Polyurethane adhesive and preparation method thereof

A technology of polyurethane adhesives and adhesives, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems that restrict the wide application of polyurethane adhesives, the adhesive is easy to soften and sticky, poor reworkability, etc., and achieves good results Bending resistance and high temperature washing resistance, improving mechanical properties and heat aging resistance, improving the effect of initial adhesion and peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

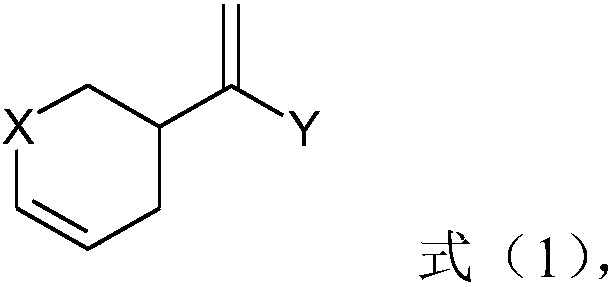

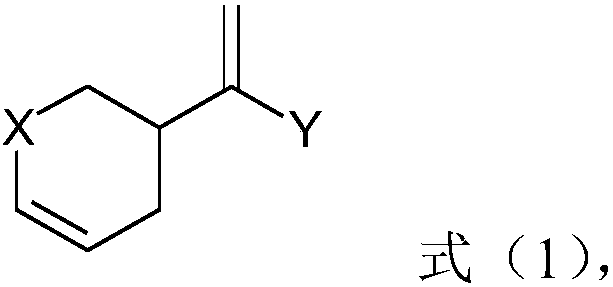

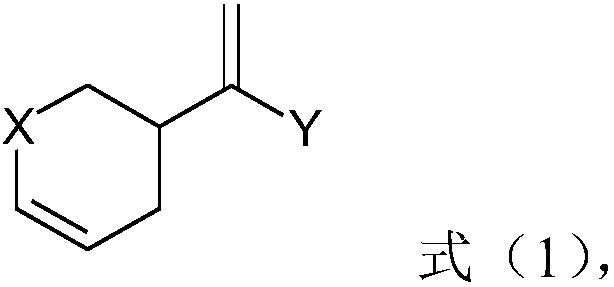

Method used

Image

Examples

Embodiment Construction

[0042] Unless otherwise specified, "parts" in the examples of the present invention refer to "parts by mass", and "%" refers to percentage by mass.

[0043] The present invention and its beneficial effects will be further described in detail below in conjunction with the examples, but the implementation of the present invention is not limited thereto.

[0044] Shoe material test sample preparation: (1) When the adhesive contains one component, brush the adhesive on the outer edge of the upper surface and the inner edge of the sole, dry it in an oven at 80°C for 2 minutes, stick the sole and upper by hand, and then use Sole molding machine molding molding 10s. (2) When the adhesive contains two components, first brush the adhesive A on the outer edge of the upper surface and the inner edge of the sole, and dry it in an oven at 80°C for 2 minutes; then brush the adhesive B on the outer edge of the upper surface and the inner edge of the sole , dry in an oven at 80°C for 2 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com