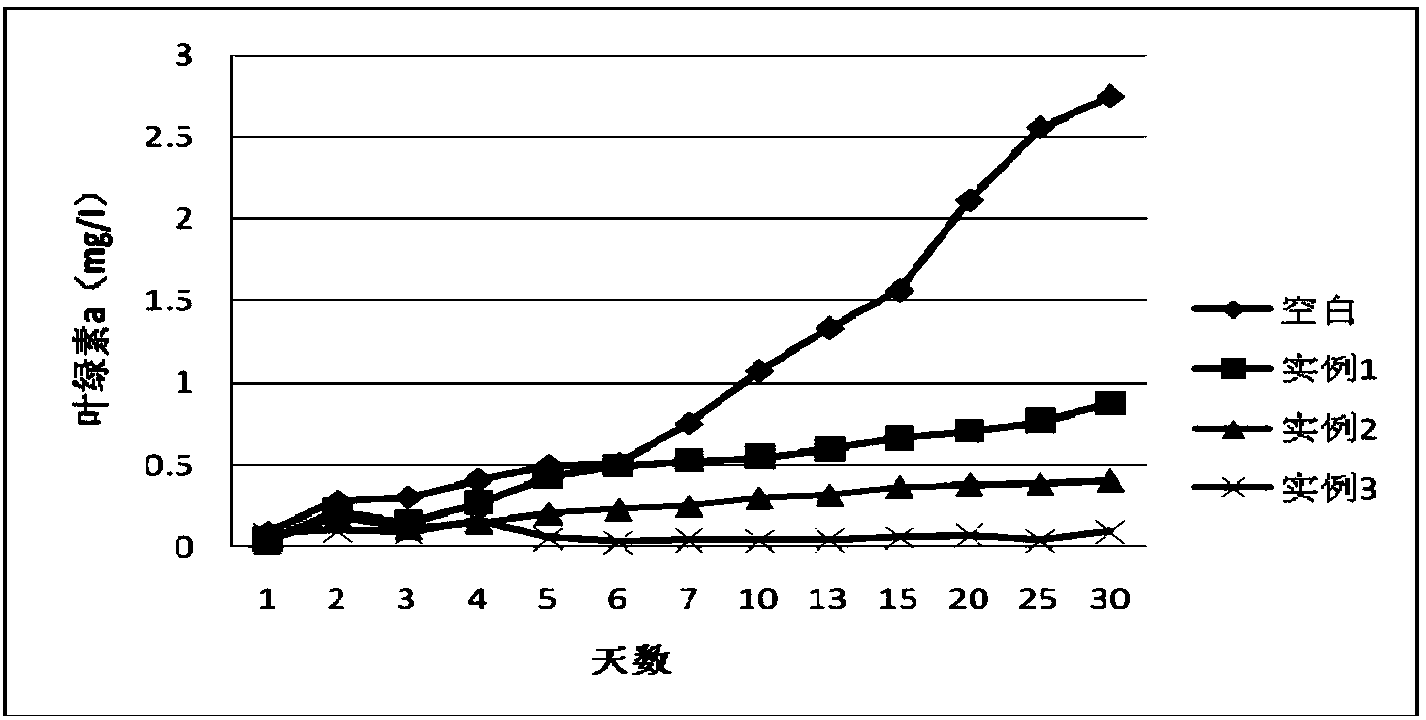

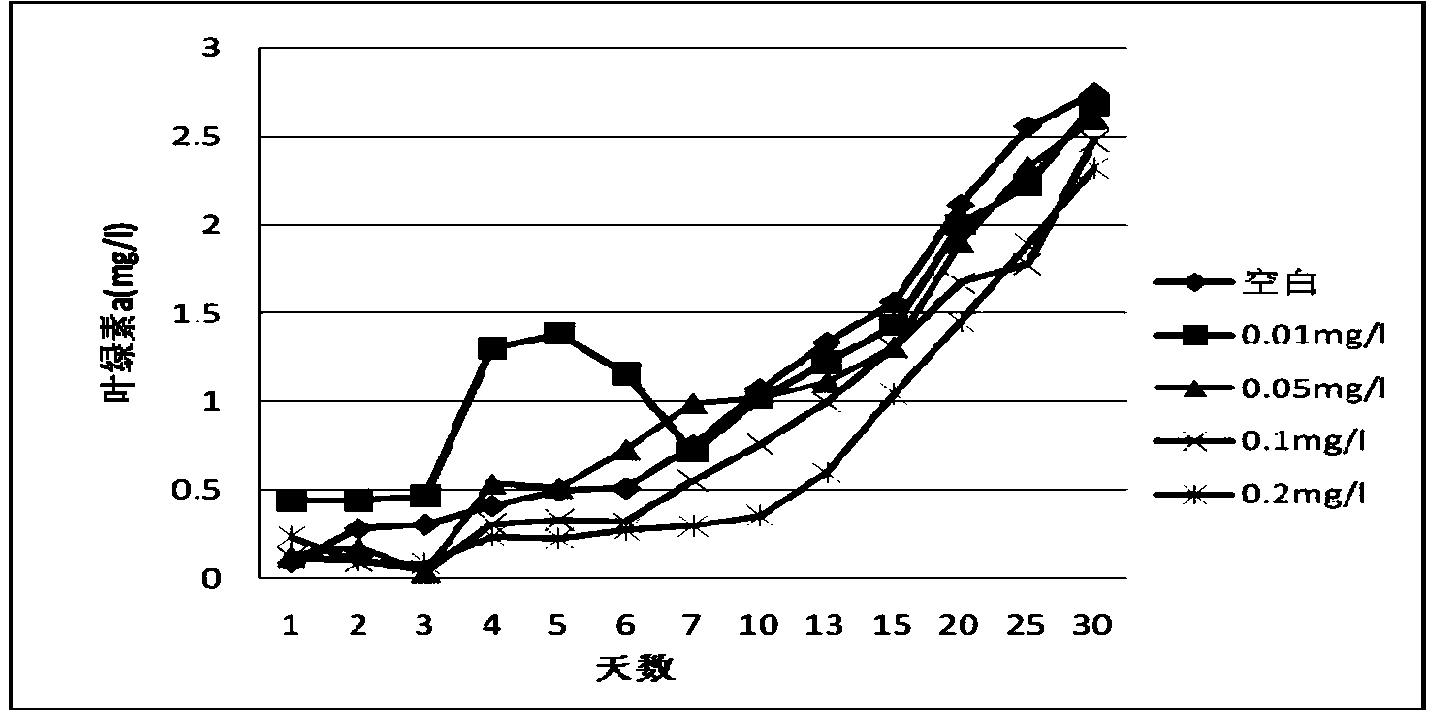

Method for preparing linoleic acid sustained-release algal inhibiting agent

InactiveCN103478125AReduce releaseGood biocompatibilityBiocideAnimal repellantsMicrosphereCross linker

A method for preparing a linoleic acid sustained-release algal inhibiting agent comprises the following steps that firstly, linoleic acid is dissolved through ethyl oleate, emulgator is added into the linoleic acid, and the emulsified linoleic acid is added into a solution of sodium alginate tech grade; secondly, the solution obtained in the first step is dropwise added into a glacial acetic acid solution containing chitosan and calcium chloride to form microspheres; thirdly, after the microspheres are cooled to the indoor temperature, a cross-linking agent is added into the cooled microspheres; fourthly, the process of suction filtration is carried out, and the microspheres to which the cross-linking agent is added are washed by petroleum ether and distilled water; fifthly, the linoleic acid sustained-release algal inhibiting agent is obtained after drying. Algal inhibition effective time is prolonged, the algal inhibition effect is improved, and cost is reduced. All adopted preparing materials are natural polymer materials which are non-toxic, good in biocompatibility and biodegradable, and the problems of secondary pollution caused by chemical algal removing and bio-concentration and biological amplification caused by chemical medicines can be effectively avoided.

Owner:HOHAI UNIV

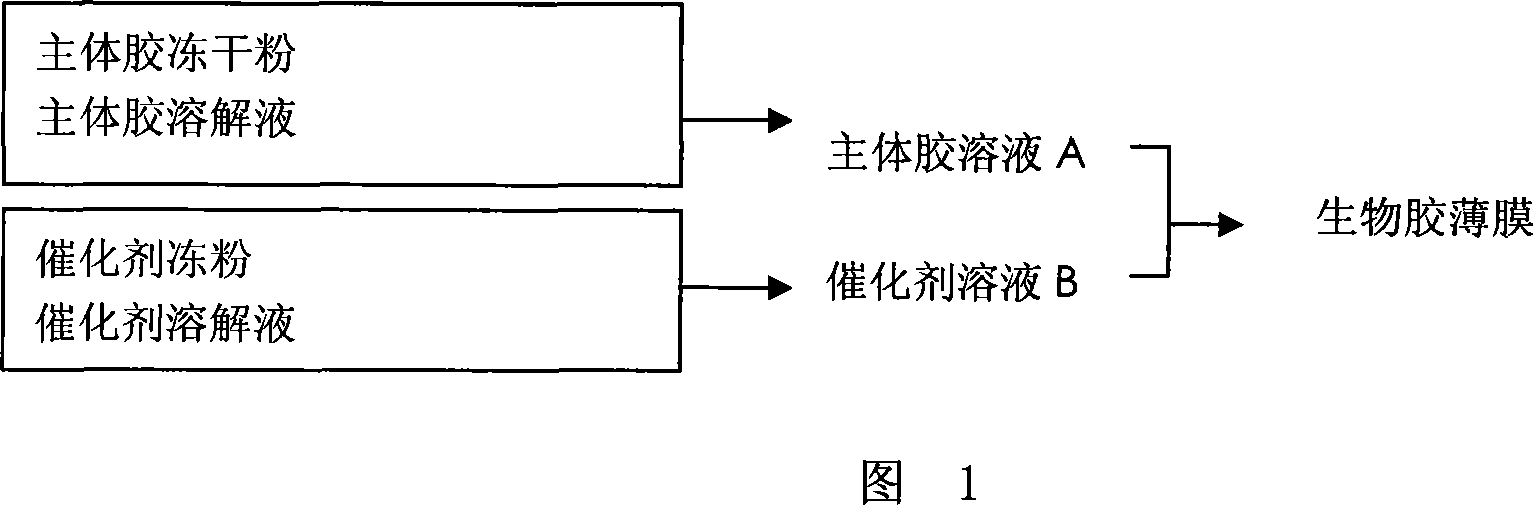

High-efficiency biogum sealant and uses thereof

ActiveCN101214391AReasonable compositionSimple preparation processSurgical adhesivesPharmaceutical containersSealantCardiothoracic surgery

The invention relates to a high-efficiency bio gel sealant and application thereof, which consists of main gel lyophilized powder, catalyst lyophilized powder, main gel cytolysate and catalyst cytolysate; during use, the main gel lyophilized powder is dissolved in the main gel cytolysate and the catalyst lyophilized powder is dissolved in the catalyst cytolysate, which are respectively absorbed in an aseptic injector of a double-cavity liquid pusher; the two solution are evenly mixed by the conehead of the double-cavity liquid pusher, and then sprayed on the wounds after surgery and bleeding, so as to form a semi-transparent ivory film; the invention also discloses a method of preparing all components of the high-efficiency bio gel sealant, including preparation of the main gel lyophilized powder, the catalyst lyophilized powder, etc. with pig blood as the raw material; the product of the invention is an absorbable bio gel combination which can be used immediately for blood stopping, sealing and adhesion of tissues, and is widely applicable in surgery fields, such as general surgery, orthopedics, cardiothoracic surgery, neurosurgery, obstetrics and gynaecology, etc.

Owner:GUANGZHOU BIOSEAL BIOTECH

Two-component solvent-free plant oil-based adhesive

ActiveCN105969293AImprove initial tack performanceHigh strengthMineral oil hydrocarbon copolymer adhesivesPolyureas/polyurethane adhesivesAdhesiveHeat resistance

The invention provides a two-component solvent-free plant oil-based adhesive, which comprises components A and B, wherein component A comprises modified plant oil, tackifying resin, a coupling agent, a filler, microencapsulated microspheres and a chain extender; component B comprises isocyanate or a mixture of isocyanate and modified plant oil. The two-component solvent-free plant oil-based adhesive with high comprehensive performance is safe in use, economical, moderate in curing speed, adjustable in hardness, high in initial cohesiveness, water resistance and heat resistance, strong in adhesive strength, wide in application range, green and environment-friendly.

