Patents

Literature

98results about "Coumarone-indene polymer adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multicomponent coating and adhesive material

InactiveUS7005476B1Extended storage timeImprove melting abilityMonocarboxylic acid ester polymer adhesivesPolyurea/polyurethane coatingsEndcappingPolymer science

Disclosed is a multicomponent, isocyanate-terminated or silane-functionalized coating and adhesive material which is continuously produced by mixing the individual components and by heating the latter and continuing mixing until said components reach a liquid state, wherein the resulting reactive coating and adhesive material is fed for direct use especially in profile sheathing plants, coating plants or the like. In the case of isocyanate-terminated material, one component has a reactive high-molecular weight starting polymer and a second component has a reactive isocyanate-terminated cross-linking agent. In the case of the silane- functionalized material, one component has a high-molecular weight starting material and a second component has a reactive, silane-functionalized cross-linking agent.

Owner:JOWAT LOBERS & FRANK

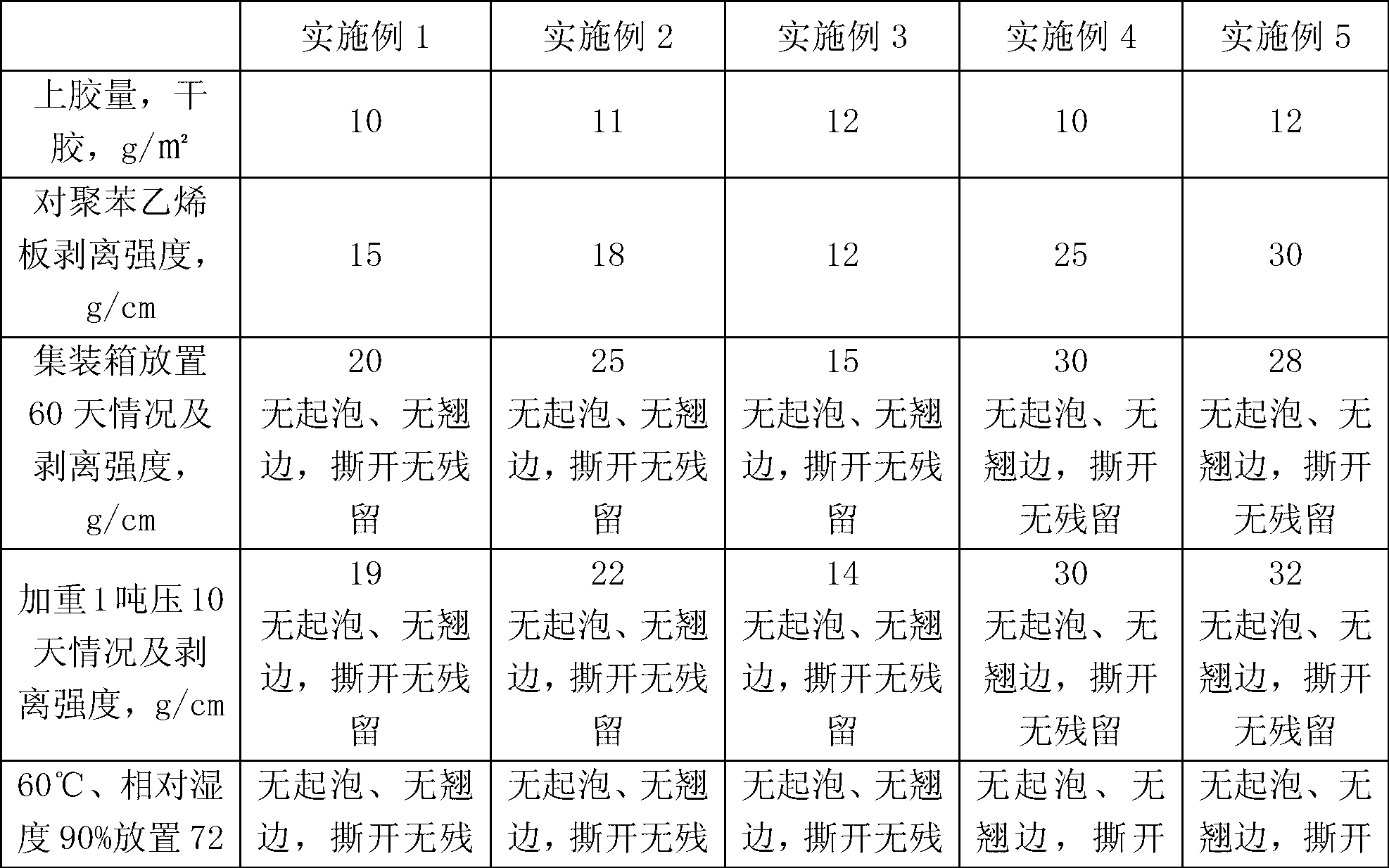

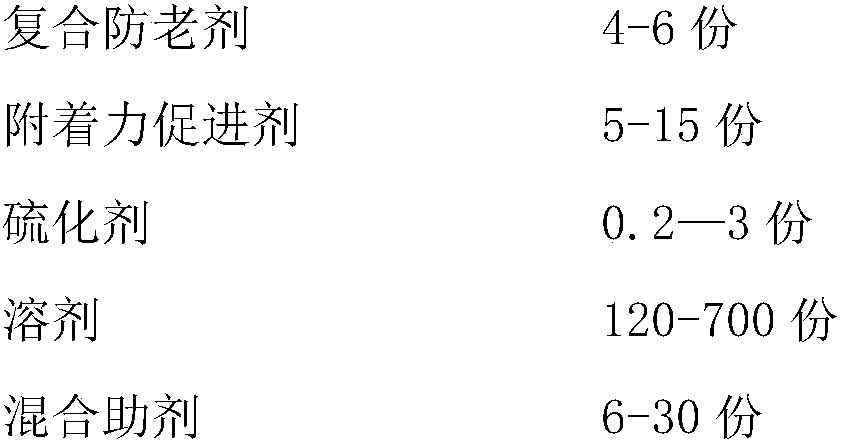

Aqueous pressure-sensitive adhesive and preparation method thereof

InactiveCN103013383AAchieve protectionMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesPolycarbonate plasticPolymer science

The invention provides an aqueous pressure-sensitive adhesive, which comprises the following components in percentage by weight: 54-81% of rubber latex, 5-10% of acrylic resin emulsion, 10-30% of tackifying resin emulsion and 4-6% of anti-aging agent emulsion, wherein the weight percentages of the various components are dry basis weights of the components. The invention further provides a preparation method of the aqueous pressure-sensitive adhesive. When being applied to surface protective paper, the aqueous pressure-sensitive adhesive provided by the invention is capable of protecting surfaces of products, such as acrylic plates, polycarbonate plastic plates, polystyrene plates, polyvinyl chloride plates, glass, marble and wood furniture decorative plates, under the ultra-low peeling strength, and avoiding the conditions, such as foaming, edge warping, and residual after tearing.

Owner:麦广明

Low volatile organic compound adhesive for attaching thermoplastic polyolefin roofing membranes

Adhesive compositions formulated with blends of styrene-isoprene-styrene block copolymers and hydrocarbon resins are provided. Also provided are methods for bonding substrates, including roofing membranes, using the adhesive compositions. The adhesive compositions are characterized by high solids contents, low viscosities and improved bonding characteristics, including high peel strengths when adhered to roofing membranes, such as thermoplastic polyolefin (“TPO”) membranes.

