Hot melt adhesive with high rolling ball initial adhesion and preparation method of hot melt adhesive

An initial tack, hot melt adhesive technology, applied in the direction of adhesives, adhesive types, other rubber adhesives, etc., can solve problems such as weakened bond strength, large temperature differences, and inconvenience for customers to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

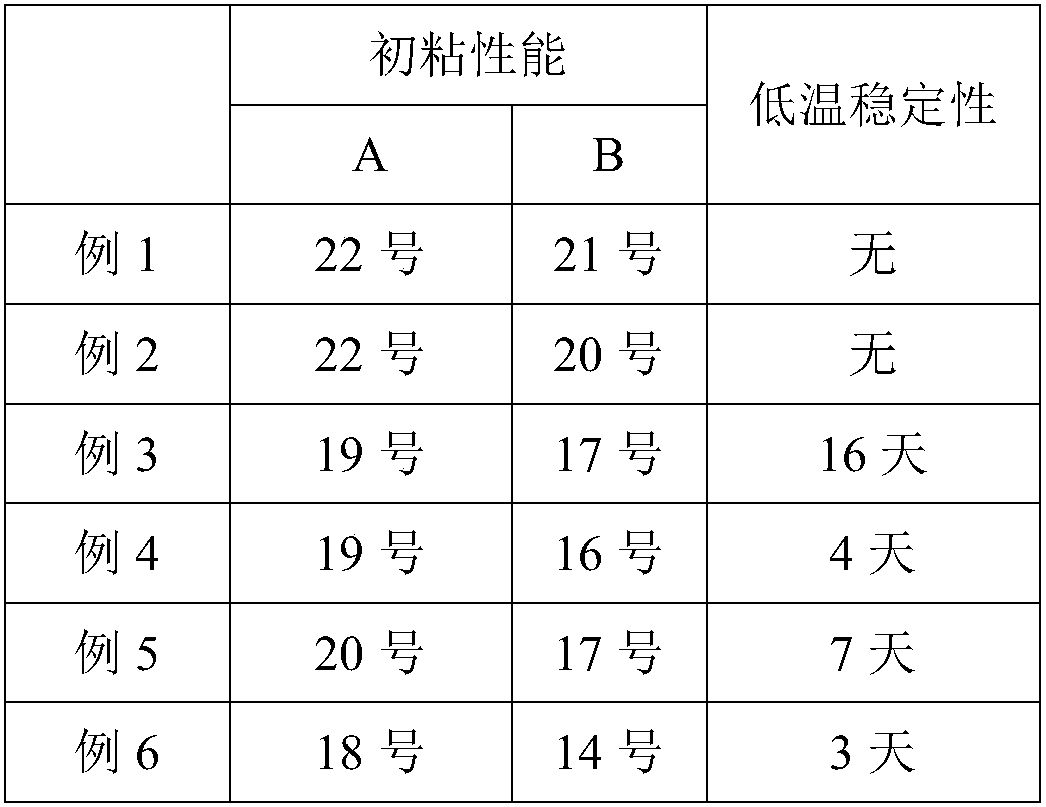

Examples

preparation example Construction

[0042] The preparation method of the modified EPDM is as follows: EPDM and acid anhydride are added into a mixer at a weight ratio of 100:8, blended at 185° C. for 3 hours, and then extruded.

[0043] In some preferred embodiments, the filler is selected from zinc oxide.

[0044] In some subdivided applications in the label industry, such as special express delivery sheets, the requirements for hot-melt pressure-sensitive adhesive rolling ball initial adhesion are high, fast labeling, and labels will not drop during use. At present, the hot-melt pressure-sensitive adhesive products on the market can meet the peel strength requirements of customers, but they do not meet the requirements of high rolling ball tack at the same time. This product can meet the high peel strength of customers while greatly improving the rolling ball tack performance of the product. , especially the initial tack properties at low temperatures.

[0045] In some embodiments, the tackifying resin is sel...

Embodiment 1

[0050] Hot melt adhesive, in parts by weight, consists of 80 parts of styrene-butadiene-styrene block copolymer, 20 parts of styrene-ethylene-butylene-styrene block copolymer, 37.5 parts of 4010 naphthenic oil , 7.5 parts of TDAE oil, 18 parts of modified EPDM, 10 parts of C5 petroleum resin, 15 parts of C9 petroleum resin, 8 parts of zinc oxide, 2 parts of 2,6-di-tert-butyl 4-methylphenol.

[0051] The preparation method of the modified EPDM is as follows: adding EPDM and pyridine-3,4-dicarboxylic acid anhydride into a mixer at a weight ratio of 100:8, blending at 185° C. for 3 hours, and extruding to obtain the obtained product.

[0052] The method for preparing a hot melt adhesive comprises the following steps: under an inert gas atmosphere, adding 80 parts of styrene-butadiene-styrene block copolymer, styrene-ethylene-butylene-styrene block copolymer 20 parts of compound, 18 parts of modified EPDM, 10 parts of C5 petroleum resin, 15 parts of C9 petroleum resin, heated to 2...

Embodiment 2

[0054] Hot melt adhesive, in parts by weight, consists of 80 parts of styrene-butadiene-styrene block copolymer, 20 parts of styrene-ethylene-butylene-styrene block copolymer, 37.5 parts of 4010 naphthenic oil , 7.5 parts of TDAE oil, 18 parts of modified EPDM, 10 parts of C5 petroleum resin, 15 parts of C9 petroleum resin, 8 parts of zinc oxide, 2 parts of 2,6-di-tert-butyl 4-methylphenol.

[0055] The preparation method of the modified EPDM is as follows: adding EPDM and 2,3-pyridine dicarboxylic acid anhydride into a mixer at a weight ratio of 100:8, blending at 185° C. for 3 hours, and extruding to obtain the obtained product.

[0056] The method for preparing a hot melt adhesive comprises the following steps: under an inert gas atmosphere, adding 80 parts of styrene-butadiene-styrene block copolymer, styrene-ethylene-butylene-styrene block copolymer 20 parts of compound, 18 parts of modified EPDM, 10 parts of C5 petroleum resin, 15 parts of C9 petroleum resin, heated to 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com