Owner:福建省南平星源辉生物科技有限公司

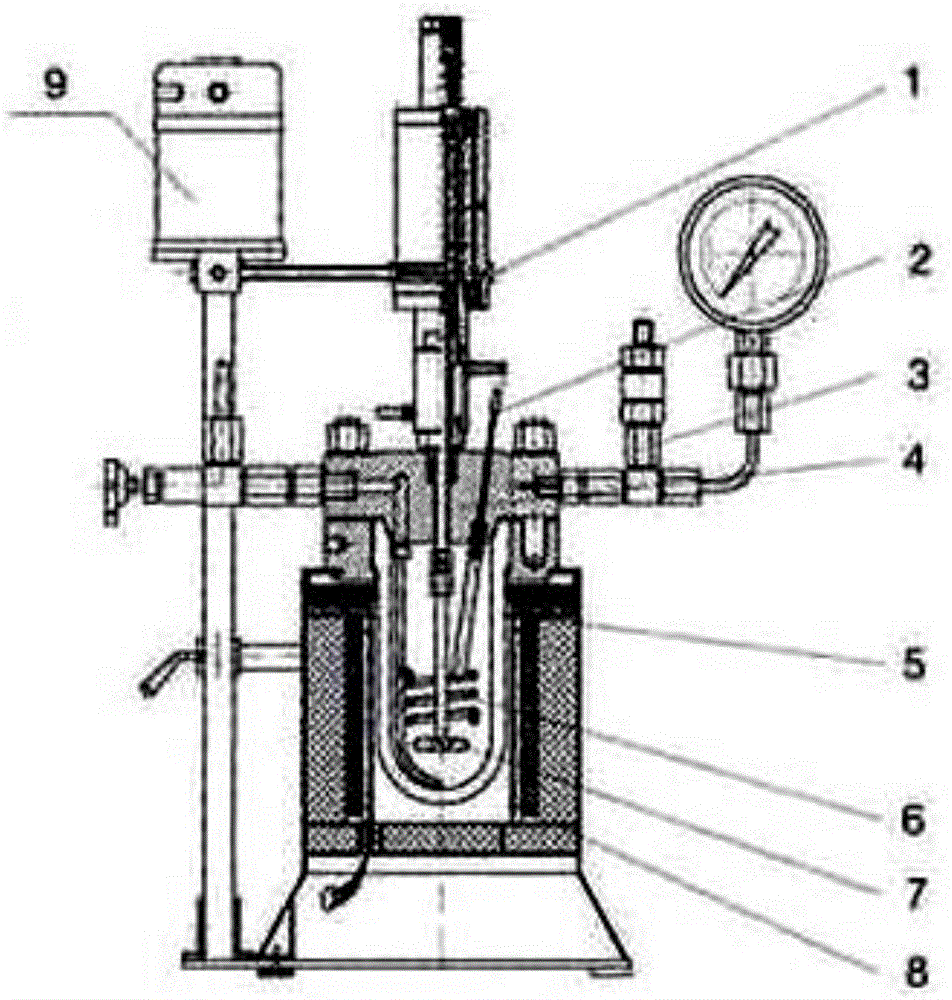

Liquid calcium/zinc heat stabilizer, preparing method thereof and device for implementing method

ActiveCN105111620AProduction safety and environmental protectionTakes a long timeCalcium hydroxideZinc hydroxide

The invention discloses a liquid calcium / zinc heat stabilizer. The liquid calcium / zinc heat stabilizer comprises, by weight, 10 parts to 15 parts of calcium oxide and / or calcium hydroxide, 10 parts to 20 parts of zinc oxide and / or zinc hydroxide, 30 parts to 40 parts of acid liquor, 1 part to 2 parts of azeotropic agents, 10 parts to 20 parts of saturated cycloparaffin solvents and 10 parts to 20 parts of heat-proof assistants. The invention further discloses a preparing method of the liquid calcium / zinc heat stabilizer and a device for implementing the method. According to the liquid calcium / zinc heat stabilizer, the product performance is stable, floccule can not be separated out during placing, the product is free of pungent smells, and the body of an operator can not be hurt. The preparing method of the liquid calcium / zinc heat stabilizer adopts a one-step method, the production technology is simplified, the unsafe factors in the production process are reduced, the production efficiency is improved, and the output rate is increased.

Owner:GUANGZHOU YINGSU NEW MATERIAL TECH CO LTD

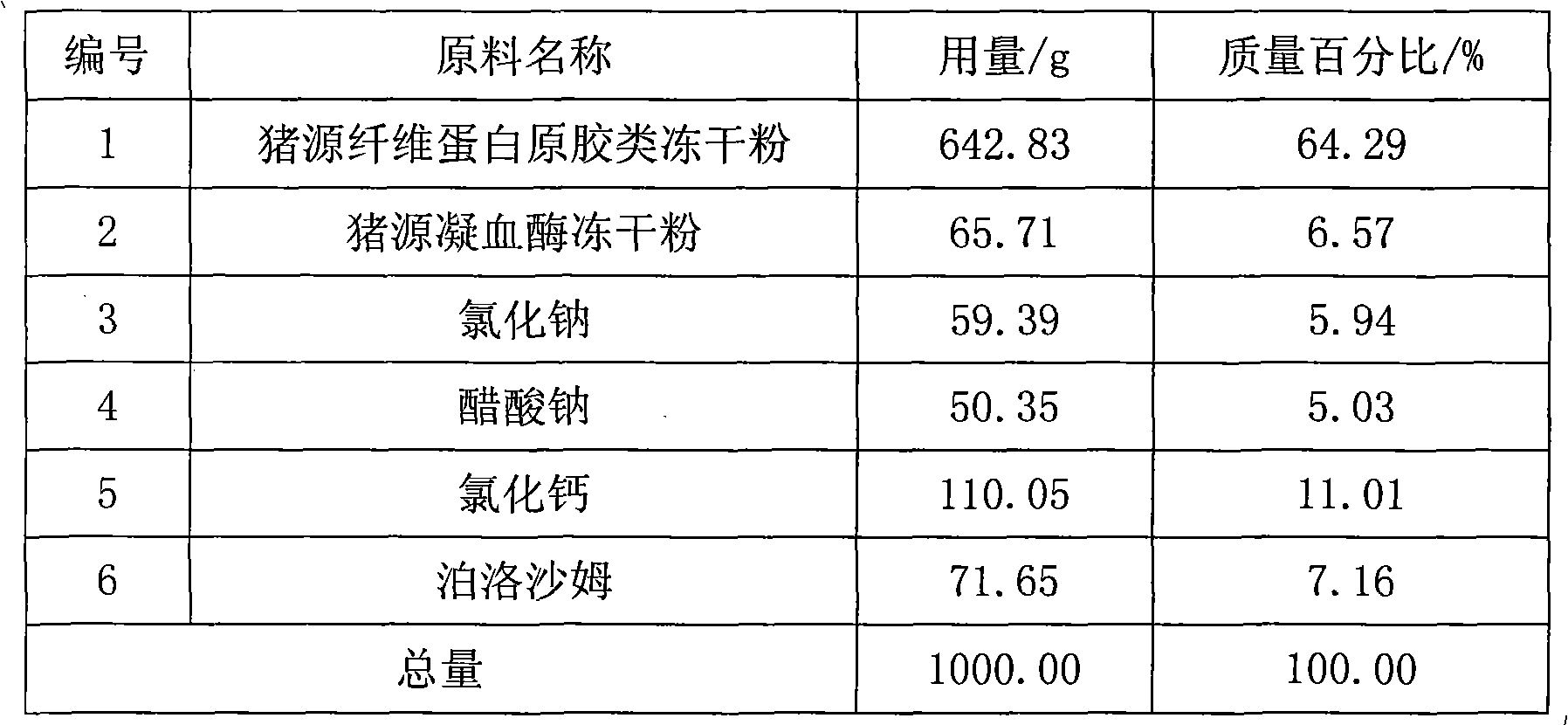

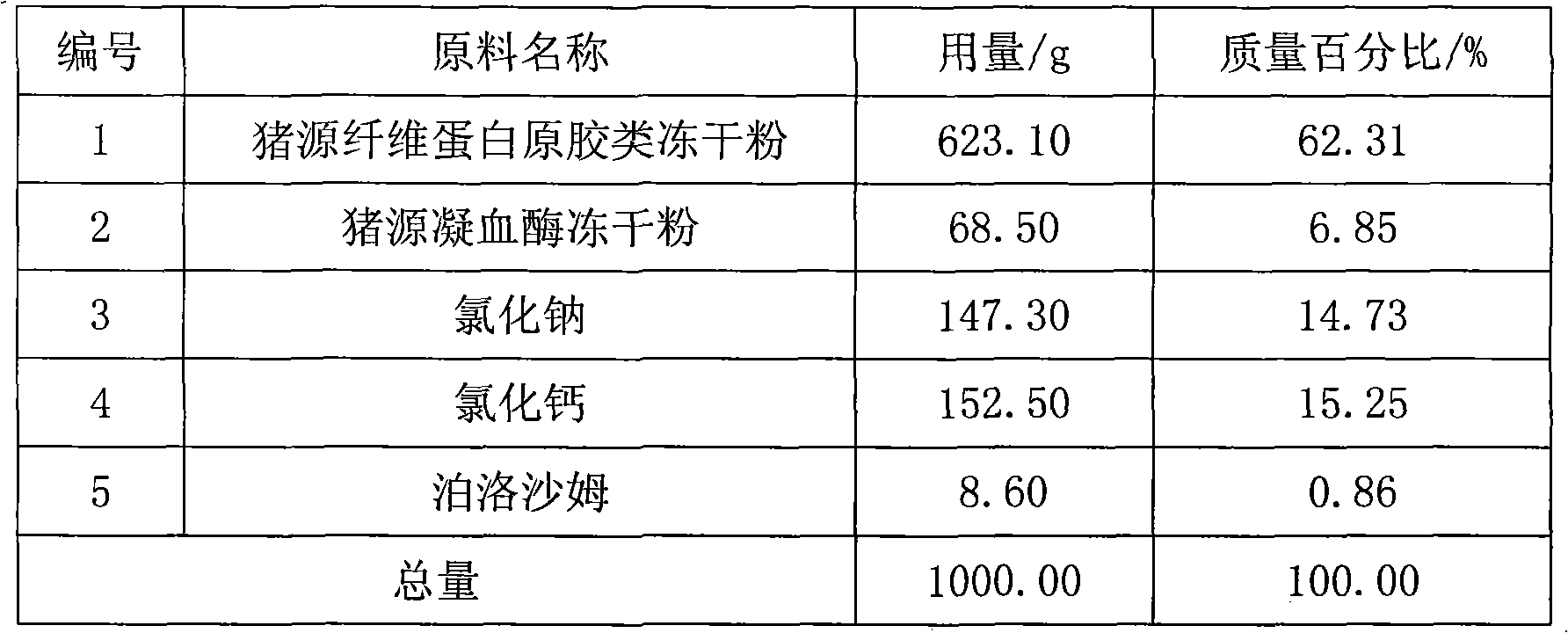

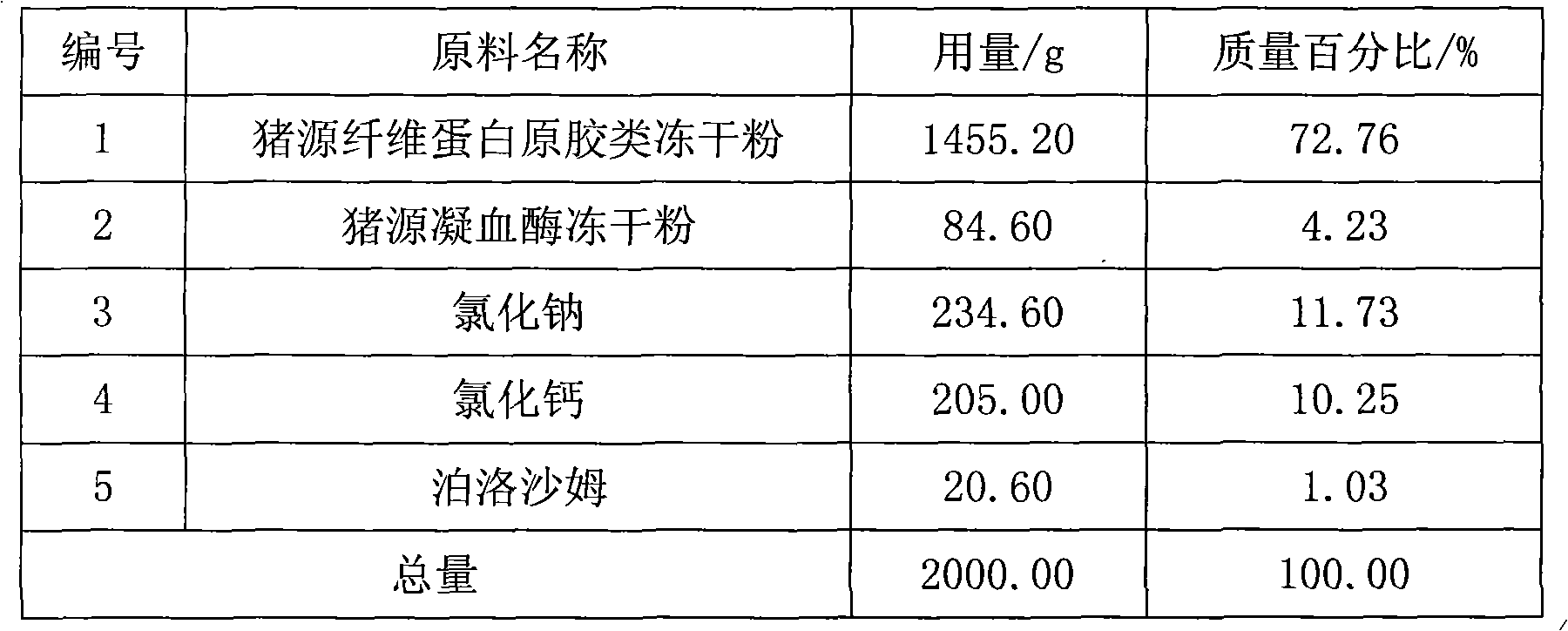

Swine fibrin glue powder inhalation and preparation method and application thereof

ActiveCN101890181AReasonable compositionSimple preparation processPeptide/protein ingredientsAerosol deliverySodium acetateFibrin glue

The invention relates to a swine fibrin glue powder inhalation and a preparation method and application thereof. The swine fibrin glue powder inhalation comprises swine fibrin original gum lyophilized powder, swine thrombin lyophilized powder, sodium chloride and / or sodium acetate, calcium chloride and / or tromethamine and a physiologically acceptable antistatic agent. The preparation method comprises the following steps of: grinding the components into powder with suitable particle size, then uniformly mixing the powder and filling the mixture. The product is stable and convenient to carry and store and can be directly used without preparation. The swine fibrin glue preparation is sprayed on a wound surface in a powder shape, saves time for operation and wound packing, brings great convenience, has a simple production process and is safe and environmentally-friendly.

