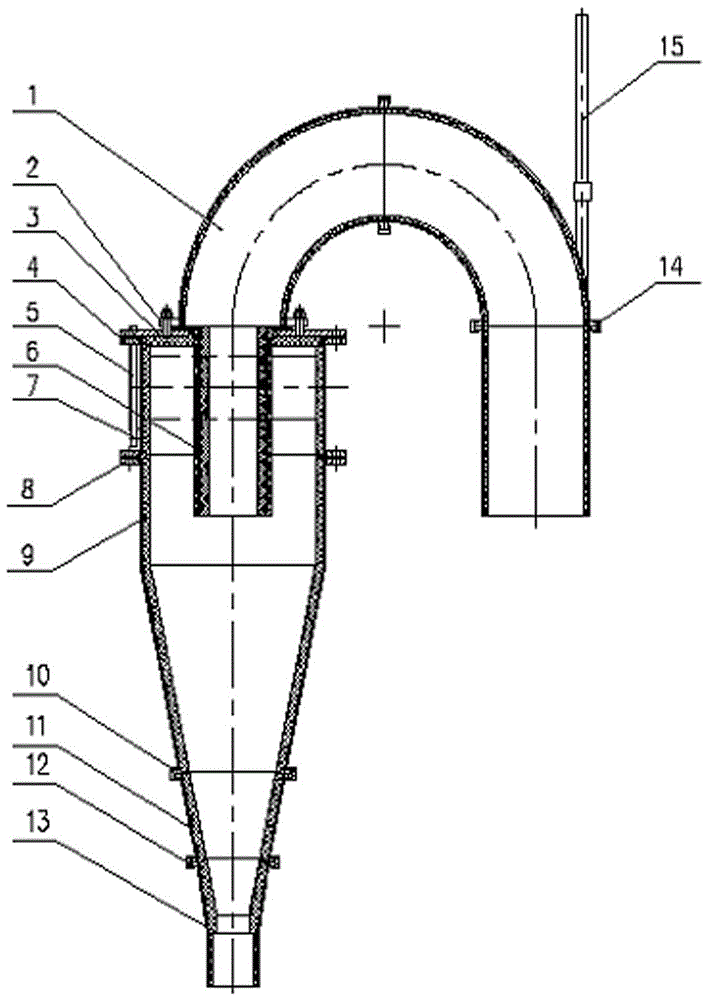

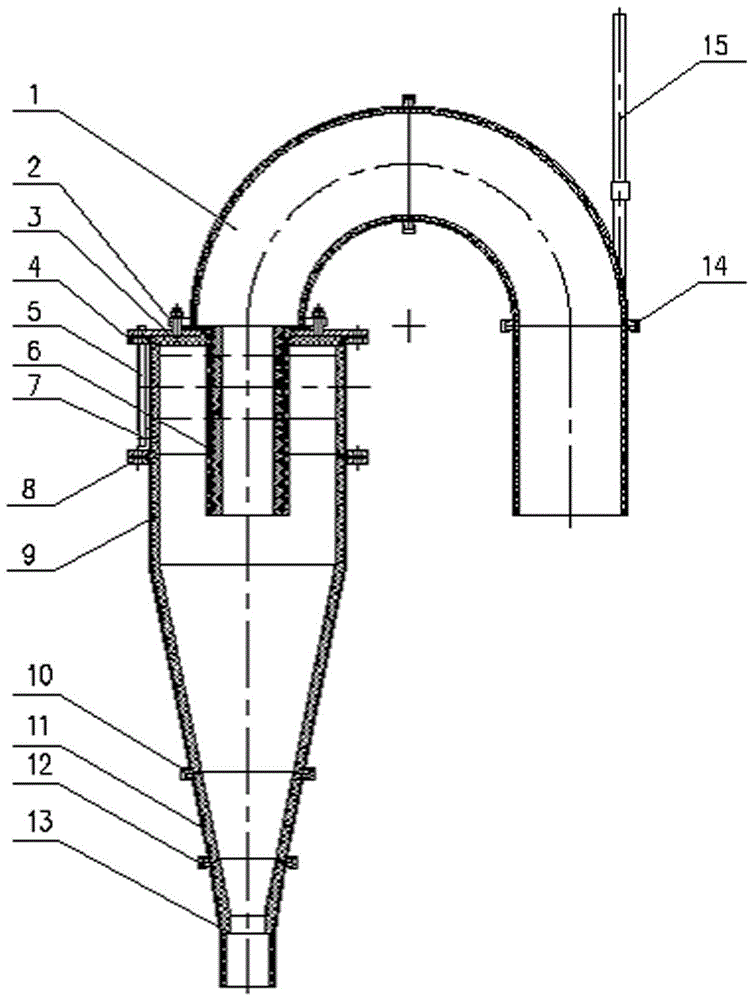

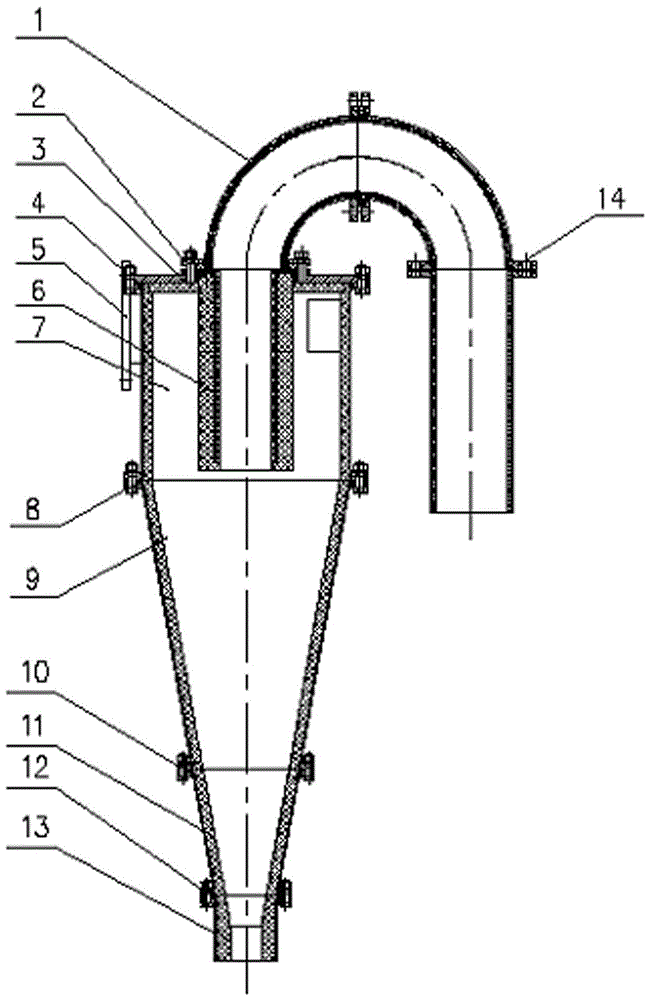

Non-equal-settling hydrocyclone and strip-shaped unit integrated technology with two overflow fineness increasing values increased and decreased correspondingly

A non-equal drop, cyclone technology, used in cyclone devices, devices with reversible cyclone axes, chemical instruments and methods, etc., to reduce the number of used counts, increase the processing capacity, and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific gravity of the middle and low-grade colloidal phosphate minerals treated by the strip unit without equal-fall cyclone in the present invention is between 2.8 and 3.2, the specific gravity of aluminosilicate gangue minerals is about 2.6, and the specific gravity difference is between 0.2 and 0.6 , according to its equal-fall theory, it can be regarded as no equal-fall mineral species, and the grading particle size boundary can be divided according to the fineness of the dissociation degree of the target phosphorus mineral monomer, without considering the specific gravity difference with gangue minerals. In other words, the non-equal-decrease cyclone divides the grading boundary to recover the target minerals by particle size, while the equal-decline cyclone divides the grading boundary to recover the target minerals by the specific gravity, small particle size and small specific gravity, and large particle size. . The unit of the former is the size of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com