Aqueous pressure-sensitive adhesive and preparation method thereof

A pressure-sensitive adhesive, water-based technology, used in adhesives, carboxyl rubber adhesives, natural rubber adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

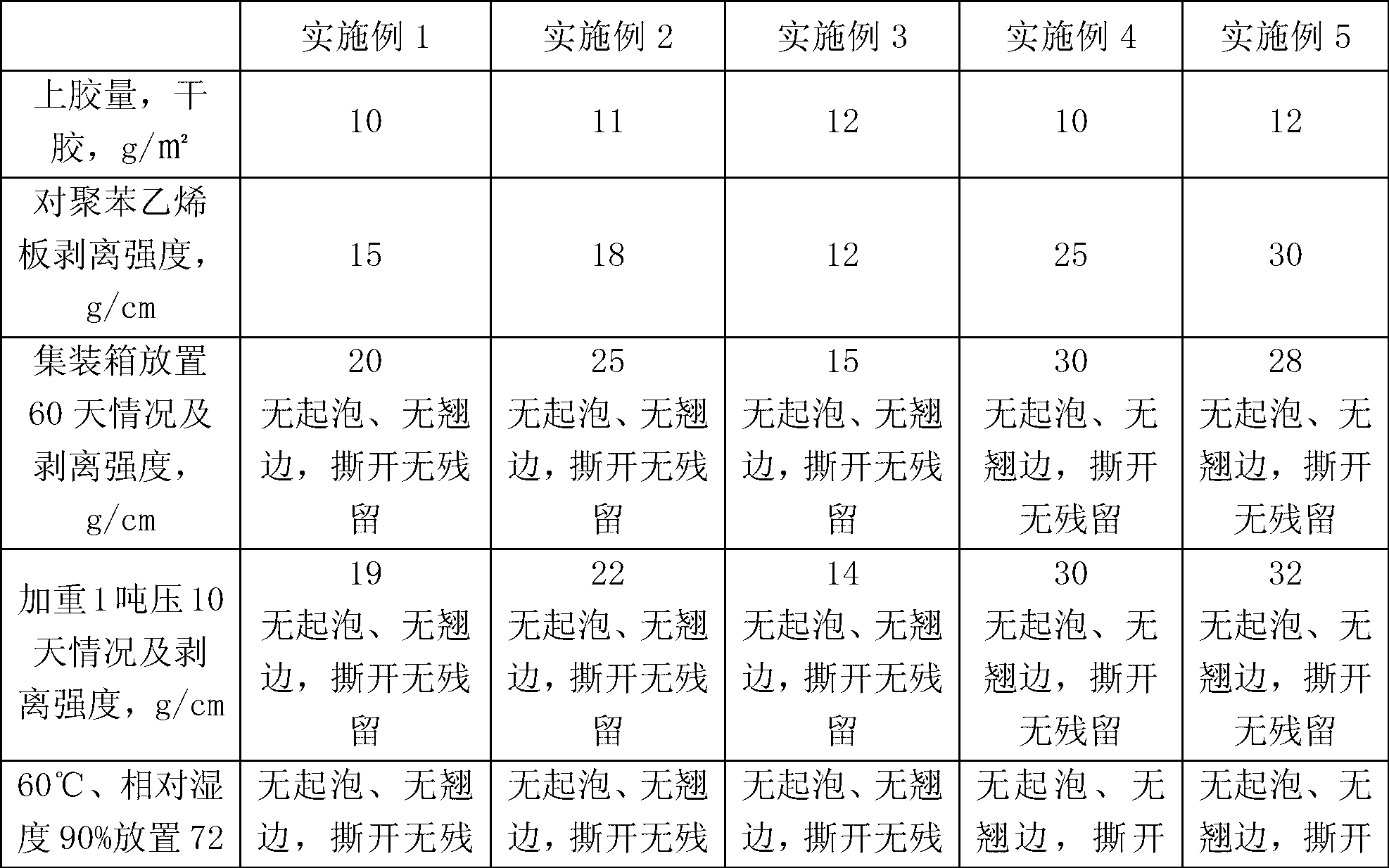

Examples

Embodiment 1

[0025] Add 54 parts of natural rubber latex to a nitrogen-protected reactor and heat up to 60°C while stirring, and start adding 6 parts of anti-aging agent composite emulsion (composed of 97% by weight of 4,4-bis(2,2-dimethylbenzyl) Diphenylamine and 3% by weight of epoxidized soybean oil), 10 parts of acrylic resin emulsion (commercially available product) with a glass transition temperature of 60°C, 30 parts of fully hydrogenated C5, C9 copolymerized petroleum resin emulsion, and then cooled to room temperature, with ammonia water After adjusting the pH value to 8-9, filter to obtain the water-based pressure-sensitive adhesive.

Embodiment 2

[0027] In the nitrogen-protected reactor, add 70 parts of nitrile latex and heat up to 55 ° C while stirring, start to add 5 parts of anti-aging agent composite emulsion (by 92% by weight of N-phenyl-N'-isopropyl-p-phenylene) Diamine, 3% by weight of machine oil and 5% naphthenic oil), 5 parts of acrylic resin emulsion with a glass transition temperature of 40°C, 20 parts of terpene resin emulsion, then cooled to room temperature, and adjusted to pH 8 with ammonia water After -9, filter to obtain the water-based pressure-sensitive adhesive.

Embodiment 3

[0029] Add 60 parts of styrene-butadiene latex to the reactor under nitrogen protection and heat up to about 62 ° C while stirring, start to add 4 parts of anti-aging agent composite emulsion (by 50% by weight of N-phenyl-β-naphthylamine, 45% by weight N-phenyl-N'-isopropyl-p-phenylenediamine and 5% by weight of stearic acid) 5 parts of acrylic resin emulsion with a glass transition temperature of 80 ° C, 21 parts of carboxylated styrene-butadiene latex, 10 parts of terpene The resin emulsion is then cooled to room temperature, adjusted to pH 8-9 with ammonia water, and filtered to obtain the water-based pressure-sensitive adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com