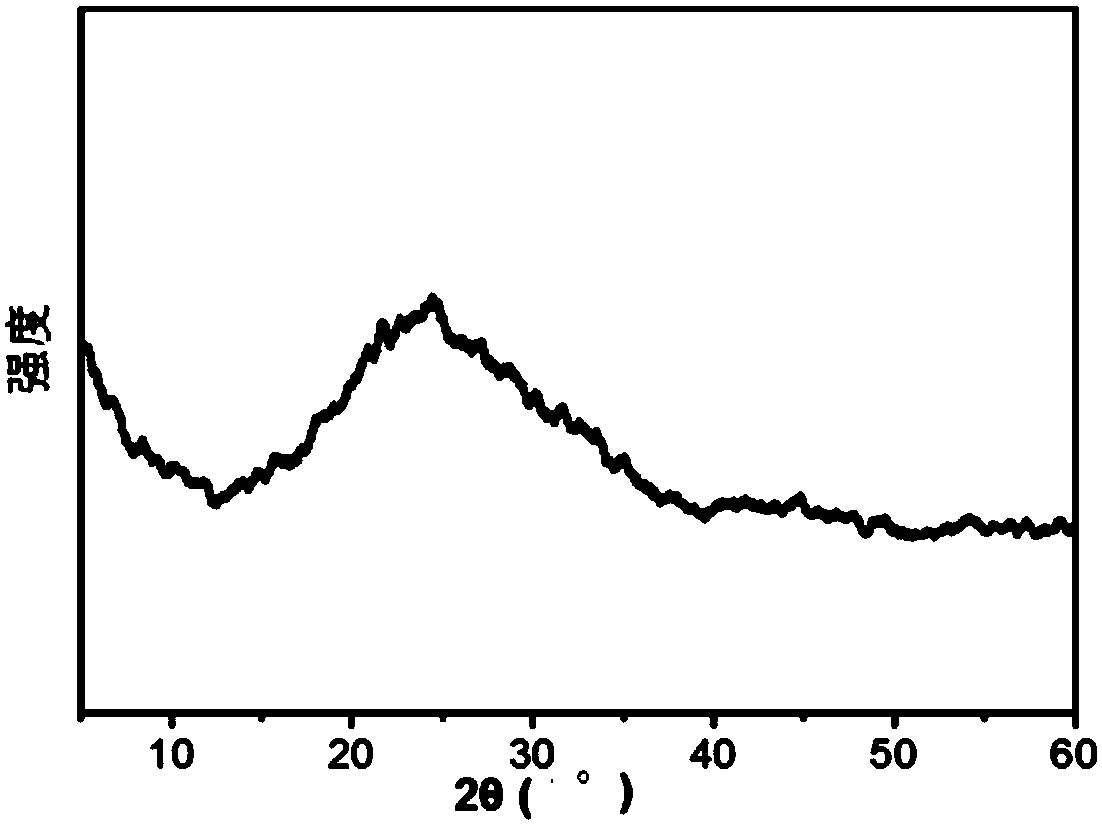

Porous carbon material and preparation method thereof

A technology for porous carbon materials and wood, applied in the field of porous carbon materials and their preparation, can solve the problems of unreusable template agent, cumbersome preparation process, long preparation cycle, etc., and achieves improved use value, simple preparation process, and excellent physical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of porous carbon material includes the following steps:

[0040] Step 1: Cut the natural fir with a miniature electric saw into wood chips with a thickness of 5mm; put the wood chips in an oven at 60°C for 24 hours until the moisture content of the wood chips drops to 3%;

[0041] Step 2: Put the dried wood chips into a tube furnace and heat to 200°C for the first calcination for 6 hours; make the bound water in the wood chips evaporate; then turn off the tube furnace and lower the temperature at room temperature;

[0042] Step 3: Take the cooled wood chips out of the tube furnace and immediately soak them in a 1mol / L potassium hydroxide aqueous solution for 5 hours, and then dry them in an oven at 60°C to remove free water in the wood chips;

[0043] Step 4: Put the wood chips obtained in Step 3 into a tube furnace and heat them with inert gas at a rate of 15°C / min to 1000°C for a second calcination for 2 hours, so that the low molecular weight substances i...

Embodiment 2

[0047] A preparation method of porous carbon material includes the following steps:

[0048] Step 1: Cut the natural fir with a miniature electric saw into thin slices of horizontal, diameter, and string with a thickness of 5μm; put the wood chips in an oven at 60℃ for 24 hours, until the moisture content of the wood chips drops to 2% ;

[0049] Step 2: Put the dried wood chips into a tube furnace and heat to 200°C for the first calcination for 6 hours; make the bound water in the wood chips evaporate; then turn off the tube furnace and lower the temperature at room temperature;

[0050] Step 3: Take the cooled wood chips out of the tube furnace and immediately soak them in a 2mol / L potassium hydroxide aqueous solution for 6 hours, and then dry them in an oven at 60°C to remove free water in the wood chips;

[0051] Step 4: Put the wood chips obtained in Step 3 into a tube furnace and heat it with inert gas at a rate of 5°C / min to 1100°C for a second calcination for 2 hours, so that t...

Embodiment 3

[0055] A preparation method of porous carbon material includes the following steps:

[0056] Step 1: Cut the natural fir with a miniature electric saw into thin slices of horizontal, diameter, and string with a thickness of 5 μm; put the wood chips in a 60 ℃ oven for 24 hours, until the moisture content of the wood chips drops to 4%;

[0057] Step 2: Put the dried wood chips into a tube furnace and heat to 200°C for the first calcination for 6 hours; make the bound water in the wood chips evaporate; then turn off the tube furnace and lower the temperature at room temperature;

[0058] Step 3: Take the cooled wood chips out of the tube furnace and immediately soak them in a 3mol / L potassium hydroxide aqueous solution for 2 hours, and then dry them in an oven at 60°C to remove free water in the wood chips;

[0059] Step 4: Put the wood chips obtained in Step 3 into a tube furnace and heat it with inert gas at a rate of 5°C / min to 1100°C for a second calcination for 2 hours, so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com