Owner:ILLINOIS TOOL WORKS INC

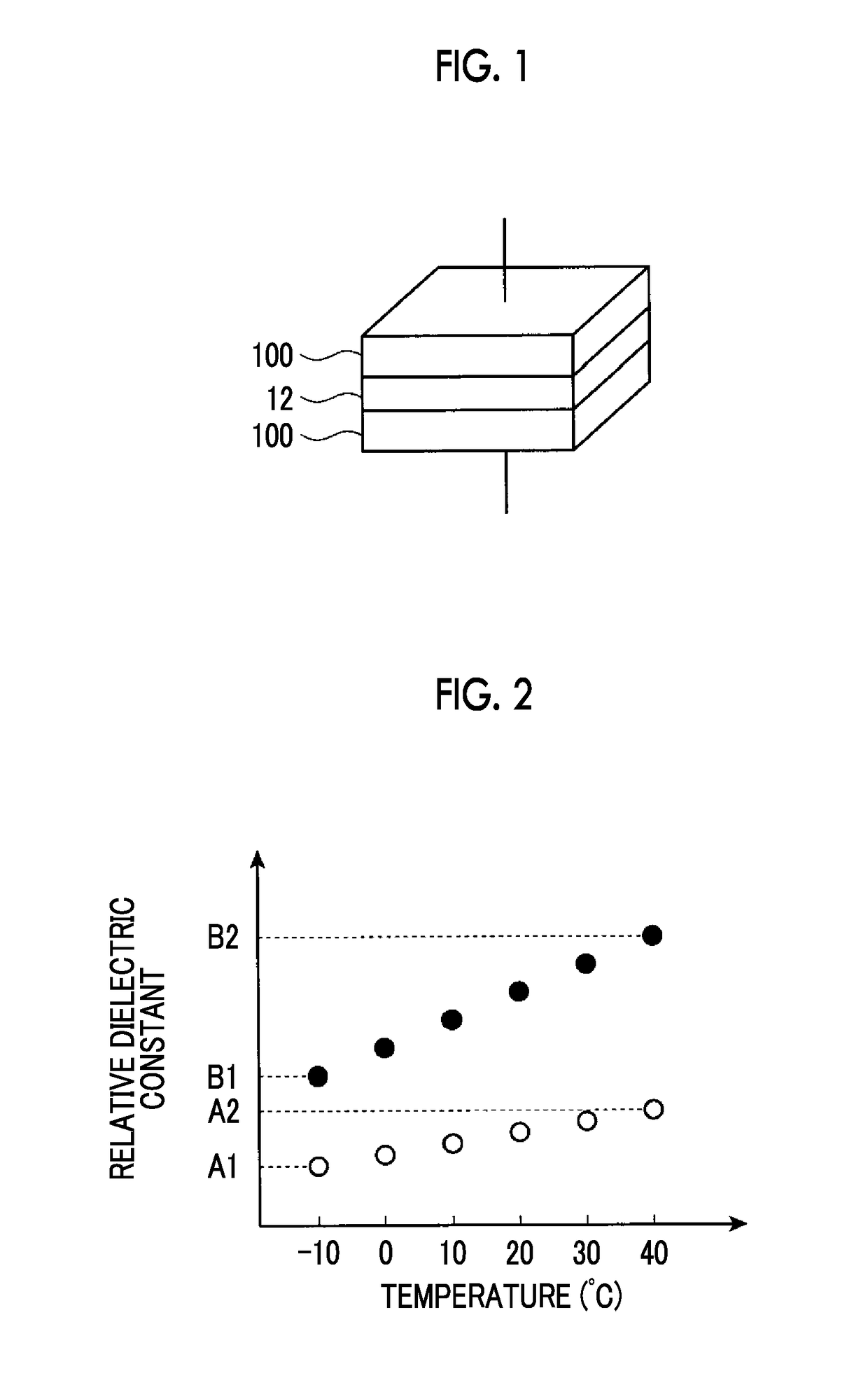

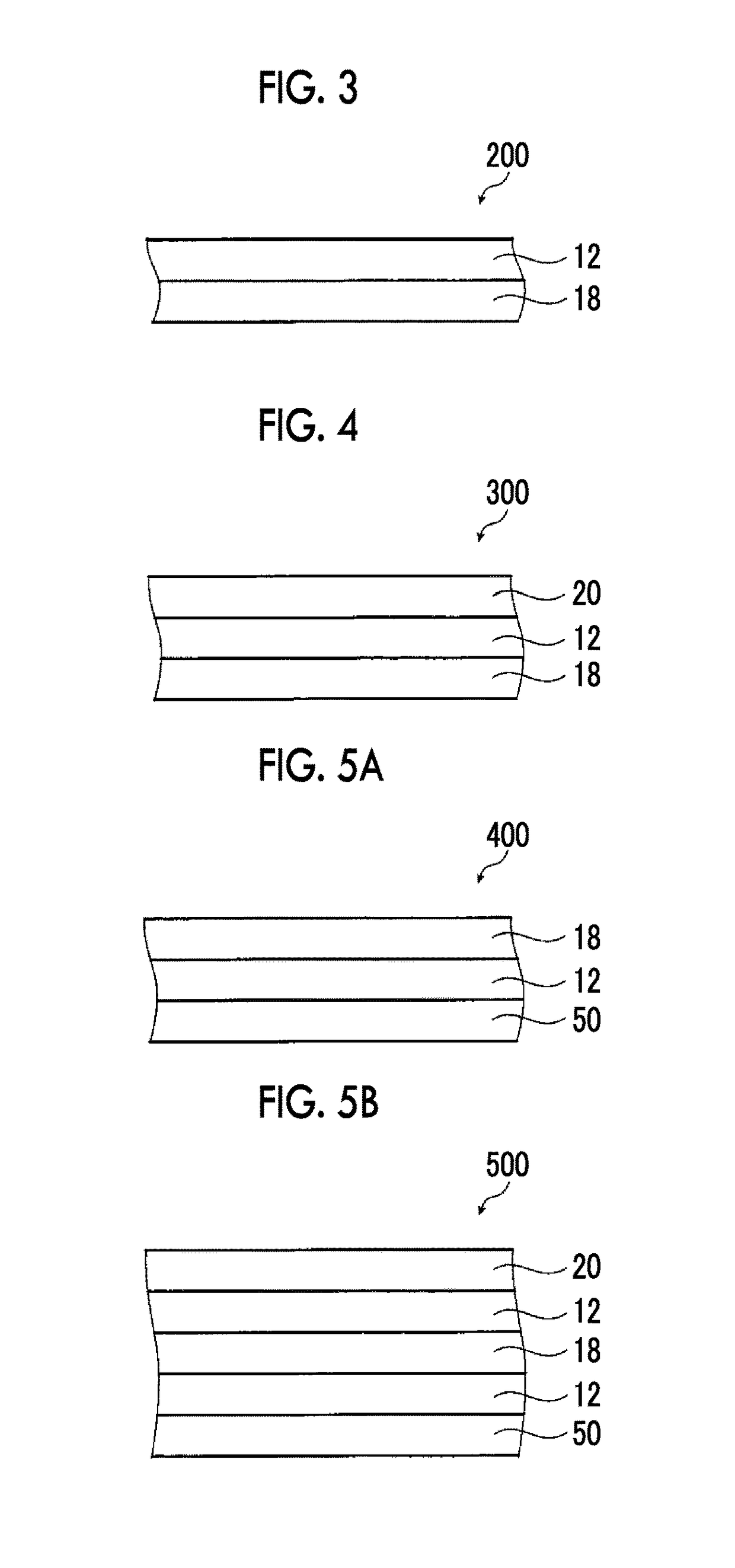

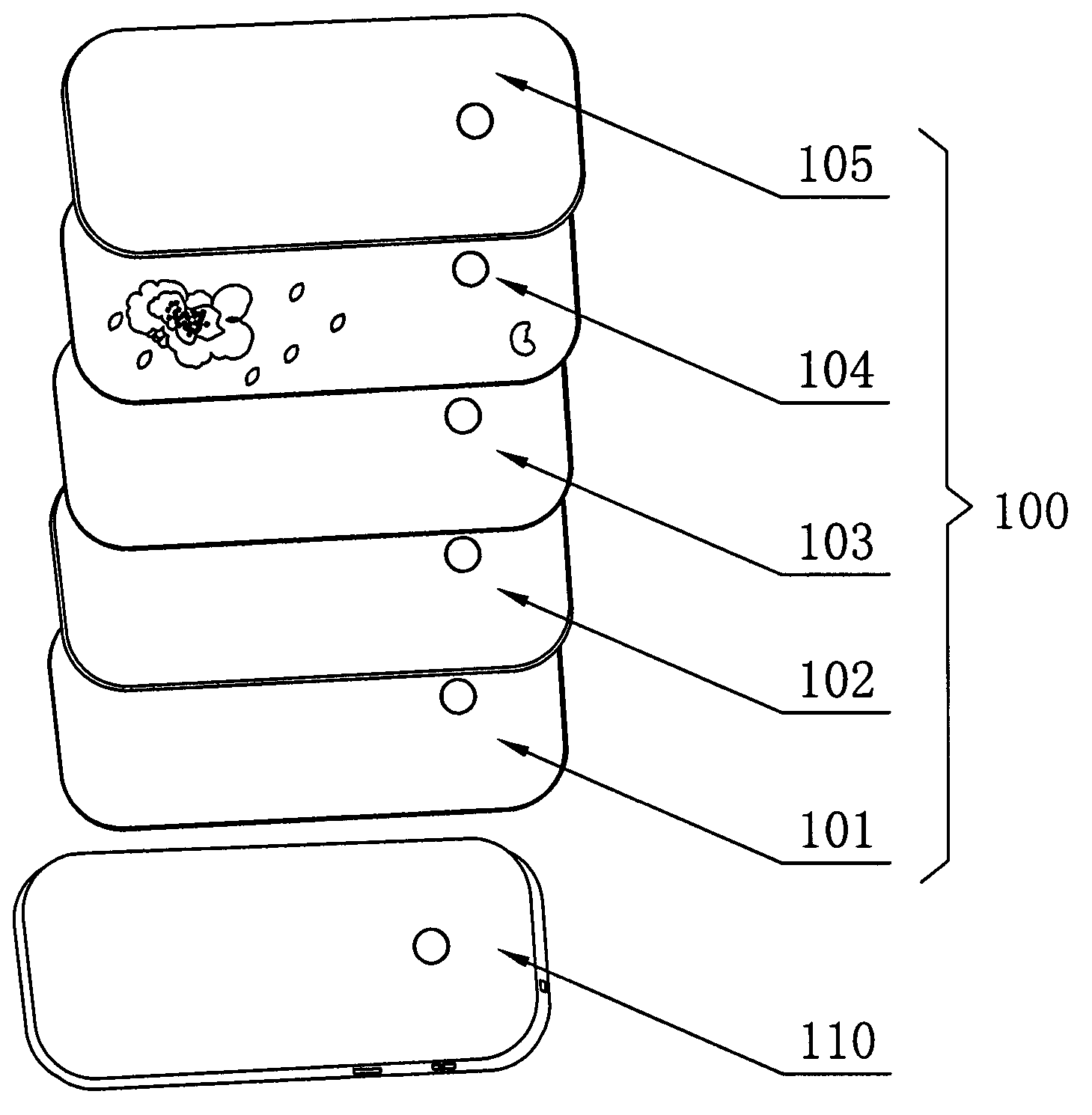

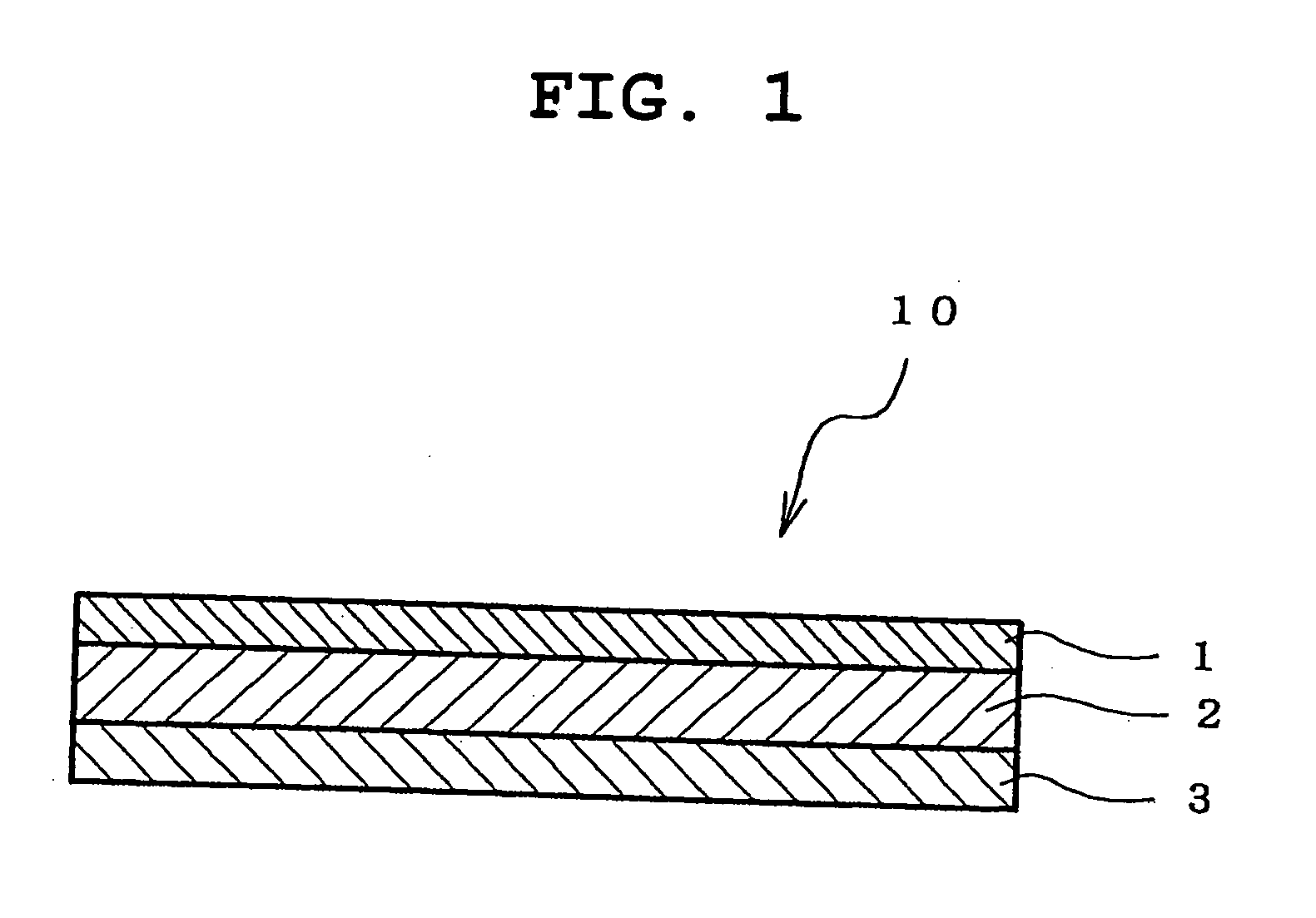

Pressure-sensitive adhesive sheet for touch panel, laminate for touch panel, and capacitance-type touch panel

ActiveUS20170355173A1Easy to operateInhibitionAdhesive articlesSynthetic resin layered productsCapacitanceTouchpad

An object of the present invention is to provide a pressure-sensitive adhesive sheet for a touch panel which is excellent for the operability of a capacitance-type touch panel, which is able to suppress the occurrence of malfunctions in a capacitance-type touch panel in a wide range of temperature environments from low temperatures to high temperatures, and which is also excellent in pressure-sensitive adhesion. In addition, another object of the present invention is to provide a laminate for a touch panel and a capacitance-type touch panel which include a pressure-sensitive adhesive sheet for a touch panel. In the pressure-sensitive adhesive sheet for a touch panel of the present invention, a relative dielectric constant obtained by impedance measurement at 1 MHz at 20° C. is 4.0 or more, a temperature dependency obtained from a temperature dependency evaluation test is 25% or less, and a 180 degree peel strength with respect to glass is 0.2 to 1.2 N / mm.

Owner:FUJIFILM CORP

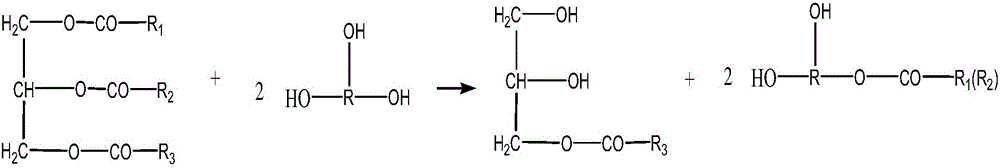

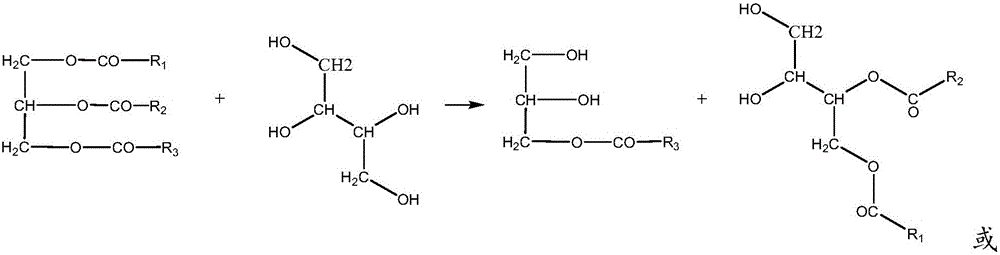

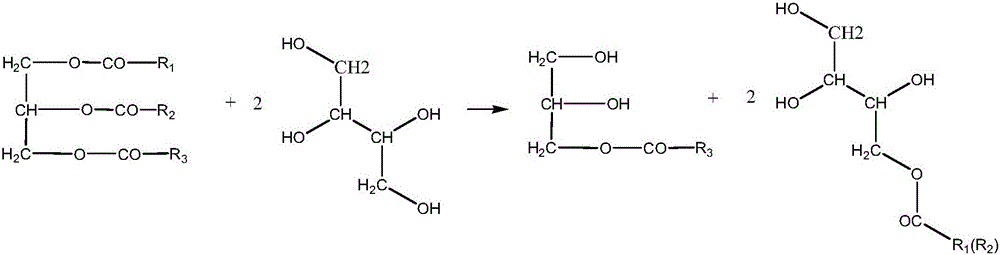

Two-component solvent-free plant oil-based adhesive

ActiveCN105969293AImprove initial tack performanceHigh strengthMineral oil hydrocarbon copolymer adhesivesPolyureas/polyurethane adhesivesAdhesiveHeat resistance

