Method for preparing linoleic acid sustained-release algal inhibiting agent

A technology of linoleic acid and algae inhibitor, which is applied in the field of preparation of linoleic acid sustained-release algae inhibitor, which can solve the problems of algae drug resistance, environmental pollution, and failure to reach the inhibitory concentration, so as to improve the algae inhibition effect , Avoid secondary pollution, reduce the effect of input times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

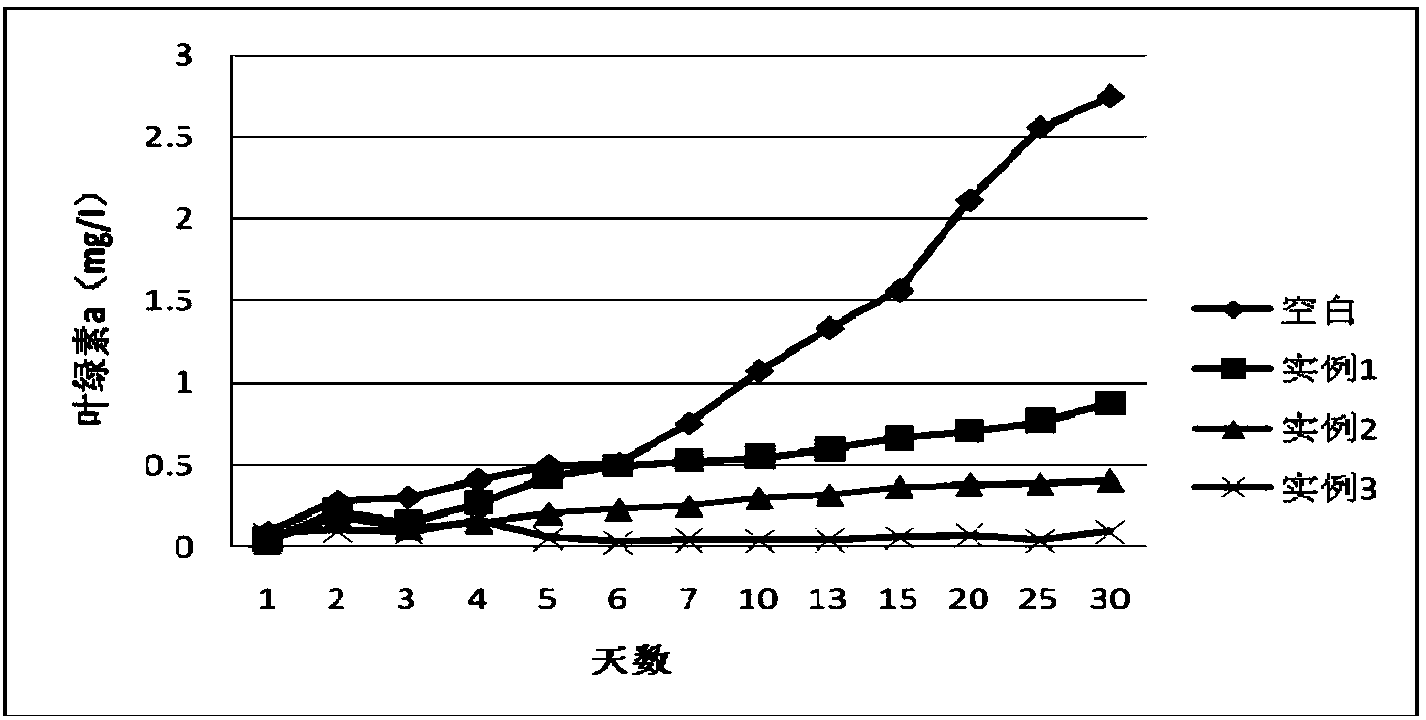

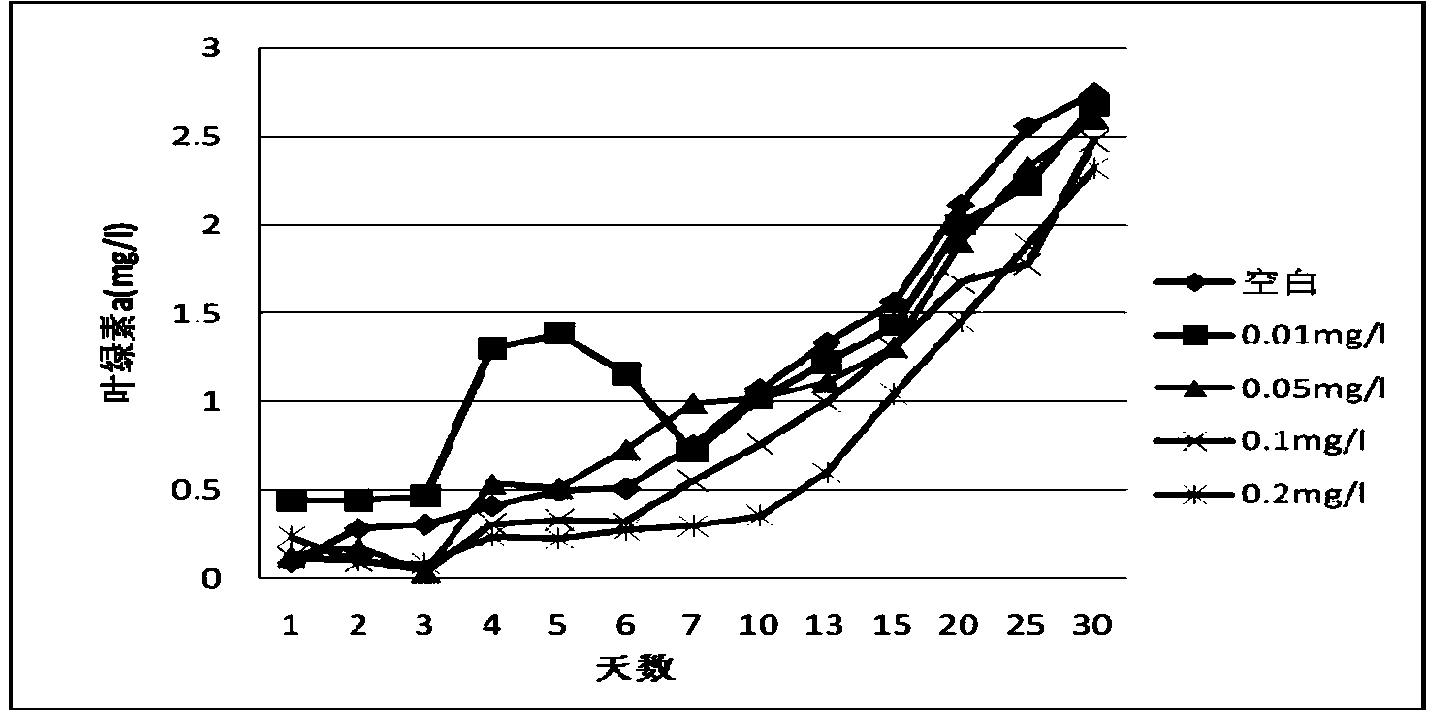

Embodiment 1

[0024] Weigh 0.1g linoleic acid and dissolve it in 1.5mL ethyl oleate, then add 0.7mL emulsifier OP-10, make a 50mL solution with distilled water, then add 1.25g sodium alginate and mix well, draw the above mixture with a syringe Drop into 100 mL of glacial acetic acid solution containing 1 g of chitosan and 4 g of calcium chloride with a content of 3 mL of glacial acetic acid to form microspheres, add 1.5 mL of glutaraldehyde after cooling to room temperature, filter with suction, and rinse with petroleum ether and distilled water for 5 -8 times; after drying for 36h-72h, the linoleic acid slow-release body algae inhibitor was obtained.

[0025] Use the linoleic acid slow-release body algae inhibitor to conduct acute toxicity experiments on aseptically cultured Microcystis aeruginosa, set up three parallel groups, observe once every 24 hours, and observe continuously for one week. When the weighed linoleic acid slow-release body algae inhibitor When the dosage is 1g, its 96h ...

Embodiment 2

