Flame-retardant quick bonding adhesive and preparation method thereof

An adhesive, flame-retardant technology, used in adhesives, graft polymer adhesives, mineral oil hydrocarbon copolymer adhesives, etc. Difficult to improve, low peel strength between bonding materials, etc., to achieve the effect of wide application range, improved aging resistance, and fast bonding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

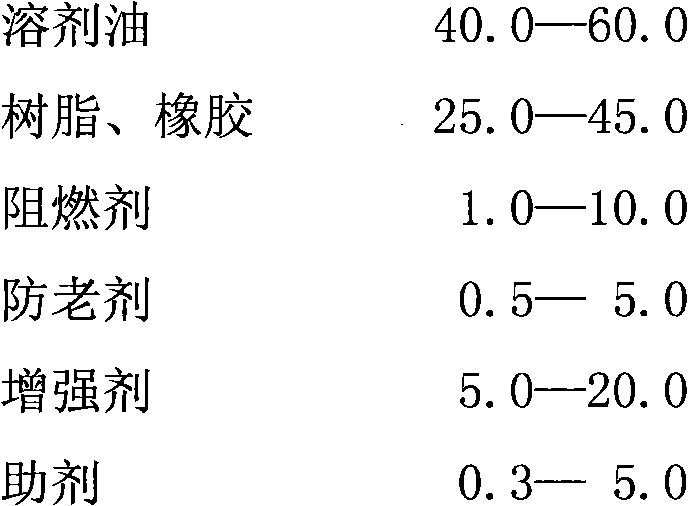

[0091] 1. Raw material composition ratio (parts by weight):

[0092]

[0093] 2. Preparation method:

[0094] The preparation method of adhesive of the present invention is carried out as follows:

[0095] a. Put quantitative 6# and 120# solvent oils into a container with a stirrer according to the formula ratio, and stir to obtain a mixed solvent;

[0096] b. Add the chloroprene rubber specified in the formula to the above mixed solvent, stir well to dissolve it completely, then add methyl methacrylate and benzoyl peroxide;

[0097] c. Turn on the heating device and raise the temperature to 70°C, carry out graft polymerization of methyl methacrylate and chloroprene rubber, continuously stir and react at a temperature of 65-70°C for 5-6 hours, and then cool down to 40°C;

[0098] d. Add SBS rubber, phenolic resin, coumarone resin or petroleum resin according to the formula, stir and dissolve into a thick liquid and continue to react for 1 hour;

[0099] e. Dissolve the a...

Embodiment 2

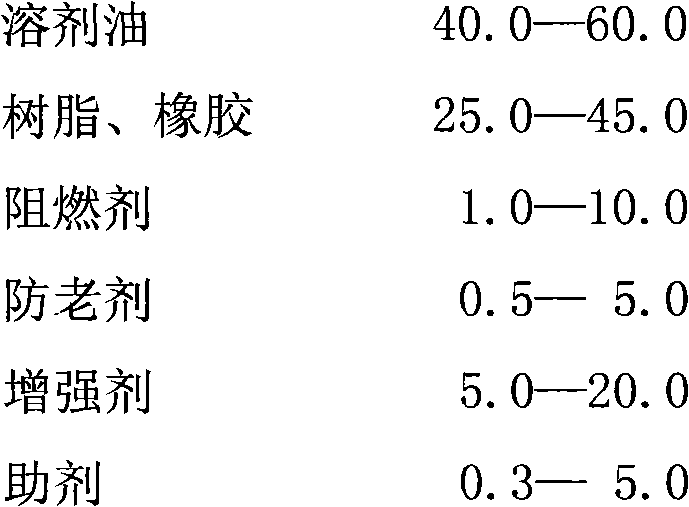

[0103] 1. Raw material composition ratio (parts by weight):

[0104]

[0105] 2. Preparation method:

[0106] The preparation method of adhesive of the present invention is carried out as follows:

[0107] a. Put quantitative 6# and 120# solvent oils into a container with a stirrer according to the formula ratio, and stir to obtain a mixed solvent;

[0108] b. Add the chloroprene rubber specified in the formula to the above mixed solvent, stir well to dissolve it completely, then add methyl methacrylate and benzoyl peroxide;

[0109] c. Turn on the heating device and raise the temperature to 70°C, carry out graft polymerization of methyl methacrylate and chloroprene rubber, continuously stir and react at a temperature of 65-70°C for 5-6 hours, and then cool down to 40°C;

[0110] d. Dissolve the anti-aging agent in a suitable container with acetone or cyclohexane for later use. This step can be arranged in advance;

[0111]e. After weighing according to the formula in tu...

Embodiment 3

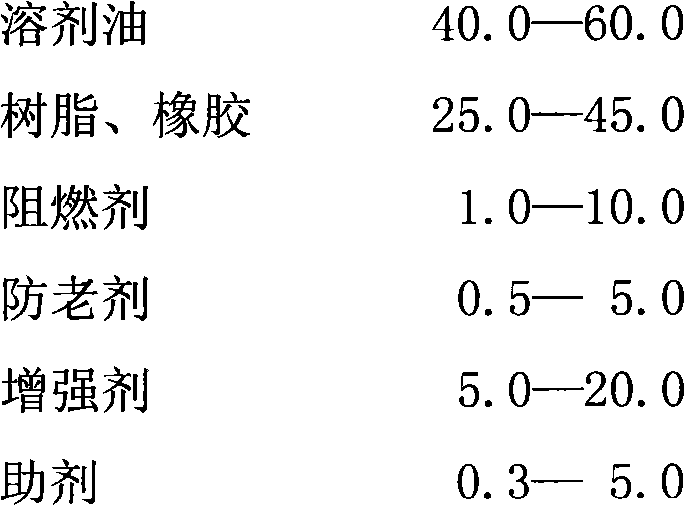

[0114] 1. Raw material composition ratio (parts by weight):

[0115]

[0116] 2. Preparation method:

[0117] The preparation method of adhesive of the present invention is carried out as follows:

[0118] a. Put quantitative 6# and 120# solvent oils into a container with a stirrer according to the formula ratio, and stir to obtain a mixed solvent;

[0119] b. Add the chloroprene rubber specified in the formula to the above mixed solvent, stir well to dissolve it completely, then add methyl methacrylate and benzoyl peroxide;

[0120] c. Turn on the heating device and raise the temperature to 70°C, carry out graft polymerization of methyl methacrylate and chloroprene rubber, continuously stir and react at a temperature of 65-70°C for 5-6 hours, and then cool down to 40°C;

[0121] d. Add SBS rubber, phenolic resin, coumarone resin or petroleum resin according to the formula, stir and dissolve into a thick liquid and continue to react for 1 hour;

[0122] e. Dissolve the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com