Owner:GUANGZHOU BIOSEAL BIOTECH

Production technology of high purity yak serum albumin

InactiveCN105384791ASimple preparation processAvoid spreading opportunitiesPeptide preparation methodsSerum protein albuminFreeze dry

The invention discloses a production technology of high purity yak serum albumin. The production technology comprises the following steps: adding sodium citrate and sodium chloride into yak blood, separating plasma and erythrocyte, subjecting plasma to centrifugation, filtering and extraction, putting the plasma extract in an interlayer reaction pot, heating the pot, adding sodium caprylate, sodium chloride, and ethanol / methanol, slowing stirring, adding hydrochloric acid for twice to adjust the pH value, carrying out centrifugation, adding a precipitating reagent into the supernate, grinding the supernate into paste, stirring, freezing the paste for a night, carrying out centrifugation, collecting the precipitate, adding water to dissolve precipitate, adjusting the pH value by a sodium hydroxide solution, allowing the solution to stand still for a while, carrying out centrifugation, saving the supernate, filtering the supernate, inactivating the virus, and freeze-drying the supernate to obtain the finished product. The preparation technology is simple, the used materials are few, the technological procedure is short, the operation is easy, the product yield is high, the cost is low, and the product quality is good. The massive and automatic production can be easily realized. Moreover, the product is more reliable and safer.

Owner:QINGDAO ARCTIC YAK BIOLOGICAL TECH CO LTD

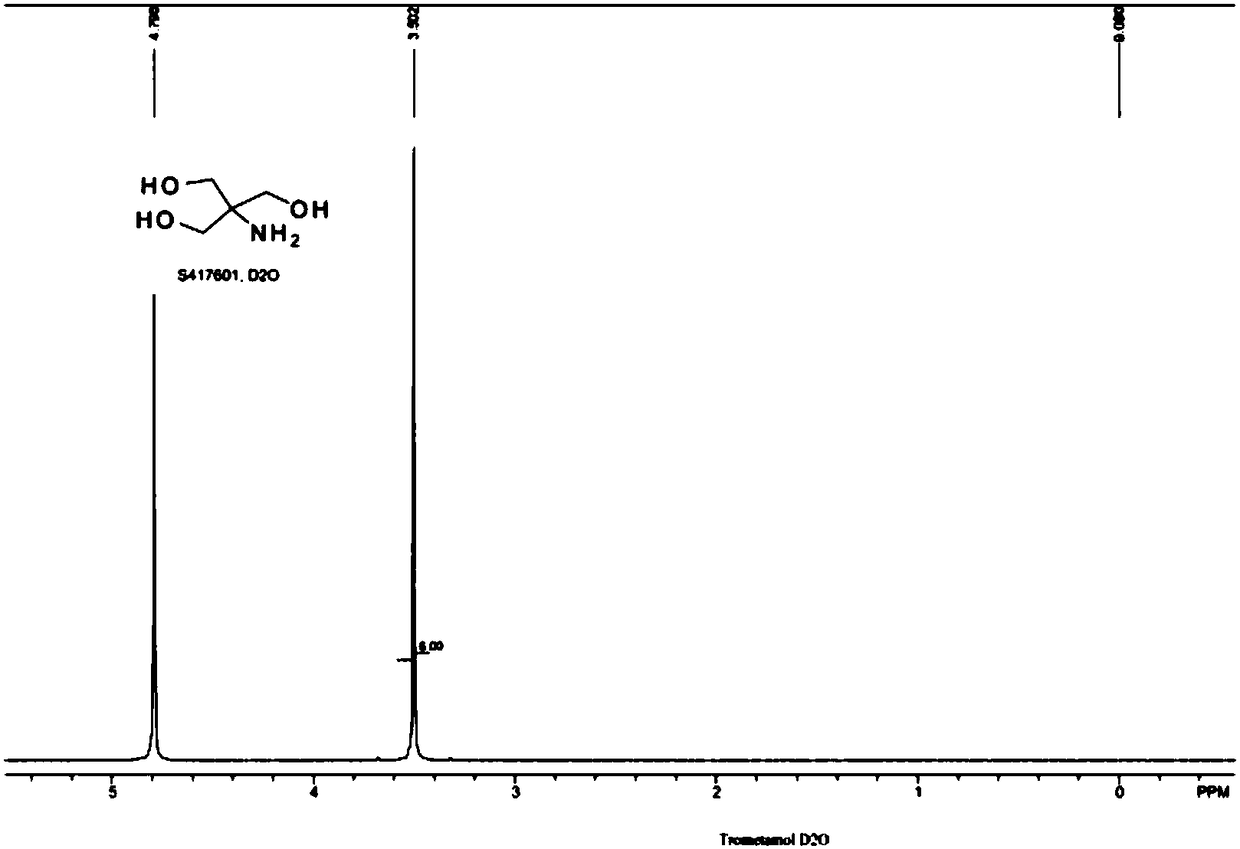

Tromethamine synthesis process

ActiveCN108299211AThe synthesis process is safe and environmentally friendlyLow costOrganic compound preparationAmino-hyroxy compound preparationCalcium hydroxideAlcohol

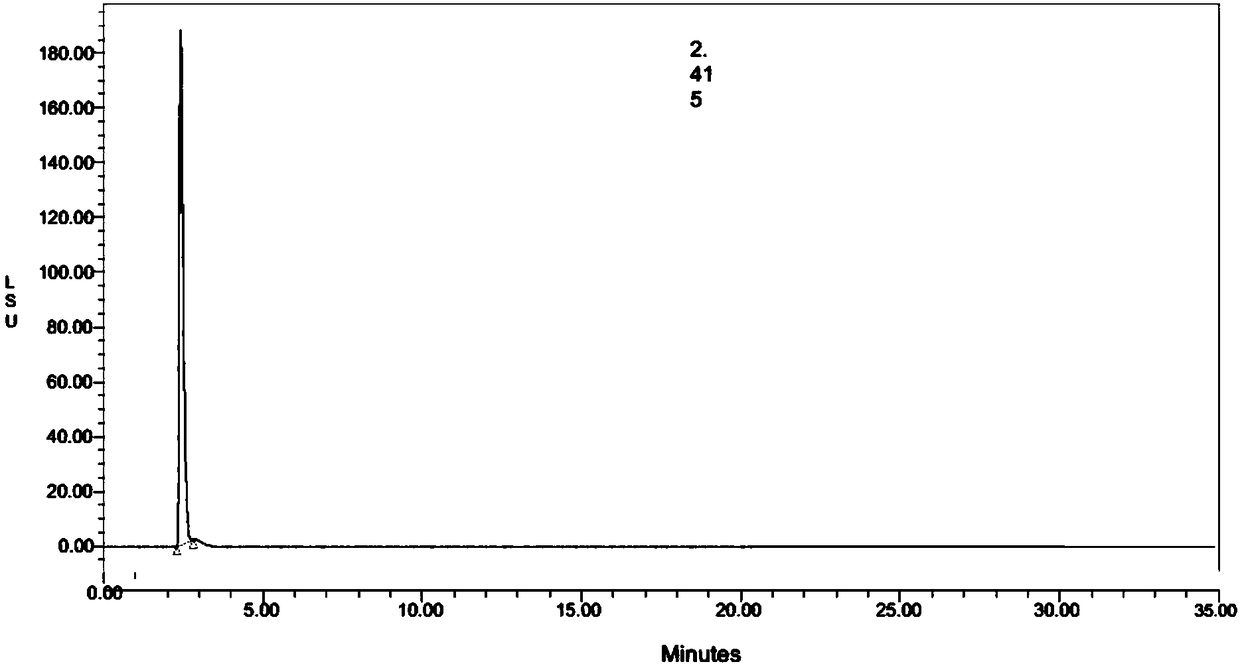

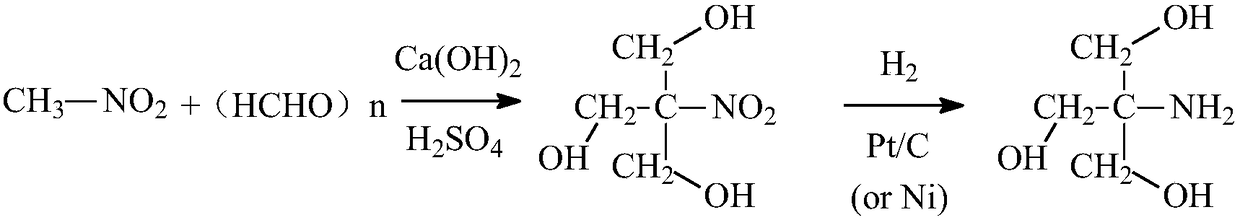

The invention discloses a tromethamine synthesis process. The tromethamine synthesis process comprises the following steps: step 1, synthesizing an intermediate: S11: pumping nitromethane into a vacuum metering tank for later use; S12: pumping methyl alcohol into a synthesis reaction kettle, adding paraformaldehyde while stirring, sealing the synthesis reaction kettle, stirring for more than 10 minutes, evenly dispersing the material; S12: raising the temperature to 35 DEG C, starting to add nitromethane and calcium hydroxide dropwise, controlling the temperature of the synthesis reaction kettle to 30-40 DEG C in the process of adding dropwise; S14: finishing adding dropwise, reacting at the temperature of 40 DEG C for 4.5-5 hours to obtain a mixed solution; S15: cooling the mixed solutionto the room temperature, adding sulfuric acid under the condition that the room temperature is controlled, regulating the pH of the mixed solution to 6-7; S16: filtering, enabling a filtrate to entera hydrogenation kettle; step 2, synthesizing a crude product; and step 3, refining the product. The tromethamine synthesis process has the advantages of safety, environmental protection, high productyield and the like, and is widely applied to the technical field of synthesis of tromethamine.

Owner:武汉本杰明医药股份有限公司

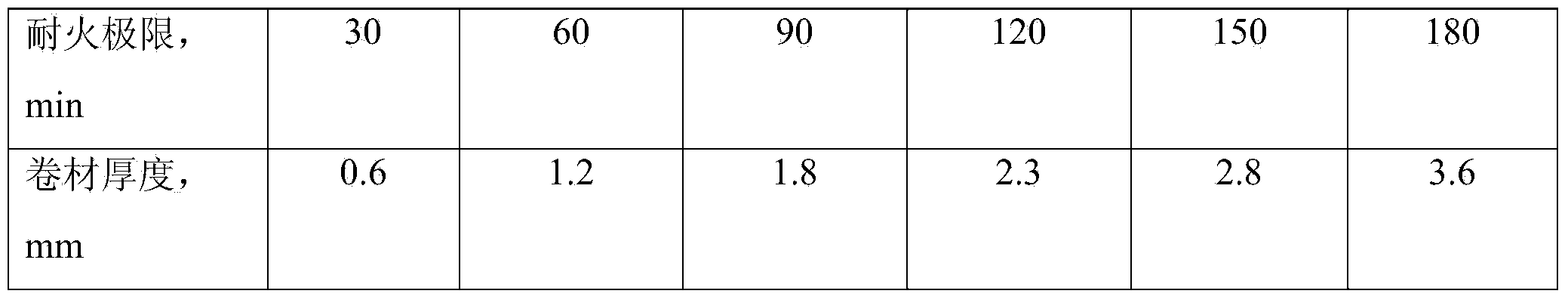

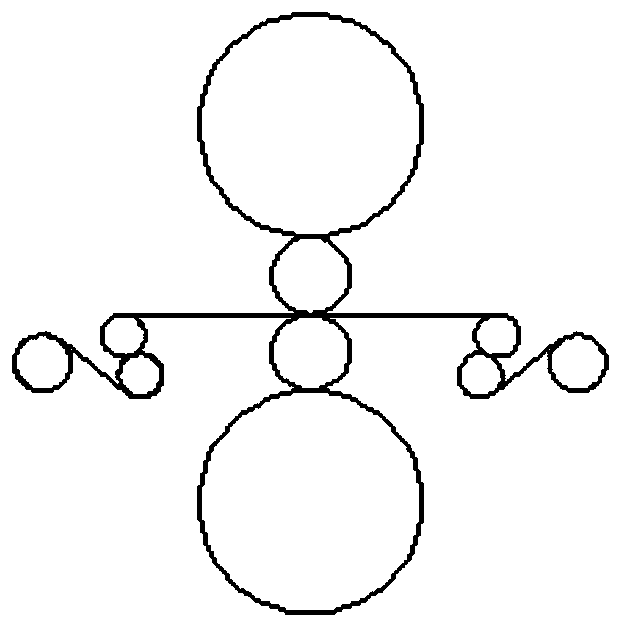

Steel structure fireproof coiled material with function layer and preparing method thereof

InactiveCN103953127AExcellent physical and chemical propertiesProduction safety and environmental protectionSynthetic resin layered productsFire proofingProduction lineWastewater

The invention relates to a steel structure fireproof coiled material with a function layer and a preparing method of the steel structure fireproof coiled material, and belongs to the field of fireproof materials. The fireproof coiled material consists of a fireproof layer and a function layer, wherein the fireproof layer consists of high molecular solid resin, expansion type fire retardants, dispersion auxiliary agents and enhancing auxiliary agents, the function layer is manufactured by additionally adding functional filling materials on the basis of the materials of the fireproof layer, and the two layers are respectively subjected to mixing, extrusion pelleting, casting tabletting, re-compounding casting and coiling into coiled materials. The steel structure fireproof coiled material can be continuously produced on a production line, the materials are processed into the coiled materials with the required thickness in one step, the production efficiency is high, the equipment is simple, the production process is safe and environment-friendly, industrial pollution such as waste water and waste gas do not exist, the fireproof coiled material can be used for producing sheet materials with different thickness according fireproof design requirements, and fireproof design requirements under different conditions can be met. The coiled material can be fast pasted on the surface of a steel structure in the use process, the fireproof design thickness can be realized through one-step pasting, the multi-time repeated brushing and coating is not needed, the work efficiency is high, the work procedures are simple, and the construction is environment-friendly and convenient.