The invention provides a two-component solvent-free plant oil-based adhesive, which comprises components A and B, wherein component A comprises modified plant oil, tackifying resin, a coupling agent, a filler, microencapsulated microspheres and a chain extender; component B comprises isocyanate or a mixture of isocyanate and modified plant oil. The two-component solvent-free plant oil-based adhesive with high comprehensive performance is safe in use, economical, moderate in curing speed, adjustable in hardness, high in initial cohesiveness, water resistance and heat resistance, strong in adhesive strength, wide in application range, green and environment-friendly.

Owner:福建省南平星源辉生物科技有限公司

Leak-proof, noise-proof, bulletproof, and explosion-proof automobile tire and manufacturing method thereof

InactiveCN103496300ANo change in dynamic balanceReduce the amount of vibrationMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesDriving safetyInert gas

The invention relates to a leak-proof, noise-proof, bulletproof, and explosion-proof automobile tire and a manufacturing method thereof. According to the invention, a high-molecular self-seal polymerized adhesive anti-leakage layer is coated on the entire inner wall surface of the automobile tire, wherein the thickness of the anti-leakage layer is no lower than 3.5mm; and a gas medium filled in the automobile tire is inert gas. The automobile tire provided by the invention has leak-proof, noise-proof, bulletproof, and explosion-proof effects, and can be used in military or civilian vehicles for ensuring driving safety. The method provided by the invention is suitable for manufacturing of leak-proof, noise-proof, bulletproof, and explosion-proof automobile tires, and can be used for upgrading common automobile tires into leak-proof, noise-proof, bulletproof, and explosion-proof tires.

