Preparation method of adhesive for photovoltaic backplate

A photovoltaic backplane and adhesive technology, applied in the direction of adhesive additives, adhesive types, starch adhesives, etc., can solve the problems of applicability limitations, poor temperature resistance and other problems, and achieve good application performance and peel strength High, improve the effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This embodiment relates to an adhesive for a photovoltaic backplane, which is composed of the following raw materials in parts by weight:

[0073] 64 parts of gelatinized mung bean starch;

[0074] 27 parts of coumarone resin;

[0075] 6 parts Faku clay;

[0076] 9 parts of rectorite powder;

[0077] 4 parts of neopentyl glycol dimethacrylate;

[0078] 2 parts of polyvinyl ether;

[0079] 3 parts of diacetone acrylamide;

[0080] 1.5 parts of phenyl phosphorus dichloride;

[0081] 2.8 parts of compound crosslinking agent;

[0082] 1 part of compound coupling agent;

[0083] 0.8 parts of compound accelerator;

[0084] 1 part of compound antioxidant.

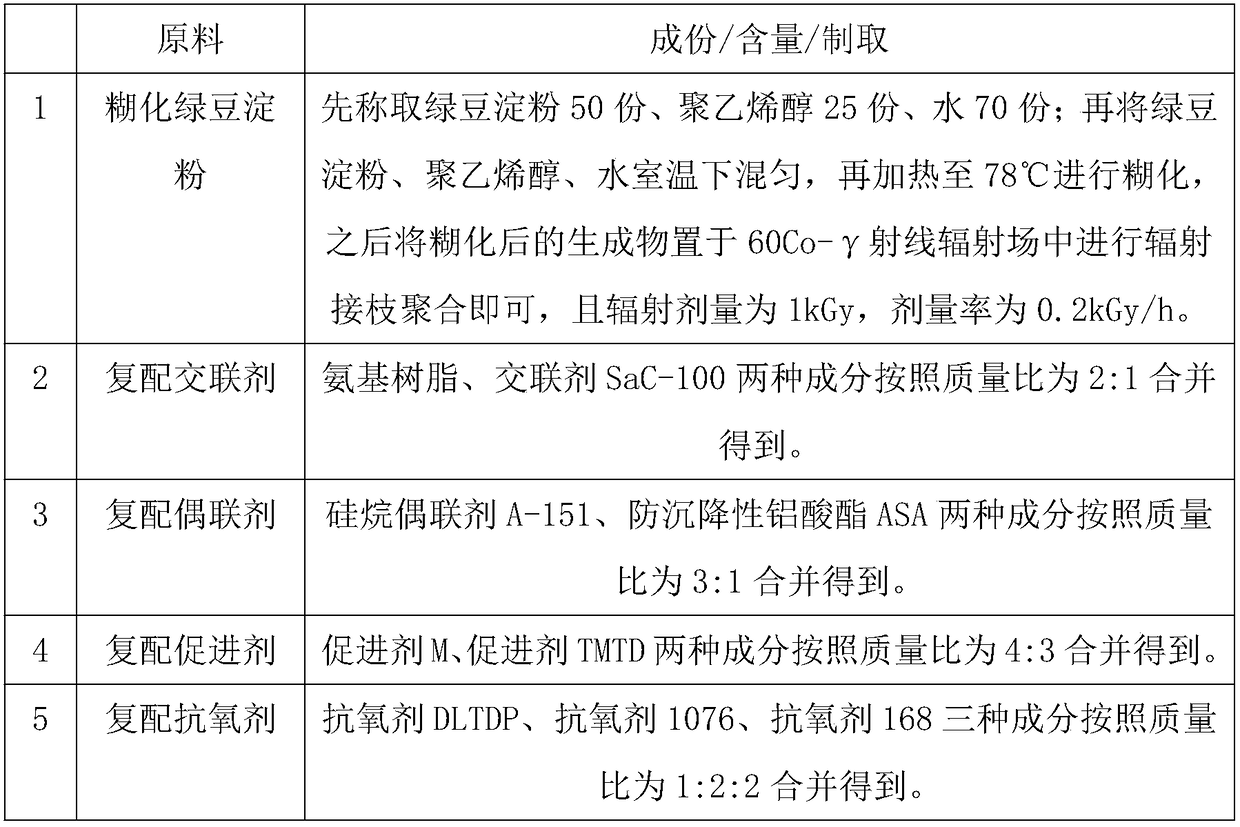

[0085] The selection and preparation of gelatinized mung bean starch, compound crosslinking agent, compound coupling agent and compound antioxidant in the present embodiment are shown in Table 1 below:

[0086] Table 1

[0087]

[0088] The preparation method of adhesive in the present embodiment generally car...

Embodiment 2

[0094] This embodiment relates to an adhesive for a photovoltaic backplane, which is composed of the following raw materials in parts by weight:

[0095] 68 parts of gelatinized mung bean starch;

[0096] 30 parts of coumarone resin;

[0097] 7 parts Faku clay;

[0098] 10 parts of rectorite powder;

[0099] 4.5 parts of neopentyl glycol dimethacrylate;

[0100] 2.5 parts of polyvinyl ether;

[0101] 3.5 parts of diacetone acrylamide;

[0102] 1.8 parts of phenyl phosphorus dichloride;

[0103] 3.3 parts of compound crosslinking agent;

[0104] 1.3 parts of compound coupling agent;

[0105] 0.9 parts of compound accelerator;

[0106] 1.4 parts of compound antioxidant.