Owner:天津宝宸恒远科技有限公司

Method for preparing low-iron polyaluminium sulfate by using aluminiferous waste sulfuric acid mother liquor

ActiveCN104773748ARaw materials are easy to getEasy to operateAluminium sulfatesPolymerizationWater treatment

The invention relates to a method for preparing low-iron polyaluminium sulfate by using an aluminiferous waste sulfuric acid mother liquor. The method includes the following steps: adding aluminiferous waste sulfuric acid mother liquid into a pretreatment reactor, adding a heavy metal capturing agent, and conducting filter pressing separation to obtain a reaction liquid I; mixing and reacting industrial sulfuric acid and calcium aluminate powder according to a certain proportion to obtain a reaction solution II; conducting an alkalization polymerization on the reaction liquid I and reaction liquid II under a certain temperature, adding a stabilizer, then continuing the polymerization reaction, conducting filter pressing separation and cooling to obtain a liquid low-iron polyaluminium sulfate product. The invention has the beneficial effects of easily available raw materials, simple process operation, safe and environment-friendly production, high production efficiency, extremely low content of insoluble matters in the product, extremely low iron content in the product, high added value, application to fine paper manufacturing, special requirements for water treatment, production of high-grade titanium dioxide and application as a high filler.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

Preparation method of slump retaining ether type polycarboxylic water reducing agent

The invention relates to a preparation method of a slump retaining ether type polycarboxylic water reducing agent. The method includes steps: (1) dissolving 80-100 parts of unsaturated polyether macromonomers into 60-85 parts of water, well stirring, and heating to 50-70 DEG C at a rate of 30-50 DEG C per hour to obtain a mixed solution; (2) keeping the temperature of the mixed solution at 50-70 DEG C, adding 0.5-1 part of an initiator, and well stirring to obtain a mixed solution; (3) keeping the temperature of the mixed solution at 50-70 DEG C while dropwise adding 15-30 parts of unsaturated carboxylic acid and unsaturated carboxylic acid derivative micromonomer solution and 20-30 parts of molecular weight regulator solution, keeping the temperature at 50-70 DEG C for 1-2h after adding is finished, and ageing to obtain a mixed solution; (4) adding 50-80 parts of water into the mixed solution, and dropwise adding sodium hydroxide solution to adjust a pH value to 6-7 to obtain the slump retaining ether type polycarboxylic water reducing agent.

Owner:厦门君科建材科技有限公司

Asynchronous cold rolling forming process of aluminum alloy stainless steel composite plate

ActiveCN110883093AIncrease rolling capacityImprove rolling precisionTemperature control deviceWork cooling devicesComposite plateLine heating

The invention discloses an asynchronous cold rolling forming process of an aluminum alloy stainless steel composite plate. The process comprises the following process steps: 1, rolling and compoundinga stainless steel plate and an aluminum alloy plate in an asynchronous rolling mode, and 2, after asynchronous rolling, diffusing and annealing the composite plate, specifically, in the step 1, online heating is carried out on the opposite surface of the composite plate surface of the stainless steel plate, online cooling is carried out on the opposite surface of the composite plate surface of the aluminum alloy plate online, and the heating temperature is 350 DEG C-850 DEG C; the temperature of the composite plate surface of the stainless steel plate from which the composite plate is rolledis lower than 650 DEG C, and the temperature of the composite plate surface of the aluminum alloy plate from which the composite plate is rolled is lower than 300 DEG C; the rolling reduction rate is20%-90%; the different speed ratio of a roller for asynchronous cold rolling is 1.05-1.50; the thickness ratio of the aluminum alloy plate to the stainless steel plate is 1.5-4.0; and in the step 2, the annealing temperature is 250 DEG C-500 DEG C and the annealing time is 15-120 min. The single-side online heating process for rolling the composite plate is creatively provided so as to improve theinterface bonding strength of the composite plate and realize rolling compounding in an interface semi-melting state.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

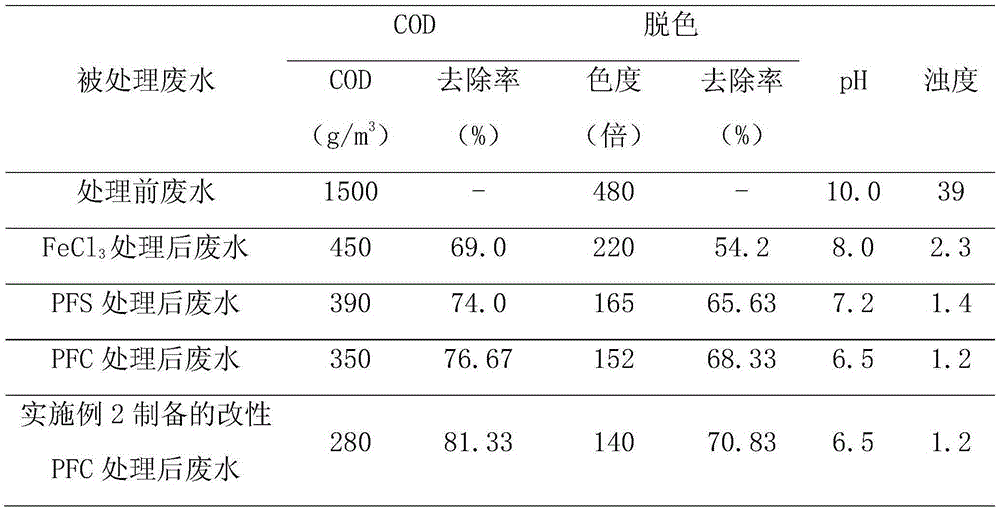

Preparation method of modified poly(iron chloride)

InactiveCN105236544ASolve pollutionRaw materials are easy to getWater/sewage treatment by flocculation/precipitationChemical oxygen demandPhosphate

The invention relates to a preparation method of modified poly(iron chloride). The preparation method is characterized by comprising the following steps: adding iron-containing waste hydrochloric acid and phosphate into a reactor, stirring, adding an oxidizing agent to carry out oxidation polymerization reactions for half hour, then adding a stabilizing retarder, and carrying on reactions for another half hour to obtain the modified poly(iron chloride) coagulant. The preparation method has the advantages that the resources are recycled, the raw materials are easily-available, the operation is simple, the production is safe and environment-friendly, the coagulation performance is excellent, and the modified poly(iron chloride) coagulant can be widely applied to sewage treatment, effectively remove soluble phosphor and phosphor in other forms in water, and reduce the chemical oxygen demand (COD) and chroma.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

Method for extracting puerarin

InactiveCN103204848ANo pollution in the processAvoid pollutionOrganic chemistryBulk chemical productionParticulatesLobata

The invention relates to a field of puerarin, and relates to a method for extracting puerarin. Specifically, an extraction and separation method is provided, wherein a carbon dioxide fluid under a supercritical state is adopted as an extracting agent, and an effective substance puerarin is extracted from pueraria lobata. The method is characterized in that: a raw material pueraria lobata is subjected to a drying treatment, and is crushed, wherein useful parts of the raw material pueraria lobata is crushed to pieces or particles with diameters of 0.5-2mm; supercritical carbon dioxide extraction is carried out; and primary and secondary reduced-pressure separations are carried out upon the carbon dioxide rich in the target extract substance. An obtained effective substance is puerarin with purity higher than 99%. According to the invention, separation and extraction are integrated, high-temperature heating is not needed, the entire process is controlled by using an automatic device, operation is convenient, process flow is greatly simplified, energy consumption and labor cost are saved, extraction and separation process is carried out in a full closed cycle, no environment pollution is caused, and the production is safe and environment-friendndly.

Owner:湖北万松堂大健康医药集团有限公司

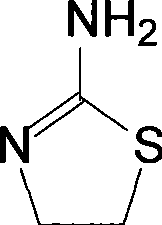

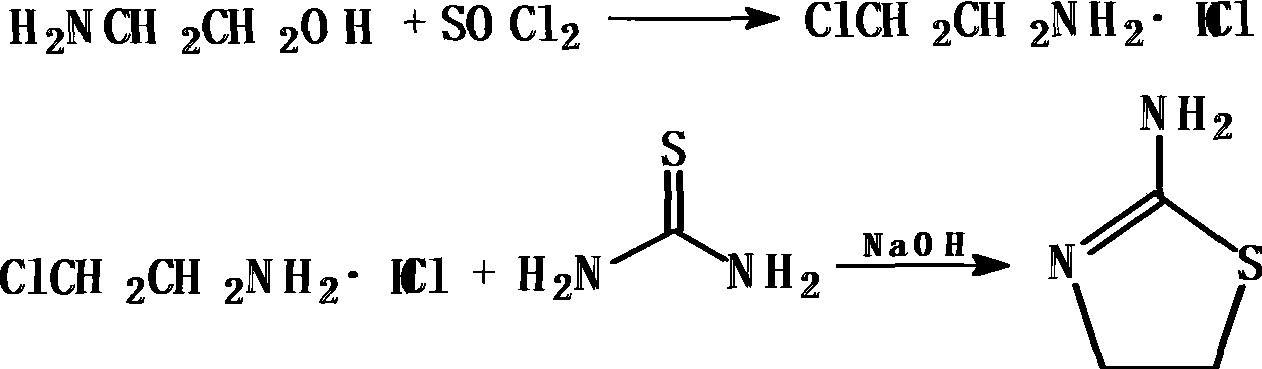

Method for synthesizing 2-amino thizaoline

ActiveCN101417985AFew reaction stepsAdvanced process routeOrganic chemistry2-aminothiazolineOrganic solvent

The invention relates to a method for synthesizing 2-aminothiazoline, which comprises the following steps: firstly, performing chlorinated reaction between ethanolamine and thionyl chloride in an organic solvent to generate 2-chloro-ethylamine hydrochloride; and secondly, performing cyclization reaction between the 2-chloro-ethylamine hydrochloride and thiourea to generate the 2-aminothiazoline. Compared with the prior art, the method does not need introduce hydrogen chloride gas and concentrated hydrochloric acid to synthesize ethanolamine hydrochloride, thereby reducing reaction reagents and the reaction steps; besides, the process route is more advanced, environment-friendly and safer, and the cyclization yield reaches more than 70 percent.