Owner:LUOYANG JUNTENG ENERGY TECH

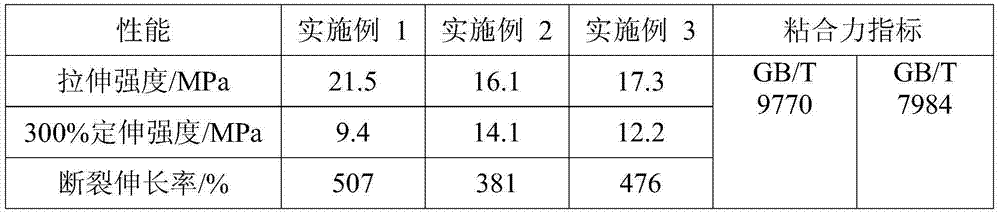

Dual-purpose adhesive for steel wire rope and canvas and preparation method of dual-purpose adhesive

InactiveCN103756592AEasy to produceReduce installation costsNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesiveEngineering

The invention relates to a dual-purpose adhesive for steel wire ropes and canvases. The adhesive is characterized by comprising the following components in parts by weight: 100 parts of mixture rubber matrix of natural rubber and synthetic rubber, 3-8 parts of activating agent, 2-6 parts of anti-aging agent, 6-12 parts of binding agent, 30-60 parts of reinforcing agent, 5-15 parts of plasticizing agent, 0.5-3 parts of accelerant and 2-5 parts of vulcanizing agent. The adhesive is prepared by adding the mixture rubber matrix of the natural rubber and the synthetic rubber into a double-roller open mill, performing plasticizing, subsequently adding the activating agent, the anti-aging agent, the binding agent, the reinforcing agent and the plasticizing agent in sequence, mixing to obtain a section of mixed adhesive, adding the accelerant, the vulcanizing agent and the binding agent into the section of mixed adhesive, and mixing so as to obtain the adhesive. By adopting the dual-purpose adhesive, both steel wire ropes and canvases can be adhered, so that convenience is brought to conveyer belt production; due to adoption of the dual-purpose adhesive disclosed by the invention, convenience is brought to a conveyer belt user when mounting connectors and the conveyer belt mounting cost is saved to a certain extent.

Owner:WUXI BOTON TECH CO LTD +1

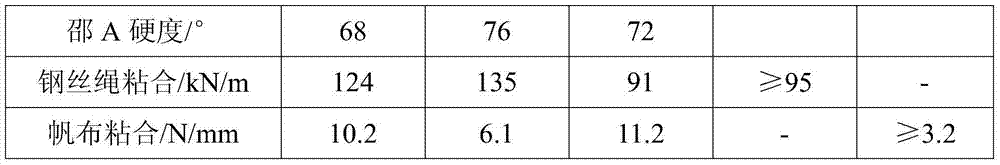

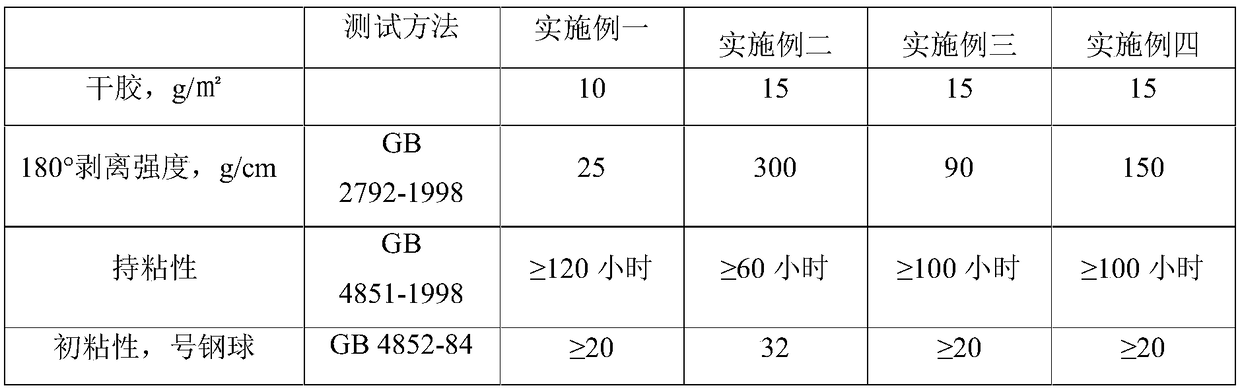

Rubber type pressure-sensitive adhesive for polyethylene protective film and preparation method thereof

PendingCN108913059AAchieve protectionLow peel strengthMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesTectorial membraneSolvent

The invention relates to a rubber type pressure-sensitive adhesive for a polyethylene protective film and a preparation method thereof. The rubber type pressure-sensitive adhesive comprises the following components in parts by weight: 30-50 parts of natural rubber, 5-50 parts of synthetic rubber, 0-100 parts of a tackifying resin, 4-6 parts of a composite anti-aging agent, 5-15 parts of an adhesion promoter, 0.2-3 parts of a vulcanizing agent, 120-700 parts of a solvent, and 6-30 parts of a mixed additive. The rubber type pressure-sensitive adhesive is applied to the polyethylene protective film, so that the surfaces of plastics, metal plates, spraying plates, glass, marble, especially fluorocarbon paint and the like are protected at very low peeling strength. In addition, the primer coating and the release agent coating (except the surface needing to be printed) are not needed during coating.

Owner:麦广明

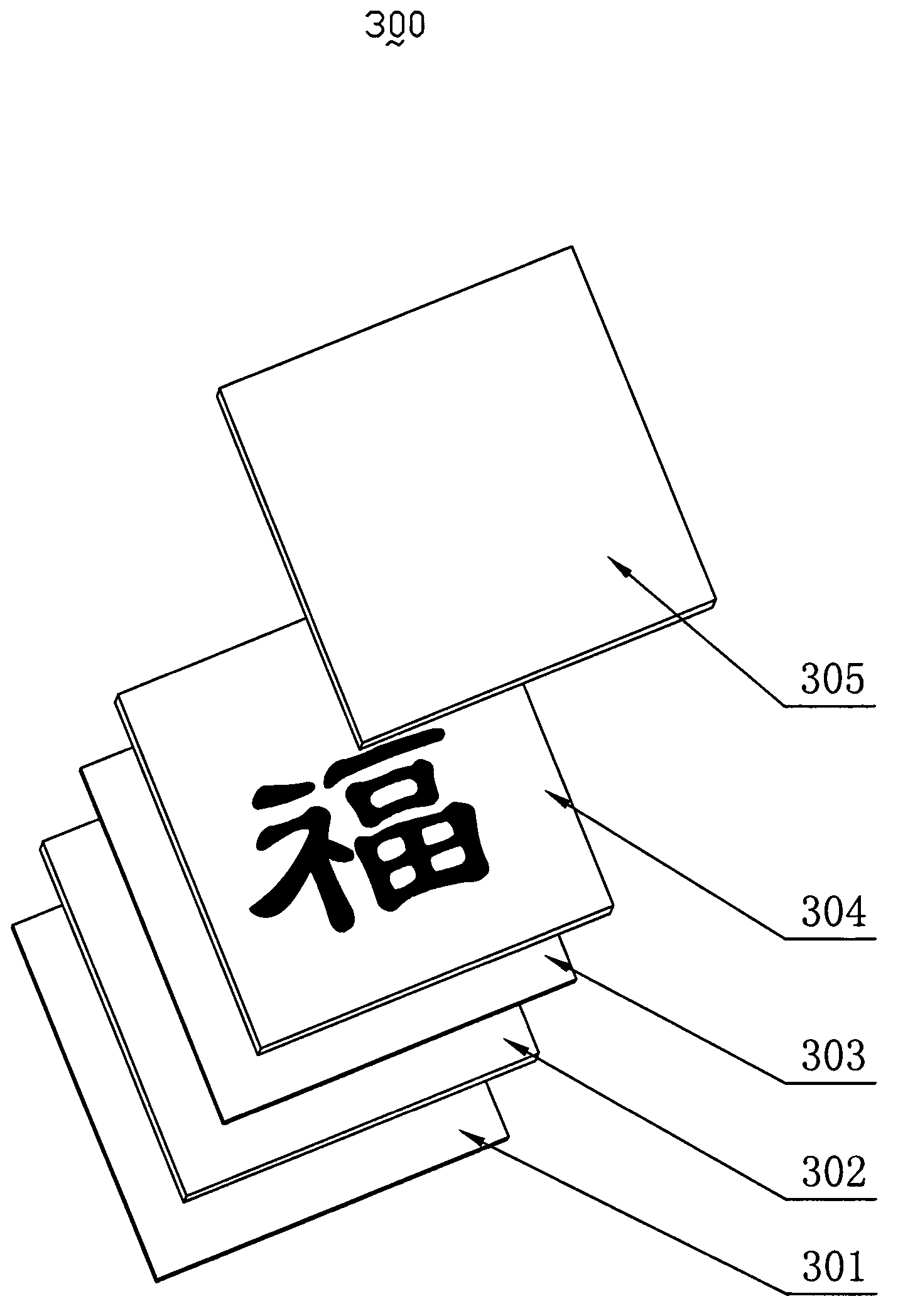

Viscose glue, viscose glue plaster prepared from viscose glue, and making method and application of viscose glue plaster

ActiveCN103834347AMaintain adhesionAdhesion can be controlledNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceViscose

The invention relates to a viscose glue and a viscose glue plaster prepared from the viscose glue, wherein the viscose glue is capable of realizing non-trace adhesion and being repeatedly used for multiple times. The main components of the viscose glue include silica gel and a tackifier, the silica gel weight accounts for 40%-60% of the overall weight of the viscose glue, and the tackifier weight accounts for 40%-60% of the overall weight of the viscose glue. The viscose glue has high activity groups, and when in use, the viscose glue can fill gaps on the glued material surface to exclude air inside the gaps so as to enable the viscose glue to attach to the glued material surface. The viscose glue mainly depends on adsorption type adhesive force for attaching, so that the viscose glue is convenient to tear off, and no residual excess viscose glue may be left on an attached material. The viscose glue plaster prepared from the viscose glue, which has a certain pattern, can be widely applied to sticky hooks, hanging pasters, electronic product pasting films and other various home furnishing, advertising and printing products, and has a great applicable range and market prospect.

