NiAl intermetallic base solid self-lubricating composite material and preparation method thereof

An intermetallic compound, solid self-lubricating technology, applied in the field of NiAl intermetallic compound-based solid self-lubricating composite material and its preparation, can solve the problem of lubricant wettability, difficult control of interface reaction and interface structure, and insufficient improvement of lubricating performance. Obviously, the stability of the lubricant is difficult to guarantee, etc., to achieve the effects of excellent tribological properties, fast preparation, and reduced synthesis costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

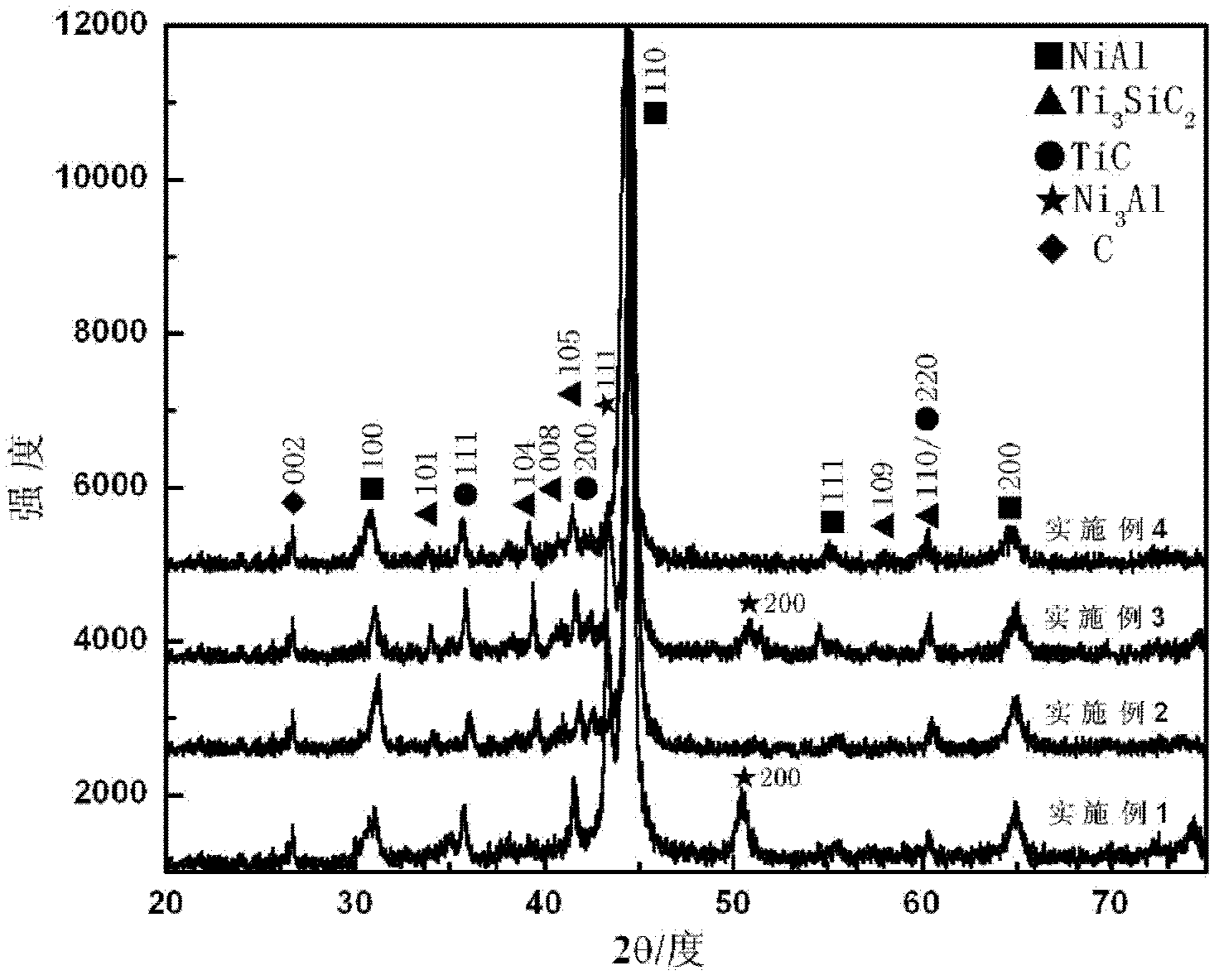

Embodiment 1

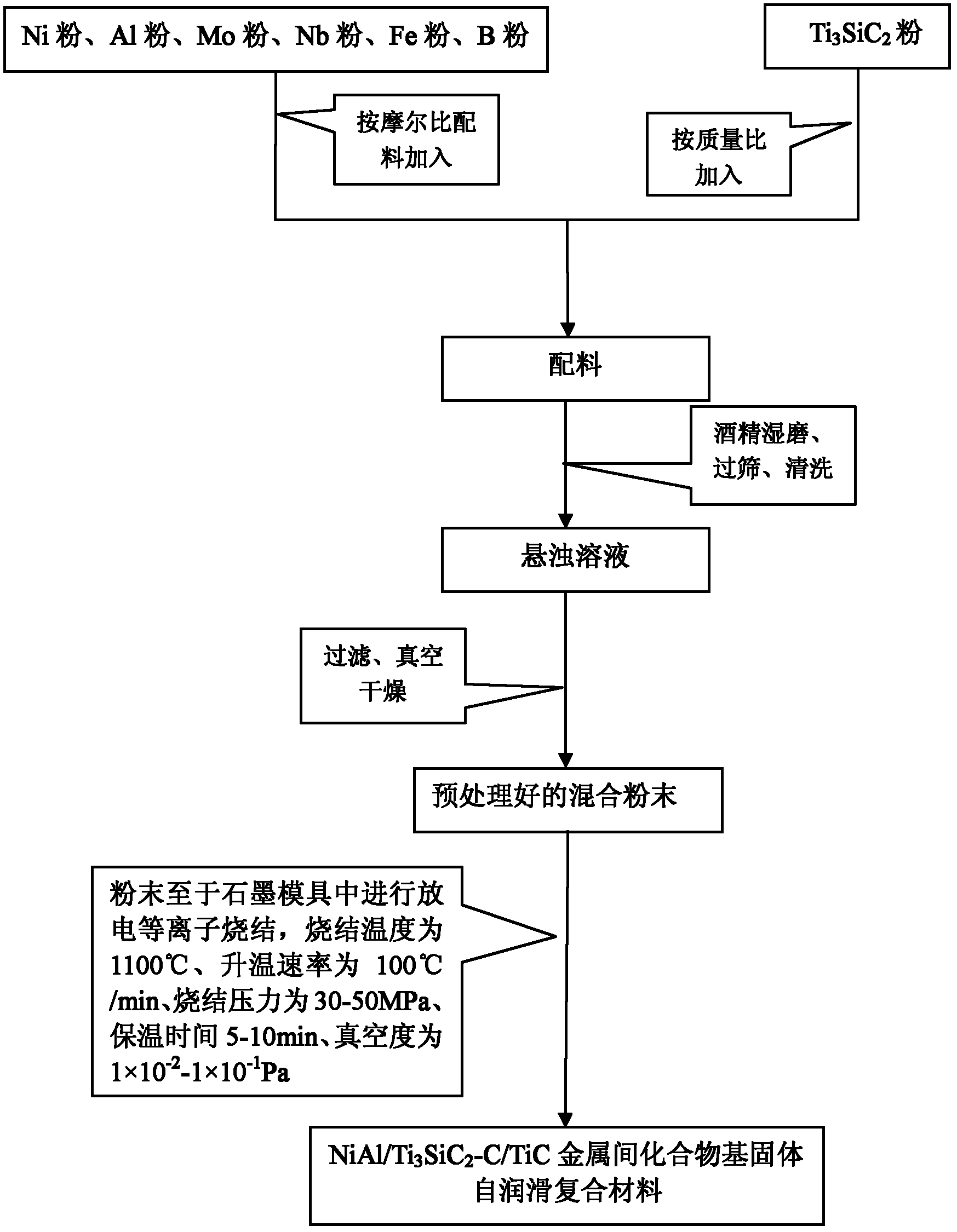

[0035] Such as figure 1 Shown, the preparation method of NiAl intermetallic compound base solid self-lubricating composite material, it comprises the steps:

[0036] 1) Using Ni powder, Al powder, Mo powder, Nb powder, Fe powder and B powder as the base material, Ti 3 SiC 2 The powder (powder material) is the lubricant reinforcement phase, according to the molar ratio of Ni: Al: Mo: Nb: Fe: B=48: 50: 1: 1: 0.5: 0.02, weigh 6.4 grams of Ni powder, 3.06 grams of Al powder , 0.22 gram of Cr