Owner:山西新天源药业有限公司

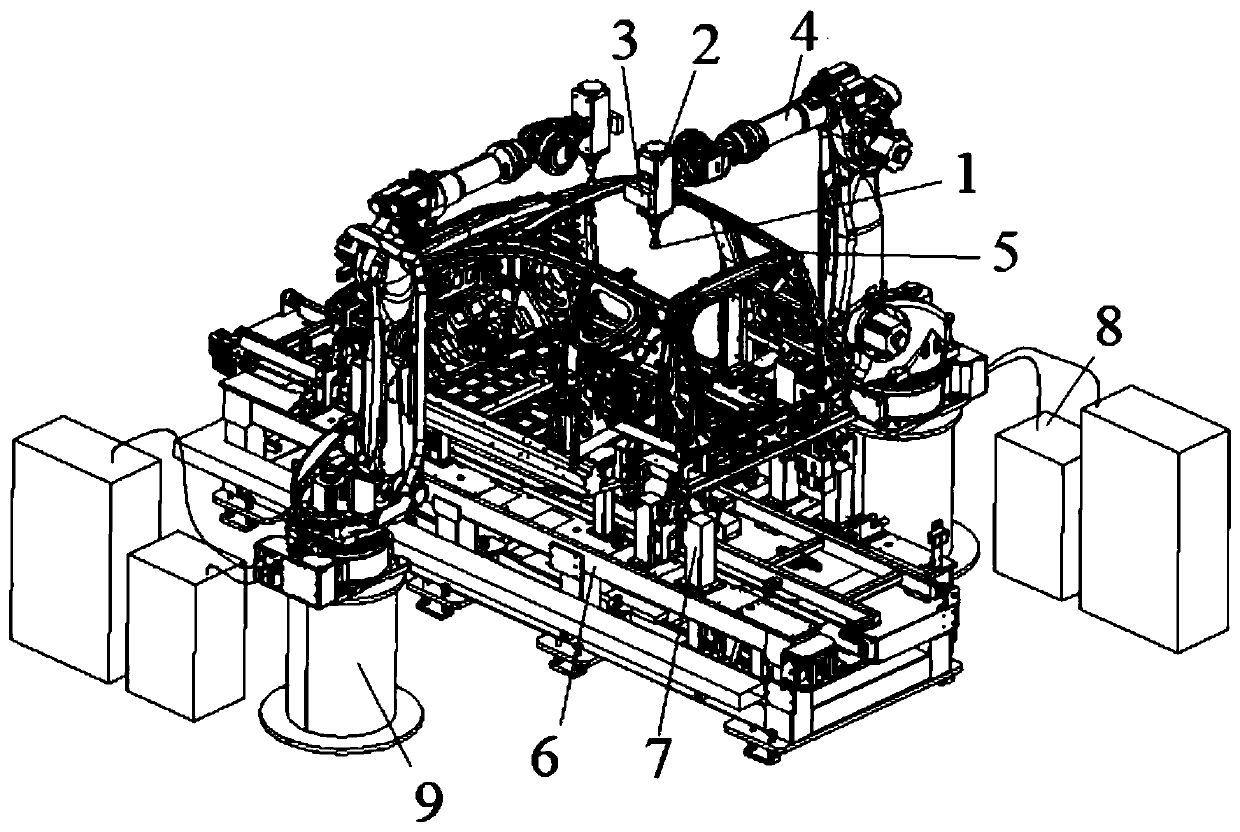

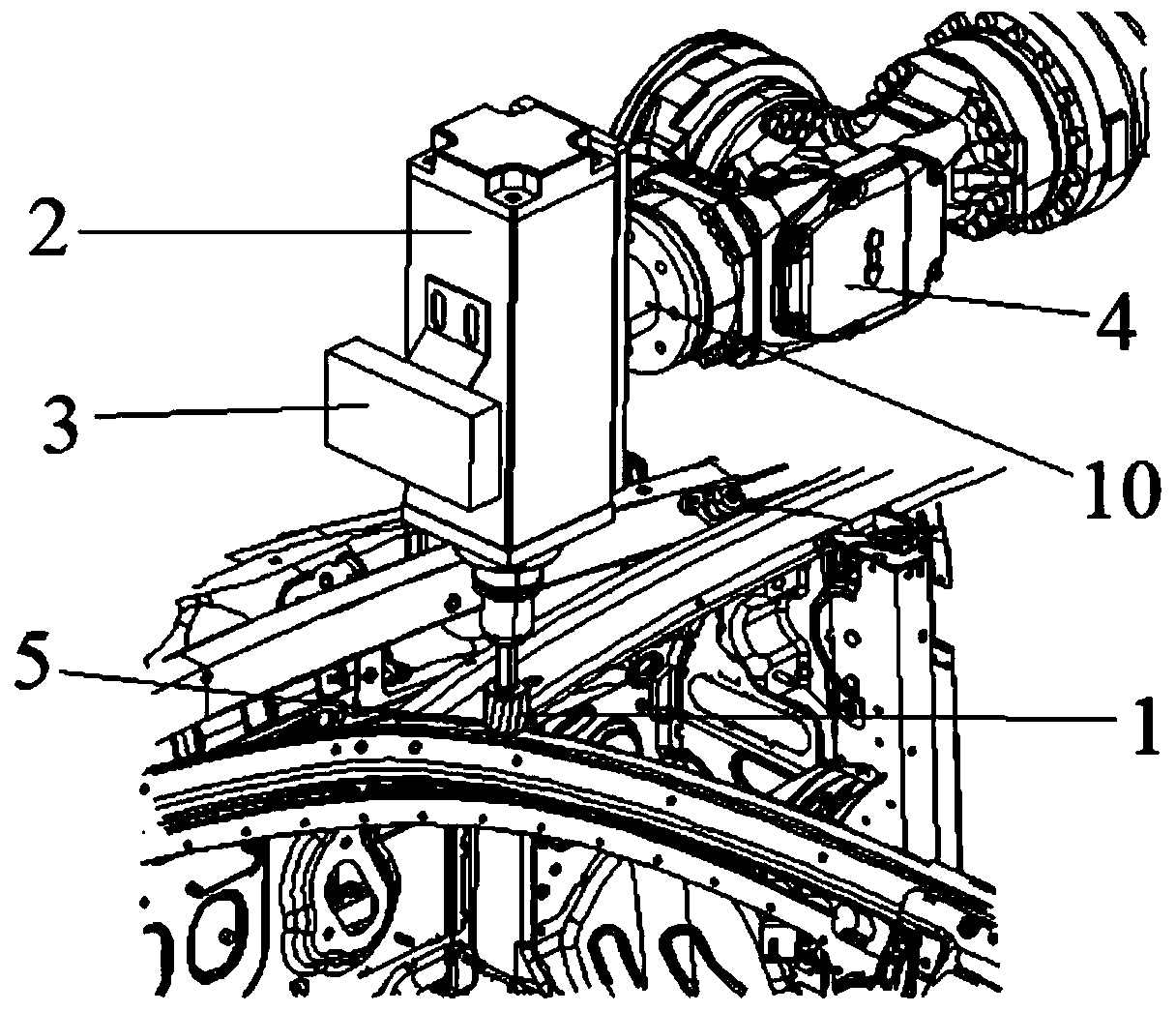

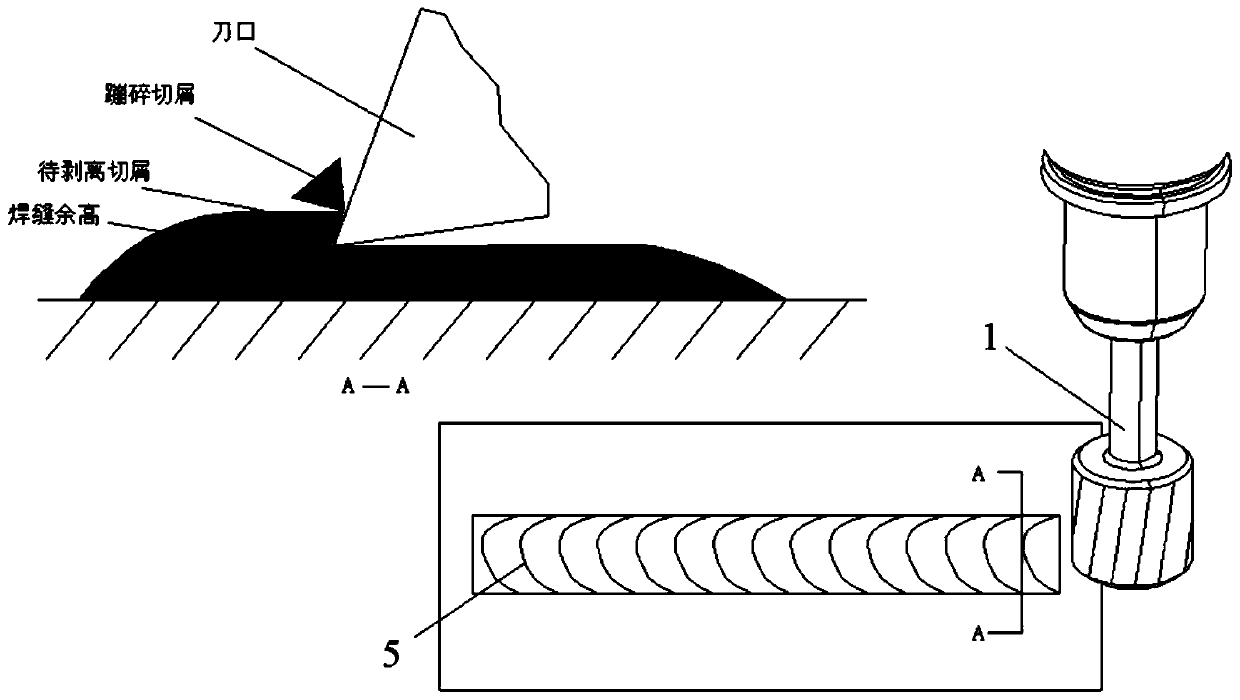

Self-adaption machining system and control method thereof and car body machining equipment

ActiveCN110560754AMeet assembly requirementsHigh accuracy consistencyMilling machinesMilling equipment detailsData controlControl engineering

The invention discloses a self-adaption machining system and a control method thereof and car body machining equipment. The self-adaption machining system is used for machining a workpiece and comprises an executing system, a motorized spindle, a milling tool head, a visual detecting device and a control device. The executing mechanism is in transmission connection with the motorized spindle and drives the motorized spindle to move. The motorized spindle drives the milling tool head to move. The executing mechanism and the motorized spindle are in communication connection with the control device, and the control device comprises a memorizer storing preliminary machining data and waste parameters of the workpiece. The control device carries out operation to obtain intermediate parameters, machining data is further obtained, the control device adjusts a first work parameter and a second work parameter according to post machining data and the waste parameters to control the motion of theexecuting mechanism and the motorized spindle correspondingly, and therefore it is guaranteed that the milling parameters of the milling tool head meet the requirement of the waste parameters. The self-adaption machining system and the control method thereof and the car body machining equipment have the advantages that the automation degree is high, production is safe and environment-friendly, theproduction and labor cost is greatly reduced, and the precision consistency is high.

Owner:奇瑞新能源汽车股份有限公司

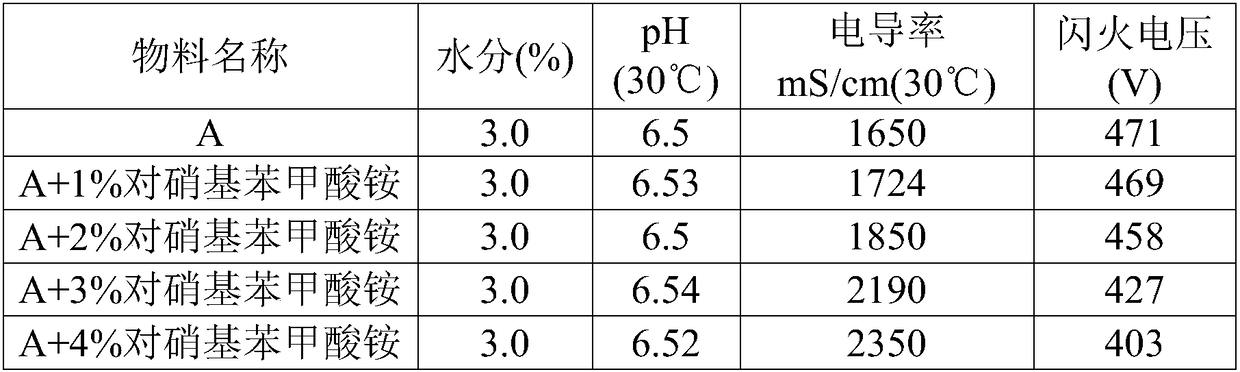

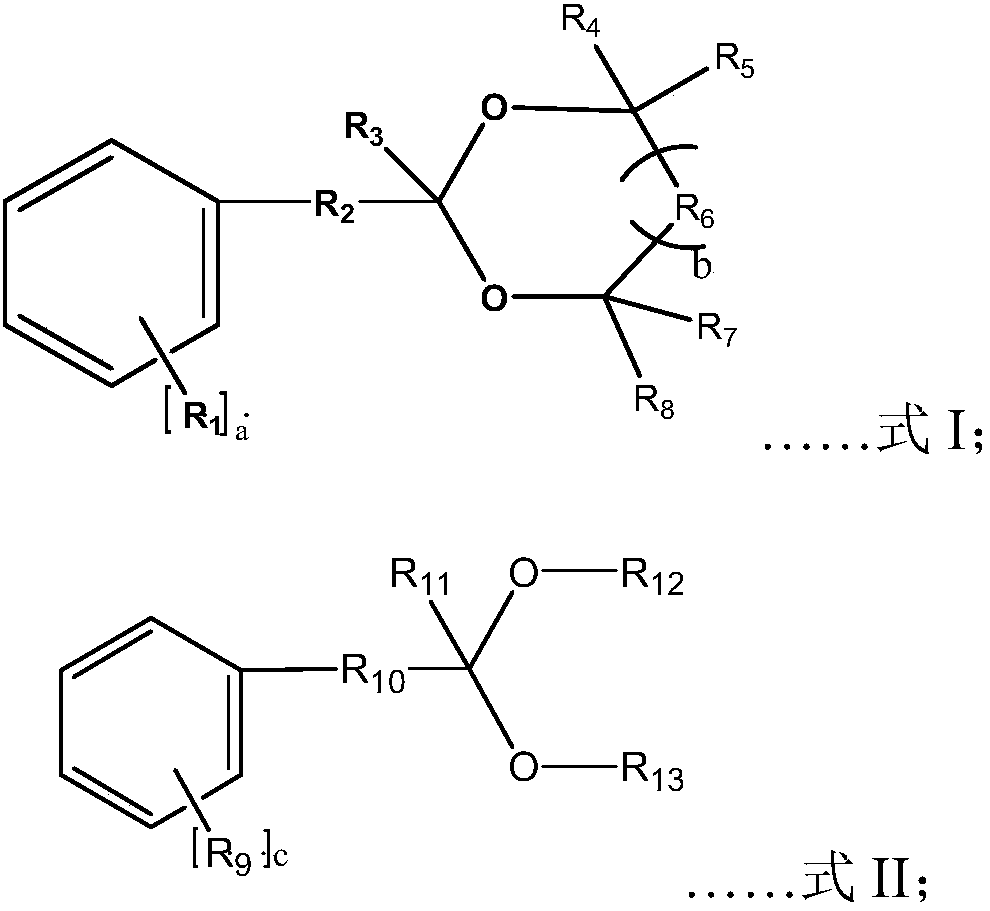

Hydrogen eliminating agent, preparation method thereof, and aluminum electrolytic capacitor electrolyte