Owner:SHENZHEN BENKS TECH

Tear-free self-adhesive rubber waterstop belt and preparation method thereof

ActiveCN104789148AWith self-adhesive functionEasy to processMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesPolymer scienceAdhesive

The invention belongs to the technical field water-proof materials of buildings and particularly discloses a tear-free self-adhesive rubber waterstop belt and a preparation method of the tear-free self-adhesive rubber waterstop belt. The invention adopts the major technical scheme that the rubber waterstop belt comprises a rubber base material, as well as a high polymer self-adhesive layer and an isolation layer that are pasted on one side face of the base material. The rubber base material is prepared from natural rubber, ZnO, stearic acid, an antiager, a reinforcing agent, operating oil, functional filling and a valcanizer via an extrusion technology, the high polymer self-adhesive layer is formed by melting SBS (styrene-butadiene-styrene) or / and SIS (styrene isoprene styrene) resin softening oil, an antiager, an reinforcing agent, operating oil, functional filling and an antioxidant via a stirrer, and the isolation layer is formed by stirring and mixing natural zeolite, metakaolin, wollastonite and stearic acid, and then the prepared high polymer self-adhesive layer and the isolation layer are applied on the rubber base material for calendering to form the belt. The waterstop belt has the self-adhesive layer which is securely connected with a concrete boundary layer, greatly improves adhesion between the rubber waterstop belt and concrete, and effectively solves the problems of water leakage and dampening of an expansion joint, a deformation joint and a construction joint.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER

Adhesive composition for patch and use thereof

InactiveUS20100092544A1Improve skinImprove cohesionFilm/foil adhesivesVinyl aromatic copolymer adhesivesElastomerPolymer science

The present invention provides an adhesive composition for patch, containing a rubber elastomer and a tackifier having a weight average molecular weight of 1200-2500, a patch having a support and an adhesive layer containing the composition, which is provided on at least one surface of the support, and a patch preparation having an adhesive layer containing a percutaneously absorbable drug (excluding bisoprolol).

Owner:NITTO DENKO CORP

Adhesive sticker for rubber products and rubber non-drying tape

InactiveCN102618188AExtended shelf lifeGood adhesionNatural rubber adhesivesFilm/foil adhesivesPolymer scienceDrying time

The invention relates to an adhesive sticker for bonding rubber products. The adhesive sticker mainly comprises 100 parts of rubber, 5-20 parts of tackfying resin, 2-5 parts of accelerating agent, 5-10 parts of activating agent and a right amount of solvent. The adhesive sticker does not contain a vulcanized agent, can be stored for long term and can be used for conveniently and firmly bonding the rubber products. The invention also relates to a rubber type non-drying tape containing the adhesive sticker.

Owner:SHANGHAI JIAFU NEW MATERIAL TECH CO LTD

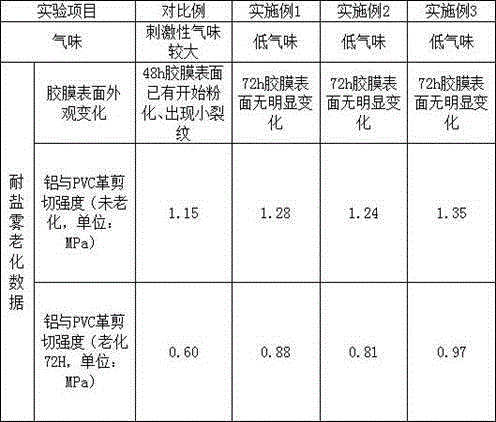

Salt spray resistant SBS adhesive and preparation method thereof

ActiveCN105153980ALess pungent odorPromote environmental protectionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAdhesive cementPolymer science

The invention provides a salt spray resistant SBS adhesive and a preparation method thereof, relating to the technical field of adhesives. The adhesive comprises the following components in parts by weight: 15-25 parts of thermoplastic butadiene styrene rubber, 10-25 parts of tackifying resin, 0.1-5 parts of salt spray resistant additives, 0.1-5 parts of silane coupling agent, 0.1-5 parts of anti-aging agent and 45-60 parts of solvent. The salt spray resistant SBS adhesive sends out small amount of pungent smell in actual use, has better environment friendliness, also has very excellent salt spray resistance and can well meet the operating requirements of coastal or high salt spray environments.

Owner:HUNAN JINHUA SCI & TECH GRP

Waterproof material prepared from fluid rubber and preparation method thereof

InactiveCN103897635AImprove healing abilityGood compatibilityNon-macromolecular adhesive additivesBituminous material adhesivesOrganic solventHuman skin

The invention belongs to the technical field of architectural waterproof materials, and discloses a waterproof material prepared from fluid rubber. The preparation method comprises the following steps: heating an organic solvent for dehydration, adding fluid rubber and an antioxidant, and dissolving by heating; and cooling, adding a liquid resin, petroleum asphalt, a reinforcer and an organic activating agent, dissolving, finally adding mixed ore powder and sodium silicate, dissolving, and cooling to obtain the waterproof material. The waterproof material obtained by the technique enables concrete and the coiled material to be compactly embedded into an integral body, and enhances the properties of the concrete; the waterproof material has the advantages of heat resistance and no cracking, has the air-permeable functions of water seepage resistance and perspiration discharge like human skin, and has superhigh healing capacity for fine cracks.

Owner:衡水中裕铁信防水技术有限公司

Hydroxyl coumarone resin and preparation method thereof

ActiveCN105566569AImprove performanceGood compatibilityCoumarone-indene polymer adhesivesCoatingsChemical reactionEthyl cinnamate

The invention provides a hydroxyl coumarone resin and preparation method thereof, and belongs to the field of resin preparation. The hydroxyl coumarone resin is prepared from a polymerizable component-containing mixture and 4-hydroxystyrene or 4-hydroxyl methyl cinnamate or 4-hydroxyl ethyl cinnamate, and the polymerizable component-containing mixture is obtained through distilling a heavy benzene fraction of coal tar; and polymerizable components comprise indene and coumarone, and the mass of 4-hydroxystyrene or 4-hydroxyl methyl cinnamate or 4-hydroxyl ethyl cinnamate is 1-20% of the mass of the polymerizable components. The hydroxyl coumarone resin contains hydroxyl groups, so the hydroxyl value of coumarone resin is substantially improved, and the coumarone resin has good compatibility with polar resins; and the coumarone resin carrying the hydroxyl groups chemically reacts with other components to form interpenetrating network crosslinking, so the performances of coatings and adhesives are further improved.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Preparation method of natural rubber pressure sensitive adhesive

InactiveCN103013381ASimple processIncrease stickinessNatural rubber adhesivesNon-macromolecular adhesive additivesChemical industryChemical reaction

The invention discloses a preparation method of a natural rubber pressure sensitive adhesive, and belongs to the field of chemical industry. The natural rubber pressure sensitive adhesive is prepared by taking natural rubber, butyl rubber, polysulfide rubber, a mixture of benzene and solvent gasoline, coumarone resin, dioctyl phthalate, lanolin, alumina powder and anti-aging agent RD as raw materials and using a chemical reaction kettle as a reaction container based on proper temperature and a proper reaction duration. The preparation method disclosed by the invention has the advantages of simple production process and general purpose of the adopted equipment; the product is good in permanent adhesion, excellent in low-temperature performance, rapid in adhesion and good in adhesive force, and the shortcoming of poor aging resistance is greatly improved by the addition of a modified rubber.

Owner:张芳远

High-polymer modified asphalt anti-corrosion waterproof latex clay and preparation method thereof

InactiveCN104559919AGood mechanical propertiesImprove deformation resistanceNatural rubber adhesivesNon-macromolecular adhesive additivesEpoxyAccelerant

The invention provides high-polymer modified asphalt anti-corrosion waterproof latex clay and a preparation method thereof. The high-polymer modified asphalt anti-corrosion waterproof latex clay is characterized by being prepared from the following components in percentage by weight: 3% of epoxy resin, 13% of coumarone resin oil, 4% of natural rubber, 25% of petroleum asphalt, 8% of sericite powder, 13% of light calcium carbonate, 15% of talcum powder, 16% of xylene, 1% of an accelerant, 1% of a defoaming agent, 0.5% of a chain extender and 0.5% of an anti-ageing agent. The preparation method comprises the following steps: firstly adding xylene to a reaction tank; adding the epoxy resin, the coumarone resin oil and the natural rubber at the formula ratio; and rotating the reaction tank, and stirring for six hours. The high-polymer modified asphalt anti-corrosion waterproof latex clay has the advantages of wide application range, good mechanical property, safety of construction, simplicity of operation, simplicity of preparation method, good preparation effect and the like.

