Two-component solvent-free plant oil-based adhesive

A solvent-free, oil-based glue technology, applied in the field of polymer chemistry, can solve problems affecting human health, polluting the environment, and strong odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

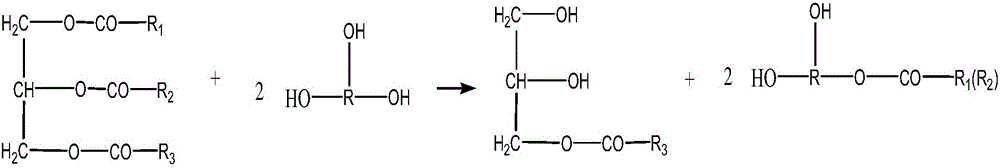

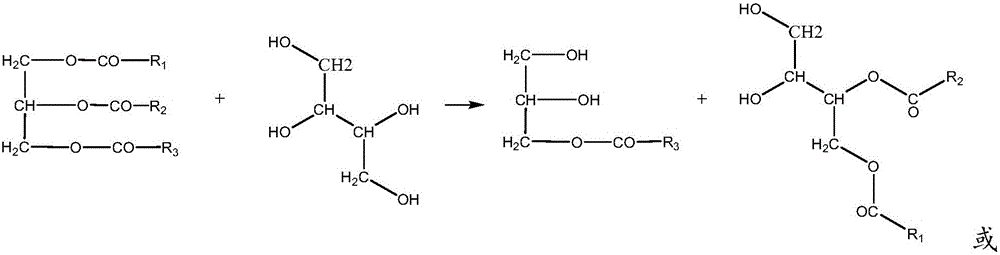

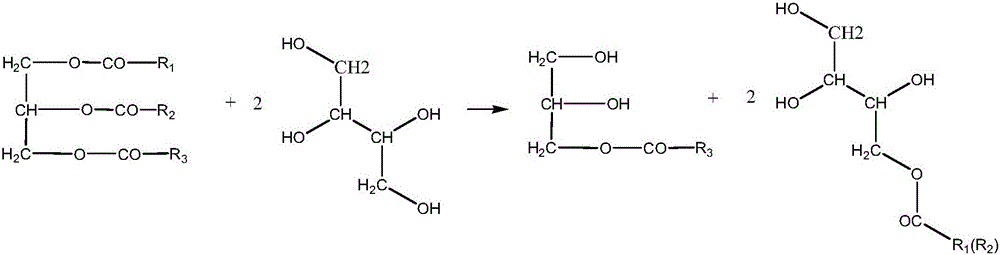

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The concrete processing method of the present embodiment is as follows:

[0088] A two-component solvent-free vegetable oil-based adhesive, characterized in that the two-component solvent-free vegetable oil-based adhesive comprises two components A and B with a mass ratio of 1:2:

[0089] Component A includes:

[0090] The modified vegetable oil of 30 parts by weight; The modified vegetable oil is selected from modified soybean oil;

[0091] The tackifying resin of 60 parts by weight; The tackifying resin is C5 resin;

[0092] The coupling agent of 1 weight part; The coupling agent is vinyltrichlorosilane;

[0093] The filler of 80 parts by weight; Filler is light calcium carbonate;

[0094] 10 parts by weight of the chain extender; the chain extender is propylene glycol.

[0095] The preparation method of component A is:

[0096] The modification method of the modified vegetable oil is: mixing soybean oil and glycerin with a molar ratio of 1:3 and sulfuric acid ac...

Embodiment 2

[0102] The concrete processing method of the present embodiment is as follows:

[0103] A two-component solvent-free vegetable oil-based adhesive, characterized in that the two-component solvent-free vegetable oil-based adhesive comprises two components A and B with a mass ratio of 5:1:

[0104] Component A includes:

[0105] The modified vegetable oil of 90 parts by weight; The modified vegetable oil is selected from modified palm oil;

[0106] The tackifying resin of 10 parts by weight; The tackifying resin is a copolymerized petroleum resin;

[0107] The coupling agent of 5 parts by weight; The coupling agent is vinyltriethoxysilane;

[0108] The filler of 10 parts by weight; Filler is calcite powder;

[0109] 10 parts by weight of microcapsule expanded microspheres; the wall shell of microcapsule expanded microspheres is sodium alginate, and the expanded diameter of microcapsule expanded microspheres is 10 microns;

[0110] The preparation method of component A is:

...

Embodiment 3

[0118] The concrete processing method of the present embodiment is as follows:

[0119] A two-component solvent-free vegetable oil-based adhesive, characterized in that the two-component solvent-free vegetable oil-based adhesive comprises two components A and B with a mass ratio of 1:1:

[0120] Component A includes:

[0121]The modified vegetable oil of 40 parts by weight; The modified vegetable oil is selected from modified peanut oil;

[0122] The tackifying resin of 50 parts by weight; The tackifying resin is piperylene petroleum resin;

[0123] The coupling agent of 2 parts by weight; The coupling agent is isopropyl tris (dioctyl pyrophosphate acyloxy) titanate;

[0124] The filler of 70 weight parts; Filler is mica powder;

[0125] 1 weight part of microcapsule expanded microspheres; the wall shell of microcapsule expanded microspheres is chitosan, and the diameter of microcapsule expanded microspheres after expansion is 210 microns;

[0126] The chain extender of 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com