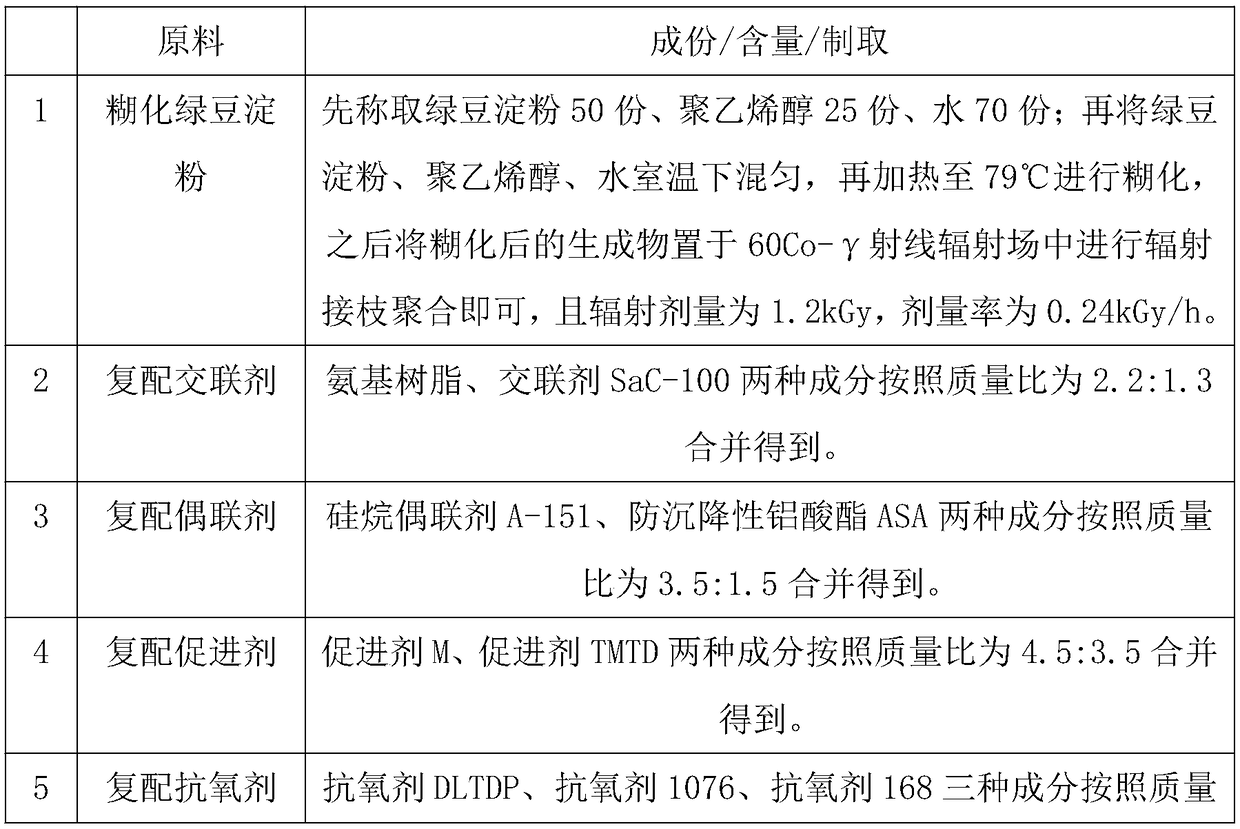

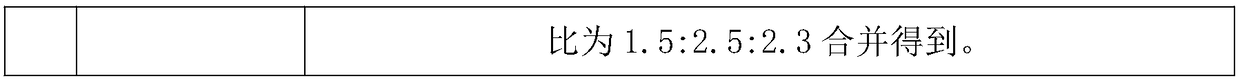

[0107] The selection and preparation of gelatinized mung bean starch, compound crosslinking agent, compound coupling agent and compound antioxidant in the present embodiment are shown in Table 2 below:

[0108] Table 2

[0109]

[0110]

[0111] The preparation method of adhesive in the present...

Embodiment 3

[0117] This embodiment relates to an adhesive for a photovoltaic backplane, which is composed of the following raw materials in parts by weight:

[0118] 70 parts of gelatinized mung bean starch;

[0119] 31 parts of coumarone resin;

[0120] 8 parts Faku clay;

[0121] 11 parts of rectorite powder;

[0122] 5 parts of neopentyl glycol dimethacrylate;

[0123] 2.8 parts of polyvinyl ether;

[0124] 4 parts of diacetone acrylamide;

[0125] 2 parts of phenyl phosphorus dichloride;

[0126] 3.5 parts of compound crosslinking agent;

[0127] 1.5 parts of compound coupling agent;

[0128] 1 part of compound accelerator;

[0129] Compound antioxidant 1.5 parts.

[0130] The selection and preparation of gelatinized mung bean starch, compound crosslinking agent, compound coupling agent and compound antioxidant in the present embodiment are shown in Table 3 below:

[0131] table 3

[0132]

[0133] The preparation method of adhesive in the present embodiment generally ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com