Owner:陈红军

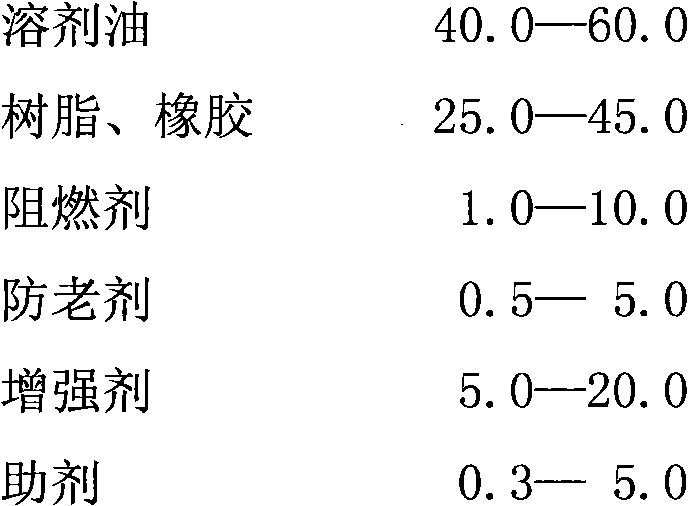

Flame-retardant quick bonding adhesive and preparation method thereof

InactiveCN102321445AImprove flame retardant performanceImprove the flame retardant indexMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesSolventFire retardant

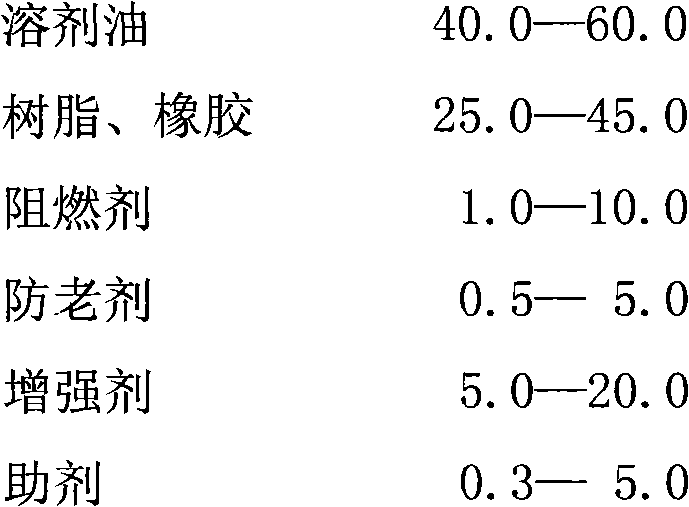

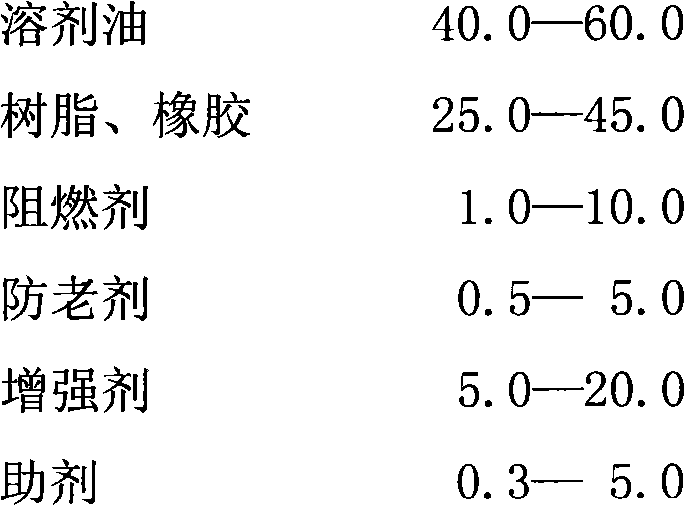

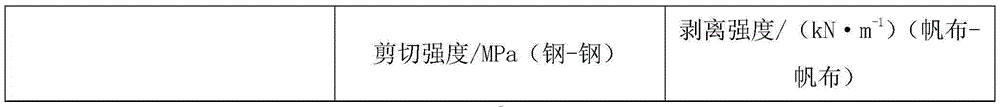

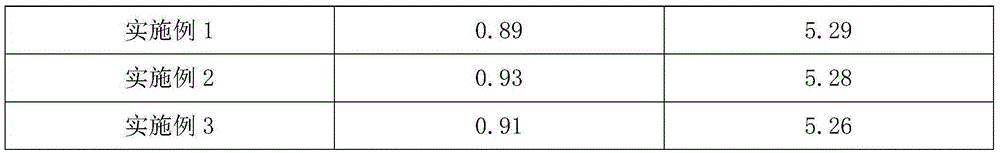

The invention relates to an adhesive material, in particular to an adhesive with a flame-retardant function and a quick bonding characteristic and a preparation method thereof. The adhesive consists of the following raw materials in part by weight: 40.0 to 60.0 parts of solvent oil, 25.0 to 45.0 parts of resin and rubber, 1.0 to 10.0 parts of flame retardant, 0.5 to 5.0 parts of anti-aging agent, 5.0 to 20.0 parts of reinforcing agent and 0.3 to 5.0 parts of aid. The adhesive has the characteristics of high flame retardance, initial viscosity, weather resistance, peel strength and bonding speed, environment friendliness, no toxicity, wide application range and the like, and is suitable for bonding various building materials such as various wood plates, aluminum-plastic plates, cement plates, glass, metal and ceramic surfaces and the like.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD +1

Carboxyl coumarone resin and preparation method thereof

InactiveCN105693930AGood compatibilityHigh glossInksCoumarone-indene polymer adhesivesMethacrylateAdhesive

The invention belongs to the field of resin preparation, and in particular relates to a carboxycoumarone resin and a preparation method thereof. The carboxyl coumarone resin is prepared by redistilling the heavy benzene fraction of coal tar to obtain a mixture containing polymerizable components and methacrylate or acrylate; the polymerizable components are indene and coumarone, The mass of the methacrylate or acrylate is 2-15% of the mass of the polymerizable component. The carboxyl coumarone resin has carboxyl groups and has good compatibility with polar resins to further improve the performance of coatings, adhesives and inks; the preparation method has mild conditions, simple process and easy industrial production.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Environment-friendly sealant and preparation method thereof

InactiveCN106634706AReduce decompositionInhibition of destructionMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesAntioxidantStearic acid

The invention discloses an environment-friendly sealant which comprises, by weight, 31-35 parts of butyl rubber, 29-31 parts of natural rubber, 70-84 parts of gasoline, 50-60 parts of ethyl acetate, 30-36 parts of acetone, 3-6 parts of rutile titanium dioxide, 12-14 parts of light calcium carbonate, 50-70 parts of talcum powder, 10-15 parts of stearic acid, 20-23 parts of sericite, 32-38 parts of petroleum resin, 10-13 parts of vulcanized paste, 30-50 parts of infusorial earth, 50-60 parts of tert butyl phenolic resin and coumarone resin, 3-4 parts of magnesium oxide, 0.4-0.6 part of ultraviolet stabilizers and 0.05-0.1 part of antioxidants. The environment-friendly sealant has the advantages that the sealant with high viscosity, denseness, solid content and bonding strength and aging resistance is obtained by optimizing components, usage of harmful substances is reduced, environmental pollution is decreased, and the preparation process is updated according to the optimized components.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