powder, 0.21 gram of Nb powder, 0.06 gram of Fe powder and 0.05 gram of B powder, a total of 10 g, mixed to obtain mixed powder; then add 0.5 gram of high-purity Ti 3 SiC 2 Powder (purity ≥ 99.5wt.%) is added to the above-mentioned mixed powder to obtain ingredients (batch);

[0037] 2) Put the above-mentioned ingredients and steel balls in a stainless steel vacuum ball mill tank, and wet-mill on a planetary ball mill for 5 hours; the wet-milling medium is alcohol; wherein: the speed of th...

Embodiment 2

[0042] The preparation method of NiAl intermetallic compound base solid self-lubricating composite material, it comprises the steps:

[0043] 1) Using Ni powder, Al powder, Mo powder, Nb powder, Fe powder and B powder as the base material, Ti 3 SiC 2 The powder is the lubricant reinforcement phase, according to the molar ratio of Ni:Al:Mo:Nb:Fe:B=48:50:1:1:0.5:0.02, weigh 6.4 grams of Ni powder, 3.06 grams of Al powder, 0.22 grams of Cr powder, 0.21 gram of Nb powder, 0.06 gram of Fe powder and 0.05 gram of B powder, a total of 10 g, mixed to obtain a mixed powder; then add 1.0 gram of high-purity Ti 3 SiC 2 Powder (purity ≥ 99.5wt.%) is added to the above mixed powder to obtain ingredients;

