Environment-friendly sealant and preparation method thereof

An environmentally friendly, sealant technology, applied in the field of sealants, can solve problems such as human harm and load pollution, and achieve the effects of improving heat resistance, weakening decomposition, and increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

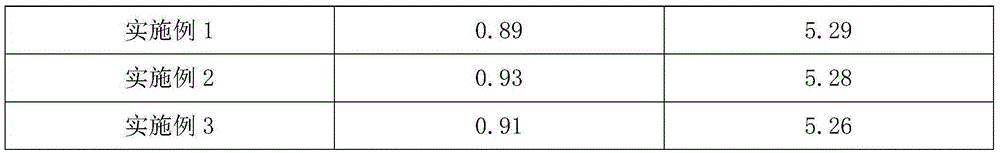

Embodiment 1

[0033] Prepare as follows:

[0034] S1: Weigh each raw material according to the ratio of parts by weight;

[0035] S2: Mix gasoline, ethyl acetate, and acetone to form a mixed solvent;

[0036] S3: the tert-butylphenol-formaldehyde resin is dissolved in the mixed solvent that is based on 35% of the tert-butylphenol-formaldehyde resin weight part in the mixed solvent that S2 obtains, then adds the magnesium oxide based on 5% of the tert-butyl-phenol-formaldehyde resin weight part, at room temperature Stir under 8 hours, carry out chelation reaction, obtain viscous shape chelate;

[0037] S4: Mix butyl rubber and natural rubber and masticate 5 times on an open mill to obtain a masticated product;

[0038] S5: Add the remaining amount of magnesium oxide, stearic acid, vulcanized paste, diatomaceous earth, sericite, rutile titanium dioxide, light calcium carbonate, talcum powder, and ultraviolet stabilizer to the masticated product obtained in S4 in order , Antioxidant, extrud...

Embodiment 2

[0041] Prepare as follows:

[0042] S1: Weigh each raw material according to the ratio of parts by weight;

[0043] S2: Mix gasoline, ethyl acetate, and acetone to form a mixed solvent;

[0044] S3: the tert-butylphenol-formaldehyde resin is dissolved in the mixed solvent that is based on 35% of the tert-butylphenol-formaldehyde resin weight part in the mixed solvent that S2 obtains, then adds the magnesium oxide based on 5% of the tert-butyl-phenol-formaldehyde resin weight part, at room temperature Under stirring 6 hours, carry out chelation reaction, obtain viscous shape chelate;

[0045] S4: Mix butyl rubber and natural rubber and masticate 3 times on an open mill to obtain a masticated product;

[0046] S5: Add the remaining amount of magnesium oxide, stearic acid, vulcanized paste, diatomaceous earth, sericite, rutile titanium dioxide, light calcium carbonate, talcum powder, and ultraviolet stabilizer to the masticated product obtained in S4 in order , Antioxidant, extr...

Embodiment 3

[0049] Prepare as follows:

[0050] S1: Weigh each raw material according to the ratio of parts by weight;

[0051] S2: Mix gasoline, ethyl acetate, and acetone to form a mixed solvent;

[0052] S3: the tert-butylphenol-formaldehyde resin is dissolved in the mixed solvent that is based on 35% of the tert-butylphenol-formaldehyde resin weight part in the mixed solvent that S2 obtains, then adds the magnesium oxide based on 5% of the tert-butyl-phenol-formaldehyde resin weight part, at room temperature Stir under 7 hours, carry out chelation reaction, obtain viscous shape chelate;

[0053] S4: Mix butyl rubber and natural rubber and masticate 4 times on an open mill to obtain a masticated product;

[0054] S5: Add the remaining amount of magnesium oxide, stearic acid, vulcanized paste, diatomaceous earth, sericite, rutile titanium dioxide, light calcium carbonate, talcum powder, and ultraviolet stabilizer to the masticated product obtained in S4 in order , Antioxidant, extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com