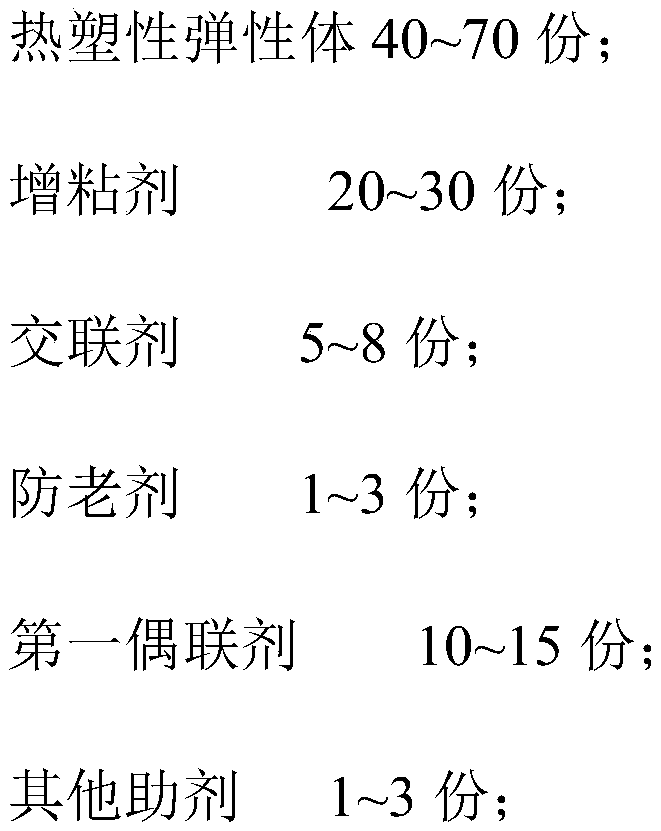

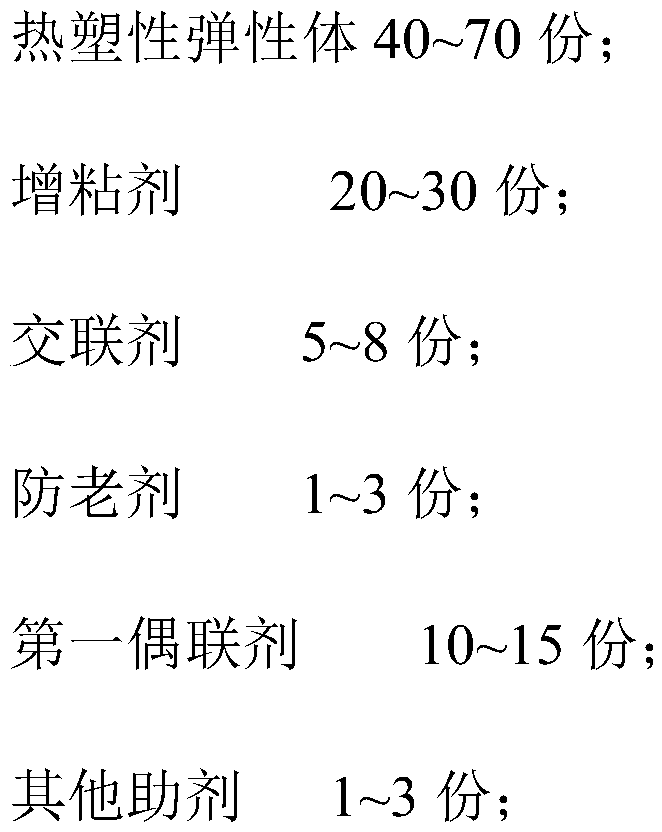

Hot melt pressure sensitive adhesive for environmental protection and sanitary articles and preparation method thereof

InactiveCN110157366AHigh bonding strengthImprove wettabilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantNano al2o3

The invention relates to a hot melt pressure sensitive adhesive for environmental protection and sanitary articles, which comprises the following components in parts by weight: 40-70 parts of thermoplastic elastomer; 20-30 parts of tackifier, 5-8 parts of cross-linking agent, 1-3 parts of antioxidant; 10-15 parts of first coupling agent, 1-3 parts of other auxiliary agents. The tackifier is prepared from tackifier resin, reactive monomer, second coupling agent and inorganic nanoparticles. The tackifier resin can be selected from aromatic series tackifier resin, inorganic nanometer ion is nanoalumina, and thermoplastic elastomer is two or more compositions of SBS, SIS and SEBS. More than two kinds of thermoplastic elastomers are used to make the hot melt pressure sensitive adhesive achieveequilibrium complementarity in initial viscosity, holding viscosity and fluidity. The viscosifier adopts a unique composition formula, which makes the viscosifier increase viscosity, fluidity and wettability, at the same time, it can improve the bond strength and water resistance.

Owner:恩平市盈嘉丰胶粘制品有限公司

High-temperature-resistant sealant and preparation method thereof

InactiveCN105885729AImprove high temperature resistanceGood oil resistanceNatural rubber adhesivesNon-macromolecular adhesive additivesEpoxyFiber

The invention discloses a high-temperature-resistant sealant and a preparation method thereof. The high-temperature-resistant sealant comprises, by weight, 50-70 parts of natural rubber, 5-6 parts of styrene butadiene rubber, 5-10 parts of acrylonitrile butadiene rubber, 5-7 parts of calcium sulfate crystal whisker, 10-30 parts of ceramic fiber, 10-13 parts of rice bran vinegar, 30-40 parts of cashew nut shell oil, 5-6 parts of gas-phase white carbon black, 5-8 parts of nano calcium carbonate, 10-15 parts of sepiolite powder, 10-12 parts of epoxy linseed oil, 6-8 parts of coumarone resin, 0.5-1.5 parts of dibutyl tin diacetate, 3-5 parts of 2-mercaptobenzothiazole, 5-10 parts of triethyl acetyl citrate, 1-2 parts of molybdenum boride, 6-10 parts of modified dolerite powder and 5-12 parts of a binding auxiliary. The high-temperature-resistant sealant has excellent resistance to high temperature, oil and radiation, has the advantages of high crack resistance and impact resistance and is high in compactness and comprehensive performance.

Owner:杨玉双

Modified non-asphalt-base self-adhesion waterproof coiled material with floating beads

InactiveCN107674619AHigh strengthImprove adhesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPolymer science

The invention provides a modified non-asphalt-base self-adhesion waterproof coiled material with floating beads. The modified non-asphalt-base self-adhesion waterproof coiled material is characterizedby comprising, by weight, 15-48% of electron-rich system softening oil (which is a mixture, contains large pi bonds and accordingly is an electron-rich system), 0.5-6% of hot melt adhesive grade elastomers, 2-10% of styrene-butadiene-styrene block copolymers, 1-5% of tackifying rubber, 5-20% of waste rubber elastomers, 0.1-0.5% of anti-ultraviolet agents, 3-8% of high-temperature resin, 8-20% oftackifying resin, 0.1-0.2% of interfacial agents, 5-30% of floating beads and 5-15% of waste edible oil. The electron-rich system softening oil, the hot melt adhesive grade elastomers, the styrene-butadiene-styrene block copolymers, the tackifying rubber, the waste rubber elastomers, the anti-ultraviolet agents, the high-temperature resin, the tackifying resin, the interfacial agents, the floatingbeads and the waste edible oil are prepared to obtain the modified non-asphalt-base self-adhesion waterproof coiled material.

Owner:湖北蓝盾之星科技有限公司

Shoe rubber and production method therefor

InactiveCN103709962AImprove breathabilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer sciencePolyolefin

The invention relates to the hot melt adhesive field, and especially discloses a soft, air-permeable shoe rubber without pollution and a production method therefor. The shoe rubber is composed of, by weight, 0-5 parts of polyethylene wax, 10-20 parts of naphthenic oil, 5-15 parts of metallocene catalysis polyolefin, 10-25 parts of amorphous-form poly-alpha-olefin, 5-15 parts of hydrogenated ethylene-isoprene-styrene copolymers, 5-10 parts of phenolic aldehyde-terpene resins, 10-20 parts of hydrogenated C5 petroleum resins, 5-10 parts of polyisobutylene, 0.8-1.5 parts of antioxidants and 0.5-1.5 parts of coupling agents. The produced shoe rubber is soft and good air permeability. In seal air permeability tests, sealing is carried out with the shoe rubber under 1.5 barometric pressure, inside and outside air pressure balance is achieved after 1h, the breaking elongation rate of the shoe rubber is more than 300%, the tensile strength is more than or equal to 3 MPa, the viscosity is 3000+ / -1000MPa.S (180 DEG C, a rotary viscosimeter), the C peel strength is more than 40N / 2.5cm ( peeling at the temperature of 180 DEG C), and the softening point is more than 135+ / -5 DEG C.

Owner:浙江固特新材料科技股份有限公司

Oil-proof silicone rubber sealant

InactiveCN107760255AGood solvent resistanceGood acid and alkali resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceSealant

The invention discloses an oil-proof silicone rubber sealant which is characterized in that the sealant comprises the following raw material ingredients in parts by mass: 30-50 parts of silicone rubber, 20-50 parts of fluororubber, 10-15 parts of tackifier, 10-20 parts of filling, 10-20 parts of calcium stearate, 1-10 parts of vinyltris (methylethylketoximino) silane, 2-5 parts of white carbon black, 1-3 parts of epoxy soybean oil and 0.5-3 parts of valcanizer. The oil-proof rubber sealant has the advantages of good heat and low temperature resistance, oil resistance, chemical resistance and decreased elongation at break.