[0044] 2) Put the above-mentioned ingredients and steel balls in a stainless steel vacuum ball mill tank, and wet-mill on a planetary ball mill for 5 hours; the wet-milling medium is alcohol; wherein: the speed of the planetary ball mill is 180 rpm, and the mass ratio of balls to mate...

Embodiment 3

[0049] The preparation method of NiAl intermetallic compound base solid self-lubricating composite material, it comprises the steps:

[0050] 1) Using Ni powder, Al powder, Mo powder, Nb powder, Fe powder and B powder as the base material, Ti 3 SiC 2 The powder is the lubricant reinforcement phase, according to the molar ratio of Ni:Al:Mo:Nb:Fe:B=48:50:1:1:0.5:0.02, weigh 6.4 grams of Ni powder, 3.06 grams of Al powder, 0.22 grams of Cr powder, 0.21 gram of Nb powder, 0.06 gram of Fe powder and 0.05 gram of B powder, a total of 10 g, mixed to obtain mixed powder; then add 1.5 gram of high-purity Ti 3 SiC 2 Powder (purity ≥ 99.5wt.%) is added to the above mixed powder to obtain ingredients (batch);

[0051] 2) Put the above-mentioned ingredients and steel balls in a stainless steel vacuum ball mill tank, and wet-mill on a planetary ball mill for 5 hours; the wet-milling medium is alcohol; wherein: the speed of the planetary ball mill is 200 rpm, and the mass ratio of balls t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com