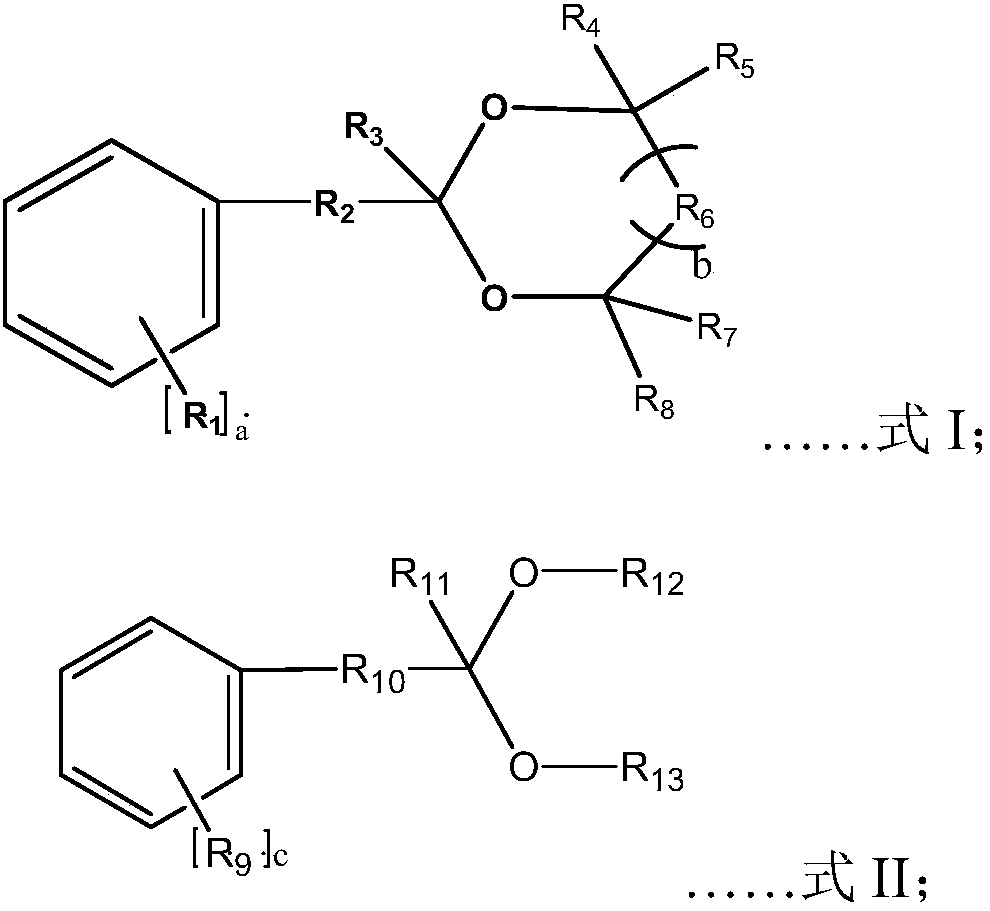

ActiveCN109390156AExcellent hydrogen elimination effectHydrogen elimination effect is obviousOrganic chemistryLiquid electrolytic capacitorsSolubilityCompound a

In order to solve problems that the dissolving performance of the current hydrogen eliminating agent for an aluminum electrolytic capacitor is poor and flash fire voltage will be affected, the invention provides a hydrogen eliminating agent. The structural formula of the hydrogen eliminating agent comprises at least one kind of a compound A shown in the formula I and a compound B shown in the formula II. The solubility of the hydrogen eliminating agent in the aluminum electrolytic capacitor electrolyte reaches 7% or more. When the additive amount of the electrolyte reaches 7%, the hydrogen eliminating agent will not be separated out from the electrolyte and other components in the electrolytic will not be separated out. By adding the hydrogen eliminating agent in the electrolyte, the conductivity and flash fire voltage of the electrolyte will not be affected at all; the gas production quantity is small; and electrolyte shows good hydrogen elimination performance.

Owner:HUIZHOU CAPCHEM CHEM CO LTD

Preparation method of chlorphenesin carbamate

InactiveCN101624354AGood for healthReduce arsenic levelsCarbamic acid derivatives preparationOrganic compound preparationChlorphenesin carbamateEthyl acetate

The invention relates to a preparation method of chlorphenesin carbamate, which comprises the following steps: heating chlorphenesin and reacting the chlorphenesin with diethyl carbonate under the action of less ester exchange catalyst; adding tertiary butanol and dimethyl formamide to be used as mixed solvent after the reaction is finished, reacting the mixture with ammonia water to prepare a target object, filtering, and washing by using pure water containing less ammonia; and refining by using ethanol containing less ammonia and ethyl acetate as mixed solvent to obtain the chlorphenesin carbamate of raw material medicine. The used solvents have lower toxicity and hazard, the refining method is special and comprises the steps of washing by the pure water containing less ammonia to remove most of impurities and refining by taking ethanol with less ammonia and the ethyl acetate as the mixture, thereby leading the product not to nearly contain toxic and hazardous organic solvent and optimizing the production environment.

Owner:朱岩安

Comprehensive treatment method for harmless recycling of pickling sludge and pickling waste liquid

The invention discloses a comprehensive treatment method for harmless recycling of pickling sludge and pickling waste liquid. The comprehensive treatment method comprises the following steps: (1) mixing the pickling sludge with the pickling waste liquid, and successively carrying out a reaction and filtering so as to obtain a filter cake and a filtrate; (2) adding waste scrap iron into the filtrate, and then carrying out filtering; (3) adding waste iron scraps to a filtrate obtained in the step 2, and successively carrying out a reaction and filtering; (4) adjusting the pH value of a filtrateobtained in the step 3, adding an auxiliary agent, successively carrying out stirring, standing and filtering, and measuring the total Fe concentration of the obtained filtrate; (5) adding water intothe filtrate for dilution so as to obtain a solution I, adjusting the pH value of the solution I, adding an oxidant for oxidation, controlling a pH value and a ratio of Fe<3+> to Fe<2+> in a system, preparing iron black or iron yellow, successively carrying out filtering, drying and grinding so as to obtain iron black or iron yellow powder, and calcining the powder to obtain iron oxide red. A solid obtained in the step (1) is used as a building material, and liquid and solids obtained in the rest steps can be used in the corresponding steps of next treatment. The comprehensive treatment methodof the invention solves technical problems in the treatment of the pickling sludge and the pickling waste liquid, and high economic return is obtained through preparation of the medium-grade and high-grade iron oxide.

Owner:德沃科技(天津)有限责任公司

Efficient zinc-rich coating added with aluminum powder and rare earth element and preparation method thereof

InactiveCN103013254AGood physical and mechanical propertiesExcellent corrosion performanceAnti-corrosive paintsRare-earth elementAcrylic resin

An efficient zinc-rich coating added with aluminum powder and a rare earth element is prepared from a dry film and a volatile solvent, wherein the dry film comprises the following components by mass percent: 91-95% of zinc powder, 1-5% of aluminum powder, 0.15-0.62% of rare earth powder, 2.0-6.6% of resin and 1.0-1.42% of auxiliary agent; and the volatile solvent is 10-30% of the total weight of the dry film. The invention further provides a preparation method of the efficient zinc-rich coating. The total content of zinc, aluminum and rare earth in the dry film is above 96% and the zinc content is 91%, so that physical and mechanical properties are excellent, corrosion performance is excellent, and no red rust exists within 4500 hours in a neutral salt spray test; acrylic resin and amino resin is taken as a resin solvent system and butyl acetate is taken as a diluent, so that the efficient zinc-rich coating is very low in toxicity and small in pollution, does not contain benzene, methylbenzene, dimethylbenzene and other undesirable components, and is safe and environment-friendly in production and use; and a product preparing process is simple and easy to operate, easy to implement and promote and wide in application prospect.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Resource recycling method of iron-containing waste sulfuric acid solution

InactiveCN108101121AIncrease profitEasy to storeSulfur-trioxide/sulfuric-acidIron sulfatesIron saltsDisinfectant

The invention discloses a resource recycling method of an iron-containing waste sulfuric acid solution. The method comprises steps as follows: the iron-containing waste sulfuric acid solution is addedto a pretreatment reaction kettle, iron powder and a heavy metal trapping agent are added to the pretreatment reaction kettle for a mixing and stirring reaction, filtration is performed and a reaction liquid is obtained; the reaction liquid is lifted to a crystalizing reaction kettle, industrial sulfuric acid is added to the crystalizing reaction kettle in a certain proportion during cooling, themixture is mixed and stirred, reactive crystallization and filtration are performed, and two products, namely, high-purity ferrous sulfate crystals (solids) and a diluted sulfuric acid solution, areobtained. The method has the benefits as follows: two products, namely, the high-purity ferrous sulfate crystals (solids) and the diluted sulfuric acid solution, are obtained from the iron-containingwaste sulfuric acid solution; the process operation is simple, production is safe and environmentally friendly, the sulfuric acid utilization rate is high, no waste liquids are discharged, and the economic benefits are good. Obtained ferrous sulfate is convenient to store and transport, has very low content of heavy metals, is high in additional value and is used for preparing iron salt, iron oxide pigments, mordants, water purifiers, preservatives, disinfectants and the like.

Owner:大拇指环保设备(天津)有限公司

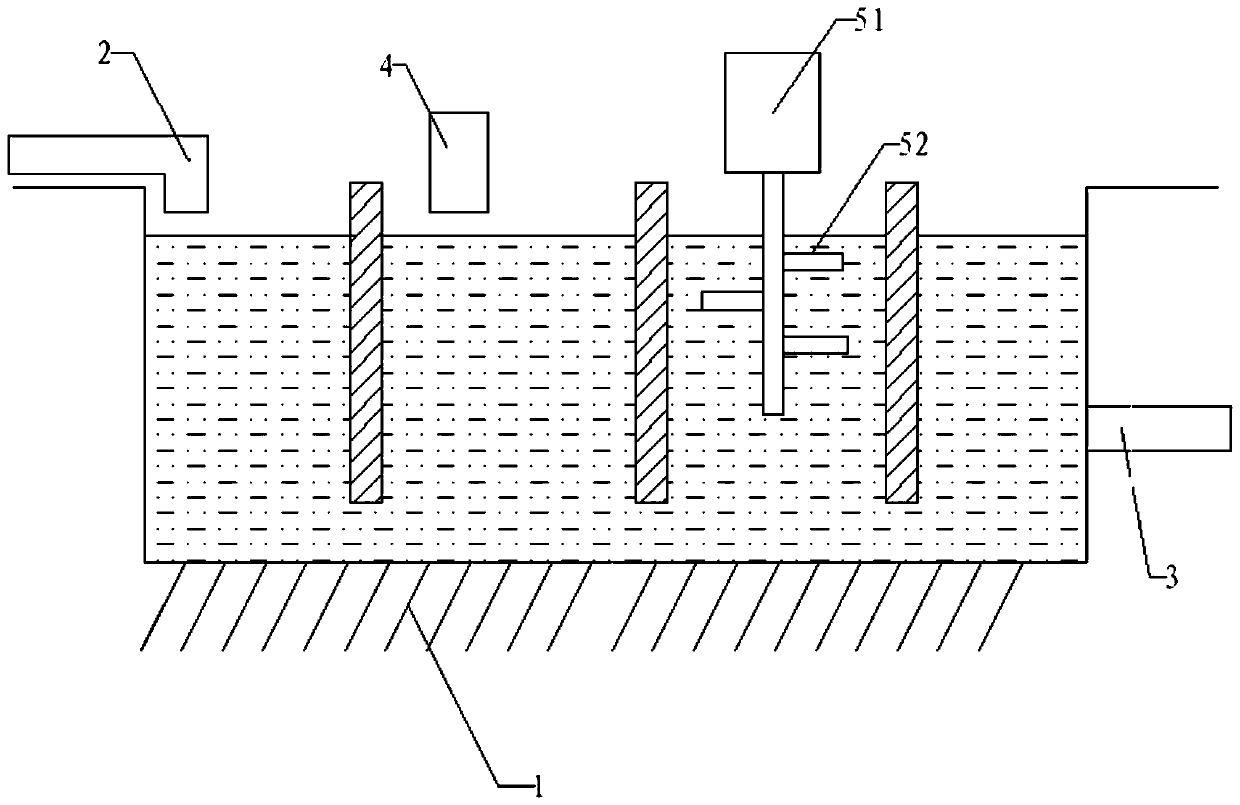

Acid-base neutralization tank

InactiveCN110697860ASmall footprintGood value for moneyWater/sewage treatment by neutralisationAlkaline waterAcid water

The invention discloses an acid-base neutralization tank, comprising a pool, wherein the pool is divided into a plurality of communicating cavities by a plurality of partition plates; an acid water inlet is formed in the pool; a water outlet is also formed in the pool; an alkaline water inlet is formed between the acid water inlet and the water outlet; and a pH detector is formed between the alkaline water inlet and the water outlet. The acid-base neutralization tank with a novel structure is small in occupied area, can be reproduced in each factory, has high cost performance, long service life and low price; and treated water is neutral and can be recycled, so persulfate production is environment-friendlier and safer.