[0028] Weigh 0.2g linoleic acid and dissolve it in 1.5mL ethyl oleate, then add 0.6mL emulsifier OP-10, make a 50mL solution with distilled water, then add 1.25g sodium alginate and mix well, draw the above mixture with a syringe Drop into 100mL glacial acetic acid solution containing 0.75g chitosan and 1g calcium chloride with 3mL glacial acetic acid content to form microspheres, add 1.5mL glutaraldehyde after cooling to room temperature, suction filter, rinse with petroleum ether and distilled water 5-8 times; after drying for 36h-72h, the linoleic acid slow-release body algae inhibitor is obtained.

[0029] Use the linoleic acid slow-release body algae inhibitor to conduct acute toxicity experiments on aseptically cultured Microcystis aeruginosa, set up three parallel groups, observe once every 24 hours, and observe continuously for one week. When the weighed linoleic acid slow-release body algae inhibitor When the agent is 1g, its 96h inhibition rate to Microcystis aerugin...

Embodiment 3

[0032] Weigh 0.3g of linoleic acid and dissolve it in 1.5mL of ethyl oleate, then add 0.8mL of emulsifier OP-10, make a 50mL solution with distilled water, then add 0.75g of sodium alginate and mix well, draw the above mixture with a syringe Drop into 100mL glacial acetic acid solution containing 0.25g chitosan and 2g calcium chloride with 3mL glacial acetic acid content to form microspheres, add 1.5mL glutaraldehyde after cooling to room temperature, filter with suction, rinse with petroleum ether and distilled water 5-8 times; after drying for 36h-72h, the linoleic acid slow-release body algae inhibitor is obtained.

[0033] Use the linoleic acid slow-release body algae inhibitor to conduct acute toxicity experiments on aseptically cultured Microcystis aeruginosa, set up three parallel groups, observe once every 24 hours, and observe continuously for one week. When the weighed linoleic acid slow-release body algae inhibitor When the agent is 1g, its 96h inhibition rate to Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com