Owner:TIANJIN JINLING TECH

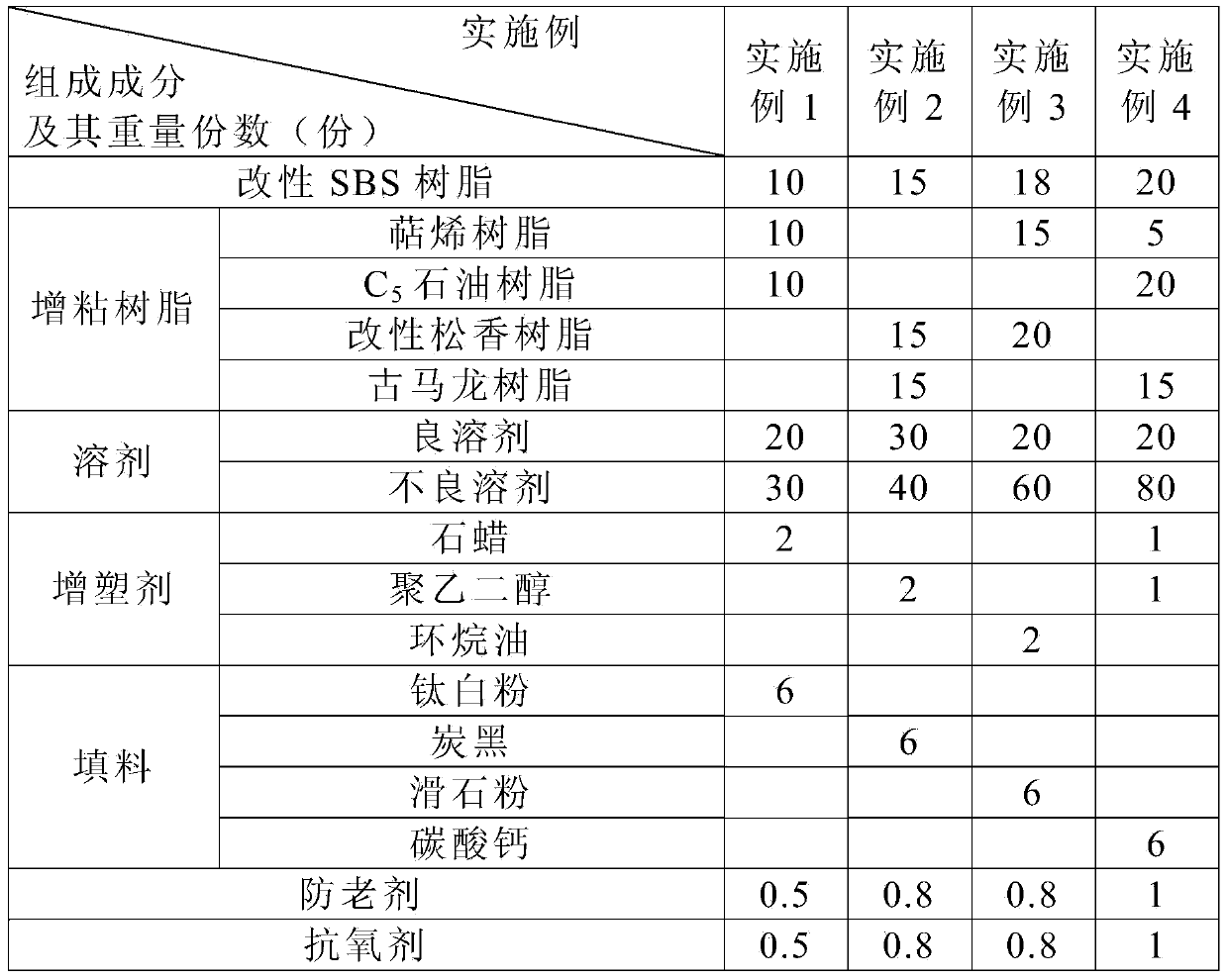

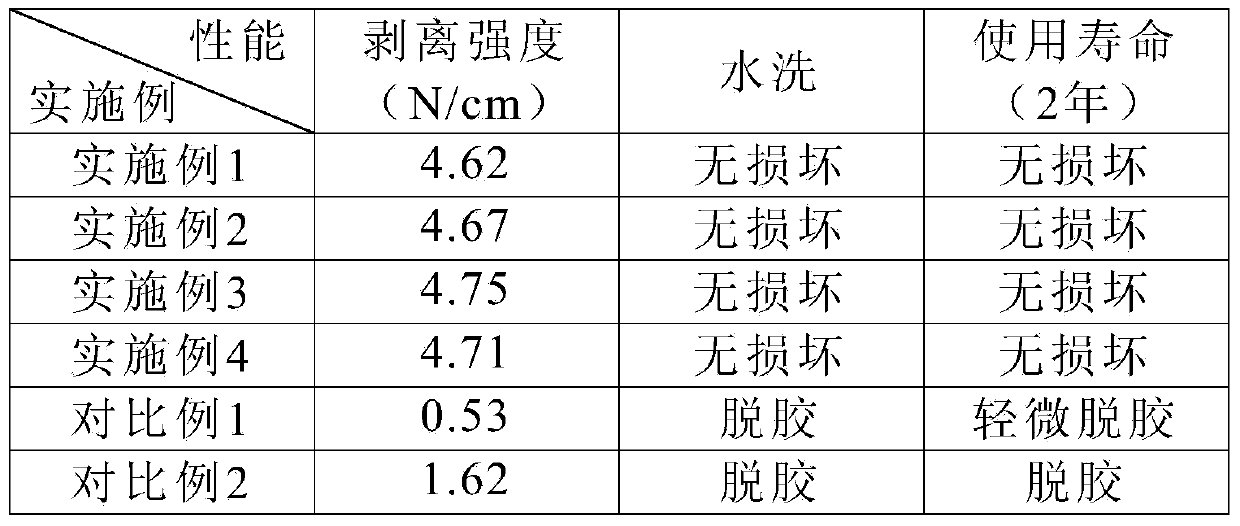

Matting without warps and processing technology thereof

ActiveCN104188438ADistinctive visual effectsExtended service lifeMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPlasticizerAdhesive

The invention relates to a kind of matting without warps. The matting comprises a matting body. Bamboo battens are used as the wefts of the matting, and the adhesive tape is used for replacing warps to bond the bamboo battens so that the matting body can be formed. The adhesive tape is composed of base materials and adhesive. The adhesive is prepared from, by weight, 10 parts to 20 parts of modified SBS resin, 15 parts to 40 parts of tackifying resin, 50 parts to 100 parts of solvent, 1 part to 3 parts of plasticizer, 5 parts to 8 parts of filler, 0.5 part to 1 part of anti-aging agent and 0.5 part to 1 part of antioxidant. According to the processing technology of the matting, first, the bamboo battens are used as the wefts, the bamboo battens are hot-pressed together with the adhesive tape at the temperature from 30 DEG C to 60 DEG C under the pressure from 2 MPa to 6 MPa, and the matting body is obtained; then, the fracture surface of the matting body is wrapped with edge lining cloth, compaction is performed, edge covering is performed, and the matting without warps is made. Only the wefts rather than warps of the matting can be seen from the front face of the matting, and the matting has a distinctive visual effect, and is good in firmness and long in service life.

Owner:江苏伟森家居有限公司

High-performance damping film

InactiveCN107177338AHigh dampingIncrease stickinessMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesSheet filmEngineering

The invention relates to a high-performance damping film. The high-performance damping film is characterized in that butyl rubber is taken as a substrate; the bonding performance of the film is improved by a tackifying resin and a filler; on the premise of ensuring high viscosity of the damping film, high damping performance of the whole damping film is ensured in a wider temperature range. Moreover, a damping layer is provided with a reflecting layer, so that the film strength can be enhanced, and noise is dispersed. During construction, only the film needs to be attached to the surface of the substrate, and sulfur treatment is not required. The high-performance damping film is simple in preparation process, is convenient for construction, is environmentally friendly, contributes to energy saving, and has remarkable damping and denoising effects.

Owner:三友(天津)高分子技术有限公司

Root penetration-resistant self-adhesive polymer modified asphalt waterproof coiled material

ActiveCN112391126AGood dispersionImprove root puncture resistanceNon-macromolecular adhesive additivesRoof covering using flexible materialsEpoxyFiber

The invention relates to a root penetration-resistant self-adhesive polymer modified asphalt waterproof coiled material which comprises an upper isolation layer, a base layer and a lower isolation layer, wherein the two surfaces of the base layer are coated with modified asphalt mastic; and the modified asphalt mastic is prepared from the following raw materials in parts by weight: 100-105 parts of petroleum asphalt, 8-12 parts of butadiene styrene rubber, 6-8 parts of SBS, 10-15 parts of modified nano-zinc oxide, 6-8 parts of coumarone resin, 1-2 parts of octyl epoxy stearate, 10-15 parts ofmodified fly ash fiber powder, 3-5 parts of an antioxidant and 1-5 parts of a stabilizer. The specially modified nano-zinc oxide and fly ash fiber powder are added into the modified asphalt used in the waterproof coiled material, so that the waterproof coiled material has excellent root penetration resistance.

Owner:潍坊市宇虹防水材料(集团)有限公司

Preparation method of adhesive for photovoltaic backplate

InactiveCN109337606AImprove surface molecular activityHigh bonding strengthNon-macromolecular adhesive additivesStarch adhesivesAdhesiveUltimate tensile strength

The invention discloses a preparation method of an adhesive for a photovoltaic backplate, and relates to the technical field of photovoltaic materials. The preparation method comprises the following steps: drying, grinding, blending, grinding and dispersing gelatinized mung bean starch, coumarone resin, Faku clay, rectorite powder and other components. The adhesive for the photovoltaic backplate has significantly improved peeling strength, waterproofness, oxidative aging resistance, temperature resistance and other performance, and the overall performance of the adhesive is improved, the application performance is improved, the service life is better guaranteed, and good popularization values are achieved.

Owner:安徽兆拓新能源科技有限公司

Hot melt adhesive with high rolling ball initial adhesion and preparation method of hot melt adhesive

ActiveCN108441148AMineral oil hydrocarbon copolymer adhesivesCoumarone-indene polymer adhesivesPolymer scienceAntioxidant

A hot melt adhesive with high rolling ball initial adhesion is at least prepared from, in parts by weight, 100 parts of thermoplastic elastomers, 40-60 parts of rubber oil, 10-20 parts of modified EPDM (ethylene propylene diene monomer), 20-30 parts of tackifying resin, 5-15 parts of filler and 1-5 parts of an antioxidant.

Owner:SHANGHAI JIAHAO ADHESIVE PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com