Owner:邳州华创新能源电池研究院有限公司

Lactobacillus casei for producing gamma-glutamyl transpeptidase in high yield and application of lactobacillus casei in production of L-theanine

ActiveCN111073830AHigh yieldHigh purityBacteriaMicroorganism based processesBiotechnologyIon exchange

The invention relates to lactobacillus casei TH139 for producing gamma-glutamyl transpeptidase in a high yield. The lactobacillus casei TH139 is preserved in China General Microbiological Culture Collection Center, and the preservation number is CGMCC No.18686; the strain is used to produce the gamma-glutamyl transpeptidase through fermentation at 37 DEG C and pH of 7.0; after centrifugation is performed to collect bacterial cells, the bacterial cells are subjected to bioconversion in the presence of L-glutamine and ethylamine at 40 DEG C and pH of 9.0 to obtain L-theanine; and the reaction solution is subjected to membrane separation, ion exchange resin separation is performed, and concentration crystallization is performed to obtain a qualified L-theanine finished product. The method forproducing the L-theanine by using the lactobacillus casei developed by the invention has the advantages of food safety, environmental protection, simple operation and low costs, and has good industrial application value.

Owner:HENAN JULONG BIOLOGICAL ENG CO LTD

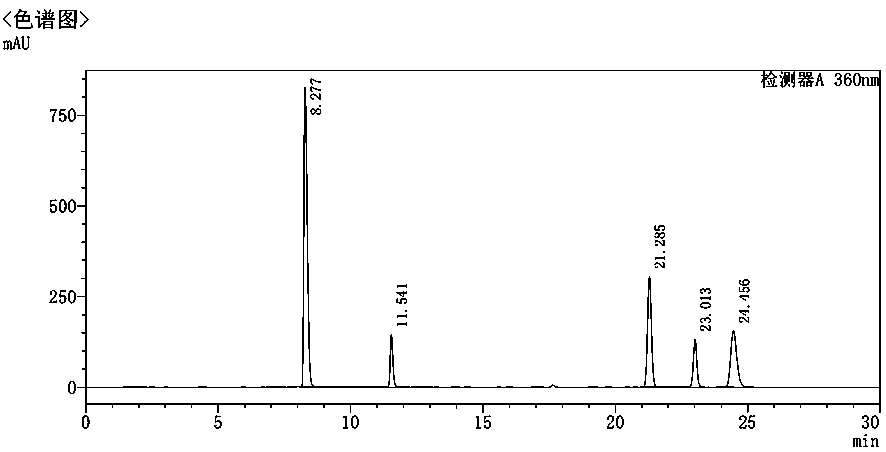

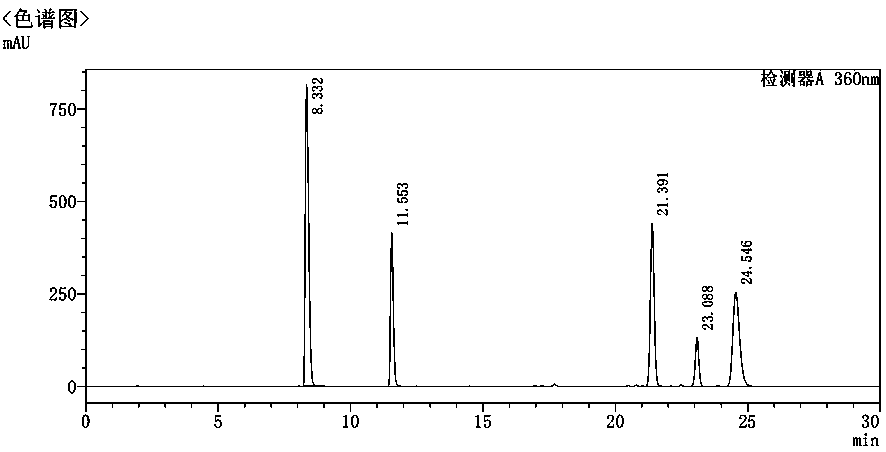

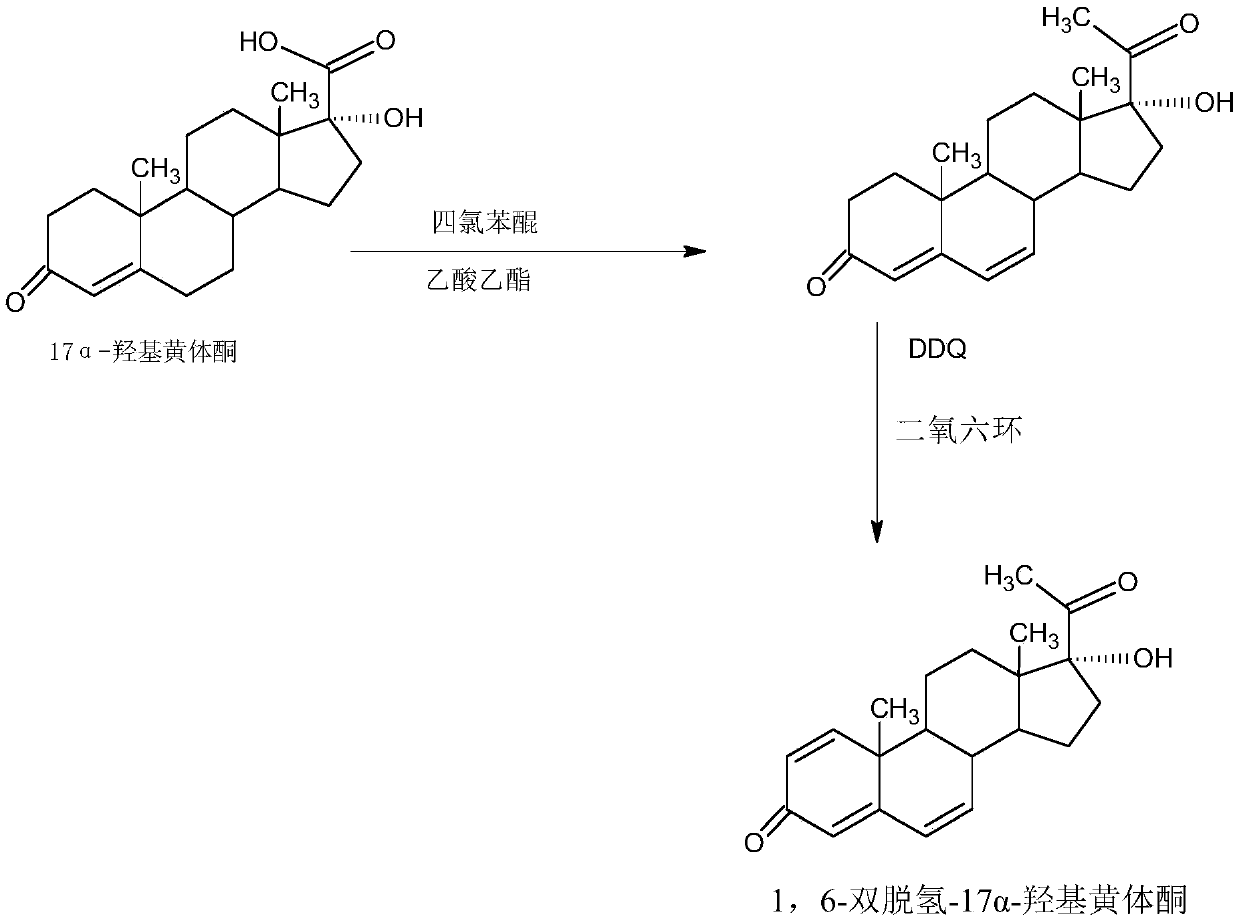

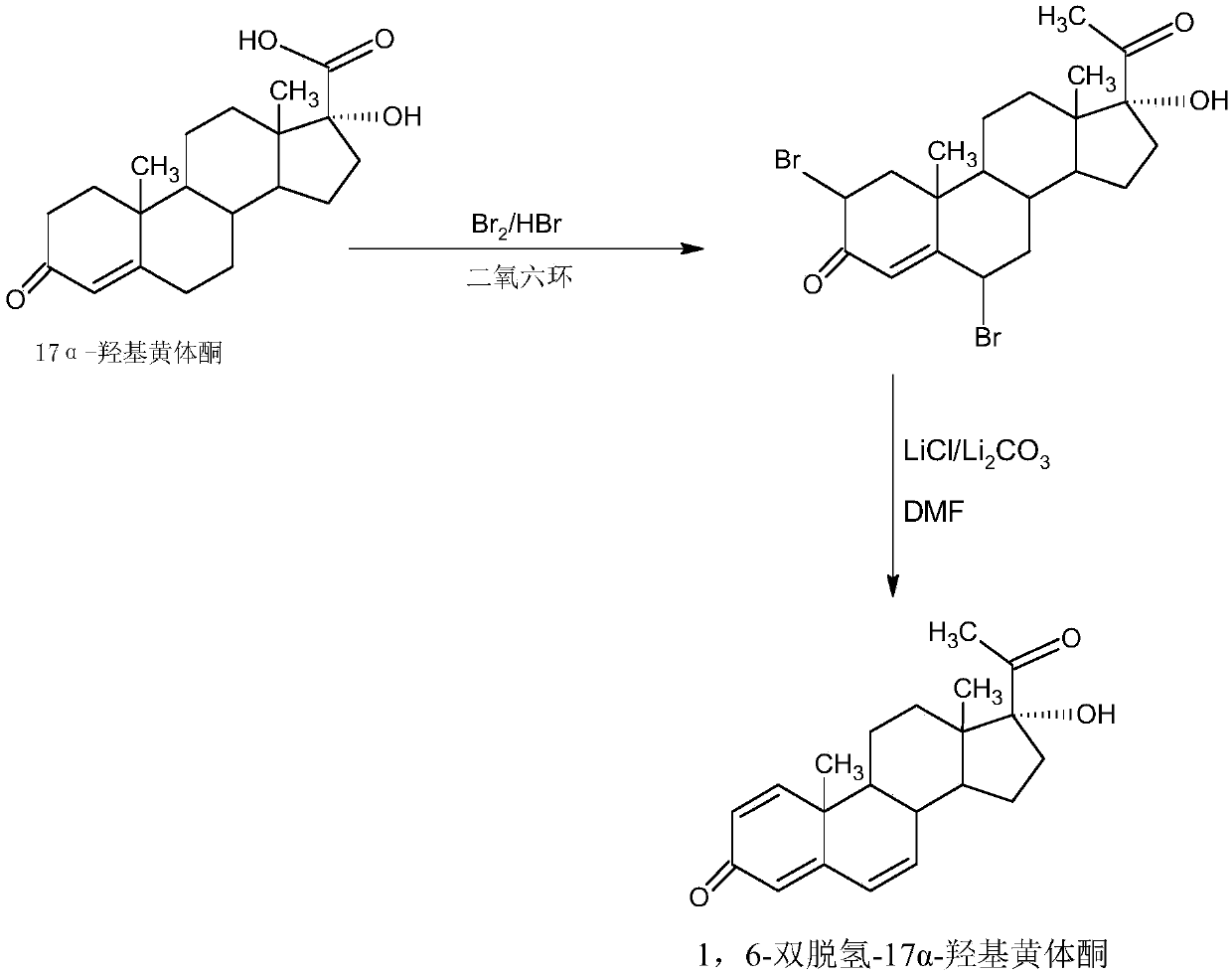

Preparation method of 2,6-dibromo 17a-hydroxyprogesterone

The invention provides a preparation method of 2,6-dibromo 17a-hydroxyproxyprogesterone. The method includes the steps that 17a-hydroxyproxyprogesterone is reacted with bromine in a first organic solvent and an acid environment to obtain the dibromination product 2,6-dibromo 17a-hydroxyproxyprogesterone by making 2 and 6 sites of a 17a-hydroxyproxyprogesterone molecule subjected to dibromination,wherein a ratio of the 17a-hydroxyproxyprogesterone to the bromine to acid is 1g to (1.2 to 1.8 g) to (0.1 to 0.4 g), and a ratio of the 17a-hydroxyproxyprogesterone to the first organic solvent is 1g to (2 to 15 ml). The invention further provides a preparation method of 1,6-didehydro-17a-hydroxyproxyprogesterone correspondingly. The preparation methods of the 2,6-dibromo 17a-hydroxyproxyprogesterone and the 1,6-didehydro 17a-hydroxyproxyprogesterone have the advantages of simple and convenient process operation, safe and environment-friendly production, low production cost and the like. Compared with traditional production methods, the method has high product yield, good quality, and can reduce the product production cost by 30% to 35%; the solvent used in the process can be recovered and recycled, which is economical and environmentally friendly at the same time, and is very beneficial to industrial production.

Owner:HUNAN KEREY BIOTECH

Method for producing insoluble sulfur

InactiveCN101337660BProduction safety and environmental protectionAvoid pollutionSulfur preparation/purificationNitrogenNitrogen gas

The invention discloses a method for producing insoluble sulfur, which comprises the steps of melting sulfur, extracting, drying and pulverizing. By using the method, the insoluble sulfur is continuously produced under the totally-enclosed condition of normal pressure, nitrogen of normal pressure is used for sealing a heating groove, and the extracting step and the pulverizing step are completed in the same reactor. The specific operation steps are as follows in sequence: (1) melting the sulfur and heating up; (2) extracting and pulverizing; and (3) drying to obtain products produced through the method. The method has the advantages that: (1) the insoluble sulfur is continuously produced under the totally-enclosed condition of the normal pressure, and nitrogen is used for sealing the upper space of the sulfur heating groove, thereby resulting in no oxide leakage of carbon bisulfide and sulfur, and achieving safe and environmental-friendly production; (2) the pulverizing and quenching processes are finished in the same multifunctional rotary reactor, thus saving pulverizing devices, avoiding dust pollution when pulverizing, and protecting production environment.

Owner:广州市烨荣贸易有限公司

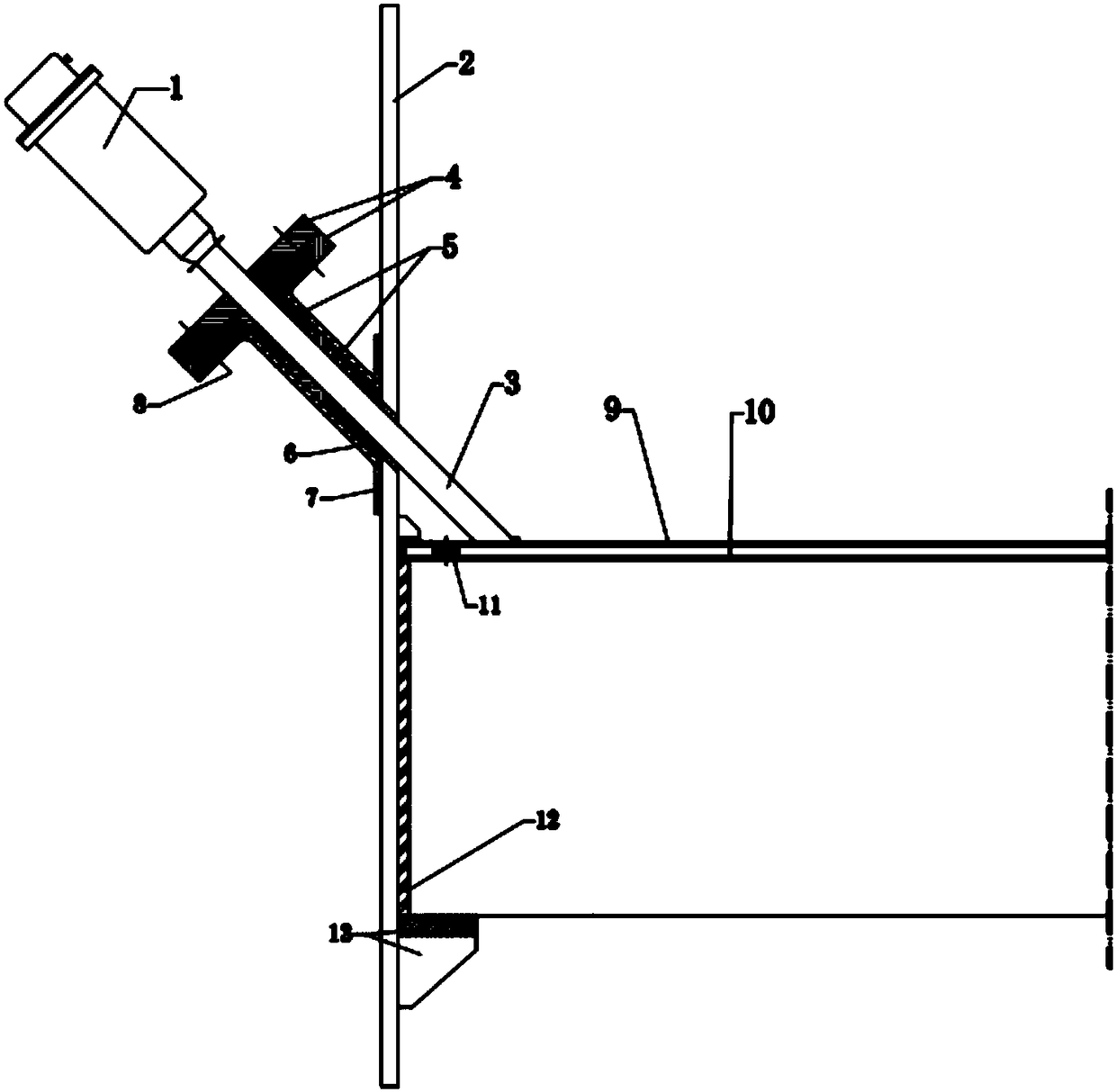

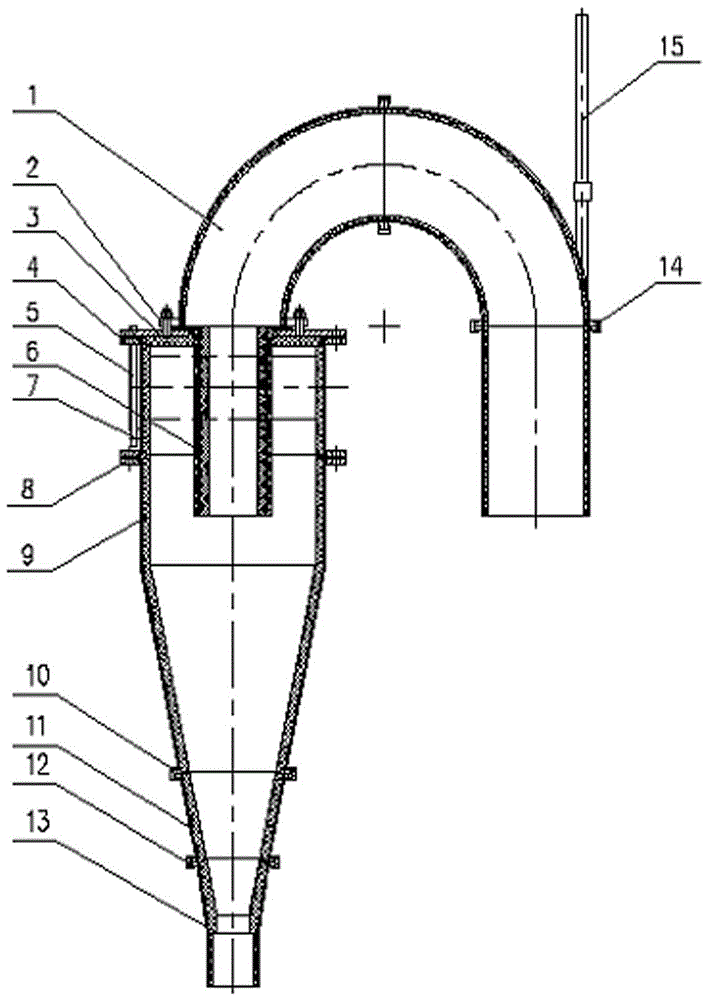

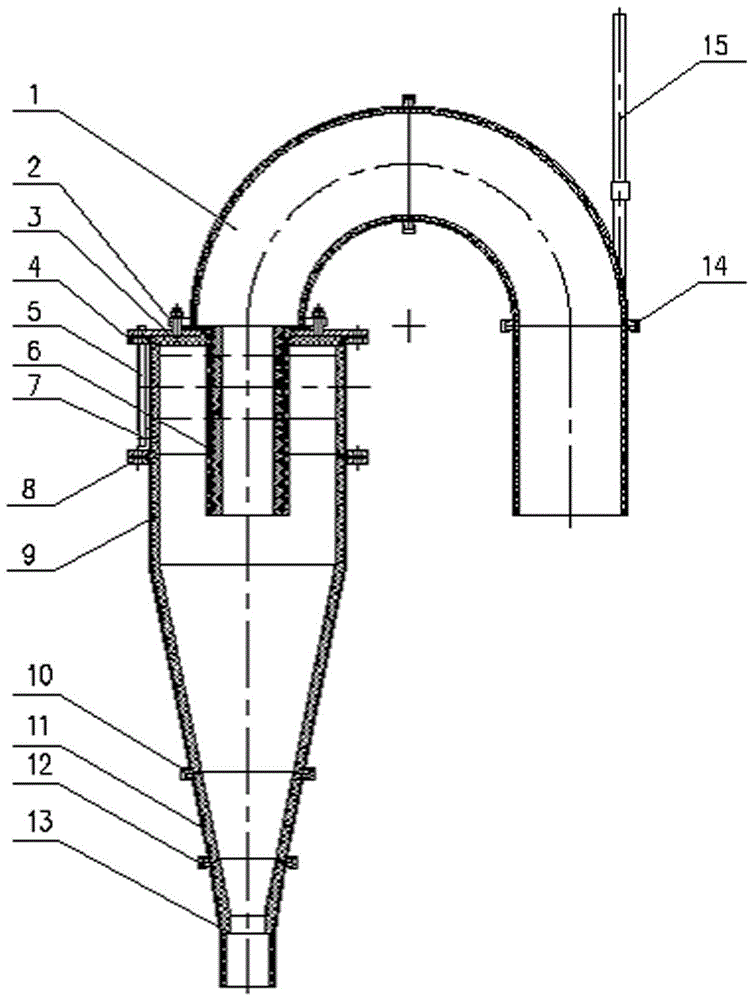

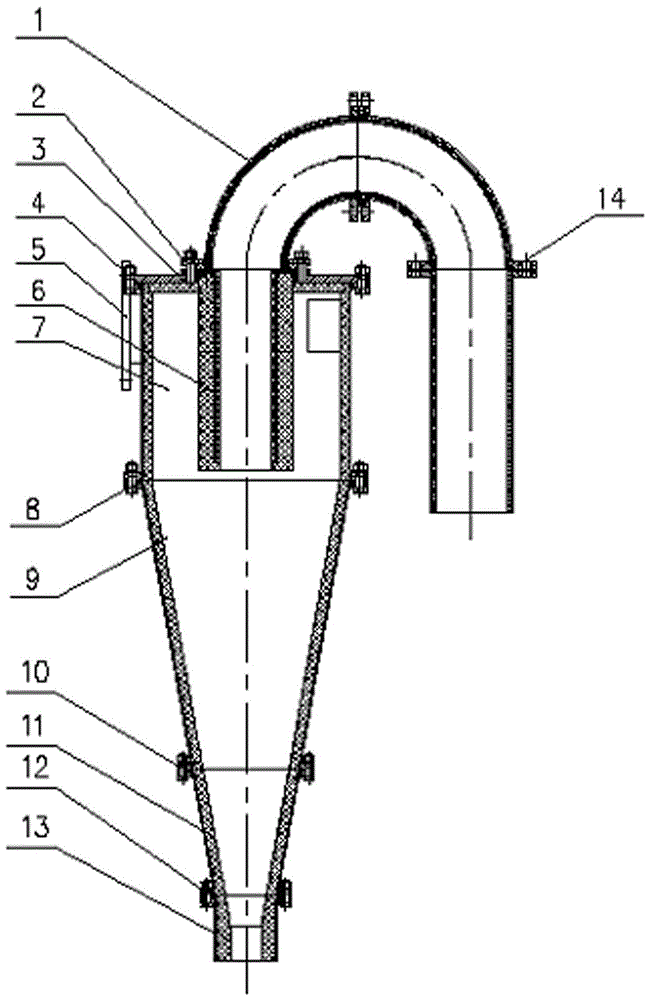

Ultrasonic anti-sticking device

PendingCN108201776AReasonable structural designLow costGas treatmentMagnesium chloridesEngineeringTower

The invention discloses an ultrasonic anti-sticking device, and belongs to the technical field of anti-sticking devices. The ultrasonic anti-sticking device comprises a tower tray support block, an ultrasonic generator, an ultrasonic guide rod, a reinforcing plate, and a sealing flange, wherein the tower tray support block is arranged between an upper tower tray and a lower tower tray of a dryingtower; the reinforcing plate is arranged at the outer side of the tower wall of the drying tower, slantwise extends upward, and is connected with the sealing flange; one end of the ultrasonic guide rod respectively penetrates through the sealing flange and the reinforcing plate, and then is arranged on the upper tower tray of the drying tower; the ultrasonic generator is arranged at the outer sideof the tower wall of the drying tower, and is arranged at the other end of the ultrasonic guide rod; a sealing layer is arranged between the reinforcing plate and the ultrasonic guide rod. The ultrasonic anti-sticking device has the advantages that the practicality is high, multiple types can be selected, the installation is flexible, the installation and construction at site are convenient, theefficiency is high, the speed is quick, the effective utilization rate of equipment is high, the service life of the equipment is long, the online continuous or intermittent working can be performed,and the safe, economic and environment-friendly effects are realized.

Owner:张孝亮 +3

Non-equal-settling hydrocyclone and strip-shaped unit integrated technology with two overflow fineness increasing values increased and decreased correspondingly

ActiveCN106179785AReduce the number of counts usedLarge amount of processingReversed direction vortexWet separationEngineeringUnit structure

The invention relates to a non-equal-settling hydrocyclone and strip-shaped unit integrated technology with two overflow fineness increasing values increased and decreased correspondingly, specifically, an existing two-segment two-closed-path equal-settling hydrocyclone and annular unit integrated technology with two overflow fineness increasing values high and low is transformed into the non-equal-settling hydrocyclone and strip-shaped unit integrated technology with the two overflow fineness increasing values increased and decreased correspondingly, and the effect of balance of the primary grinding amount and the secondary grinding amount is achieved. The important implementation supporting point of the integrated technology is that an original phi 660 mm and phi 500 mm equal-settling hydrocyclone annular unit structure in the background technology is transformed into a phi 660 mm and phi 500 mm non-equal-settling hydrocyclone strip-shaped unit structure, specifically, according to the working principle that the outer rotational flow of the hydrocyclone is converted into the inner rotational flow, the length L, which is 235 mm, of a separation cone of a primary-segment classifying equipment phi 660 mm non-equal-settling hydrocyclone is designed to account for 17.66% of the total length, 1331 mm, of a barrel cone, the length of a separation cone of a secondary-segment classifying equipment phi 500 mm non-equal-settling hydrocyclone is 184 mm, and compared with the length, which is 215 mm, of a separation cone of an equal-settling hydrocyclone, the length of the separation cone is shortened by 31 mm.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com